Chemical deposition method and device for high-purity low-hydroxyl high-uniformity quartz glass

A technology of quartz glass and chemical deposition, which is applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of poor uniformity and high hydroxyl content, and achieve high production efficiency, reduced impurity content, and high deposition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

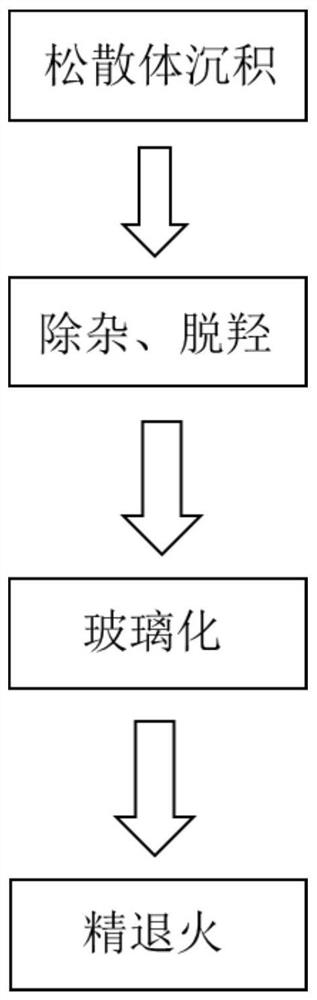

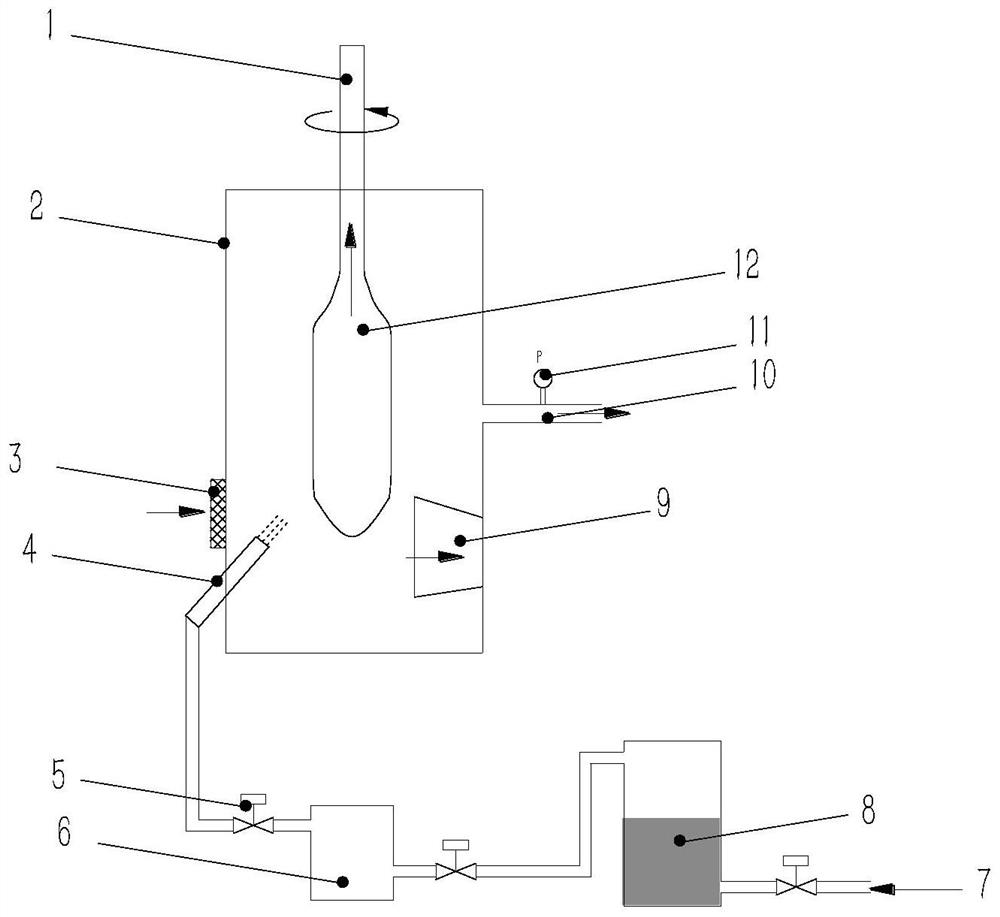

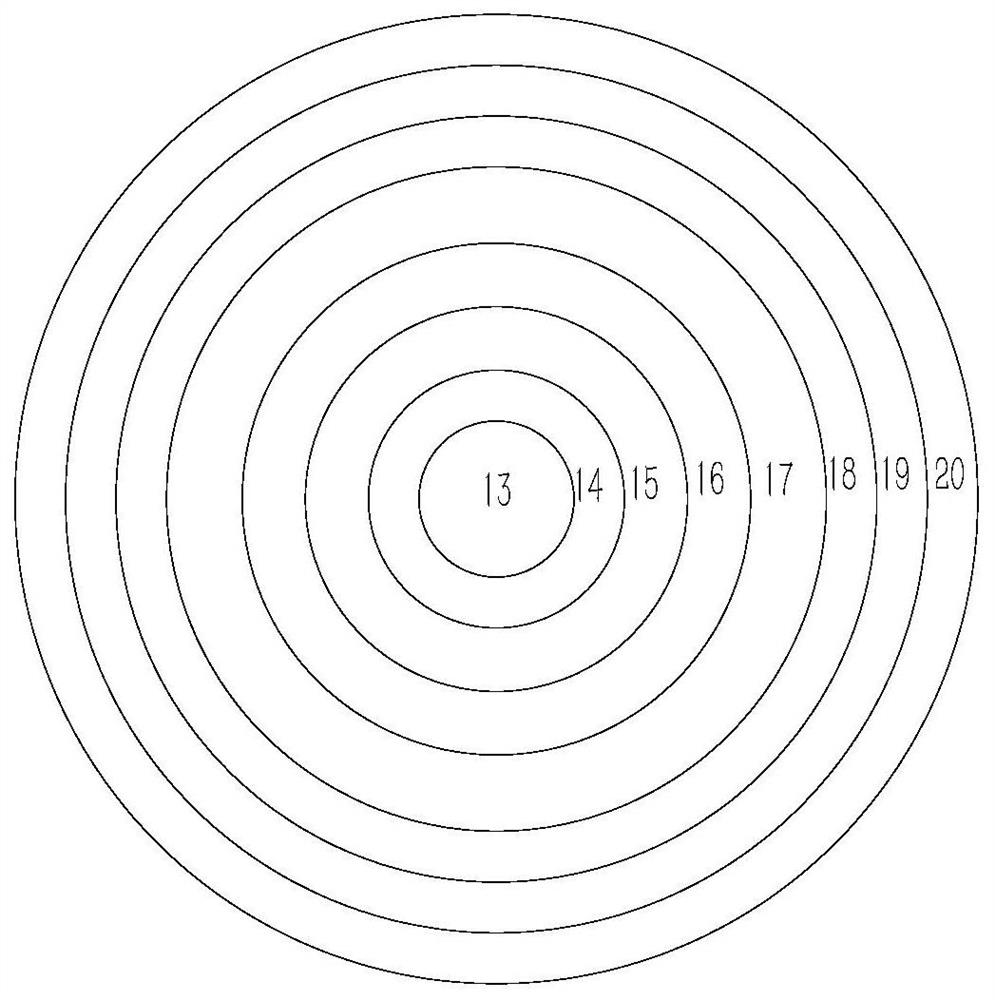

[0034] See figure 1 , the present invention provides a method for depositing high-purity, low-hydroxyl, and high-uniformity quartz glass, including low-density SiO 2 There are three main processes of deposition, sintering and fine annealing of the loose body 12, that is, the vapor phase axial deposition process (VAD) is used to first deposit and form low-density SiO 2 The loose body 12 is then sintered; the sintering process is dehydrated, dehydroxylated, degassed and densified until vitrification is achieved; after the sintering is completed, the obtained quartz glass is subjected to fine annealing to fully release the stress inside the quartz glass to ensure its Uniformity, finally obtain the finished product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com