A kind of activated carbon electrothermal regeneration equipment and using method thereof

A regeneration equipment, activated carbon technology, applied in separation methods, filter regeneration, chemical instruments and methods, etc., to achieve the effects of small footprint, low carbon loss rate, and low regeneration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

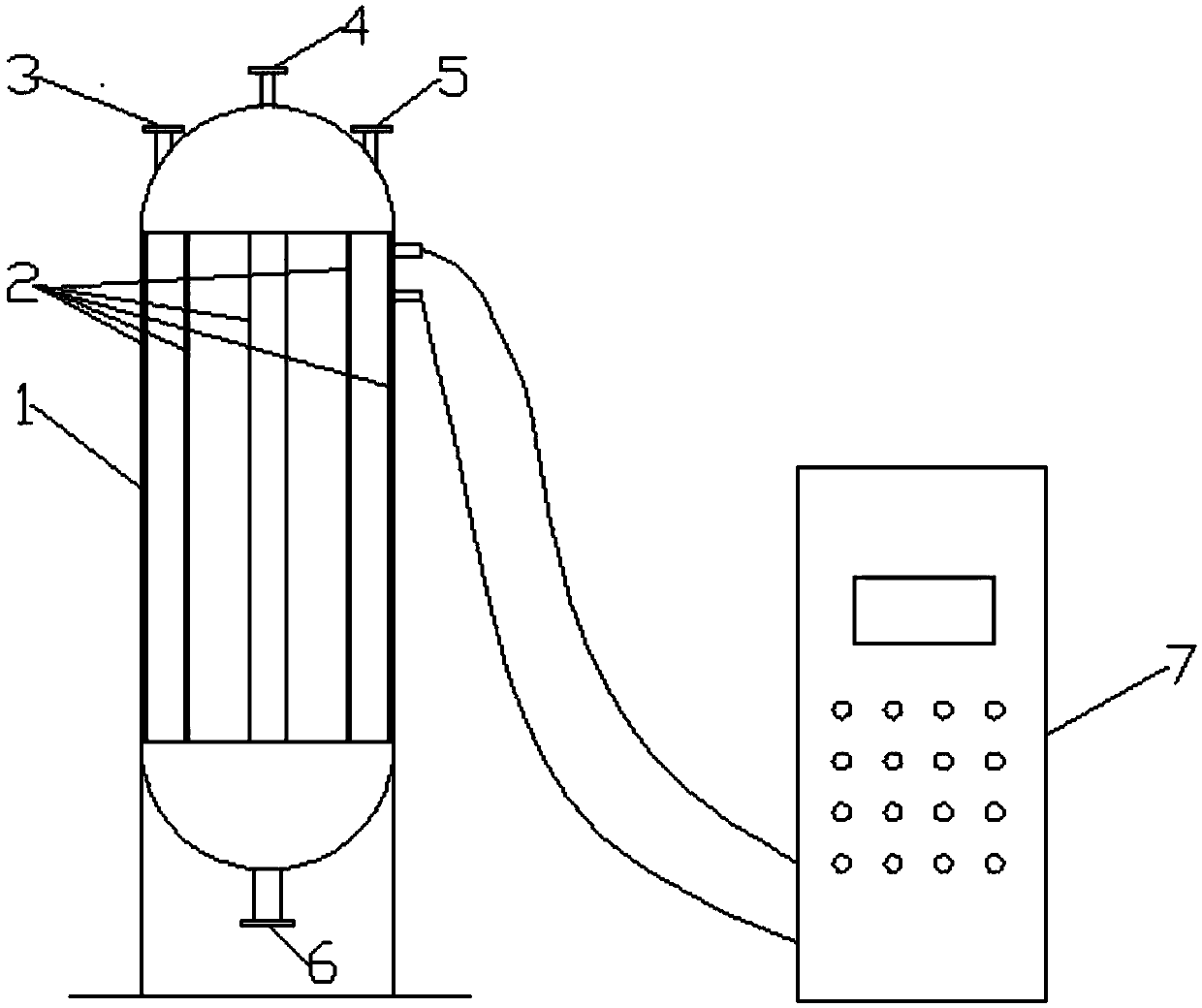

[0037] Embodiment 1 Electrothermal regeneration

[0038] After the activated carbon is saturated, close the tank, turn on the power supply 7, energize the electrode 2 to generate heat, raise the temperature in the tank 1 to 200°, and keep it for 20-30 minutes. After the end, open the exhaust port 3 and empty the tank Internal steam; after the steam is emptied, close the exhaust port 3 and the drain port 5, open the water inlet 4 and the water outlet 6, and the equipment will switch to normal adsorption operation. Regularly detect the COD of the water outlet 6. The test results are shown in Table 1. According to the results, it is found that the activated carbon is directly regenerated after the adsorption is saturated. After the regeneration, the adsorption capacity of the activated carbon was not completely restored, and the recovery was 83.3%, that is, the time required for the adsorption saturation of the activated carbon obtained in this example was 83.3% of the 48 hours r...

Embodiment 2

[0041] Example 2 Pure water backwashing and electrothermal regeneration

[0042] After the activated carbon is adsorbed and saturated, the carbon bed is backwashed with pure water first, and then regenerated by electric heating. The operation is as follows: only open the water outlet 6 and the water outlet 5, and the backwash water enters the water outlet 5 from the water outlet 6 to be discharged, and the backwash time is 2-3 minutes. After recoil, turn on the power for heating and regeneration. When the temperature rises to 200 degrees, keep at 200 degrees for 20-30 minutes, and then discharge the steam in the tank from the exhaust port 3. After the end, open the exhaust port 3 to empty the tank Steam; after the steam is emptied, close the exhaust port 3 and the drain port 5, open the water inlet 4 and the water outlet 6, and the equipment will switch to normal adsorption operation. Regularly detect the effluent COD of water outlet 6, and the test results are shown in Table...

Embodiment 3

[0045] Example 3 Pure water backwash, hydrochloric acid backwash, pure water backwash again and electric heating regeneration

[0046] Activated carbon adsorption is saturated, first use pure water to backwash the carbon bed, then backwash with hydrochloric acid, then backwash with pure water, and finally perform electric regeneration. The operation is as follows: only open the water outlet 6 and the water outlet 5, and the backwash water enters the water outlet 5 from the water outlet 6 to be discharged, and the backwash time is 2-3 minutes. After backflushing, add hydrochloric acid with pH=2 into the regeneration equipment through water outlet 6, soak for 5-10 minutes, then discharge the hydrochloric acid through water outlet 6, and then perform a pure water backwash for 2-3 minutes. After recoil, turn on the power for heating and regeneration. When the temperature rises to 200 degrees, keep at 200 degrees for 20-30 minutes, and then discharge the steam in the tank from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com