Low-ash and high-density polyethylene resin and preparation method thereof

A technology of high-density polyethylene and low ash, which is applied in the direction of electrical components, circuits, battery pack components, etc., can solve the adverse effects of battery capacity and battery life, reduce the puncture resistance of microporous diaphragms, and reduce the yield of microporous diaphragms. Advanced problems, to achieve the effect of low ash content, uniform composition and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] According to the preparation method of high-density polyethylene powder for microporous diaphragm of low ash lithium-ion battery provided by the present invention, in 200L hexane solvent, add cocatalyst triethylaluminum 4.5KG / h, loaded Ziegler-Natta successively Catalyst 2.5KG / h, stirred and mixed for about 1 hour under the protection of nitrogen, and fresh ethylene, hydrogen, etc. The average residence time in the kettle is about 1 to 2 hours to obtain the polyethylene component I; after the material is flashed to remove volatile components, it enters the second reaction kettle; no new catalyst is added to the second reaction kettle, and continuous Feed ethylene, hydrogen, and comonomer butene-1, and the average residence time of the materials is about 1 to 2 hours to obtain polyethylene component II and an ethylene polymer mixture containing polyethylene component I produced in the first kettle; After flash evaporation to remove volatile components, it enters the thir...

Embodiment 2

[0052] Basically the same as Example 1, but with the following changes:

[0053] The ethylene feed rates of the first reactor, the second reactor and the third reactor were changed to 4.0t / h, 4.5t / h and 1.5t / h respectively;

[0054] The α-olefin feed amount of the second reactor and the third reactor is changed to 0;

[0055] The hydrogen / ethylene volume ratios of the first reactor, the second reactor and the third reactor were respectively changed to 0.2-0.5%, 0.10-0.3%, 0.1-0.2%;

[0056] The temperature of the second and third reactors is controlled at 75-83°C and 79-87°C respectively.

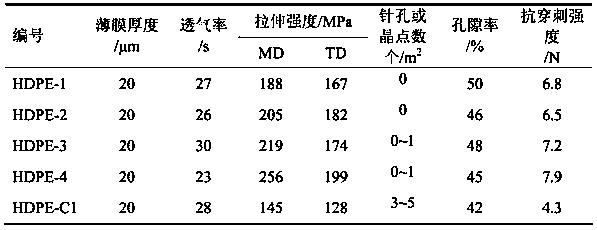

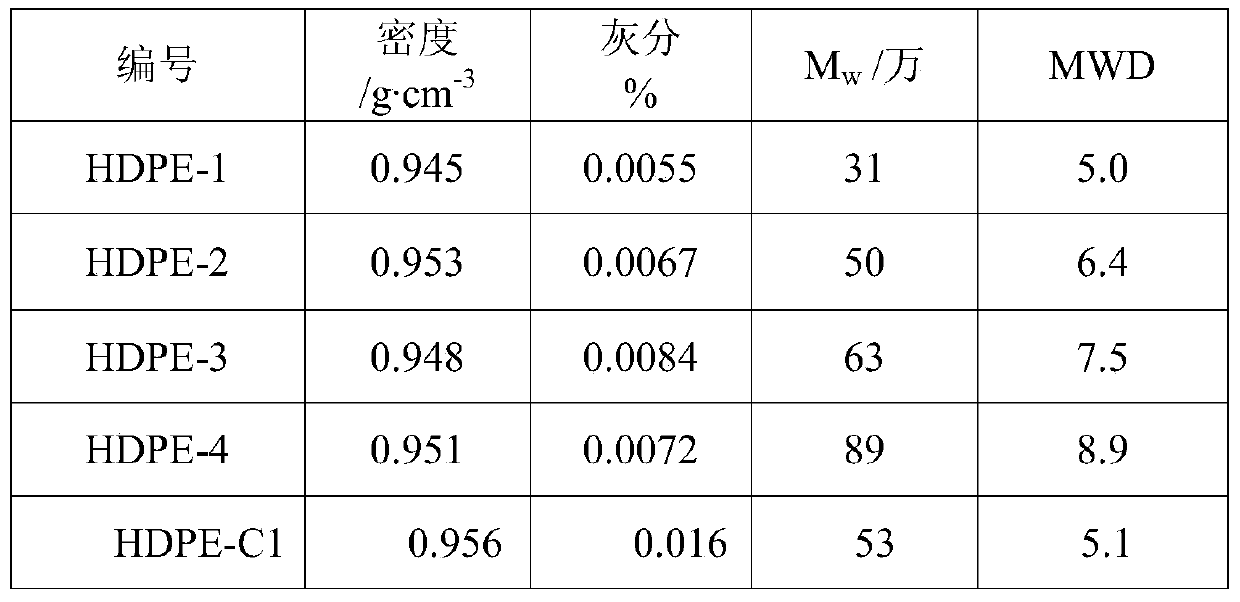

[0057] The specific production process control parameters of the reactor are shown in Table 2. The high-density polyethylene powder for wet-process lithium-ion battery microporous separator is recorded as HDPE-2, and the test results are shown in Table 6.

[0058] The production process parameter of table 2 embodiment 2

[0059]

Embodiment 3

[0061] Basically the same as Example 1, but with the following changes:

[0062] The ethylene feed rates of the first, second and third reactors were changed to 5.5t / h, 3.5t / h and 1.0t / h respectively;

[0063] The α-olefin feeding amount of the first reactor and the second reactor is all changed into propylene, and the addition is changed into 5kg / h;

[0064] The temperature control of the first reactor is changed to 65-75°C, and the pressure of the kettle is changed to 0.25-0.5MPa. The temperature of the second reactor is controlled at 70-80°C, and the pressure of the kettle is changed to 0.2-0.35MPa.

[0065] The specific production process control parameters of the reactor are shown in Table 3. The high-density polyethylene powder used for the microporous diaphragm of the low-ash lithium-ion battery is recorded as HDPE-3, and the test results are shown in Table 6.

[0066] The production process parameter of table 3 embodiment 3

[0067]

[0068]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com