Process for preparing mesopore pitch-based spherical activated carbon by post-carbonizing impregnated metal salts

A technology of spherical activated carbon and secondary carbonization, which is applied in the field of mesoporous pitch-based spherical activated carbon prepared by impregnated metal salt secondary carbonization, which can solve the problems of high loss-on-ignition rate of pitch-based spherical activated carbon, such as reduced mechanical strength and limited use, and achieves low ash content content, low metal impurity content, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

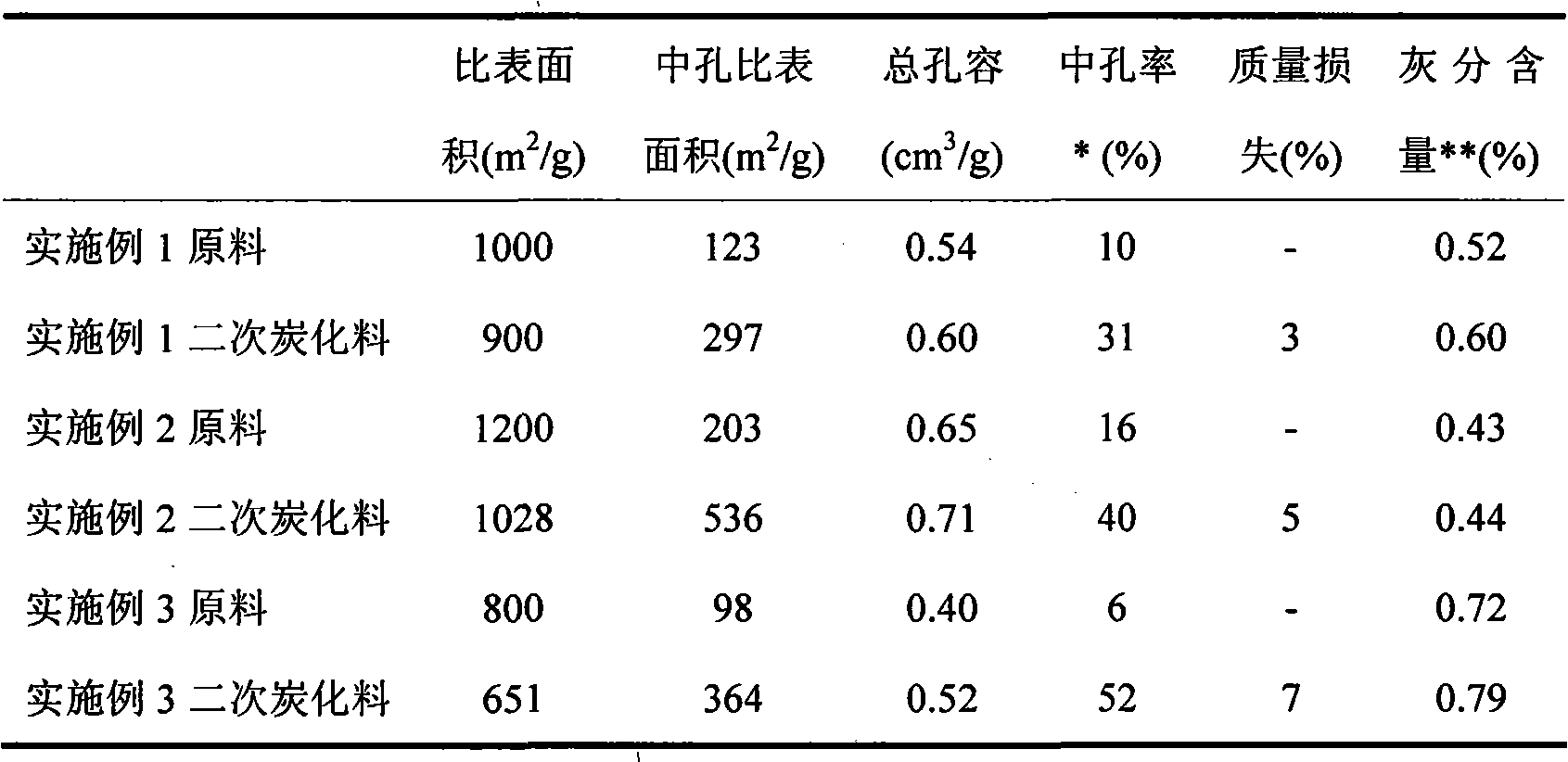

[0016] The selected specific surface area is 1000m 2 / g of pitch-based spherical activated carbon, with copper sulfate as inorganic metal salt, by mixing and impregnating with pitch-based spherical activated carbon by a mass ratio of 0.05 for 10 hours (wherein the mass concentration of the metal salt solution used is 1%), after the impregnation ends , the sample was dried in an oven at 110°C until there was no obvious liquid flow, then the impregnated sample was carbonized at 800°C for 1 hour, cooled to below 50°C, and the residual metal impurities were removed with 0.5mol / L HCl solution, that is, Pitch-based spherical activated carbon with high mesopore content.

Embodiment 2

[0018] The selected specific surface area is 1200m 2 / g of pitch-based spherical activated carbon, with ferric nitrate as inorganic metal salt, by mixing and impregnating with pitch-based spherical activated carbon by a mass ratio of 0.04 for 5 hours (wherein the mass concentration of the metal salt solution used is 2%), after the impregnation ends , the sample was dried in an oven at 100°C until there was no obvious liquid flow, then the impregnated sample was carbonized at 1000°C for 0 hour, cooled to below 50°C, and the residual metal impurities were removed with 0.5mol / L HCl solution, that is, Pitch-based spherical activated carbon with high mesopore content. .

Embodiment 3

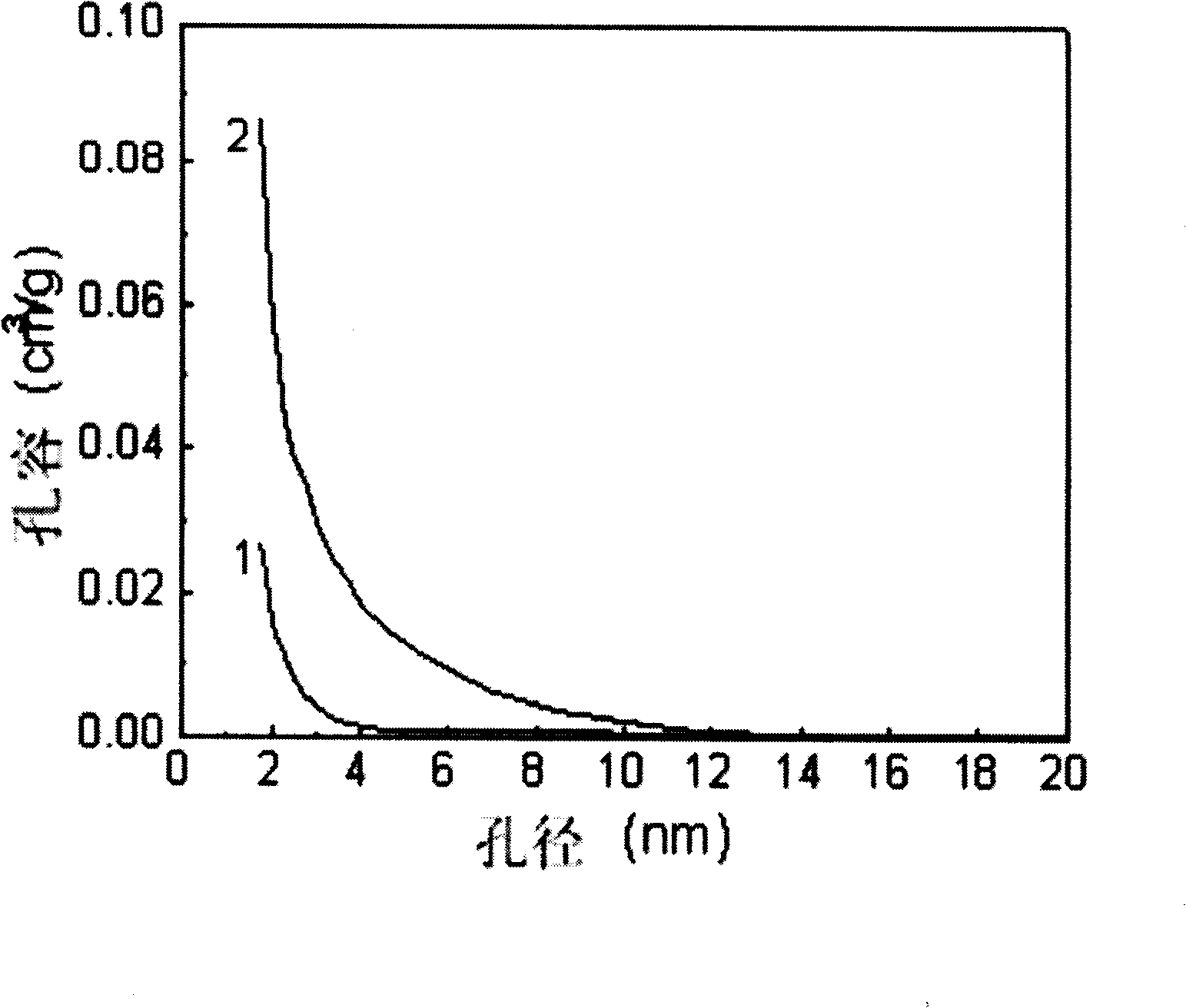

[0020] The selected specific surface area is 800m 2 / g of pitch-based spherical activated carbon, with ferric sulfate as inorganic metal salt, mixed with pitch-based spherical activated carbon in a mass ratio of 0.03 and impregnated for 15 hours (wherein the mass concentration of the metal salt solution used is 0.3%), after the impregnation ends , the sample was dried in an oven at 120 °C until there was no obvious liquid flow, then the impregnated sample was carbonized at 1100 °C for 5 hours, cooled to below 50 °C, and the residual metal impurities were removed with 1 mol / L HCl solution to obtain Pitch-based spherical activated carbon with high mesopore content. The pore size distribution in the mesopore range calculated by the BJH model with the raw material sample is shown in Figure 1.

[0021] Table 1 The pore structure parameters of the raw material pitch-based spherical activated carbon used in each example and the pitch-based spherical activated carbon after secondary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com