Preparation method of black titanium dioxide powder

A technology of black titanium dioxide and titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology for materials and surface science, etc., can solve environmental problems and safety issues, and achieve low production cost, strong practicability, and advanced technology The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

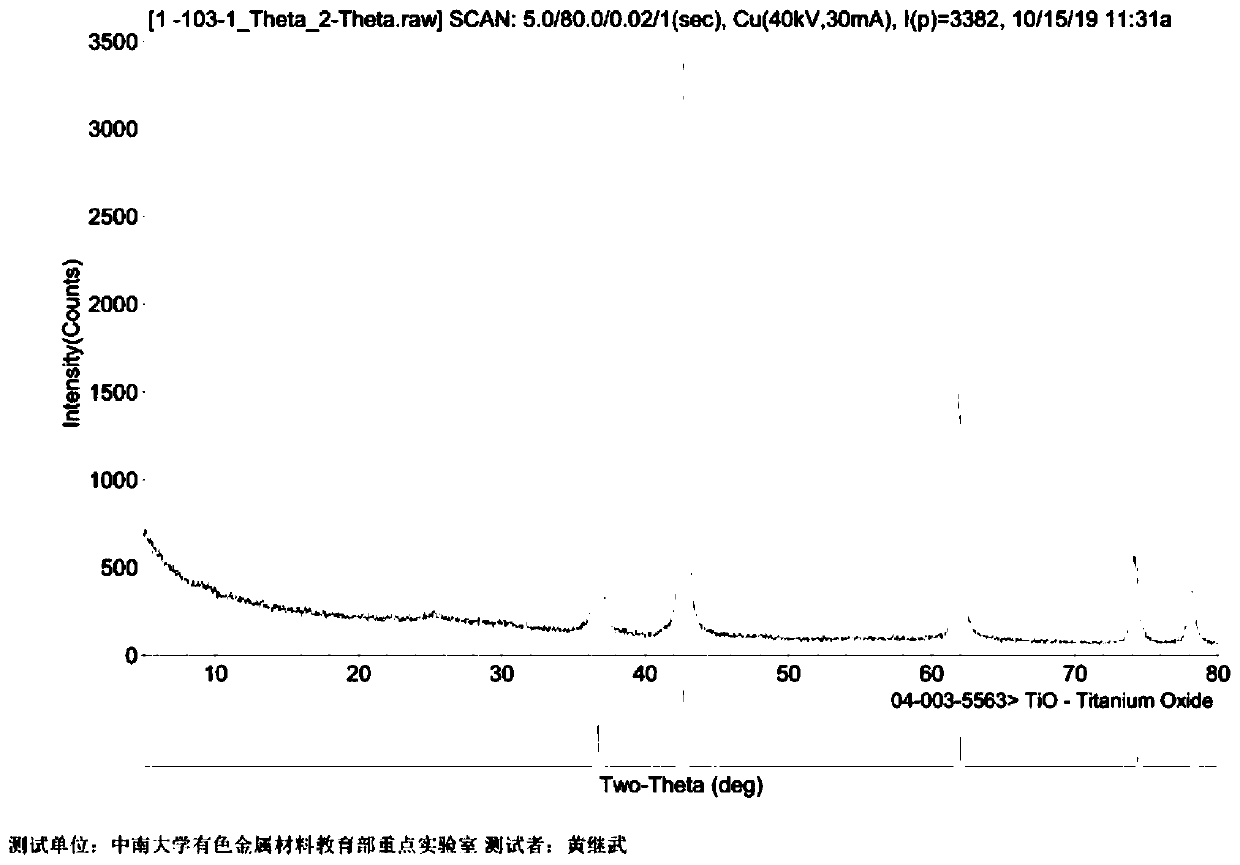

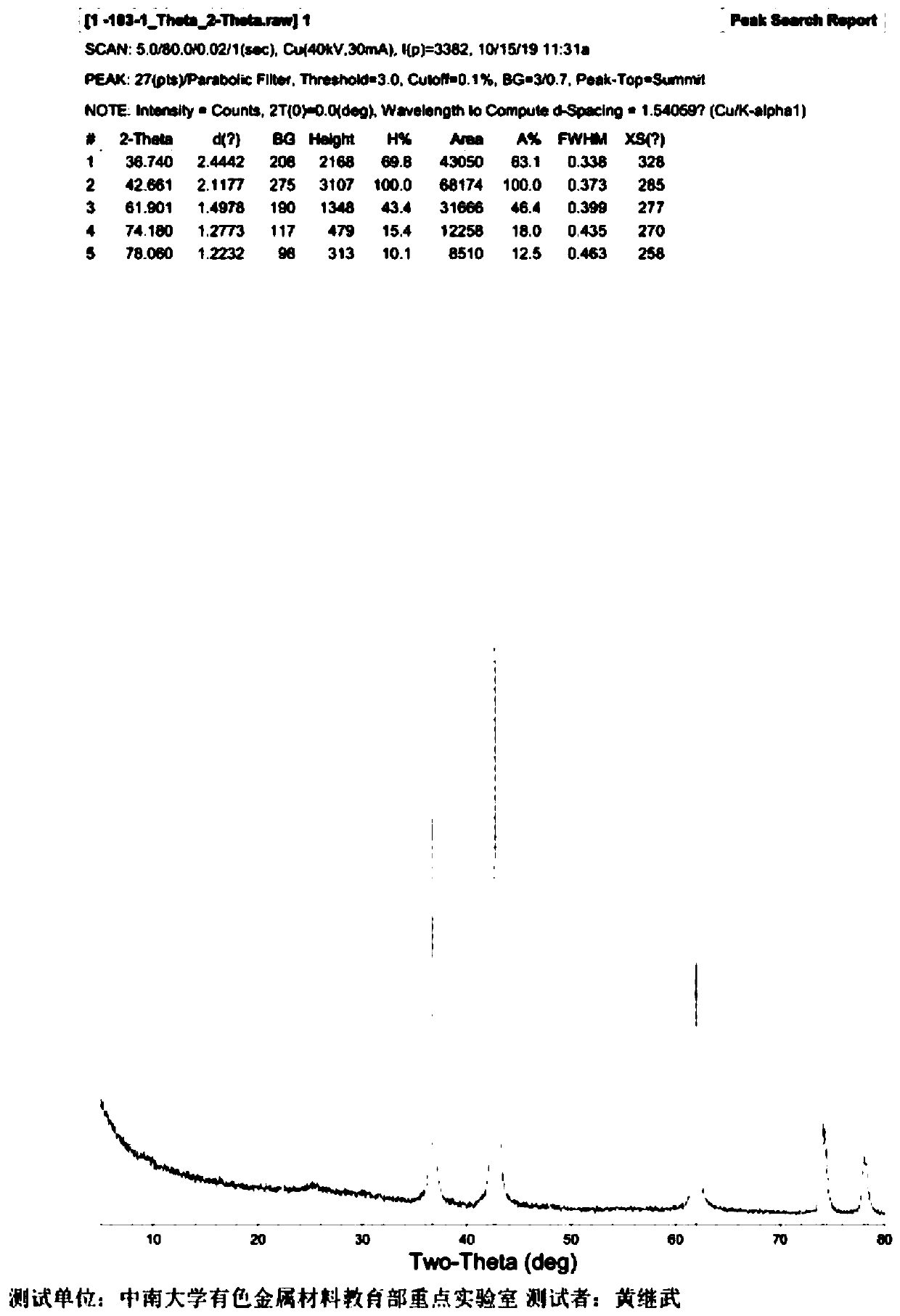

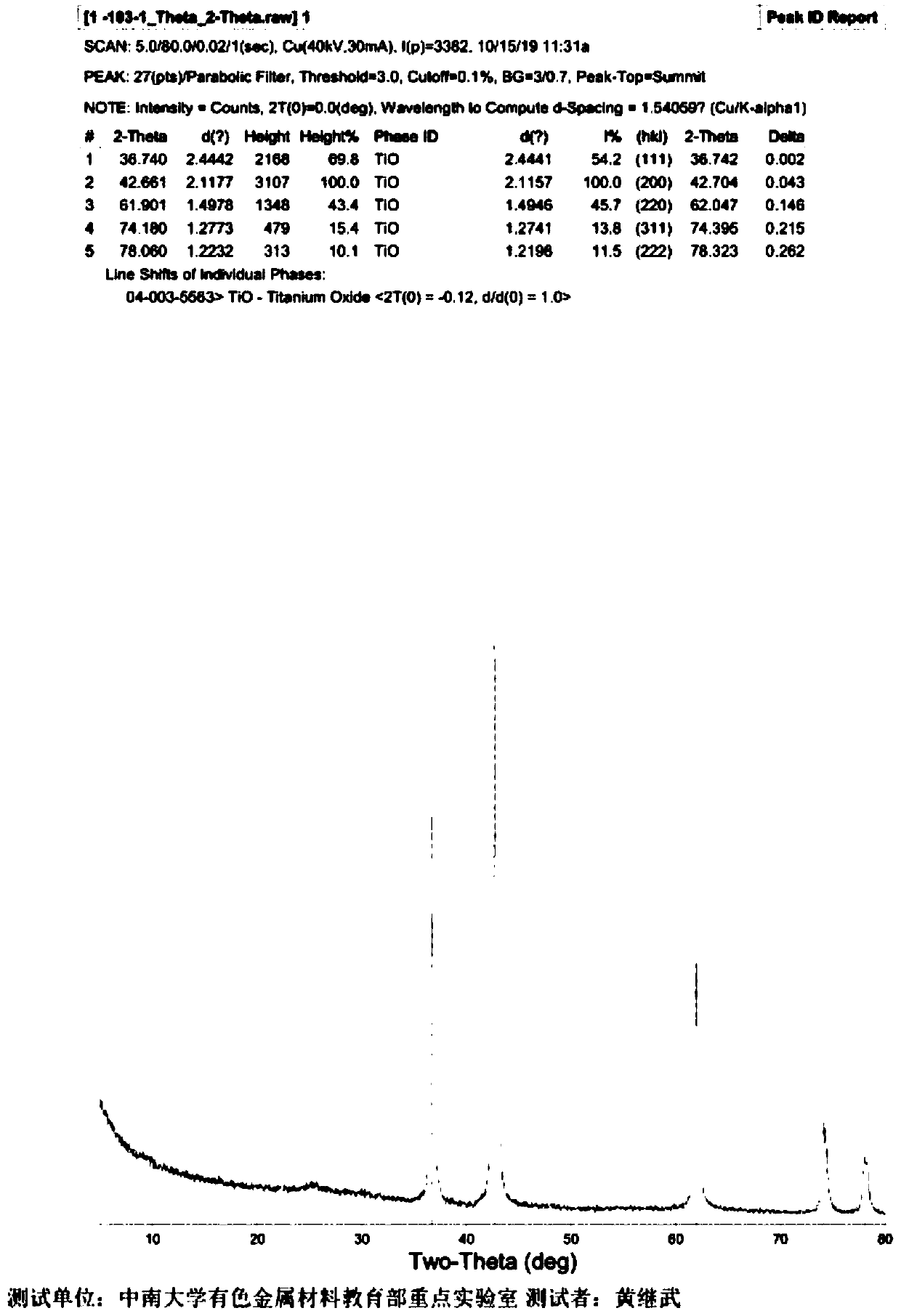

Image

Examples

Embodiment 1

[0031] A preparation method of black titanium dioxide powder, comprising the following steps:

[0032] a. Get 37.83g of ascorbic acid powder and 639.2g of titanium dioxide powder and mix and grind to obtain a mixed powder. The particle diameter of the ascorbic acid powder is 300 μm, and the particle diameter of the titanium dioxide powder is 0.18 μm;

[0033] b. Sinter the mixed powder obtained in step a under a nitrogen atmosphere, the purity of nitrogen is 99%, the rate of nitrogen introduction is 300cc / min, and the temperature is kept at 450° C. for 3 hours to obtain a sintered body;

[0034] c. naturally cooling the sintered body obtained in step b to 50° C., and then fully washing with water to obtain a washed sintered body;

[0035] d. The washed sintered body obtained in step c is dried at a temperature of 100° C. for 24 hours to obtain black titanium dioxide powder.

Embodiment 2

[0037] A preparation method of black titanium dioxide powder, comprising the following steps:

[0038]a. Take 8g of ascorbic acid powder and 320.6g of titanium dioxide powder and mix and grind to obtain a mixed powder. The particle size of the ascorbic acid powder is 0.1 μm, and the particle size of the titanium dioxide powder is 0.1 μm;

[0039] b. Sinter the mixed powder obtained in step a under a nitrogen atmosphere, the purity of nitrogen is 100%, the rate of nitrogen introduction is 280cc / min, and the temperature is kept at 500° C. for 1 hour to obtain a sintered body;

[0040] c. naturally cooling the sintered body obtained in step b to 55° C., and then fully washing with water to obtain a washed sintered body;

[0041] d. The washed sintered body obtained in step c is dried at a temperature of 80° C. for 28 hours to obtain black titanium dioxide powder.

Embodiment 3

[0043] A preparation method of black titanium dioxide powder, comprising the following steps:

[0044] a. Take 58g of ascorbic acid powder and 530.5g of titanium dioxide powder and mix and grind to obtain a mixed powder. The particle size of the ascorbic acid powder is 200 μm, and the particle size of the titanium dioxide powder is 0.2 μm;

[0045] b. Sinter the mixed powder obtained in step a under a nitrogen atmosphere, the purity of nitrogen is 99.9%, the rate of nitrogen introduction is 290cc / min, and the temperature is kept at 400° C. for 2 hours to obtain a sintered body;

[0046] c. naturally cooling the sintered body obtained in step b to 52° C., and then fully washing with water to obtain a washed sintered body;

[0047] d. Drying the washed sintered body obtained in step c at a temperature of 90° C. for 25 hours to obtain black titanium dioxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com