Method for preparing high-performance tungsten base metal parts

A high-performance, metal-based technology, applied in the field of powder metallurgy, can solve problems such as irregular shape of tungsten-rhenium alloy powder, uneven composition of alloy powder, and unsuitability for high-performance tungsten-rhenium alloy parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Preparation of high-performance pure tungsten parts

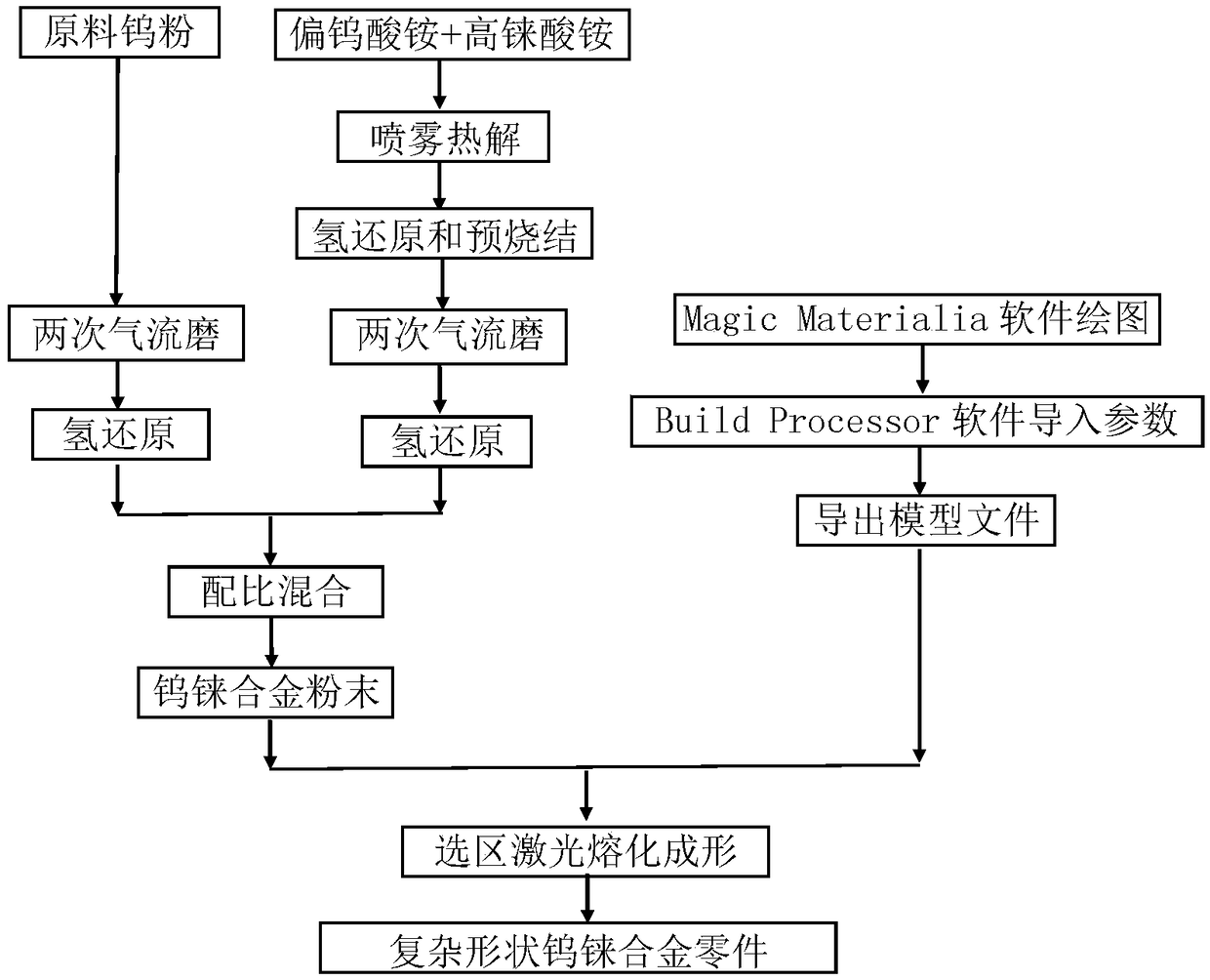

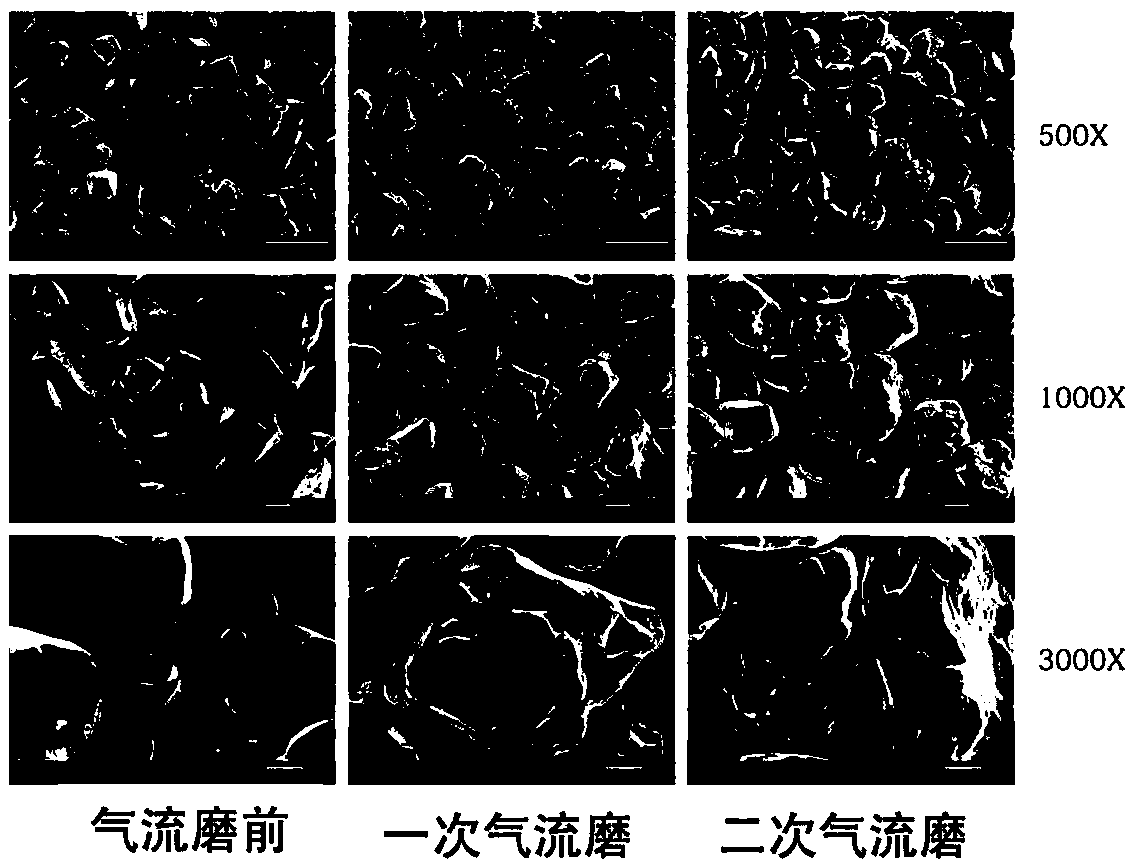

[0019] The jet milling device is used to process the raw tungsten powder twice. For the first jet mill, the pressure of the grinding chamber is set to 0.82MPa, and the frequency of the sorting wheel is 30Hz to realize the dispersion and crushing of powder. In the second jet mill, the pressure of the grinding chamber is set to 0.70MPa, and the frequency of the sorting wheel is 60Hz to make the powder surface smoother and further improve the fluidity of the powder. Both jet mills use nitrogen as the grinding medium, so that the oxygen content in the grinding chamber is ≤0.05%. Next, the modeling process is carried out. First, use the Magic Materialia software to draw a three-dimensional schematic diagram of the part, then set the processing parameters in the Build Processor modeling software, and export the model file (the various working parameters of the SLM are: scanning speed 200mm / s, scanning distan...

Embodiment 2

[0020] Embodiment 2: Preparation of high-performance W-10wt.%Re alloy parts

[0021] The design target tungsten-rhenium alloy composition is W-10wt.% Re, with high-purity ammonium metatungstate (AMT) and ammonium perrhenate (APR) as raw materials, this mixture is dissolved in deionized water (40g / L), and then The spray drying process was carried out, the feed rate was 600ml / h, the atomization pressure was 120kPa, and the drying temperature was 100°C. The precursor mixed powder was put into a tube furnace and fed with high-purity hydrogen for reduction. The reduction temperature was 1000°C, the heating rate was 5°C / min, and the reduction time was 120min to obtain the reduced precursor powder. The reduced precursor powder is alloyed and pre-sintered at 1800°C in a hydrogen atmosphere to obtain spray pyrolytic tungsten-rhenium alloy powder with low oxygen content. Using the jet-jet milling device, the raw tungsten powder and the spray pyrolysis tungsten-rhenium alloy powder are ...

Embodiment 3

[0022] Embodiment 3: Preparation of high-performance W-15wt.%Re alloy parts

[0023]The design target tungsten-rhenium alloy composition is W-15wt.% Re, with high-purity ammonium metatungstate (AMT) and ammonium perrhenate (APR) as raw materials, this mixture is dissolved in deionized water (60g / L), and then The spray drying process was carried out, the feed rate was 600ml / h, the atomization pressure was 100kPa, and the drying temperature was 90°C. The precursor mixed powder was put into a tube furnace and fed with high-purity hydrogen for reduction. The reduction temperature was 800 °C, the heating rate was 5 °C / min, and the reduction time was 120 min to obtain the reduced precursor powder. The reduced precursor powder is alloyed and pre-sintered at 1600°C in a hydrogen atmosphere to obtain spray pyrolytic tungsten-rhenium alloy powder with low oxygen content. Using the jet-jet milling device, the raw tungsten powder and the spray pyrolysis tungsten-rhenium alloy powder are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com