High-leakproofness multichannel packaging composite membrane and production technology thereof

A high-tightness, composite film technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of large width of multi-channel roll film, easy deviation of film running, and difficult film cutting, etc., to achieve excellent vertical and horizontal Tear force, excellent thickness stability, and improved packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

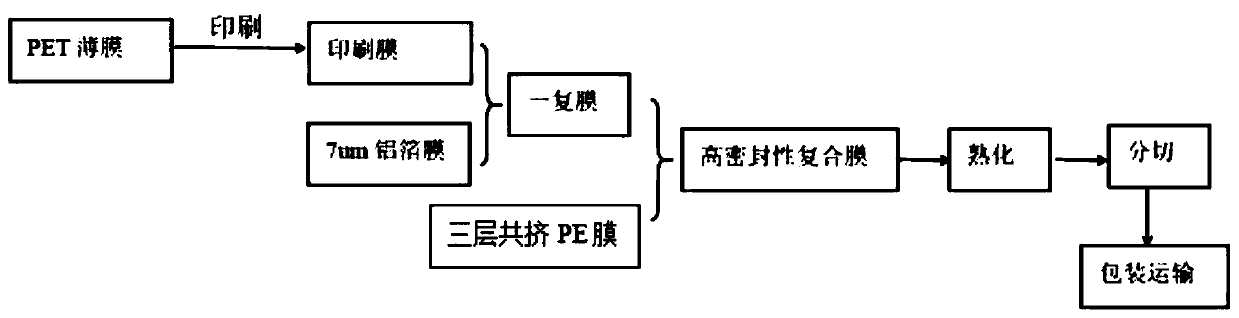

Image

Examples

preparation example Construction

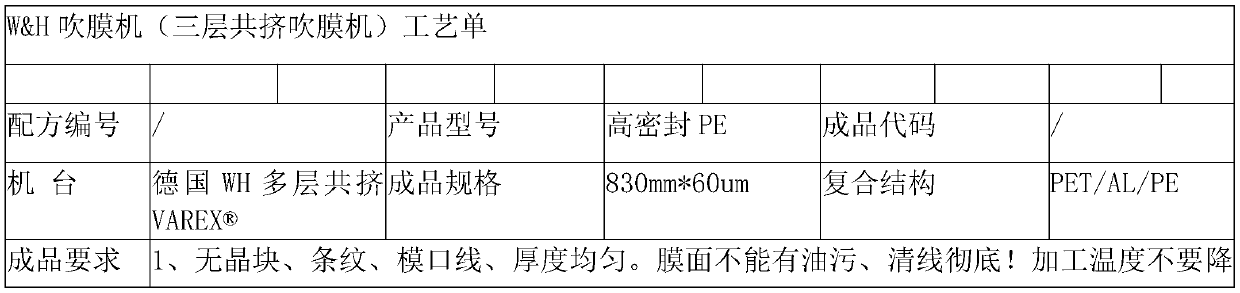

[0036] The preparation process list of the three-layer co-extruded PE film of the present invention is shown in Table 1 below:

[0037] Table 1

[0038]

[0039]

[0040]

[0041] The composite process list of composite film of the present invention is as shown in table 2 below:

[0042] Table 2

[0043]

[0044]

Embodiment 1

[0047] Step 1, prepare a three-layer co-extrusion PE film: according to the following formula requirements, add the materials in the corona layer, middle layer and heat-sealing layer to the three-layer co-extrusion blown film machine, plasticize into a melt through the corresponding barrel, and melt extrude When it comes out, it passes through a filter to filter impurities and reaches the die head; after that, the three-layer co-extruded PE film is obtained through blown film, air-cooled shaping, plywood foaming, traction cooling, corona, and winding. The preparation process is shown in Table 1. ;

[0048] The corona layer comprises a mass ratio of 59.8:33.3:6.9 linear low-density polyethylene, low-density polyethylene and fluorine-containing processing aids, and the intermediate layer comprises a mass ratio of 50:25:25 of low-density polyethylene, Linear low-density polyethylene and high-density polyethylene, the heat-sealing layer includes a first metallocene linear low-dens...

Embodiment 2

[0052] Step 1, prepare a three-layer co-extrusion PE film: according to the following formula requirements, add the materials in the corona layer, middle layer and heat-sealing layer to the three-layer co-extrusion blown film machine, plasticize into a melt through the corresponding barrel, and melt extrude When it comes out, filter impurities through the filter and reach the die head; then, the three-layer co-extruded PE film is obtained through film blowing, air-cooling and shaping, plywood foaming, traction cooling, corona, and winding;

[0053] The corona layer comprises a mass ratio of 59:33:6 linear low-density polyethylene, low-density polyethylene and fluorine-containing processing aids, and the intermediate layer comprises a mass ratio of 49:24:24 of low-density polyethylene, Linear low-density polyethylene and high-density polyethylene, the heat-sealing layer includes a first metallocene linear low-density polyethylene, a second metallocene linear low-density polyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com