Hot melting pressure-sensitive glue as well as preparation method and application thereof

A hot-melt pressure-sensitive adhesive, styrene block technology, applied in the direction of pressure-sensitive film/sheet, adhesive, adhesive type, etc., can solve the problems of reduced film transparency, low peel strength, complex process, etc. Stable force, easy unwinding, good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A preparation method for a hot-melt pressure-sensitive adhesive, comprising the following steps:

[0046] Add styrene block copolymer, tackifying resin and antioxidant into the stirring tank and mix to obtain the mixture, then put the mixture into the twin-screw extruder for underwater pelletizing at low temperature, dry, and add powder release agent during the drying process to Avoid clumping.

[0047] The hot-melt pressure-sensitive adhesive is used to prepare the protective film: the hot-melt pressure-sensitive adhesive is used as the inner layer raw material, polyethylene is used as the middle layer raw material and the outer layer raw material, the three-layer co-extruded blown film is cooled and rolled, and the thermoplastic elastomer polymer is obtained. Vinyl self-adhesive protective film.

Embodiment 1-4 and comparative example 1-2

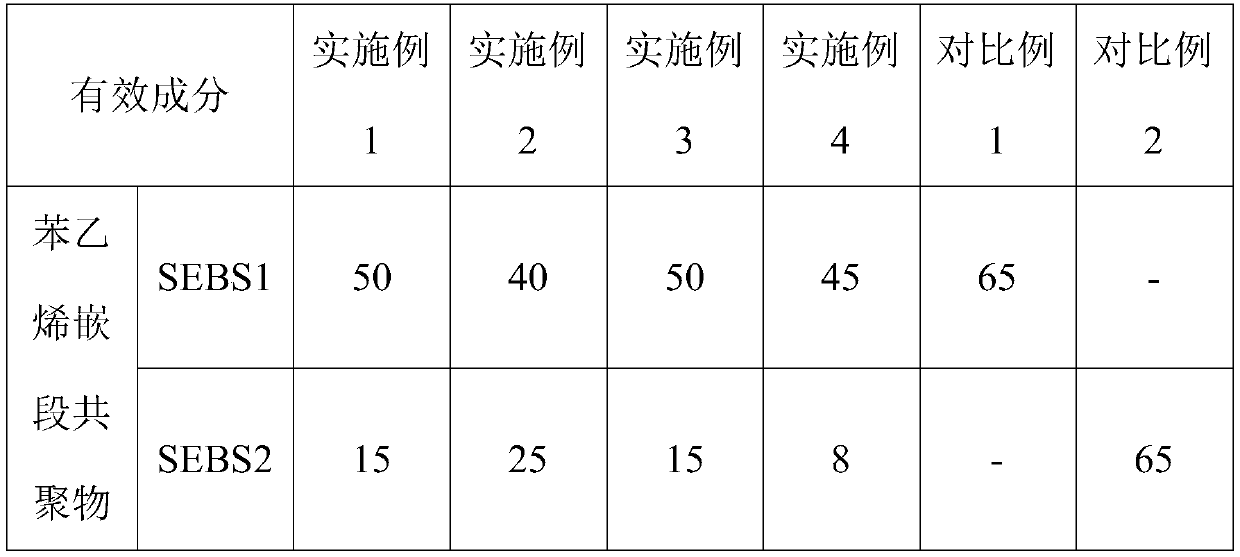

[0049] Hot-melt pressure-sensitive adhesives, including the active ingredients shown in Table 1 in parts by weight:

[0050] Active ingredients of Table 1 embodiment 1-4, comparative example 1-2

[0051]

[0052]

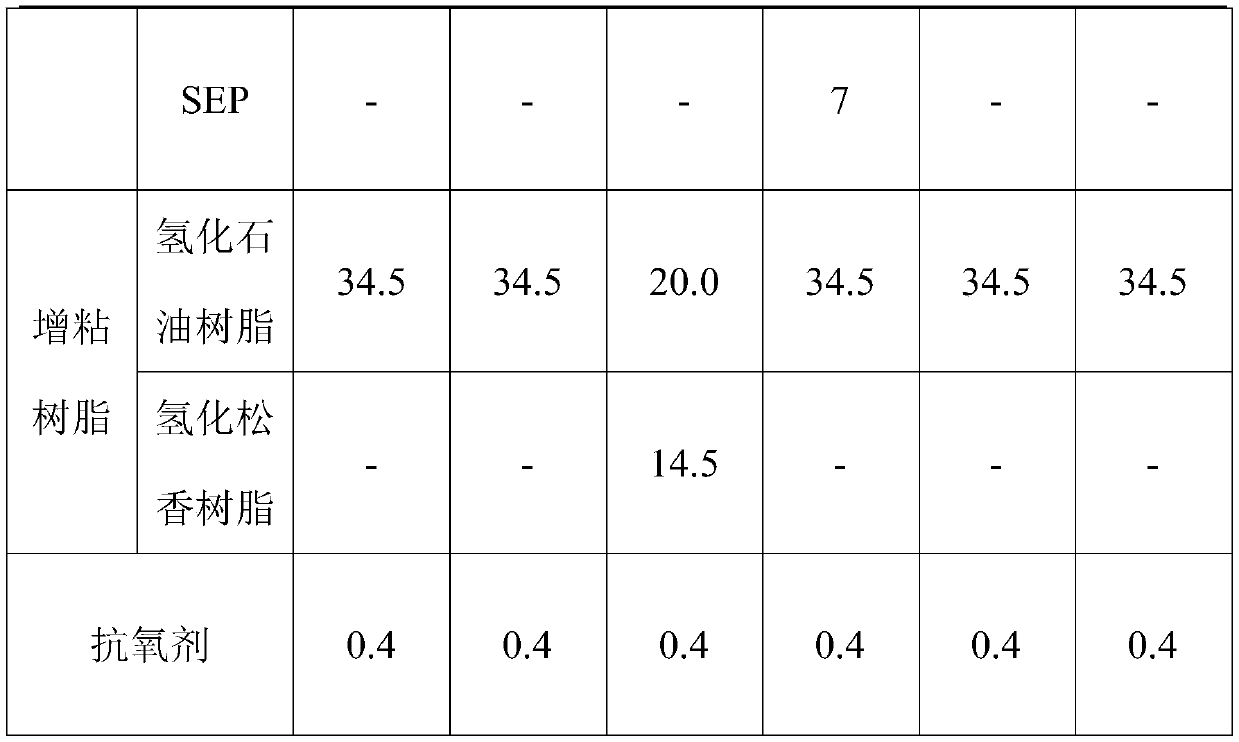

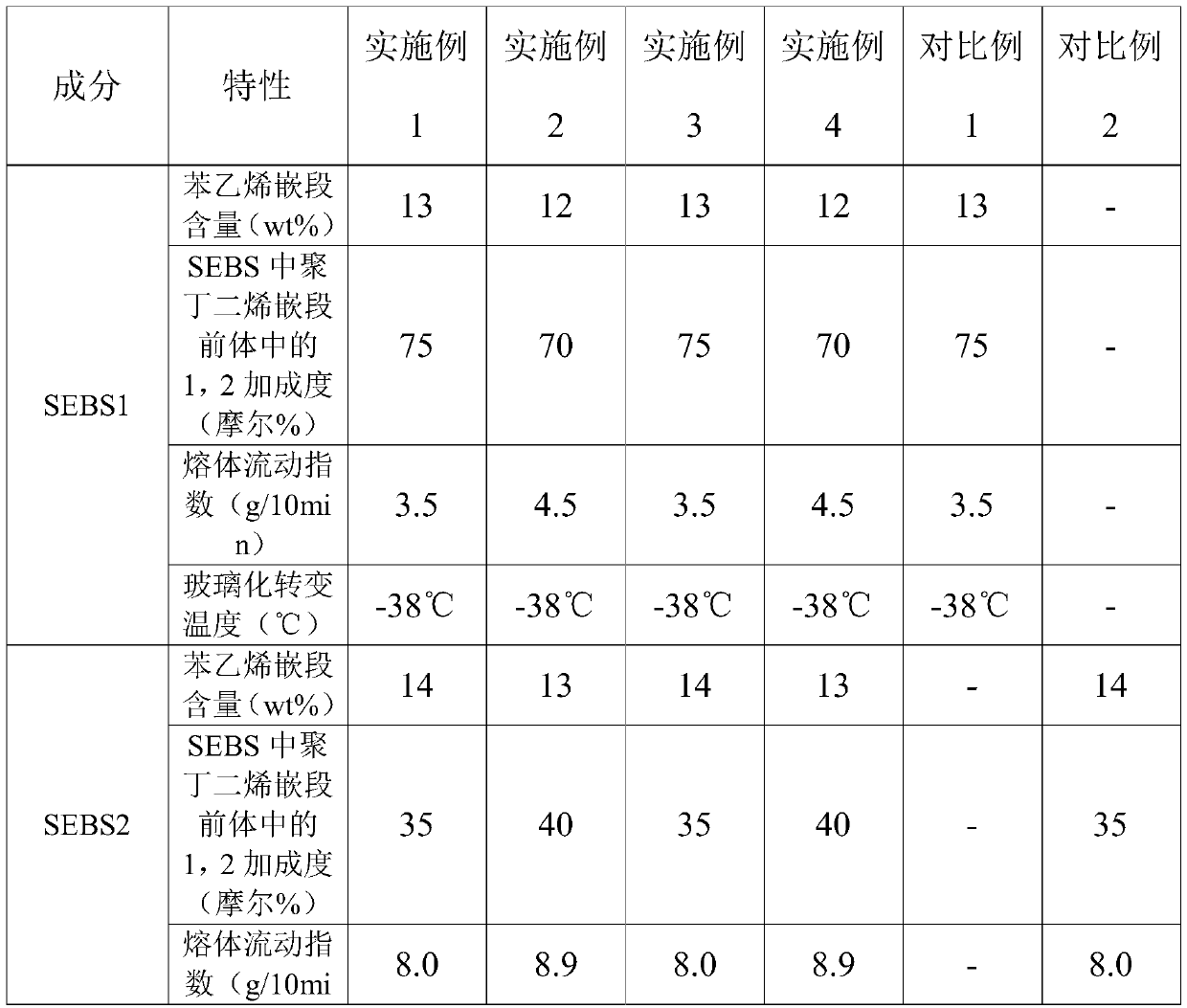

[0053] The properties of the ingredients are shown in Table 2:

[0054] Table 2 Composition characteristic parameters of Examples 1-4 and Comparative Examples 1-2

[0055]

[0056]

[0057] Examples 1-4 were prepared by the preparation method in the specific embodiment, and Comparative Examples 1-2 were prepared by conventional technical means.

[0058] The obtained hot-melt pressure-sensitive adhesives of Examples 1-4 and Comparative Examples 1-2 were measured for melt index and hardness according to national standards GB / T3682 and GB / T2411, respectively. The results are shown in Table 3:

[0059] Table 3 Melt index and hardness test data of hot melt pressure sensitive adhesive

[0060]

[0061] Using Example 1-4 and Comparative Example 1-2 as raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com