Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Low content of metal impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

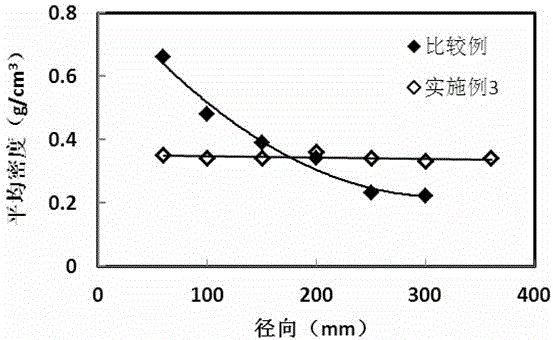

Process for preparing mesopore pitch-based spherical activated carbon by post-carbonizing impregnated metal salts

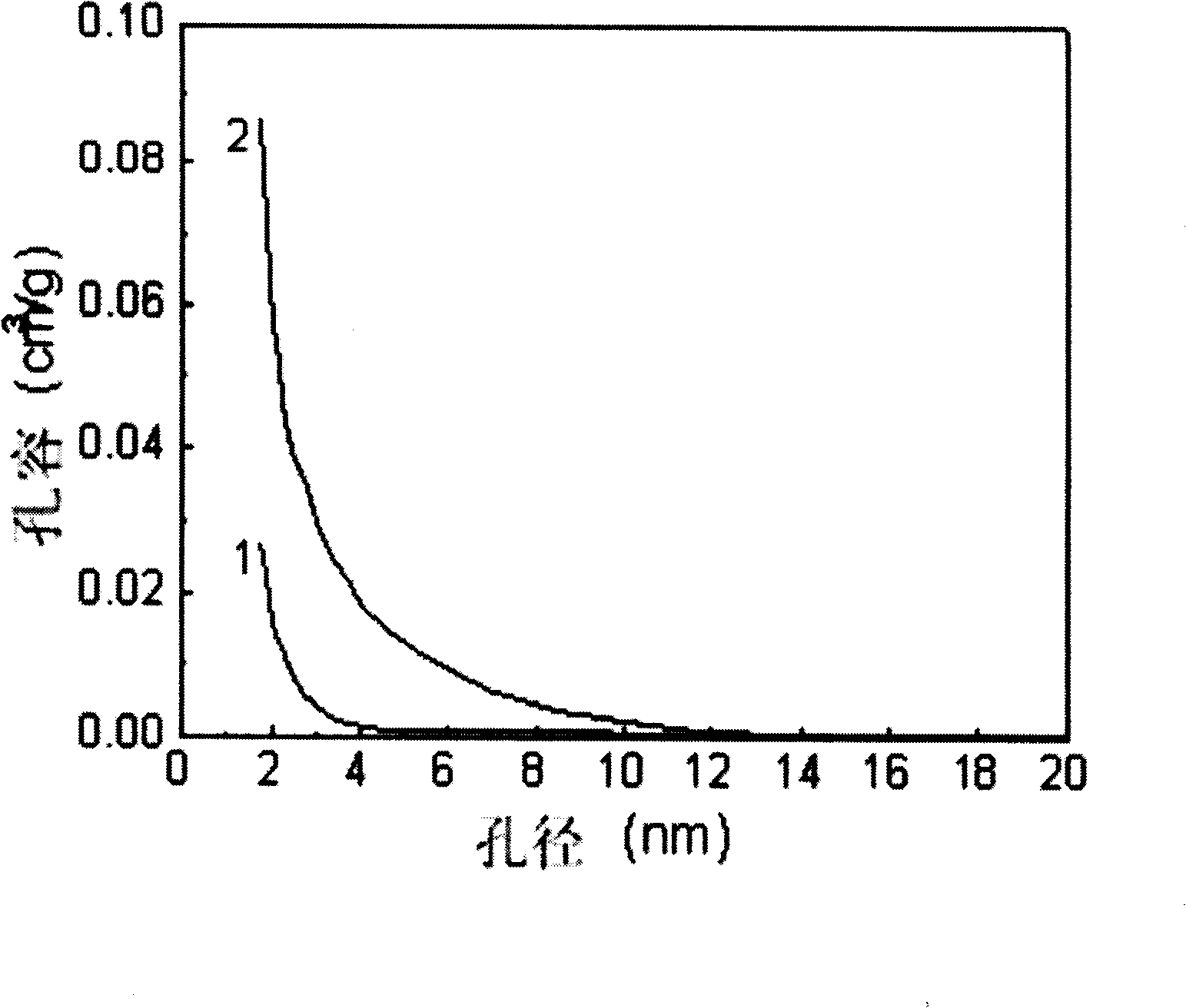

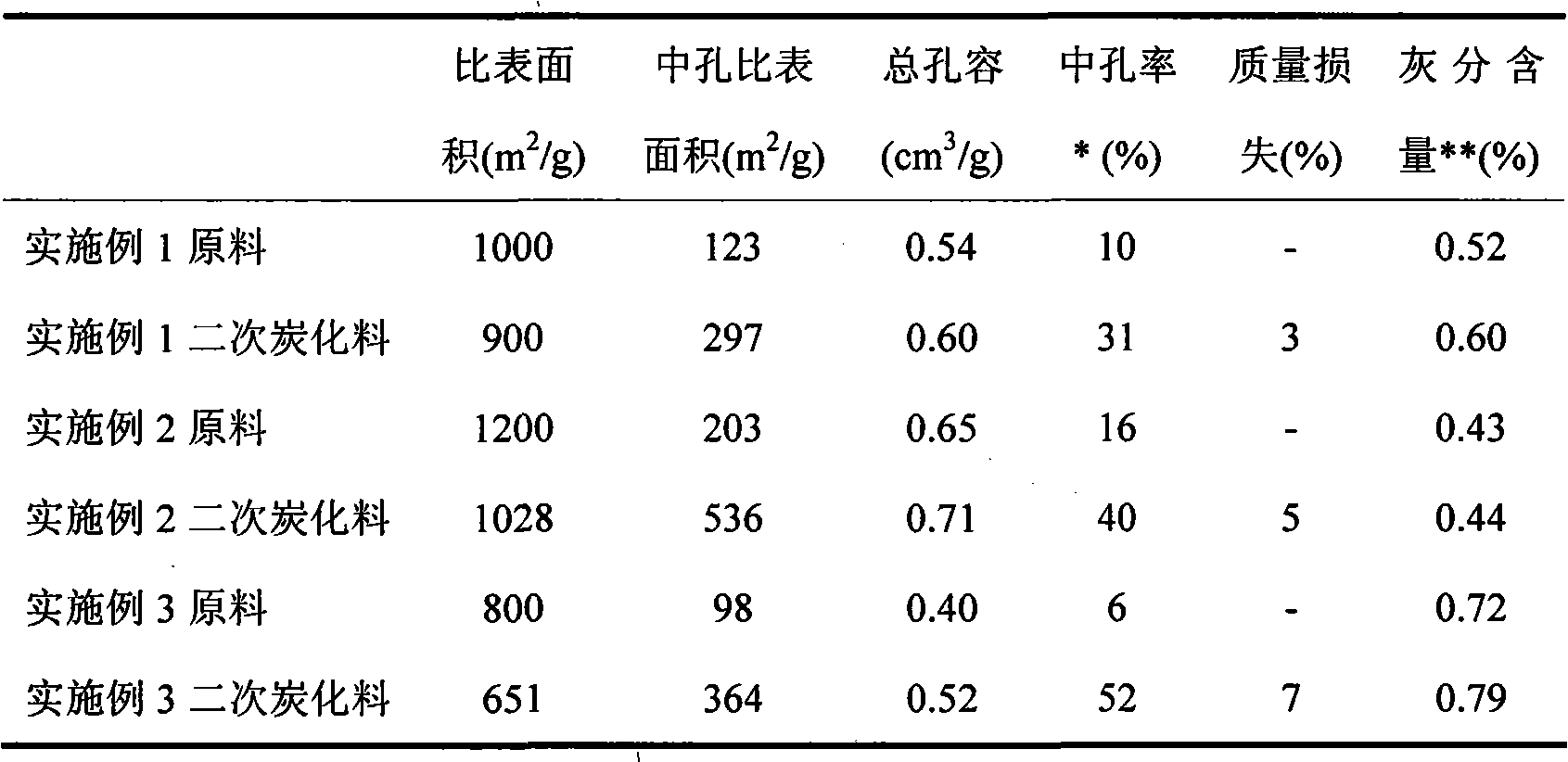

The invention provides a method for preparing mesoporous asphaltic base globular active carbon by dipping metal salt and secondary carbonization. The method comprises the steps of dipping and mixing the mipor asphaltic base globular active carbon prepared by the traditional method with an inorganic metal salt solution by a certain ration; heating under an inert atmosphere to 600-1200 DEG C at a temperature increasing rate of 1 to 20 DEG C / min for the secondary carbonization; using acid to wash off the remaining metal inside the carbonized material, so as to obtain asphaltic base globular active carbon with high mesoporous rate and narrow distribution of mesoporous spertures.

Owner:EAST CHINA UNIV OF SCI & TECH

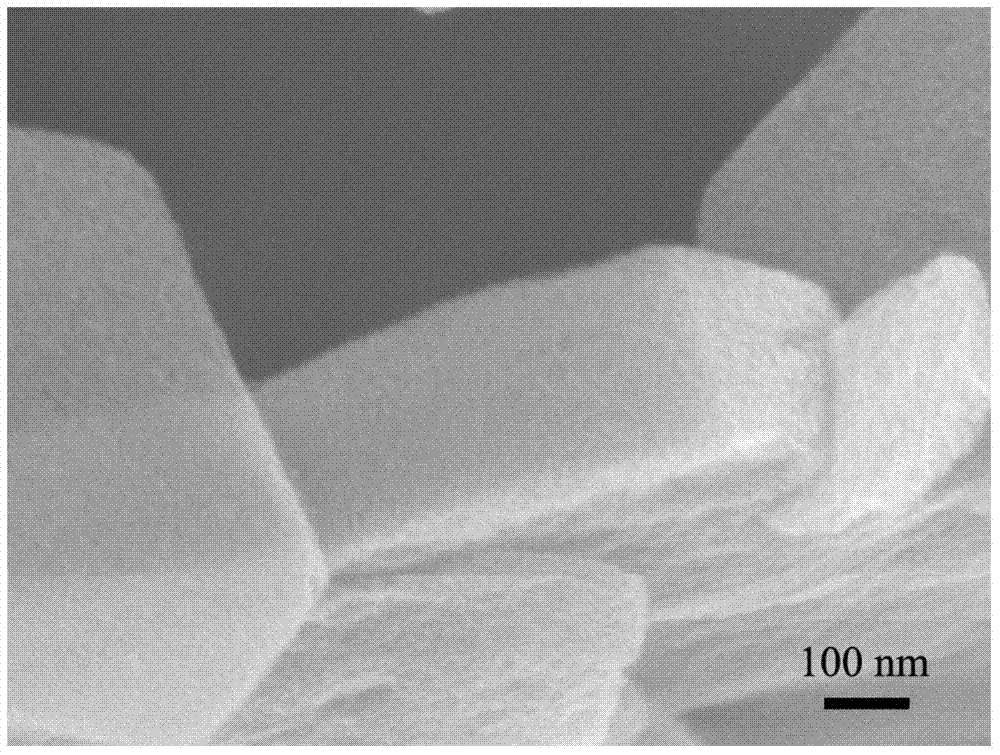

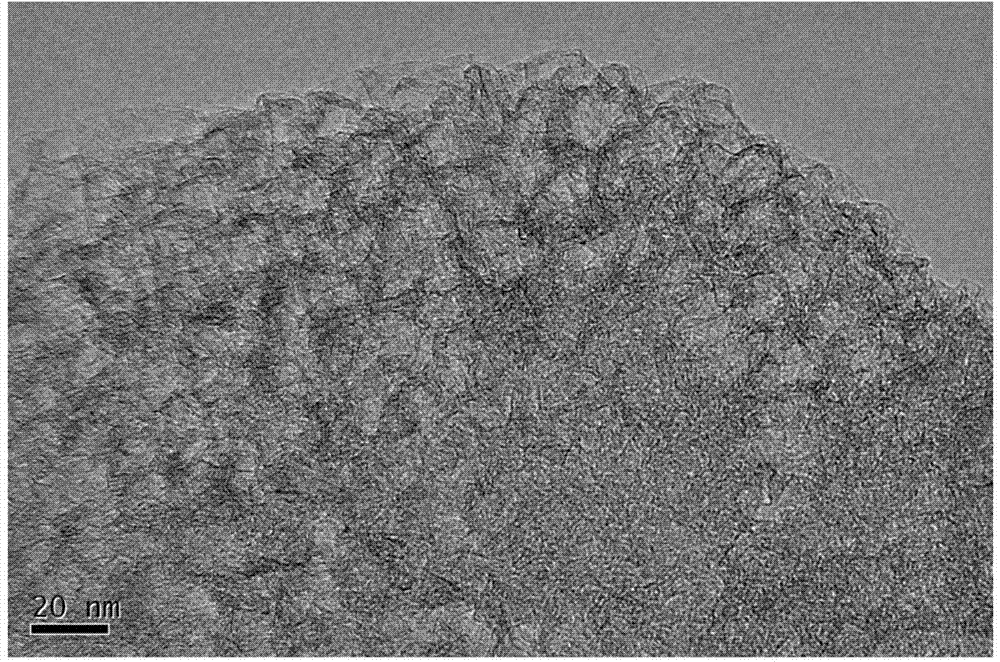

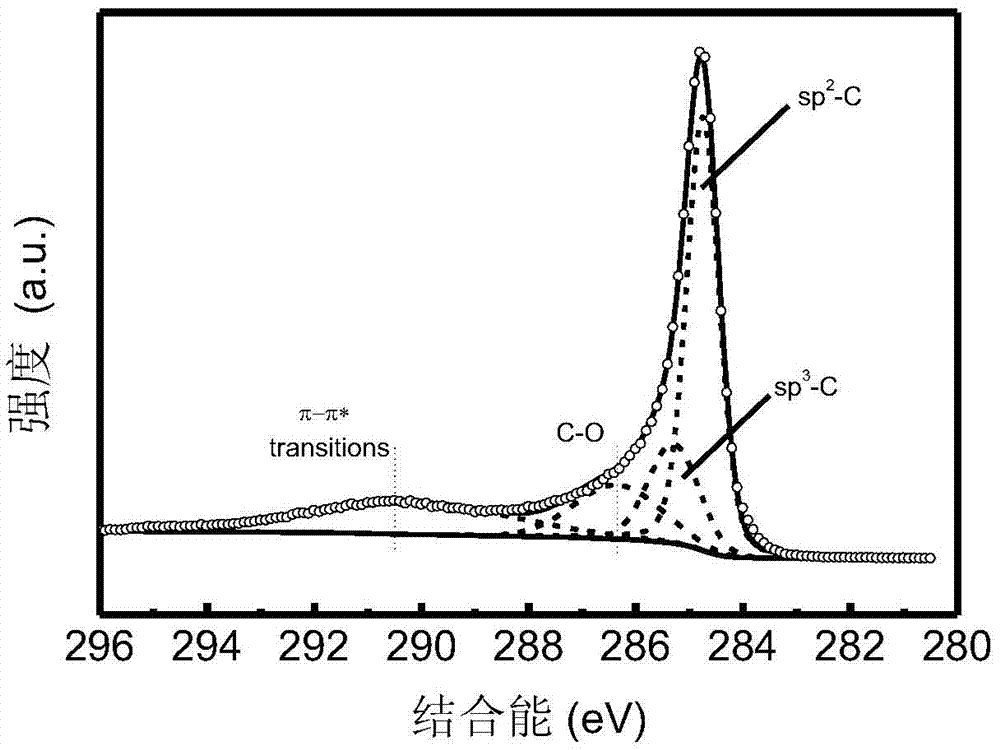

Mesoporous graphene foam as well as preparation method thereof

ActiveCN103482611AStable structureLarge specific surface areaGrapheneNanotechnologyDraw ratioElectric properties

The invention belongs to the technical fields of a novel material as well as preparation, and particularly relates to mesoporous graphene foam as well as a preparation method thereof. The invention realizes hydrothermal preparation of a magnesium oxide texture structure and preparation of the mesoporous graphene foam by using textured magnesium oxide as a template. The mesoporous graphene foam material has abundant mesoporous structures and excellent electric property and can be used as an electrode material of batteries and supercapacitors, so that the energy density and the power density of the batteries or the supercapacitors are expectedly improved to a great extent. The cycling stability of the mesoporous graphene foam material is increased, and the mesoporous graphene foam material combined with materials with high draw ratio or the mesoporous graphene foam material can soften energy storage apparatuses. The advantages have important meaning for realization of commercialization of a new generation of energy storage apparatuses for electromobiles and development of smaller, lighter and flexible portable mobile power supplies. The business prospect is wide. Meanwhile, preparation processes of the high temperature hydrothermal method and a fluidized bed can realize engineering enlargement, so that the method is expected to be industrialized.

Owner:TSINGHUA UNIV

Preparing method of high purity quartz sleeve for large-size optical fiber preform

ActiveCN105330140AAvoid it happening againNo pollution in the processGlass shaping apparatusGlass productionAcid washingOxygen

The invention relates to a preparing method of a high purity quartz sleeve for a large-size optical fiber preform. The method comprises the steps of firstly, clamping a target rod or tube subjected to acid washing and drying on upper and lower chucks of an upright deposition device; adopting an upright sectional vapor deposition method, and introducing siloxane, oxygen, natural gas or methane or hydrogen gas, nitrogen gas as a raw material into a blowtorch, wherein after igniting, high temperature flame reacts to generate silicon dioxide powder with the particle size between 5-200nm, the powder is attached to the surface of the target rod or tube and finally achieves the set target rod size; then placing the silicon dioxide powder rod obtained by depositing into a graphite resistance furnace with the temperature being 1200-1600 DEG C, and introducing Cl2 and He with a flow ratio being (1-5) to (1-20) for vitrification sintering, thus obtaining a quartz sleeve preformed unit; performing mechanical cold machining on the quartz sleeve preformed unit to obtain the quartz sleeve; then adopting a weak base solution to wash, then repeatedly washing with deionized water, soaking with acid and finally washing with the deionized water and drying.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +1

Method for preparing high-purity silicon carbide powder

InactiveCN109502589AReduce nitrogen contentLow content of metal impuritiesCarbon compoundsNitrogenPre treatment

The invention provides a method for preparing high-purity silicon carbide powder. The method is characterized by comprising the following steps: (1) selecting high-purity silicon powder and high-purity carbon powder; (2) carrying out primary purification and secondary purification on the high-purity carbon powder, a graphite crucible and a heat-insulation structure, wherein the primary purification adopts vacuum degassing purification and the secondary purification adopts high-temperature purification under inert gas; (3) putting the high-purity carbon powder subjected to the secondary purification in step (2) and the high-purity silicon powder in step (1) into the graphite crucible subjected to the secondary purification in step (2); reacting to obtain the high-purity silicon carbide powder. According to the method provided by the invention, the carbon powder, the graphite crucible and the heat-insulation structure are pre-treated, so that the nitrogen content of the high-purity carbon powder and the content of metal impurities are reduced; compared with a method of carrying out wet-process metallurgical treatment after silicon carbide is synthesized, the method is more environmentally friendly and has simpler procedures; meanwhile, impurities are not introduced from the graphite crucible and the heat-insulation structure when the silicon carbide powder is synthesized.

Owner:SICC CO LTD

Method for removing metal impurities from carbon nano tube

ActiveCN104211042AImprove conductivityLow content of metal impuritiesMetal impuritiesCarbon nanotube

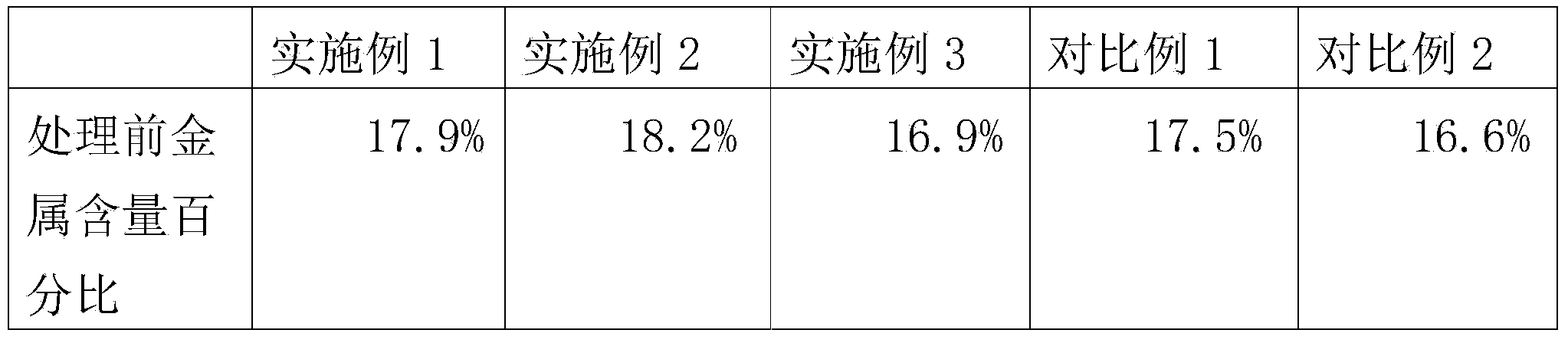

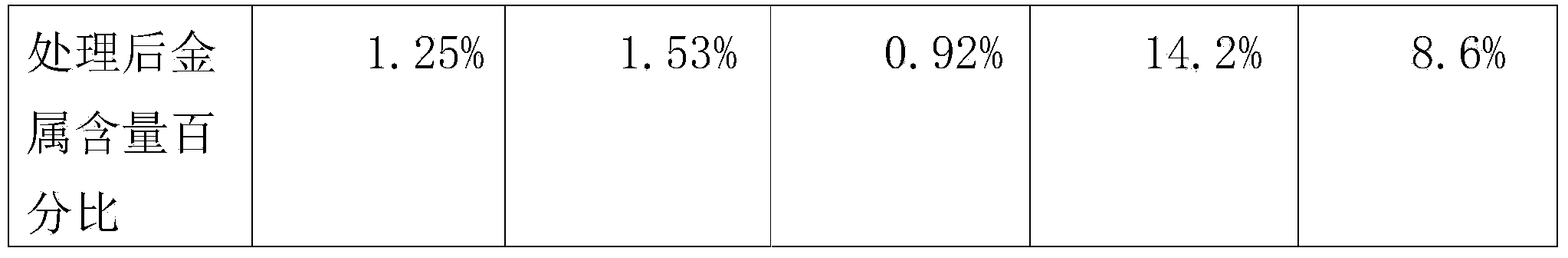

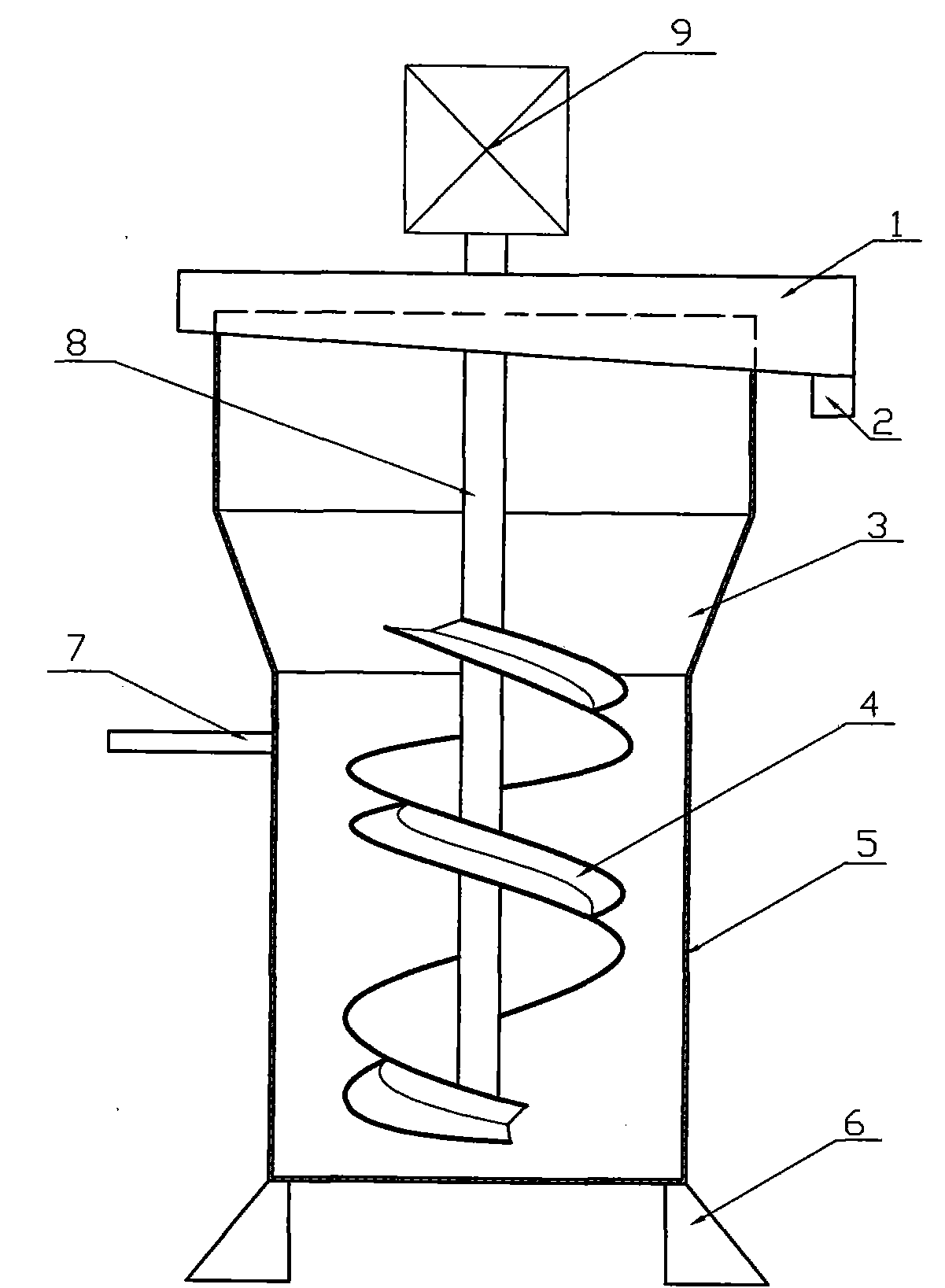

The invention discloses a method for removing metal impurities from carbon nano tubes. The method includes following steps: (1) preparing a carbon nano tube acid solution from the carbon nano tubes with an inoxidizing acid solution; (2) mixing and stirring the carbon nano tube acid solution uniformly and grinding the carbon nano tube acid solution in a grinder; (3) stirring the grinded carbon nano tube acid solution in a stirring kettle, taking out the grinded carbon nano tube acid solution and removing waste solution with a filter press to prepare a carbon nano tube filter cake; (4) feeding the carbon nano tube filter cake in the stirring kettle, adding deinoized water with stirring for cleaning metal ions in the solution until a filtrate is neutral; and (5) drying and crushihng the carbon nano tube filter cake to obtain high-purity carbon nano tubes. The method is characterized in that original lengths and structures of the purified carbon nano tubes are retained and the carbon nano tubes is excellent in electric-conductive performance. By means of the method, the content of metal impurities in the carbon nano tubes can be reduced from 20% to less than 2%. The method is high in efficiency, is simple in operations and can achieve industrialized production.

Owner:WUXI DONGHENGNEWENERGYTECHNOLOGYCO LTD

A kind of hydrometallurgical purification process of polysilicon metal impurities by metallurgical method

InactiveCN102295289ALow content of metal impuritiesLow costSilicon compoundsPurification methodsMetal impurities

The invention relates to the technical field of metallurgical polysilicon purification, in particular to a hydrometallurgical purification method. The purification method of the present invention is as follows: the silicon powder with a particle size of 100 to 200 meshes is subjected to magnetic separation by a magnetic separator for use, and is prepared by pre-cleaning, pickling with dilute hydrochloric acid, pickling with dilute hydrofluoric acid, pickling with aqua regia, and dilute hydrofluoric acid. Acid and hydrogen peroxide pickling process pickling, the solid-to-liquid ratio is 1:3, soak for 12-16 hours, stir for 15 minutes every hour during soaking, and then rinse with deionized water for many times until the pH value of the water For neutrality, centrifugal drying, drying, packaging. Using the purification method of the present invention, by optimizing the conditions such as silicon powder particles, acid concentration, soaking time and stirring, the total content of metal impurities in metallurgical polysilicon is reduced to 100ppmw in advance, and the effect of 4N purity metallurgical silicon can be obtained, and reach A simple, easy, low-cost method that can be mass-produced.

Owner:宁夏银星多晶硅有限责任公司

Quartz crucible and manufacturing method thereof

InactiveCN103484935ALow content of metal impuritiesSlow down the spreadPolycrystalline material growthSingle crystal growth detailsMetallurgyMetal impurities

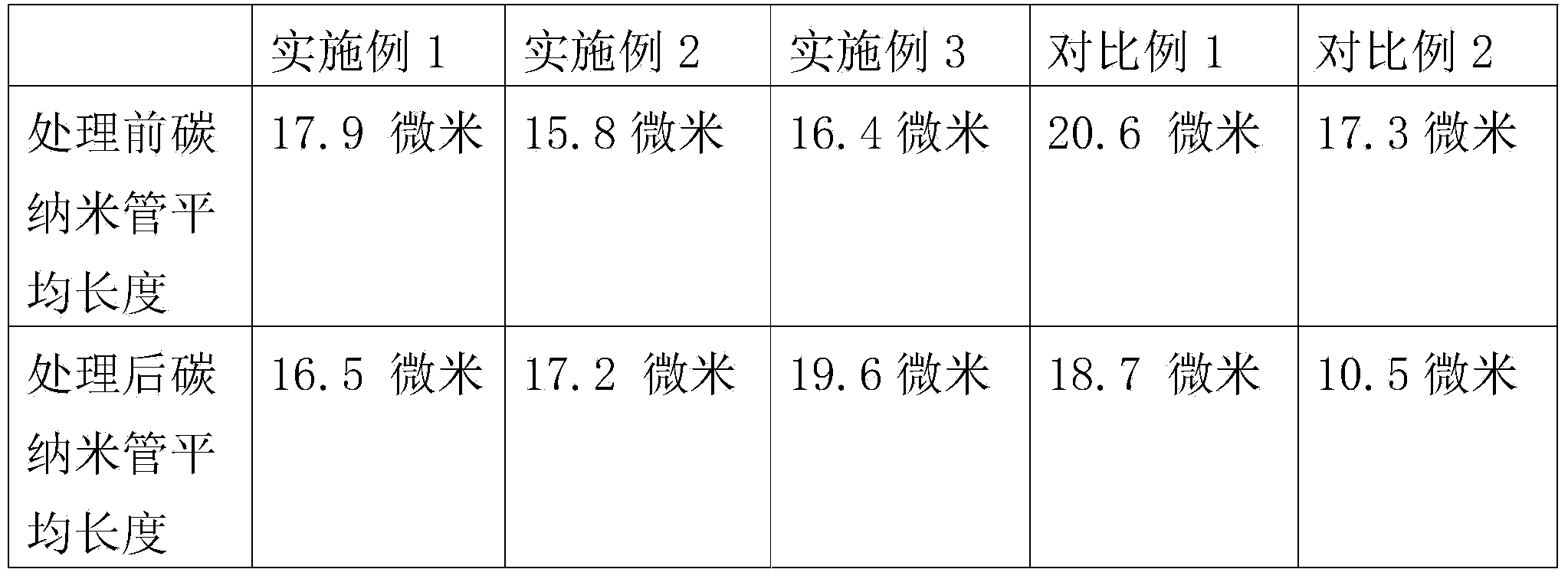

The invention discloses a quartz crucible and a manufacturing method of the quartz crucible. A glass sand coating coats the inner surface of a common quartz crucible body and plays a role in shielding between the common quartz crucible body and polycrystalline silicon ingot crystals, the speed of metal impurities diffusing toward the polycrystalline silicon ingot crystals in the common quartz crucible body is reduced, then the content of the metal impurities in the polycrystalline silicon ingot crystals is reduced, and therefore the purpose of improving service life of a non-equilibrium minority carrier is achieved. On the basis of the manufacturing method, the number of unqualified parts of the bottom surface and the side faces in the manufactured qualified polycrystalline silicon ingot crystals is reduced, the usage rate is improved, and production cost is reduced.

Owner:镇江荣德新能源科技有限公司

Preparation method of large-size silicon nitride crucible

The invention discloses a preparation method of a large-size silicon nitride crucible. According to the method, (1) silicon nitride powder, a dispersing agent, sintering aids, a binding agent and a solvent are well mixed, such that a slurry is obtained; (2) the slurry is added into a mold cavity of a gypsum mold under stirring; the mold is placed in an environment with constant temperature and constant humidity, such that the mold can absorb and discharge water; and a molded cured blank is obtained; (3) a mold core and side molds of the mold are removed, and the molded cured blank is placed in a curing furnace, such that the product is cured and dried, and a green body is obtained; (4) the green body is placed in a gas pressure sintering furnace, and is subjected to segmented sintering; when sintering is finished, the temperature is reduced, the pressure is released and the product is fetched from the furnace, such that the silicon nitride crucible is obtained. According to the invention, silicon dioxide and magnesium silicon nitride are adopted as sintering aids, such that the prepared silicon nitride crucible has low oxygen impurity and metal impurity contents, large bulk density, high high-temperature strength, and large size. The crucible can be widely applied in various non-ferrous metal smelting and silicon crystal ingot casting. The preparation method is simple to operate, and is easy to popularize.

Owner:烟台同立高科新材料股份有限公司

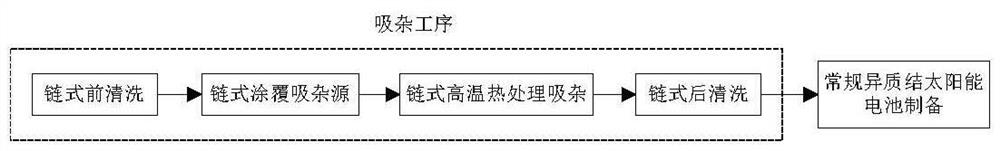

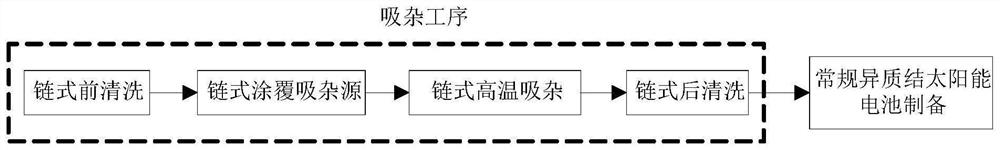

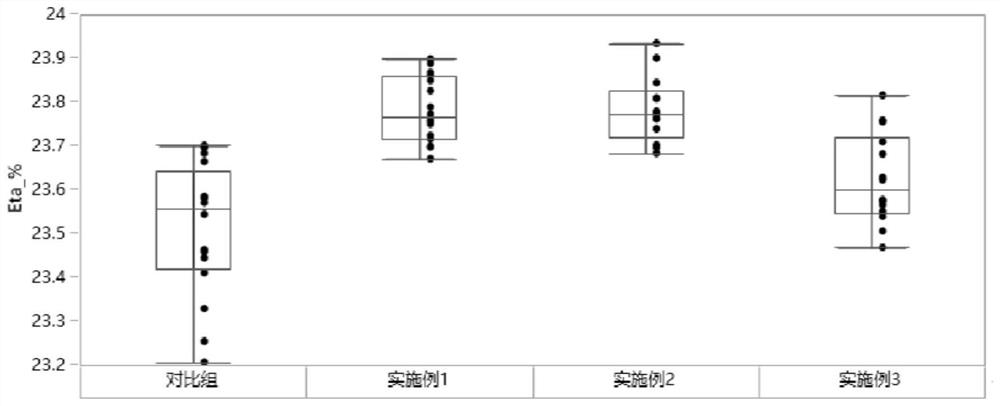

Efficient heterojunction solar cell and preparation method thereof

InactiveCN112289894ALow content of metal impuritiesImprove conversion efficiencyFinal product manufactureSemiconductor devicesElectrical batteryPhysical chemistry

The invention discloses an efficient heterojunction solar cell and a preparation method thereof, and the preparation method is characterized in that a gettering process is added before a conventionalheterojunction solar cell preparation process, and the gettering process is completed through a full-chain process; the full-chain process comprises the following steps: coating a gettering source ona silicon wafer in a chain manner; and performing chained high-temperature gettering. According to the preparation method, the conversion efficiency of the efficient heterojunction solar cell is improved by reducing the metal impurity content of the N-type silicon wafer; the efficiency distribution of the prepared efficient heterojunction solar cell is more centralized, and the product consistencyis greatly improved; the battery edge electric leakage rate is reduced, and the battery yield is improved; the full-chain gettering process shortens the circulation time of the silicon wafer in the manufacturing process, reduces the pollution probability of the silicon wafer, improves the conversion efficiency of the battery to a certain extent, and is short in time consumption, low in energy consumption, high in automation degree and beneficial to industrial popularization and application.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

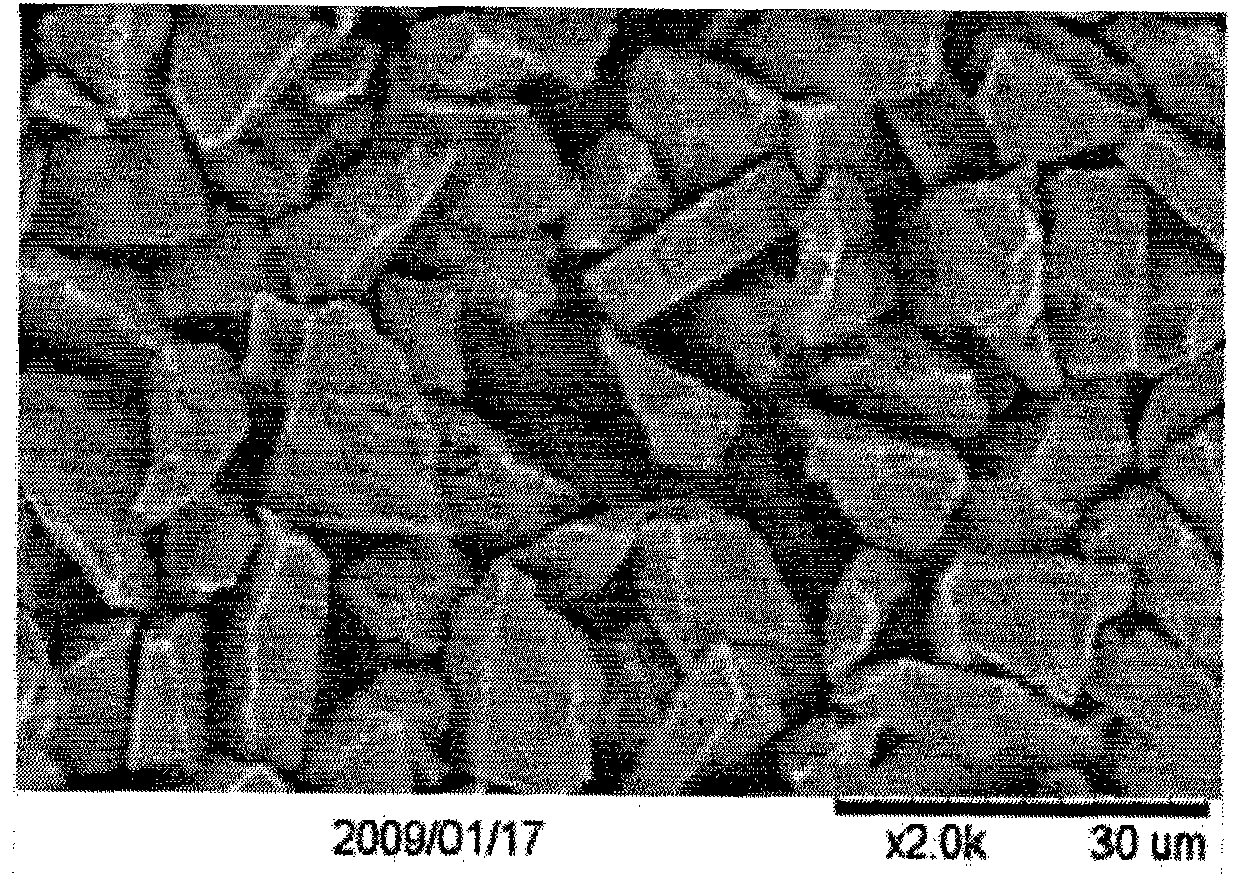

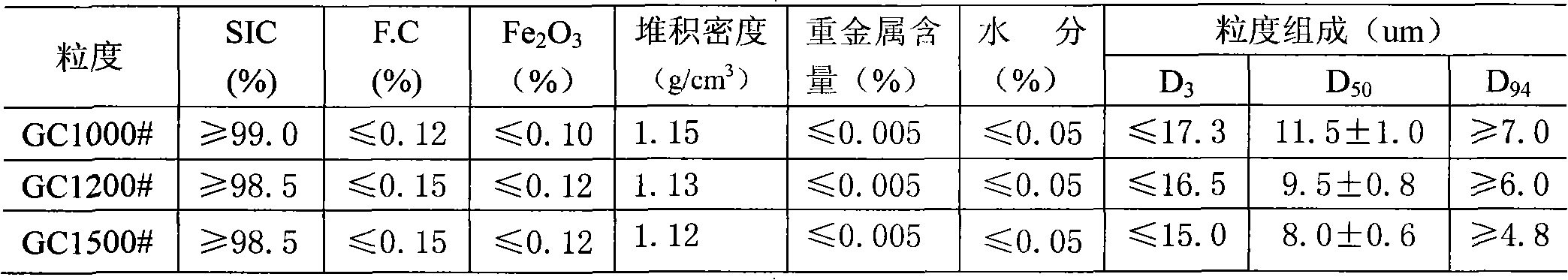

Preparation method of semiconductor wafer cutting blade material

The invention relates to a preparation method of a semiconductor wafer cutting blade material. In the preparation method, high-purity green silicon carbide and black silicon carbide are adopted as raw materials, and a wafer cutting blade material is prepared through the steps of jaw crushing and sifting, wet ball milling classification, pickling, overflow size separation, concentrating and dewatering, drying, blending, fine screening and the like. Silicon carbide blade materials prepared through the method are most in equiareal shape and keep sharp edges and strong cutting power, can minimize TTV of a silicon wafer, and have strong adaptability to cutting fluid such as polyethylene glycol and the like because blade material particles have larger specific area and clean surfaces. Products crushed by a wet ball mill are most in equiareal shape, have high output, and can avoid excessive crushing. The preparation method of the invention can reach over 50% of rate of finished products, and products milled with the technology have more uniform size and distribution of particles, thereby better cutting effect to silicon wafers can be achieved.

Owner:HENAN XINDAXIN SCI & TECH

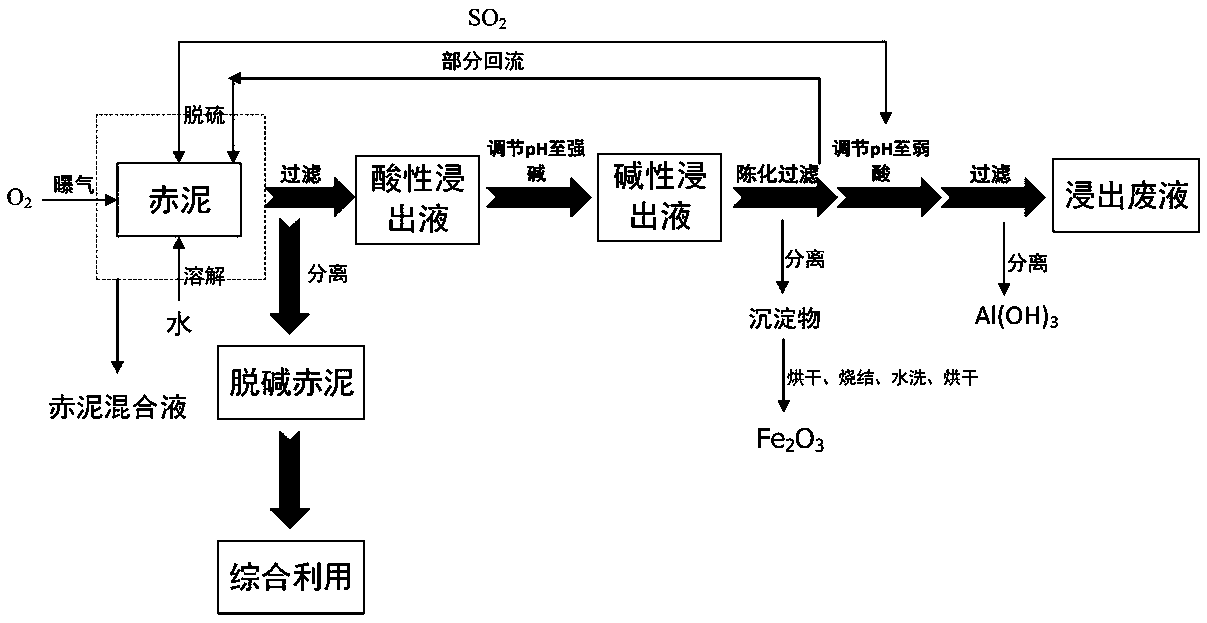

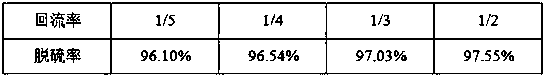

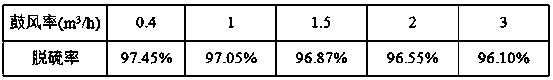

Method for dealkalizing aluminum-reinforced red mud and separating and recovering aluminum and iron

ActiveCN109987639ATo achieve the purpose of de-alkalizationLow running costGas treatmentDispersed particle separationAlkalinityPregnant leach solution

The invention discloses a method for dealkalizing aluminum-reinforced red mud and separating and recovering aluminum and iron, which comprises the following steps: dissolving red mud in water, introducing excessive SO2, introducing oxygen for aeration at the same time, and enabling a part of filtered alkaline leachate to flow back; when the pH value of a red mud mixed solution is reduced to 3 or below, conducting washing and filtering on the red mud mixed solution, then adding NaOH into an acidic leachate to adjust the pH value to strong alkalinity, conducting aging and filtering on a leachateagain, treating filter residues, recovering Fe2O3, and meanwhile, enabling the filtered alkaline leachate to flow back to the red mud mixed solution; and adjusting the pH value of the residual filtered alkaline leachate to be weakly acidic, and then conducting filtering to recover aluminum. According to the method, SO2 is introduced into the red mud mixed solution for acidification and desulfurization, a part of filtered alkaline leachate containing Al<3+> flows back to the red mud mixed solution, and thus dealkalization of the red mud is reinforced; and filter residues obtained by filteringthe alkaline leachate are subjected to the steps of drying, sintering and the like, and almost pure Fe2O3 can be obtained; and the pH value of the residual filtered alkaline leachate is adjusted to beweakly acidic, and Al(OH)3 can be recovered through filtering.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing silicon tetrachloride for optical fiber

InactiveCN102107875AReduce hydrogen impuritiesLow content of metal impuritiesSilicon halogen compoundsIndustrial scaleMaterials science

The invention provides a method for preparing silicon tetrachloride for optical fiber. The method comprises the following steps of: introducing chloride under the protective atmosphere of inactive gas or inert gas and under the condition of illumination, so that trichlorosilane is subjected to a photochemical reaction in a rectifying tower, wherein high-boiling-point silicon tetrachloride generated in the production process of polycrystalline silicon serves as a raw material; and controlling the tower kettle temperature and the tower top temperature and taking materials by selecting proper reflux ratio to obtain an intermediate product; further rectifying and purifying the intermediate product to obtain high-purity silicon tetrachloride, wherein infrared transmissivity of hydrogen-containing impurities meets the requirement of the silicon tetrachloride for the optical fiber on impurity transmissivity; and the metal ion content meets the metal content standard of the silicon tetrachloride for the optical fiber. The method has the advantages that: the trichlorosilane with the boiling point close to that of the silicon tetrachloride is removed effectively; the hydrogen-containing impurity content and the metal impurity content of the silicon tetrachloride are reduced; the quality of the silicon tetrachloride purified and prepared by the process completely meets the requirement of optical fiber products; the reaction condition and the completeness are easy to control; other impurities are not introduced; and the method is implemented in an industrial scale and in an effective and economic mode.

Owner:BEIJING GUOJING INFRARED OPTICAL TECH

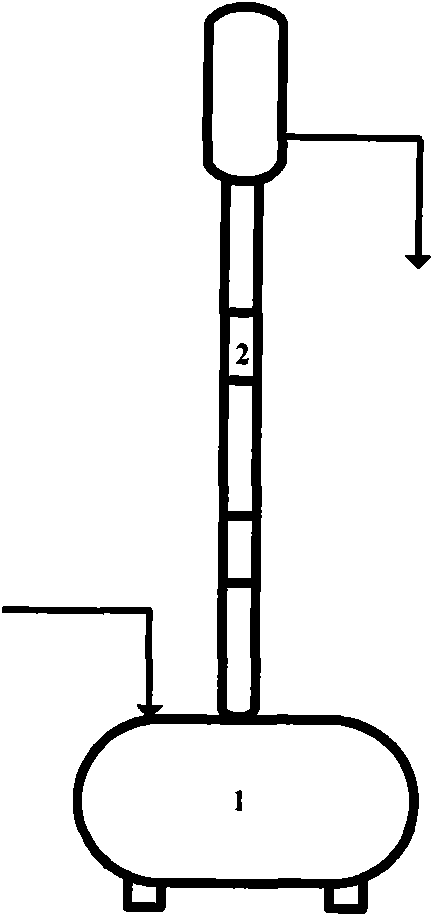

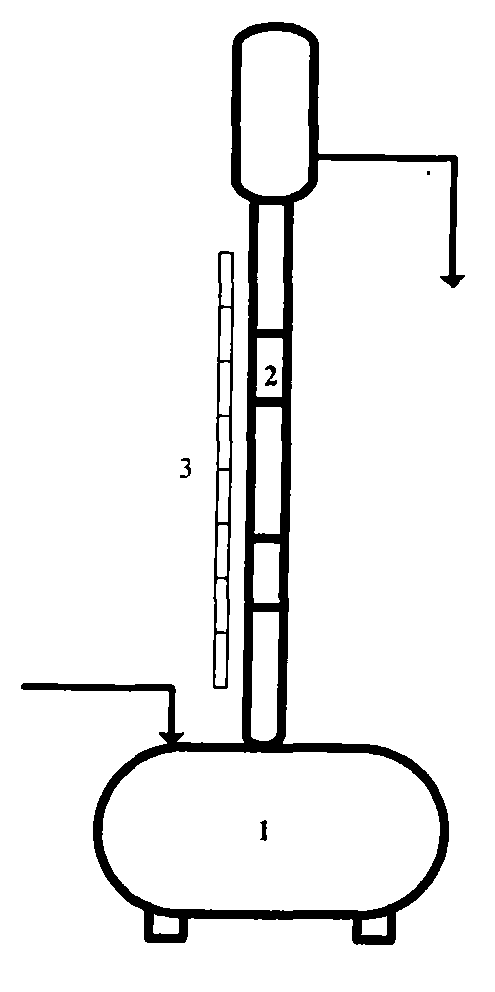

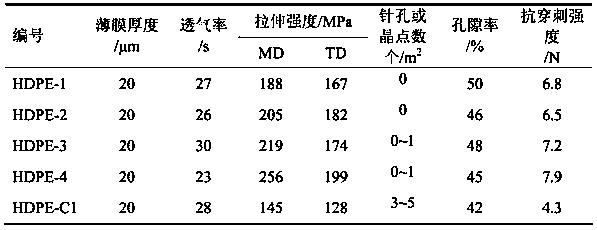

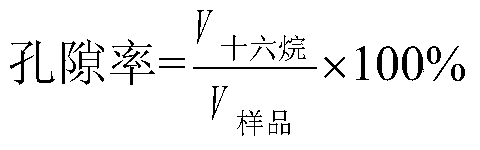

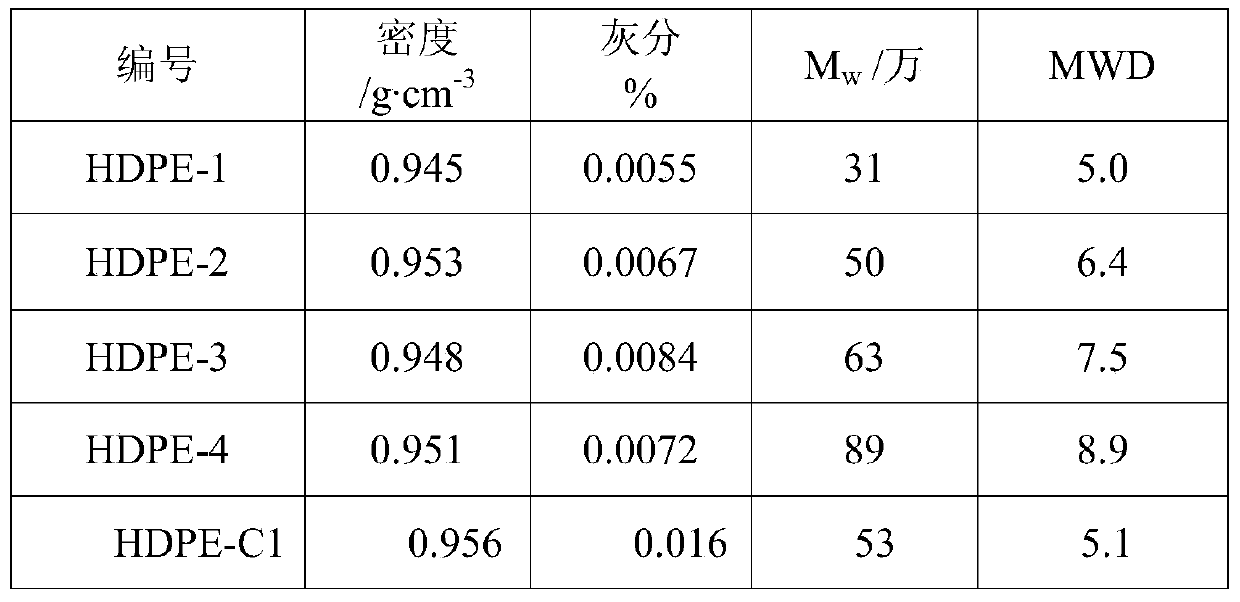

Low-ash and high-density polyethylene resin and preparation method thereof

ActiveCN105504124AUniform pore size distributionHigh tensile strengthCell component detailsBulk chemical productionLow-density polyethylenePolymer science

The present invention discloses a low-ash and high-density polyethylene resin and a preparation method thereof, wherein the weight average relative molecular mass of the low-ash and high-density polyethylene resin is 3.0*10<5>-9.0*10<5>, the relative molecular mass distribution is 5-9, the density is 0.940-0.965 g / cm<3>, and the ash content is less than 100 ppm. According to the present invention, the low-ash and high-density polyethylene resin has advantages of uniform composition, low ash, low metal impurity content, and the like; with the three-reaction kettle series connection method, the relative molecular mass, the relative molecular mass distribution and the co-polymerization monomer distribution of the polymerization product are easy to adjust, and the method can be directly used for molding of the wet lithium-ion battery separation membrane; and the molded microporous separation membrane has characteristics of uniform pore size distribution, less pinholes, less fisheye, high yield, high tensile strength, and high puncture strength.

Owner:SINOPEC YANGZI PETROCHEM +1

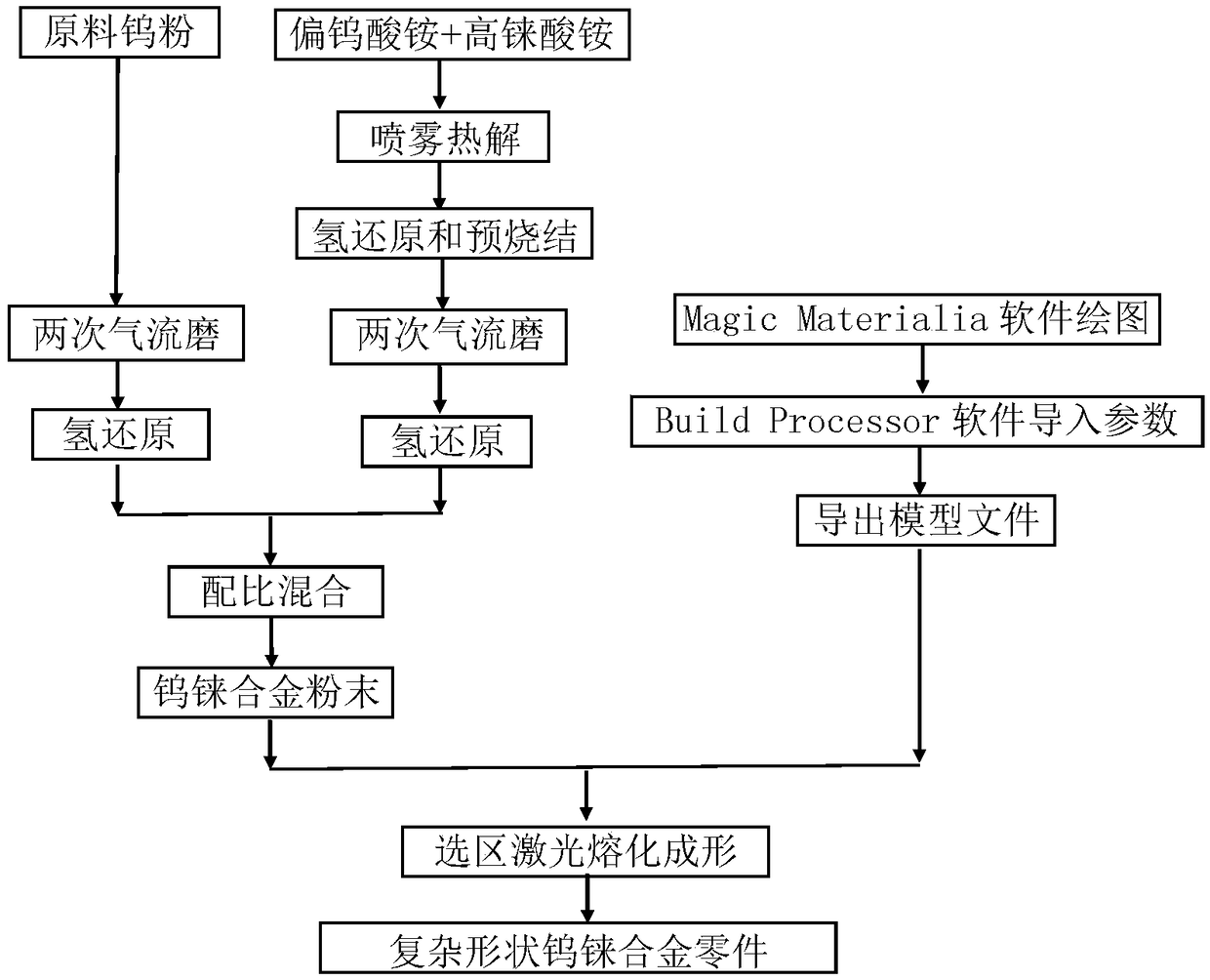

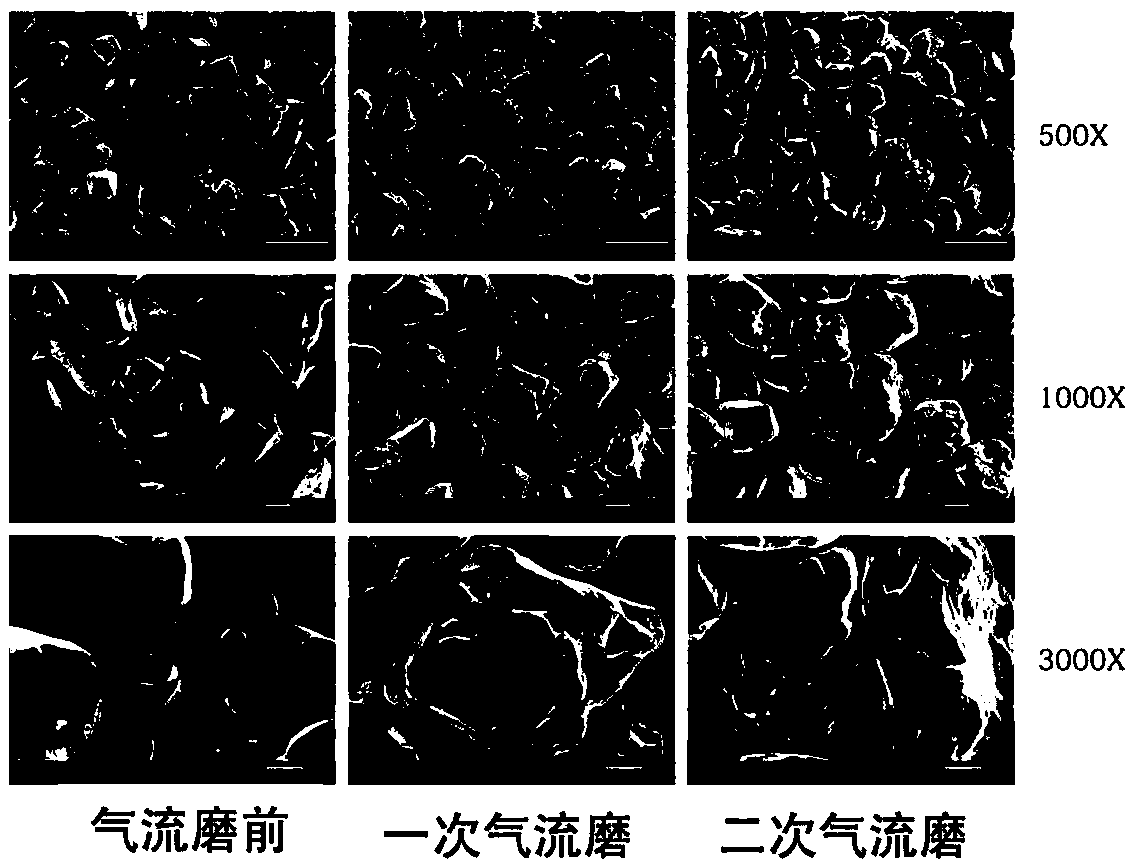

Method for preparing high-performance tungsten base metal parts

ActiveCN109128163ALow content of metal impuritiesUniform sphericityAdditive manufacturing apparatusIncreasing energy efficiencyRheniumSelective laser melting

The invention discloses a method for preparing high-performance tungsten base metal parts, and belongs to the technical field of powder added material production. Firstly, a spray pyrolysis method anda hydrogen reduction presintering method are adopted to prepare tungsten rhenium alloy powder with high purity and uniform chemical components. Then, an airflow milling technology is adopted twice toimprove the states of raw materials of tungsten powder and tungsten rhenium alloy powder; and then, the reduction is performed in a hydrogen atmosphere to finally obtain high-quality similarly spherical tungsten rhenium alloy powder. Meanwhile, a workpiece sketch map with a complicated shape and optimal machining policies are designed through computer modeling software; and printing files are derived to realize modeling. Finally, after the tungsten powder and the tungsten rhenium alloy powder are mixed in proportion, tungsten rhenium base alloy parts with final complicated shapes are preparedby SLM selective laser melting equipment. Through combination of the spray pyrolysis process with the airflow milling process, the raw material powder is prominently optimized; and the tungsten rhenium alloy parts prepared by selective laser melting are near total compact, uniform in structure and excellent in comprehensive mechanical performance.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing silicon nitride by using recovery purification silicon wafer sawdust powder

InactiveCN102849695ALow costRealize reasonable recyclingNitrogen compoundsWaste processingThermal insulationSilicon nitride

The present invention relates to a method for preparing silicon nitride by using recovery purification silicon wafer sawdust powder. The method is characterized by comprising the following steps: 1) adding silicon wafer sawdust powder to a container, introducing a protection gas, carrying out first heating under the protection of the protection gas, and carrying out a first thermal insulation treatment to obtain a powder A; 2) carrying out second heating on the powder A under the protection of the protection gas, carrying out a second thermal insulation treatment, and cooling to a room temperature to obtain a powder B, wherein the powder A is maintained to continuously rotate during the thermal insulation process; and 3) carrying out third heating on the powder B under the protection of the protection gas, carrying out a third thermal insulation treatment, and cooling to a room temperature to obtain the silicon nitride. With the method of the present invention, reasonable recovery utilization of a large amount of silicon wafer sawdust produced by photovoltaic industry can be achieved so as to reduce solar photovoltaic power generation cost.

Owner:YANGZHOU AINO PV MATERIAL TECH

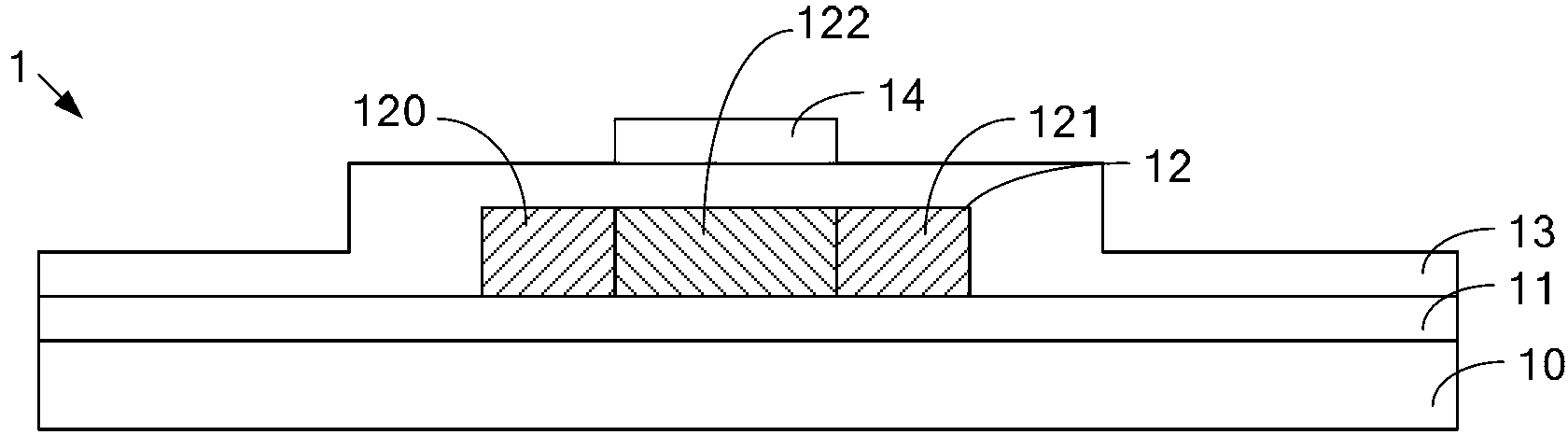

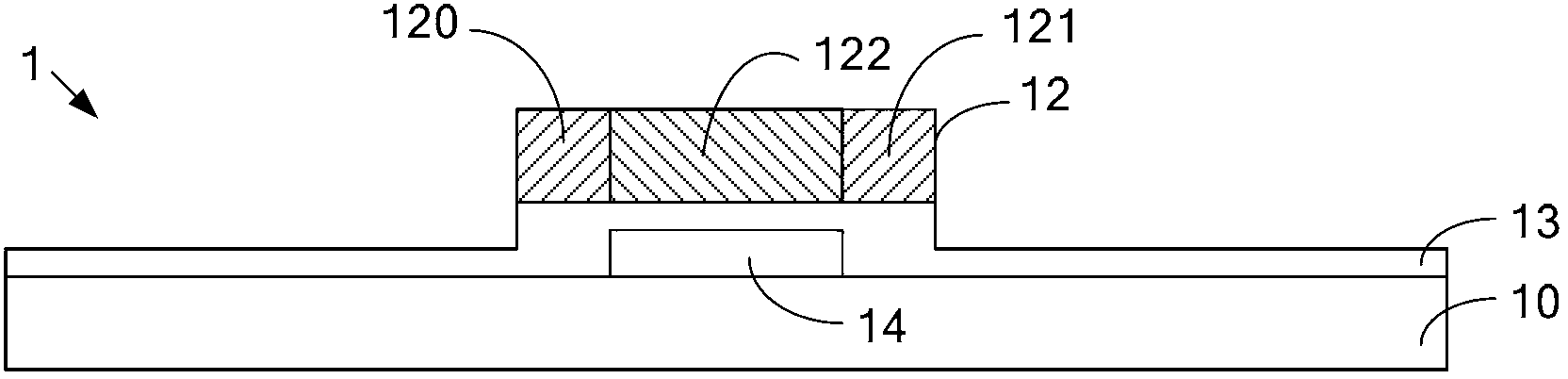

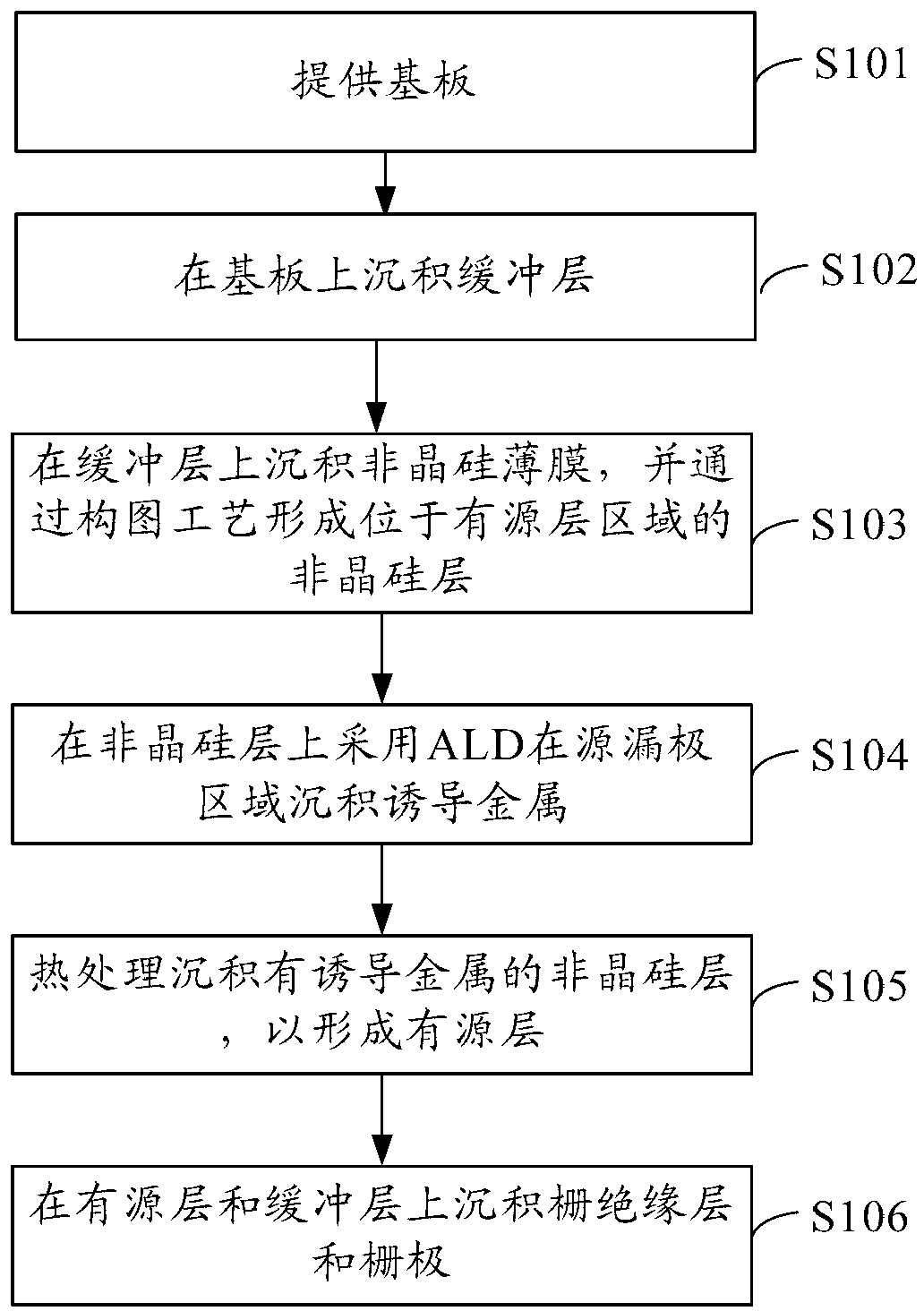

Thin film transistor and manufacturing method thereof as well as array substrate and display device

InactiveCN102842620ALow content of metal impuritiesThe content is easy to controlTransistorSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The embodiment of the invention provides a thin film transistor and a manufacturing method thereof as well as an array substrate and a display device, and relates to the field of display technologies, and a thin film transistor with low impurity content can be prepared in low temperature. The thin film transistor comprises a substrate and an active layer arranged on the substrate, wherein the active layer comprises a source electrode, a drain electrode and a channel region; the active layer is formed in the way that after inductive metal is deposited on an amorphous silicon layer on the substrate through ALD (Atomic Layer Deposition), the amorphous silicon layer on which the inductive metal is deposited is subject to heat treatment to enable the amorphous silicon layer to be subject to metal-induced crystallization and metal-induced transverse crystallization; and the active layer provides the source electrode, the drain electrode and the channel region.

Owner:BOE TECH GRP CO LTD

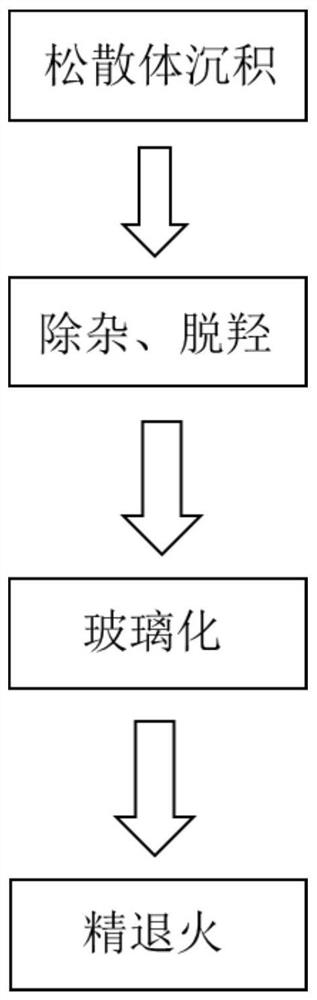

Chemical deposition method and device for high-purity low-hydroxyl high-uniformity quartz glass

PendingCN112876044AGuaranteed purityLow impurity contentGlass shaping apparatusVitrificationPhysical chemistry

The invention relates to a chemical deposition method of high-purity low-hydroxyl high-uniformity quartz glass, which comprises the following steps: (1) depositing a silicon source in a deposition cavity by adopting a vapor phase axial deposition method to obtain a low-density SiO2 loose body; wherein in the deposition process, the interior of the deposition cavity is controlled to be in a negative pressure environment, and the temperature is not higher than 500 DEG C; (2) in a closed environment filled with dehydroxylation airflow and oxygen, heating the low-density SiO2 loose body to 1100-1300 DEG C, so that the low-density SiO2 loose body is dehydrated, dehydroxylated and densified; then, placing the low-density SiO2 loose body in an inert gas environment, heating to 1470-1600 DEG C, and vitrifying the low-density SiO2 loose body to form transparent quartz glass; and (3) annealing the transparent quartz glass to obtain the high-purity low-hydroxyl high-uniformity quartz glass. The invention further discloses a device adopting the chemical deposition process. According to the chemical deposition method of the high-purity low-hydroxyl high-uniformity quartz glass, the production process is high in continuity, and the content of metal impurities in the produced quartz glass is extremely low.

Owner:江苏亨芯石英科技有限公司 +1

Graphene material and preparation method, and saggar used for graphene preparation

ActiveCN107098338AHigh temperature resistantSimple structureCell electrodesGrapheneHigh densityGraphite

The invention relates to a saggar used for graphene preparation. A material of the saggar is high-density graphite, the saggar comprises a saggar main body and a saggar cover, the top of the saggar main body is opened, the top of the saggar main body is covered by the saggar cover, wherein, the saggar main body comprises an external saggar wall body and an external cavity formed by the external saggar wall body, a gap is arranged on the external saggar wall body, so that the external cavity is communicated with the outside part; an internal saggar is arranged in the saggar main body, the internal comprises an internal saggar wall body and an internal cavity formed by the internal saggar wall body, and the external cavity is communicated with the internal cavity. The invention also provides a method for preparing a graphene material by using the saggar and the graphene material.

Owner:乌兰察布市大盛石墨新材料股份有限公司

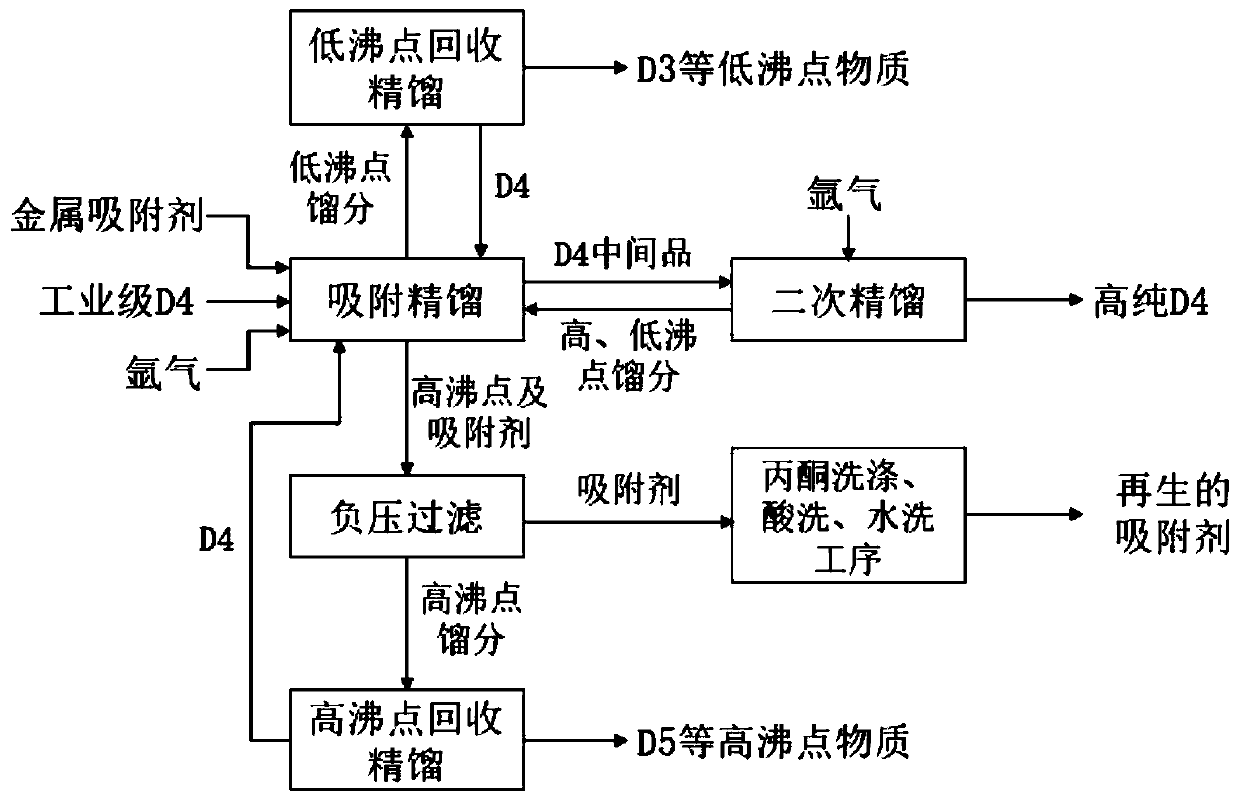

Purification process of octamethylcyclotetrasiloxane

PendingCN111574551ALow content of metal impuritiesHigh process integrationSilicon organic compoundsSiloxaneMetal impurities

The invention relates to a purification process of octamethylcyclotetrasiloxane. The purification process comprises the following steps: by using high-purity argon as a carrier gas, removing metal impurities in octamethylcyclotetrasiloxane by an adsorption reaction in a slight boiling state; carrying out rectification purification, separating octamethylcyclotetrasiloxane from the adsorbent, and removing organic impurities, water and oxygen to obtain an octamethylcyclotetrasiloxane intermediate product; and conducting secondary rectification to further purify an octamethylcyclotetrasiloxane intermediate product so as to obtain a pure octamethylcyclotetrasiloxane product with purity of greater than 99.999%. The pure octamethylcyclotetrasiloxane product meets the cladding deposition requirement of an optical fiber preform.

Owner:GRINM GUOJINGHUI NEW MATERIALS CO LTD

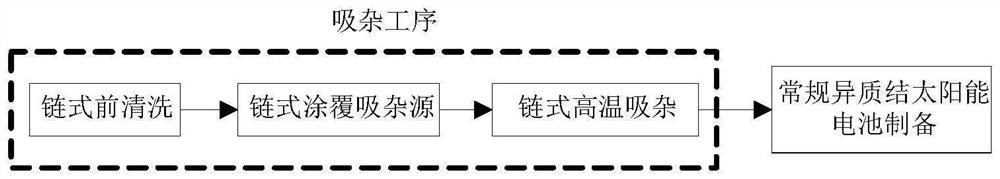

High-efficiency heterojunction solar cell and preparation method thereof

ActiveCN114551636ALow content of metal impuritiesImprove quality levelFinal product manufactureSemiconductor devicesHeterojunctionPhysical chemistry

The invention discloses a high-efficiency heterojunction solar cell and a preparation method thereof, and the preparation method is characterized in that a gettering process is added before a conventional heterojunction solar cell preparation process, and the gettering process is completed through a full-chain gettering process; the full-chain gettering process comprises the following steps: carrying out chain pre-cleaning on a silicon wafer; coating a gettering source on the surface of the silicon wafer in a chained manner; and carrying out chained high-temperature gettering on the silicon wafer. According to the preparation method, by reducing the metal impurity content of the N-type monocrystalline silicon wafer, the quality level of the silicon wafer is improved, the difference between the silicon wafers is reduced, and the conversion efficiency of the heterojunction solar cell is improved; the quality of the N-type monocrystalline silicon wafer tends to be consistent, the efficiency distribution of the prepared heterojunction solar cell is more concentrated, the discreteness of the efficiency distribution is reduced, and the product consistency is greatly improved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

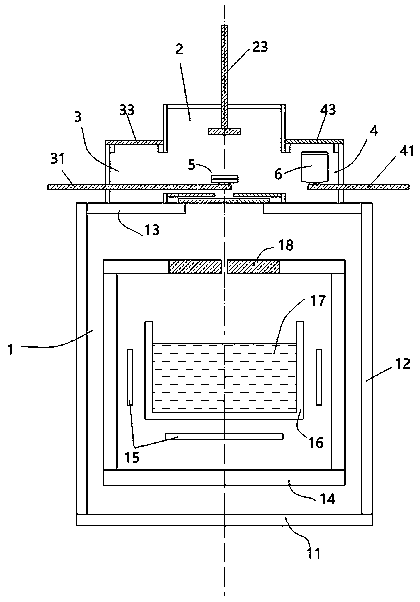

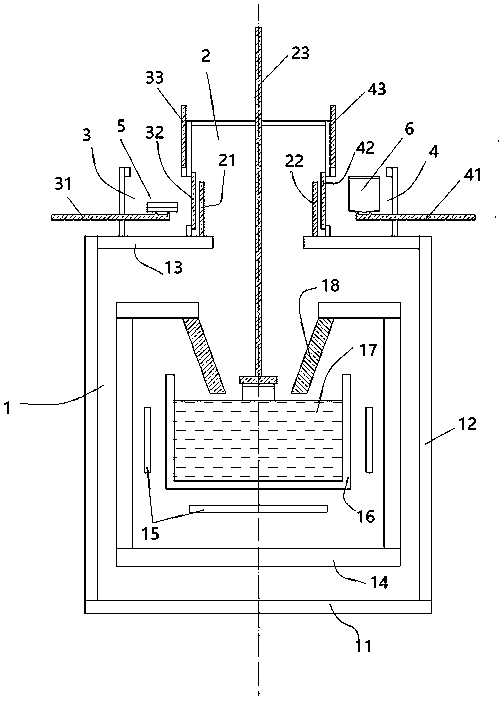

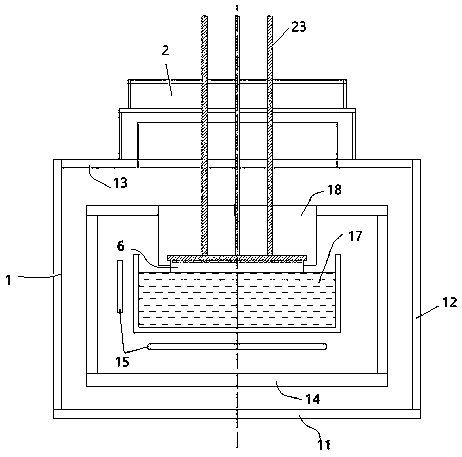

Quasi-monocrystalline silicon crystal growth method and thermal field structure

ActiveCN110205672AShort growth preparation timeQuasi-continuous growthPolycrystalline material growthBy pulling from meltCrystal orientationCrystalline silicon

The invention discloses a quasi-monocrystalline silicon crystal growth method and a thermal field structure, and relates to the technical field of solar crystalline silicon materials. Single platy seed crystals are used, and under seed crystal induction, a quasi-square crystal with the height slightly equal to the width grows from silicon melt in the seed crystal thickness direction from top to bottom. In order to implement the crystal growth method, the thermal field structure comprises a main furnace room, an auxiliary furnace room, a seed crystal loading cavity, a crystal bar unloading cavity, a crystal listing mechanism, a crucible, a heater, a heat preservation basket, a heat insulation board and the like; the crystal lifting mechanism in the auxiliary furnace room mounts the seed crystals to induce crystal growth; in the crystal growth process, seed crystal module preparation and crystal bar taking are conducted in the crystal loading cavity and the crystal bar unloading cavity,after crystal bar growth is completed, the crystal lifting mechanism can rapidly unload and re-mount a seed crystal block to grow the next crystal. The grown quasi-monocrystalline crystal has the advantages of being uniform in crystal orientation, low in edge leather ratio, high in product qualification ratio, low in defect density and high in production efficiency.

Owner:常州常晶科技有限公司

Carbon nano-tube purification method

InactiveCN109502572AHigh purityLow content of metal impuritiesCarbon nanotubesMetal chloridePurification methods

The invention relates to a carbon nano-tube purification method in the technical field of material purification. The carbon nano-tube purification method comprises the following steps: preparing a to-be-purified carbon nano-tube into an electric heating element and connecting with the inside of a pulse circuit; powering on and heating the electric heating element under vacuum and introducing chlorine gas until metals and metallic oxides on the surface the carbon nano-tube in the electric heating element react with the chlorine gas to produce a high-purity carbon nano-tube by gasification; introducing inert gas, removing mixed gases including metallic chloride gas until the high-purity carbon nano-tube is in an inert gas protection state, cooling the high-purity carbon nano-tube and finishing the purification of the carbon nano-tube. The carbon nano-tube purification method provided by the invention has the beneficial effects that the purification efficiency of the carbon nano-tube canbe improved, and the energy consumption and the pollution are reduced.

Owner:SUZHOU FIRST ELEMENT NANO TECH

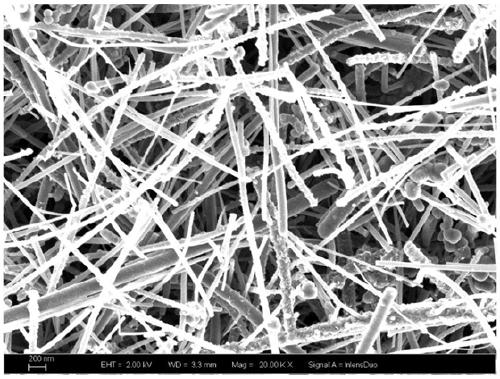

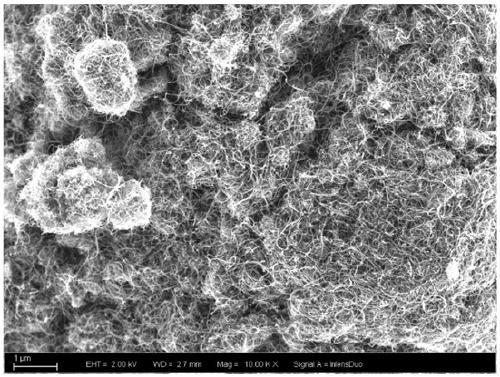

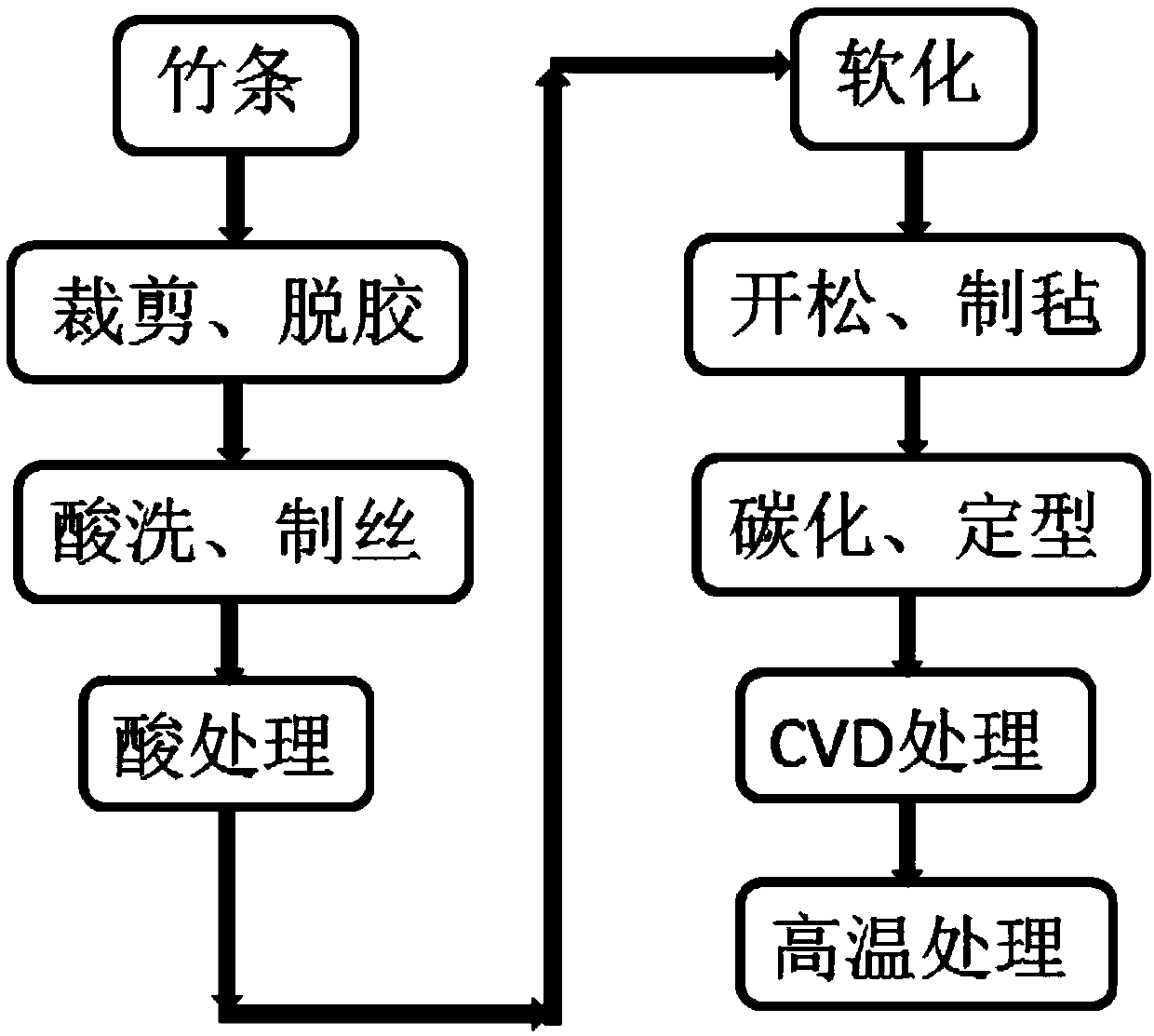

Environment-friendly cured carbon felt and preparation method thereof

ActiveCN109576899ALow content of metal impuritiesMeet the needs of useSolvent-treatmentHeating/cooling textile fabricsFiberMicrometer

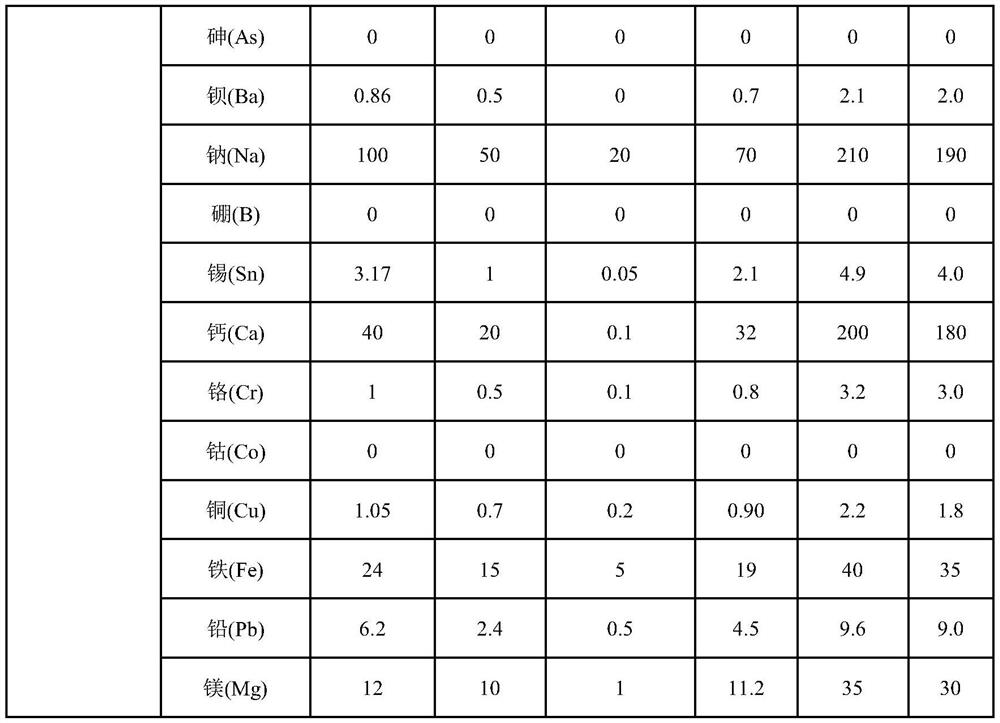

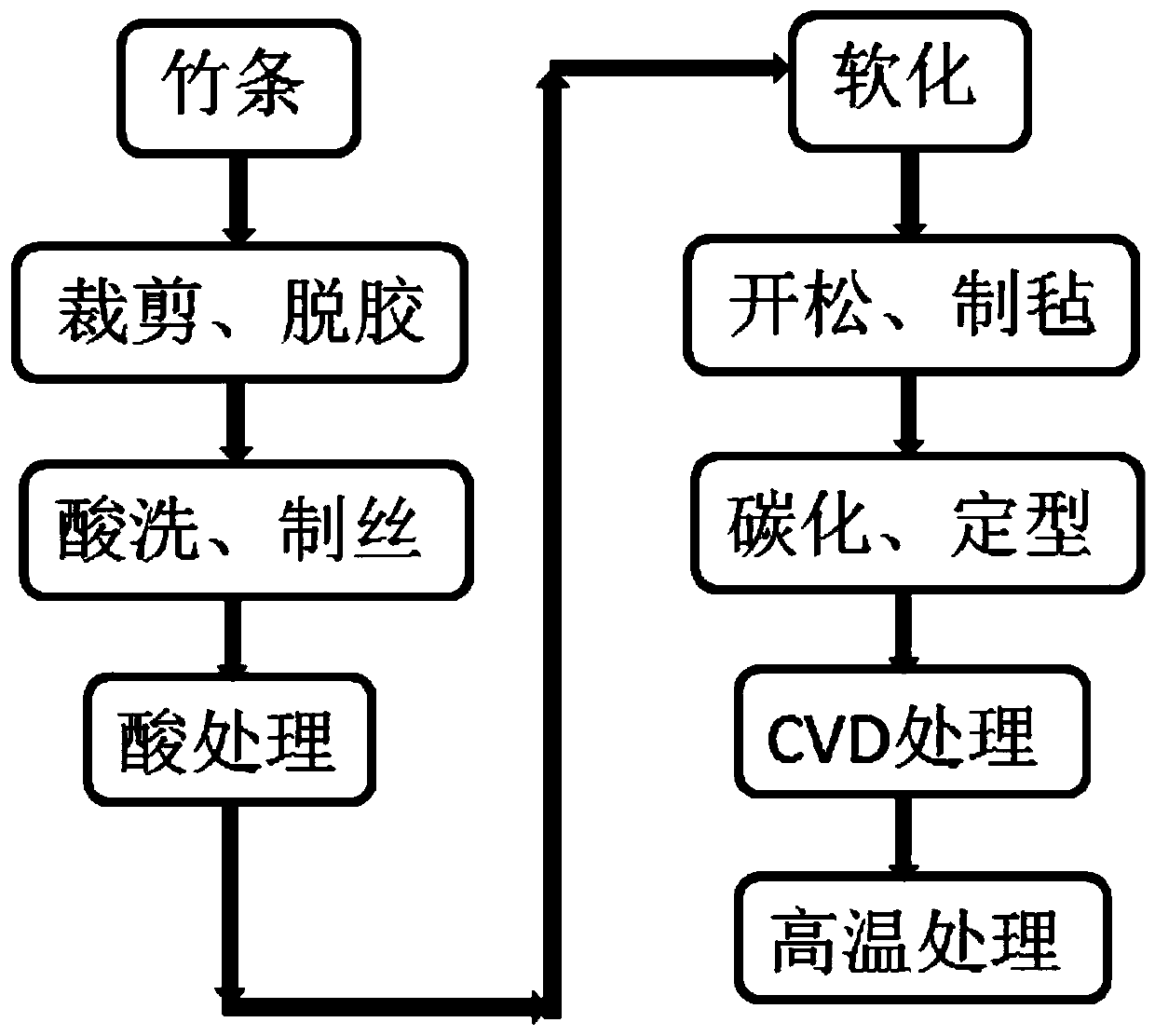

The invention discloses environment-friendly cured carbon felt and a preparation method thereof. The cured carbon felt is prepared by taking natural bamboo fiber as the raw material. The preparation method of the cured carbon felt comprises the steps of cutting and degumming, pickling and silk making, acid treatment and softening, loosening and felting, carbonization and finalization, CVD treatment and high temperature treatment. Compared with an existing cured carbon felt preparation method, the preparation method of the cured carbon felt is environmentally friendly, the raw materials are rich in source, and the price is low. The monofilament diameter of the cured carbon felt is 10-15 micrometer; the cured carbon felt is mainly carbon, and the carbon content is 95-97%; the cured carbon felt can tolerate the temperature of 2,500 DEG C to the maximum, and the metal impurity content is less than 295ppm.

Owner:湖南金创新材料有限公司

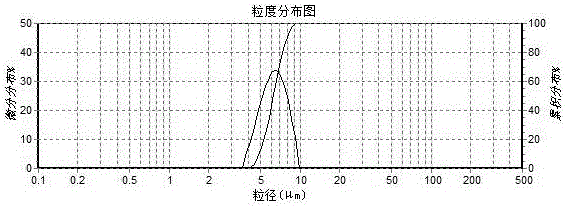

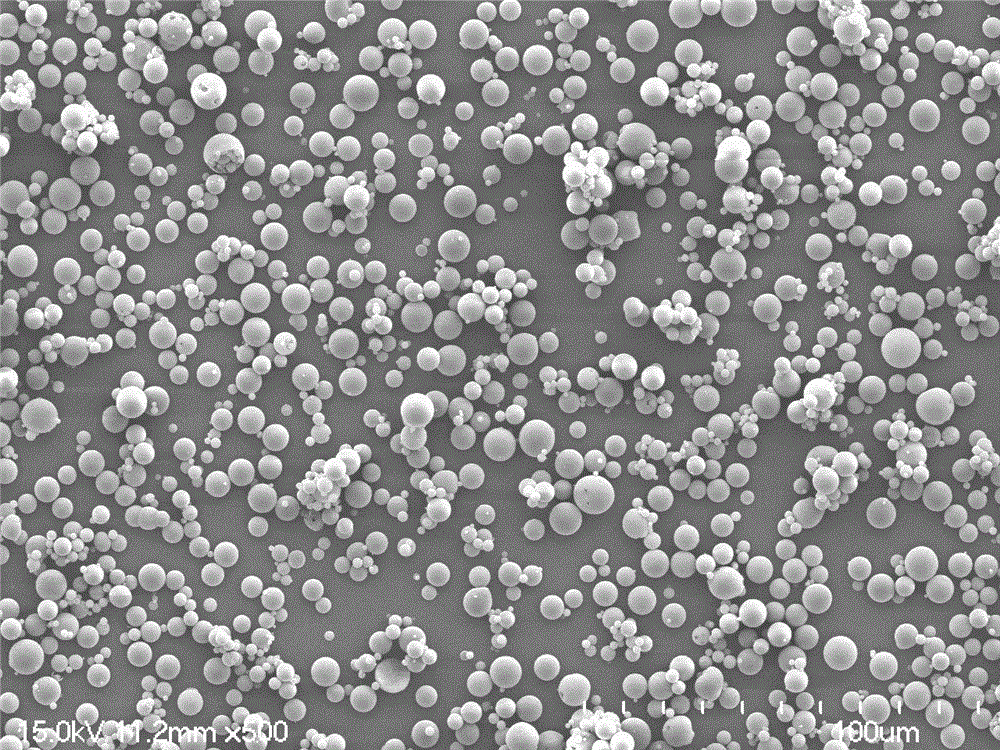

A kind of preparation method of ultrahigh-purity amorphous spherical silica powder

ActiveCN104556076BLow content of radioactive elementsNo radioactive contaminationSilicaAlkaline waterEmulsion

Owner:苏州西丽卡电子材料有限公司

Method for external refining purification of industrial silicon

The invention relates to a method for the external refining purification of industrial silicon. According to the method, refining gas is continuously introduced into a two-man ladle before industrial silicon melt is released into the two-man ladle from a submerged-arc furnace, and the silicon melt is then released into the two-man ladle for being subjected to external refining. The industrial silicon melt in the two-man ladle is heated by an external plasma heating device, the external refining temperature for the industrial silicon melt is enabled to be controlled in a certain range, and a refining agent is added into the two-man ladle so as to carry out slagging refinement. Through the external refining process, most metallic impurities, including Al, Ca, Ti, Na and Mg, and partial non-metallic impurity impurities, including B, P, S and C, can be removed from the industrial silicon melt, so that the quality of industrial silicon products is effectively improved, and high-quality industrial silicon products with low boron, phosphorus and metallic impurity content are obtained. The method has the characteristics of full energy utilization and conservation, high production efficiency, less investment in capital construction, no environmental pollution, and the like.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing high-purity manganese sulfate from alabandite and product prepared according to method

InactiveCN108217736ANo secondary pollutionLow content of metal impuritiesManganese sulfatesSulfateManganese

The invention discloses a method for preparing high-purity manganese sulfate from alabandite and a product prepared according to the method. The method comprises the following steps: I, calcining a raw material, and performing sulfuric acid leaching; II, performing decontamination; and III, performing purification, thereby obtaining the high-purity manganese sulfate. The method is simple in process, easy to operate, free of secondary environment pollution since a great amount of additive chemical reagents are not used in the preparation process, low in production cost and easy in on-scale industrial production; and the problem of heavy metal separation can be solved, the contents of heavy metal impurities of common manganese sulfate products can be remarkably reduced, and manganese sulfatewith very low metal impurities can be prepared.

Owner:衡阳市瑞麟锰业技术开发有限公司

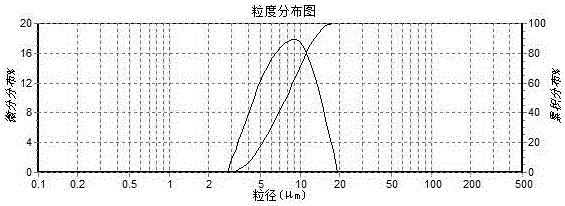

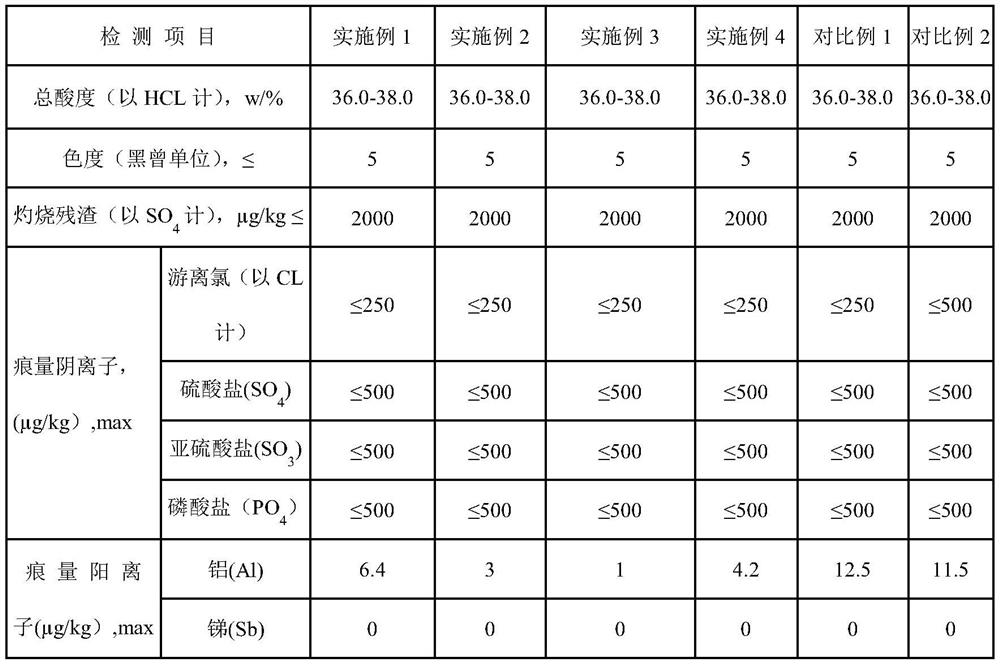

Production method of electronic-grade hydrochloric acid

ActiveCN113307228ALow content of metal impuritiesImprove product qualityChlorine/hydrogen-chloride purificationMetal impuritiesHydrogen chloride

The invention discloses a production method of electronic-grade hydrochloric acid. The production method comprises the following steps: (1) removing free chlorine in hydrogen chloride gas by adopting a reducing agent; (2) treating the hydrogen chloride gas from which the free chlorine is removed in the step (1) by adopting an acidic solution, and condensing and demisting; and (3) treating the demisted hydrogen chloride gas in the step (2) by adopting an acidic solution, condensing, then introducing into water for cyclic absorption, and carrying out two-stage filtration. The metal impurities in the hydrogen chloride gas are removed in a multi-stage washing mode, moisture in the gas is removed through condensation, finally, the electronic-grade hydrochloric acid obtained through absorption and filtration is high in purity, low in impurity content and more stable in product quality, the process is simple and convenient to operate, compared with a traditional rectification process, the energy consumption is low, pollution is avoided, the use cost is low, and the method is worthy of industrial popularization.

Owner:华融化学(成都)有限公司

A kind of environment-friendly curing carbon felt and preparation method thereof

ActiveCN109576899BLow content of metal impuritiesMeet the needs of useSolvent-treatmentHeating/cooling textile fabricsCarbonizationCarbon felt

The invention discloses environment-friendly cured carbon felt and a preparation method thereof. The cured carbon felt is prepared by taking natural bamboo fiber as the raw material. The preparation method of the cured carbon felt comprises the steps of cutting and degumming, pickling and silk making, acid treatment and softening, loosening and felting, carbonization and finalization, CVD treatment and high temperature treatment. Compared with an existing cured carbon felt preparation method, the preparation method of the cured carbon felt is environmentally friendly, the raw materials are rich in source, and the price is low. The monofilament diameter of the cured carbon felt is 10-15 micrometer; the cured carbon felt is mainly carbon, and the carbon content is 95-97%; the cured carbon felt can tolerate the temperature of 2,500 DEG C to the maximum, and the metal impurity content is less than 295ppm.

Owner:湖南金创新材料有限公司

Method of preparation white carbon black and sodium bexameta phosphate

InactiveCN1597511AIncrease costIn line with industrial policySilicaPhosphorus compoundsPhosphatePhosphoric acid

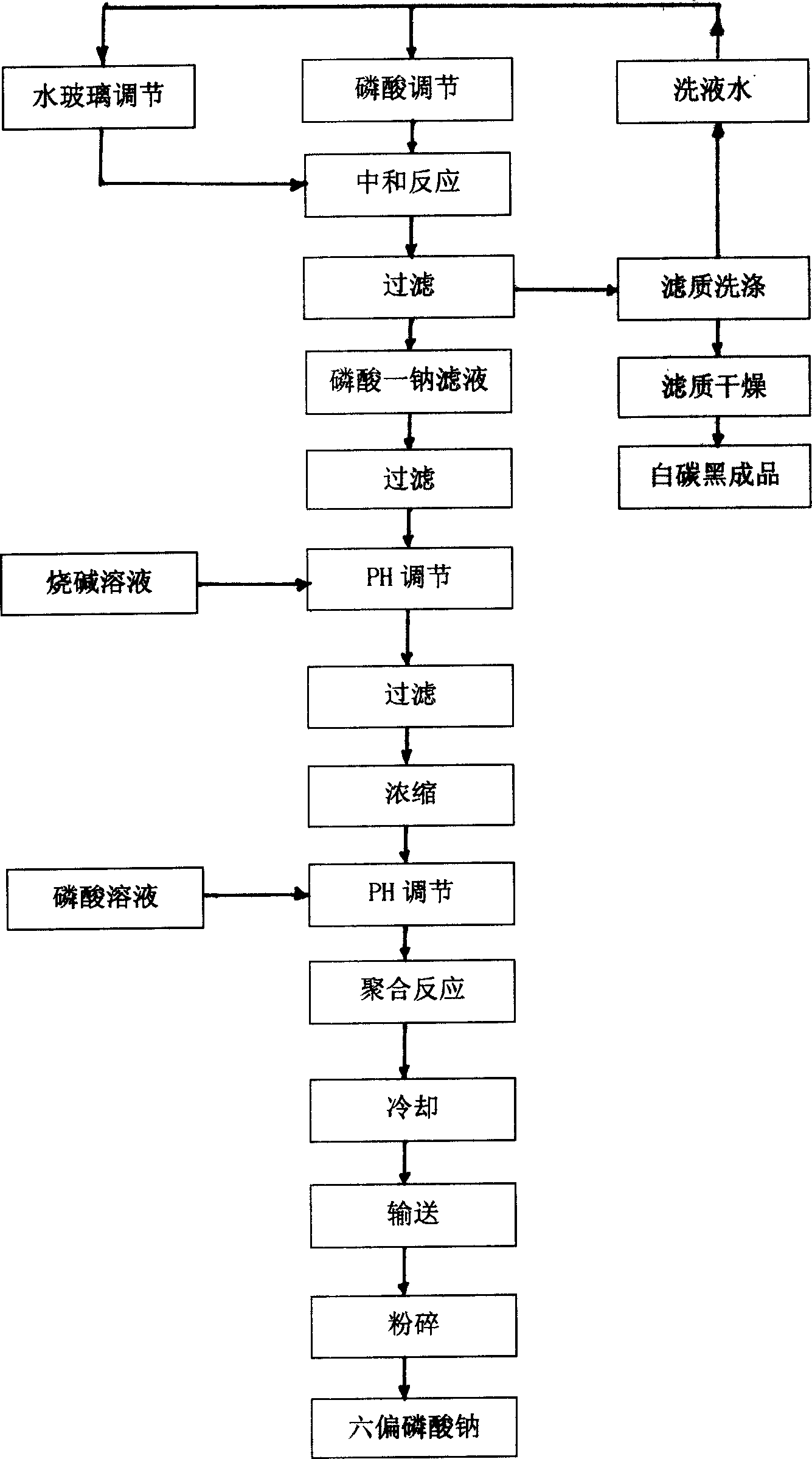

A process for preparing white carbon black and sodium hexametaphosphate incldues such steps as neutralizing reaction between phosphoric acid and water glass to obtain white carbon black, filtering the resultant liquid, regulating pH value, evaporating, polymerizing reaction, cooling by roller pair, breaking and sieving to obtain finished sodium hexametaphosphate.

Owner:绵阳市森泰新材料科技有限公司

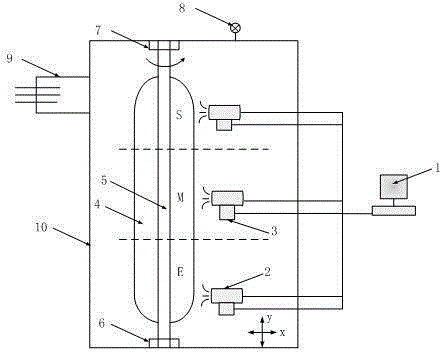

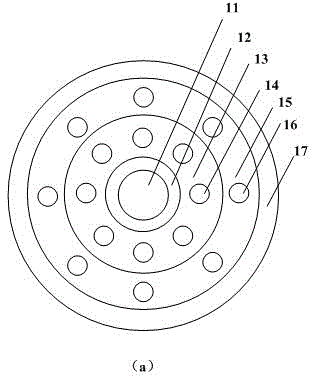

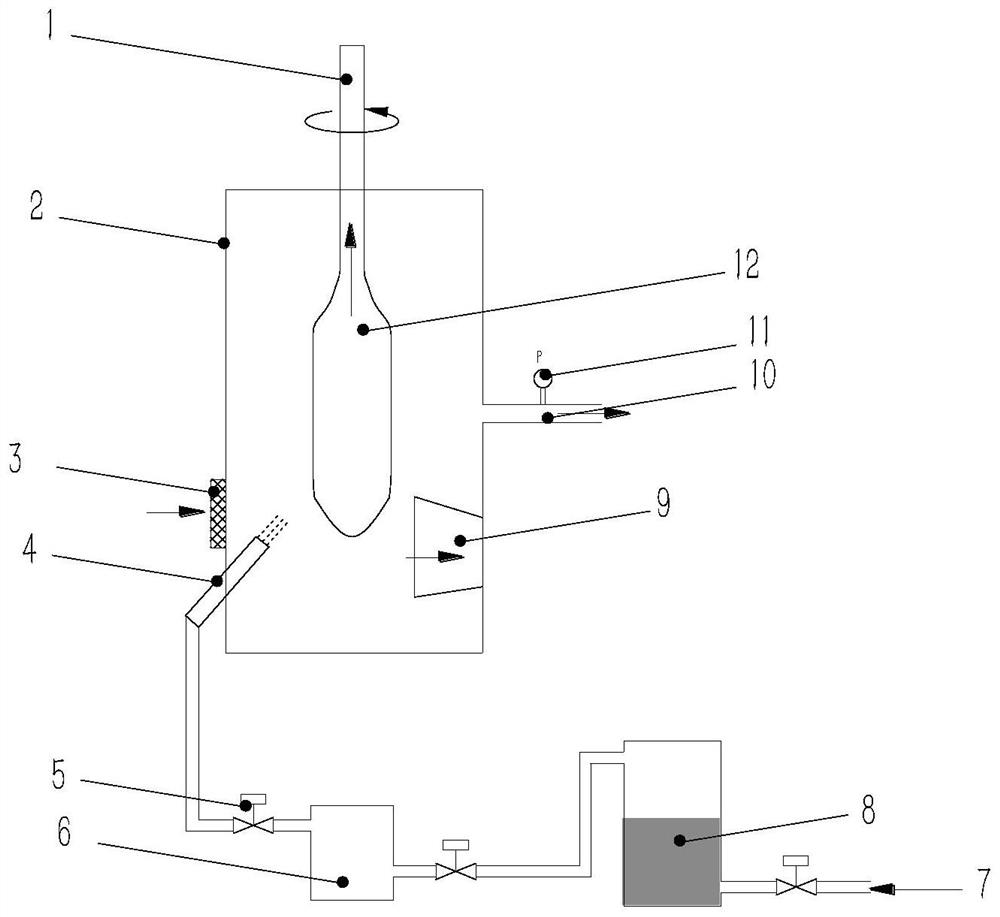

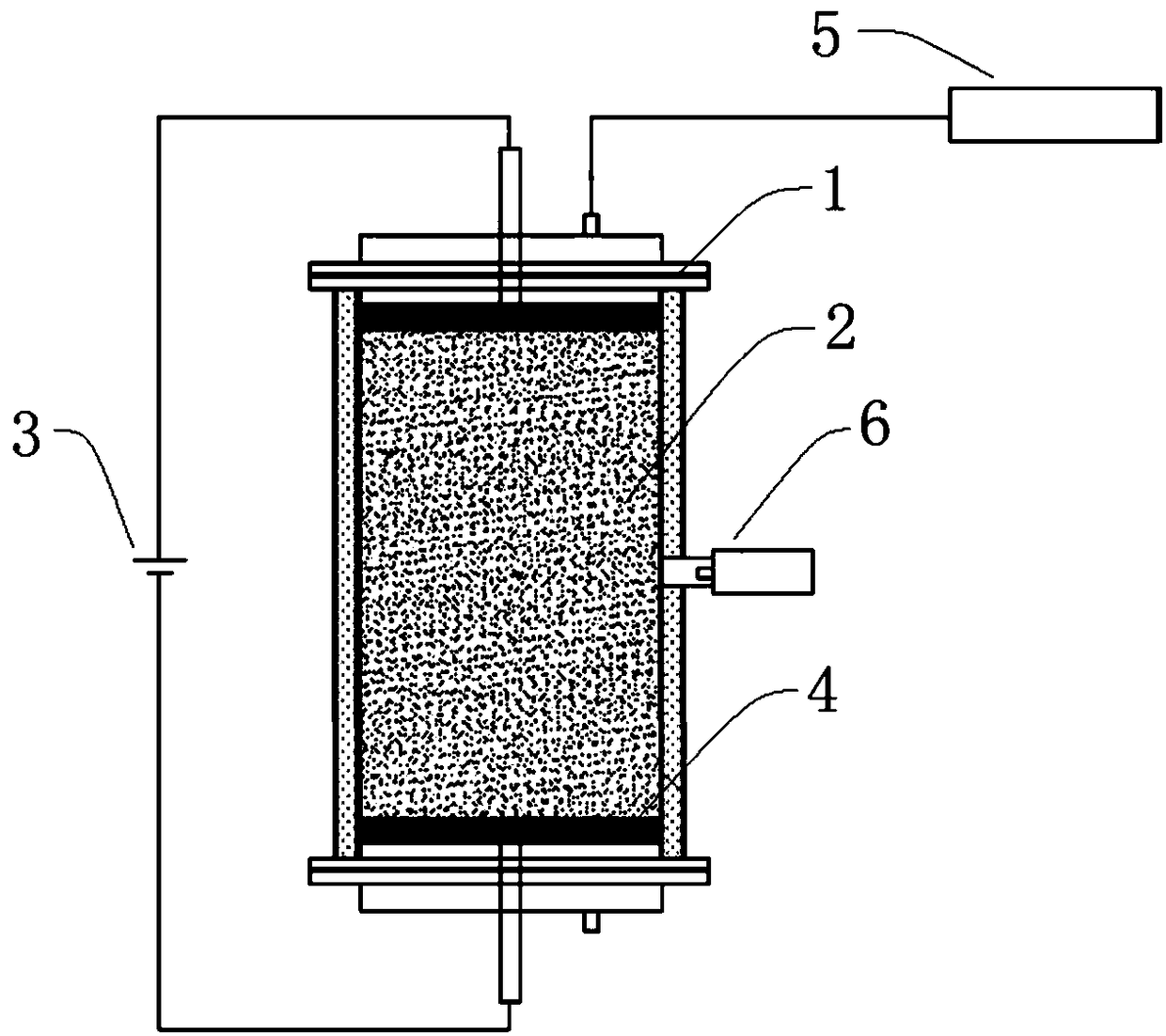

Deposition reaction device for manufacturing low-loss optical fiber preform rod and pressure adjusting method

InactiveCN105776843AUniform depositionLow content of metal impuritiesGlass making apparatusEngineeringMetal impurities

The invention discloses a deposition reaction device for manufacturing a low-loss optical fiber preform rod and a pressure adjusting method, and relates to the technical field of manufacturing of optical fiber preform rods. The device comprises a pressure gauge, a controller and a reaction vessel with an open top, wherein the pressure gauge and the reaction vessel are connected, and high-purity inert gas with purity higher than 99 percent circulates in the reaction vessel; a first blast burner for making a cladding layer and a second blast burner for making a core layer are arranged on one side of the reaction vessel, and the second blast burner is located between the first blast burner and a plane of the bottom of the reaction vessel; the bottom of the reaction vessel is connected with a matching pipe, the matching pipe is communicated with the inside of the reaction vessel, a flow adjuster is arranged on the matching pipe and the flow adjuster is connected with the pressure gauge through the controller. According to the deposition reaction device for manufacturing the low-loss optical fiber preform rod and the pressure adjusting method, metal impurities can be effectively prevented from entering glass micro-particle sedimentary bodies, the content of metal impurities in the manufactured optical fiber preform rod is low and the impurity absorption loss is smaller.

Owner:TENGCANG FENGHUO PHOTOELECTRIC MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com