Manufacturing process of biaxially stretched color base film for manufacture process protection of electronic products

A technology of biaxial stretching and electronic products, applied in the field of manufacturing process of biaxially stretched color base film for electronic product process protection, can solve the problems of solvent volatilization, environmental pollution, color, easy to fall off on other contact objects, etc., to achieve product Fast speed, uniform color distribution, enhanced antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

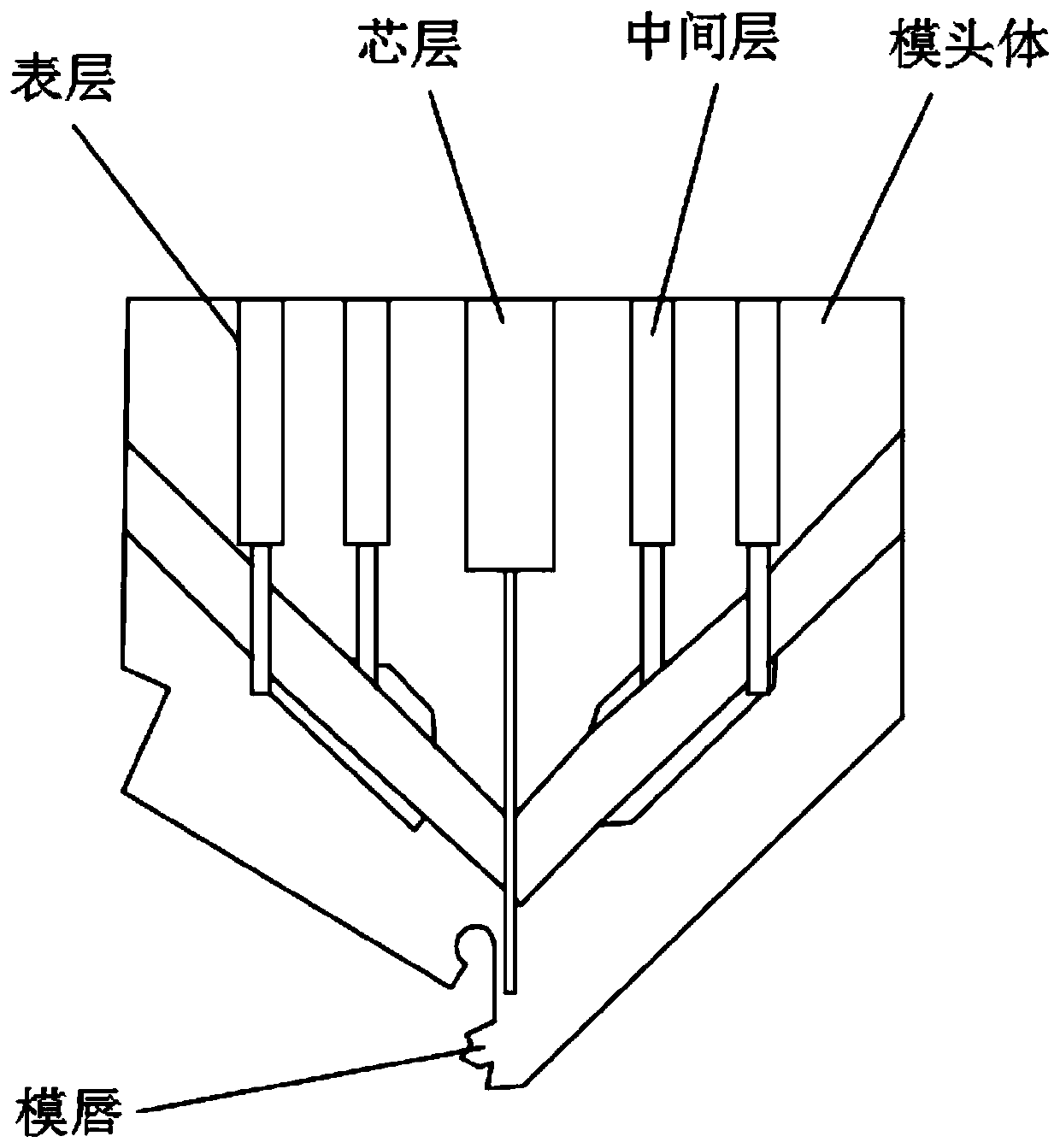

[0036] See figure 1 , A manufacturing process of biaxially stretched color base film for protection of electronic product manufacturing process, including the manufacture of color masterbatch and the use of five-layer biaxially stretched equipment to produce color film. The manufacturing of color masterbatch is produced by a tandem screw extruder. The production of color film with five-layer biaxial stretching equipment includes the following steps: drying, extrusion, casting, longitudinal stretching, transverse stretching, heat treatment and winding. Extrusion includes main extruder extrusion and auxiliary extruder extrusion. Out, the auxiliary extruder includes four auxiliary extruders, and one of the auxiliary extruders is the auxiliary extruder with colored layer, (the auxiliary extruder with colored layer: set the temperature 220-230 degrees, other Three auxiliary extruders: the temperature of the first zone is 220 degrees, and the other areas are 250 degrees) The other thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com