Quasi-monocrystalline silicon crystal growth method and thermal field structure

A crystal growth, monocrystalline silicon-like technology, which is applied in the field of solar silicon materials, can solve the problems of increasing the cost of seed crystal use, high metal impurity content, and increased metal impurity content, and achieves reduced melting time, low crystal defect density, Avoid the effects of spreading contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

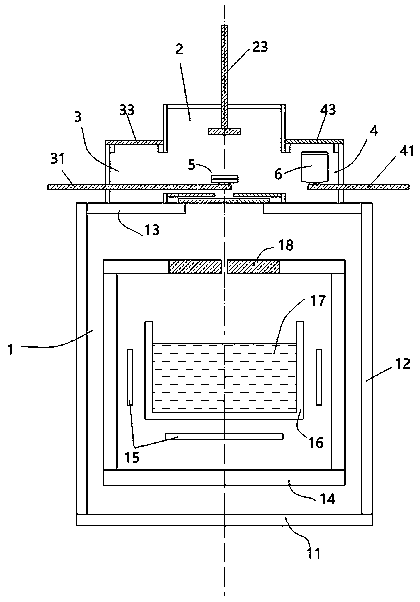

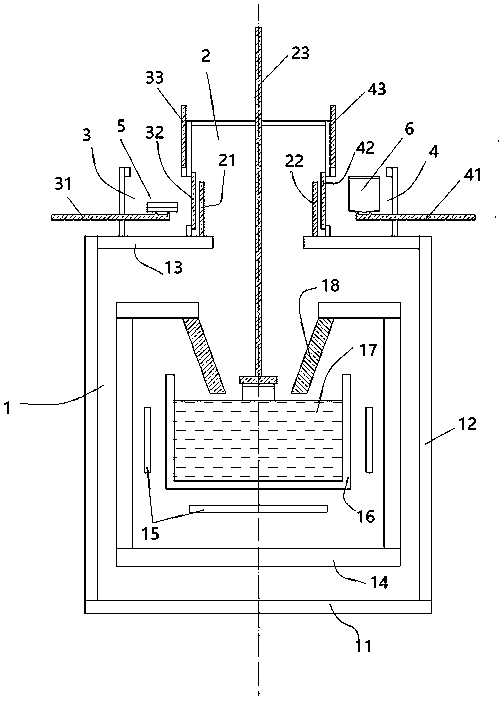

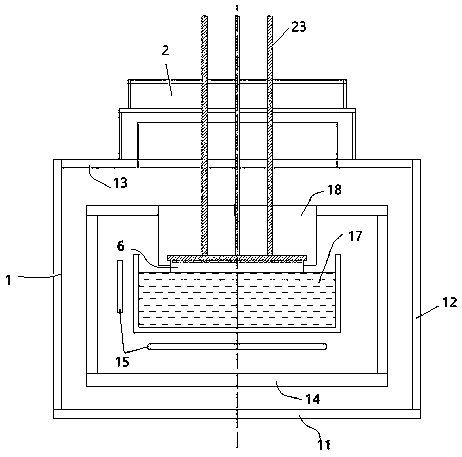

[0065] In order to match the subsequent ingot slicing equipment, the size of the seed crystal 51 is (length*width*thickness) 650mm*165mm*25mm, and the crystal orientation in the thickness direction is the direction. A polycrystalline high-purity crucible 16 purchased from the market is used, and 480 kg of silicon material is charged. The crucible 16 is connected to the furnace bottom 11 and can be opened for loading and unloading operations of the crucible 16 . After the crucible 16 is loaded into the main furnace chamber, the main furnace chamber 1 is closed, and the main furnace chamber 1 and the auxiliary furnace chamber 2 partition plates (21 and 22). The main furnace chamber 1 is vacuumed (atmospheric pressure less than 0.01mbar) and then heated, and a protective gas (argon) is introduced. The pressure in the furnace is 600mbar, and the gas flow rate is 50SLPM. The insulation board 18 is set to a horizontal state, such as figure 2 Shown, in order to reduce the heat lo...

Embodiment 2

[0076] Using the same production process as that of Example 1, the size of the seed crystal 51 is (length*width*thickness) 900mm*165mm*25mm, and the charge amount is 510kg. Since the ingot only becomes longer and the width remains unchanged, the crystal growth rate remains unchanged. The weight of a single crystal rod is about 60kg, and the weight of the rear rod (size: 159mm*159mm*900mm) is about 53kg. Eight times of growth are carried out with one feeding, the melting time of silicon material is 10 hours, and the total cycle is 42 hours. Each seed crystal is recycled 2 to 3 times, and a total of 3 new seed crystals are used, each seed crystal is 8.65kg, and the total weight is 26kg. Then the effective output of the final square rod is 424kg, the total input of silicon material is 536kg, and the qualified rate of output is 79%. The 24-hour square rod output of a single device is 242kg, and the monthly (30 days) output is 7260kg.

Embodiment 3

[0078] Adopt the same technological process as embodiment 1. In order to increase the output per unit time, a seed crystal with a size of 650mm*330mm*25mm is used, the weight of a single block is 12.5kg, and the loading capacity is 800kg. As the ingot becomes wider, the growth rate decreases, and the growth cycle of the single crystal ingot is increased to 5 hours. The weight of a single ingot is about 85kg, and two square ingots with a size of 159mm*159mm*650mm can be produced at one time, with a total weight of about 76.6kg. 9 times of growth are carried out with one feeding, the melting time of silicon material is 15 hours, and the total cycle is 60 hours.

[0079] Each seed crystal is recycled 2 to 3 times, and a total of 4 new seed crystals are used, with a weight of 50 kg. Then the final square bar output is 690kg, the total silicon material input is 850kg, and the pass rate of the product (square bar) is 81%. The 24-hour square rod output of a single device is 276kg,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com