An electrode used for activated carbon electrothermal regeneration equipment and its application method

A regenerative equipment and activated carbon technology, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of limited single-phase electric output power, high energy consumption, high temperature, etc., to make up for the limited output power, Uniform temperature distribution and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

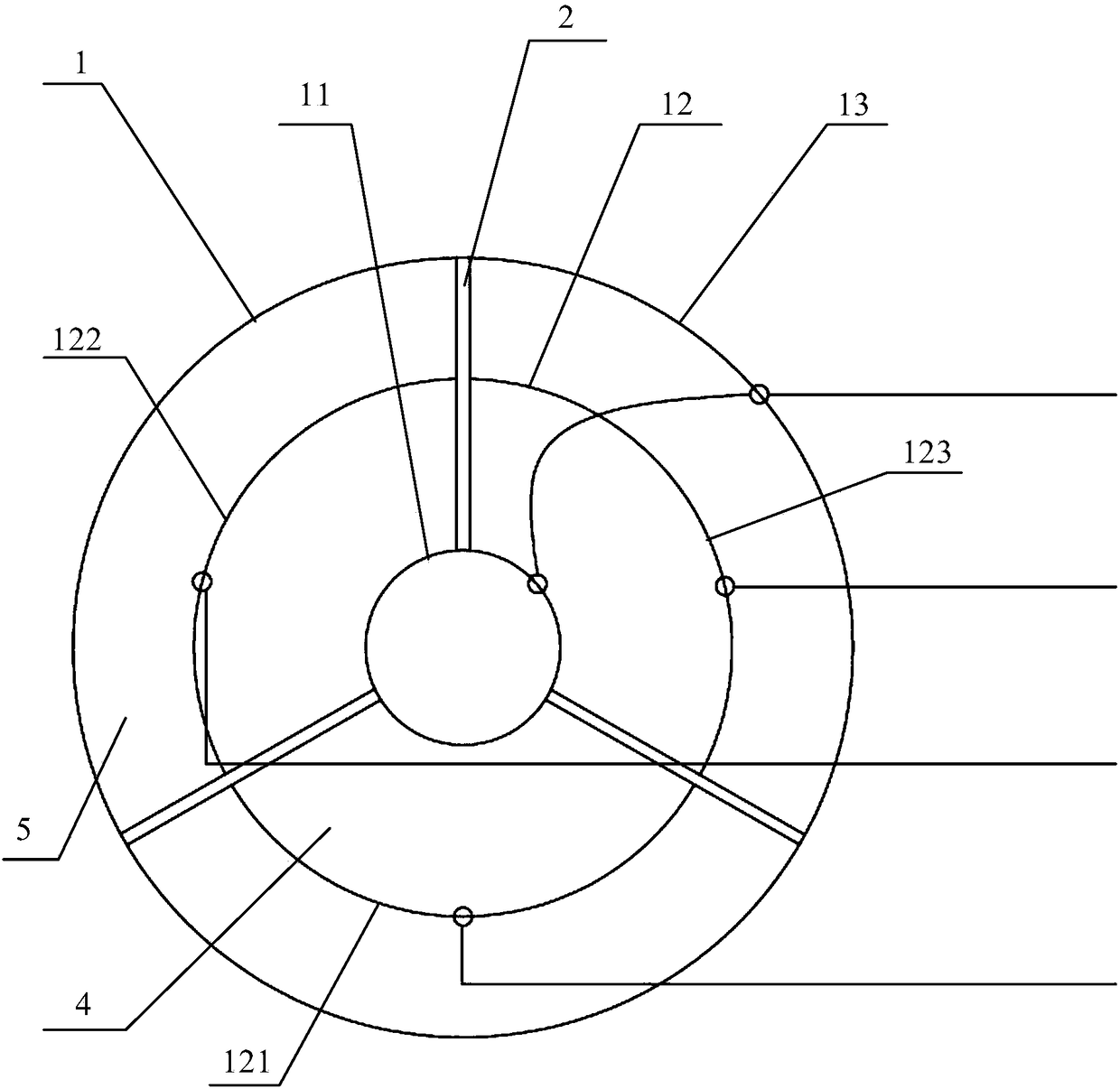

[0025] Such as figure 1 As shown, an electrode used for activated carbon electrothermal regeneration equipment includes a power-in electrode and two power-out electrodes, respectively the first power-out electrode 11 and the second power-out electrode 13, and the second power-out electrode is sheathed concentrically from the inside to the outside. A power-out electrode 11 , a power-in electrode 12 and a second power-out electrode 13 . The electrodes are evenly filled with 500kg of activated carbon, and three insulating plates are arranged at intervals of 120° on the circumference of the cylindrical motor unit, which divides the activated carbon bed into the first area, the second area and the third area, and separates the charged electrodes 12 is divided into a first power-in section 121 , a second power-in section 122 and a third power-in section 123 which are not connected to each other.

[0026] The diameter of the first power-out electrode 11 is 160 mm, the diameter of th...

Embodiment 2

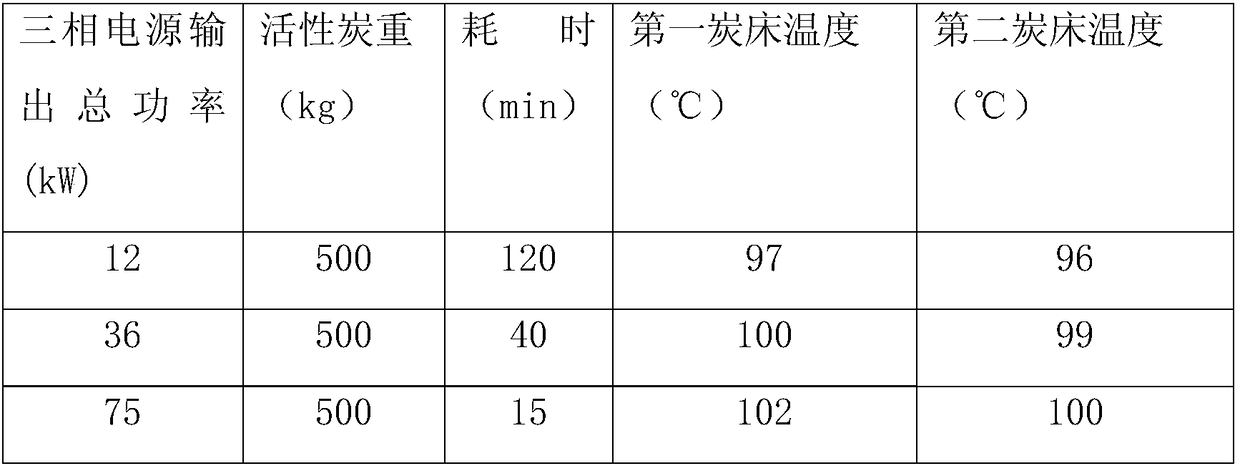

[0031] The diameters of the first outlet electrode 11, the inlet electrode 12, and the second outlet electrode 13 in Example 1 are replaced by 125mm, 250mm, and 500mm respectively, and because the diameter of each electrode decreases, the weight of the corresponding activated carbon filled 100kg, other test conditions remain unchanged, the test results are shown in Table 2, the first carbon bed and the second carbon bed are heated evenly during the heating process, and because the three-phase input of the AC power is used at the same time, the output power used by the AC power Unrestricted, the output power can reach 75KW, while ensuring the three-phase balance of the three-phase AC power supply.

[0032] Table 2

[0033]

Embodiment 3

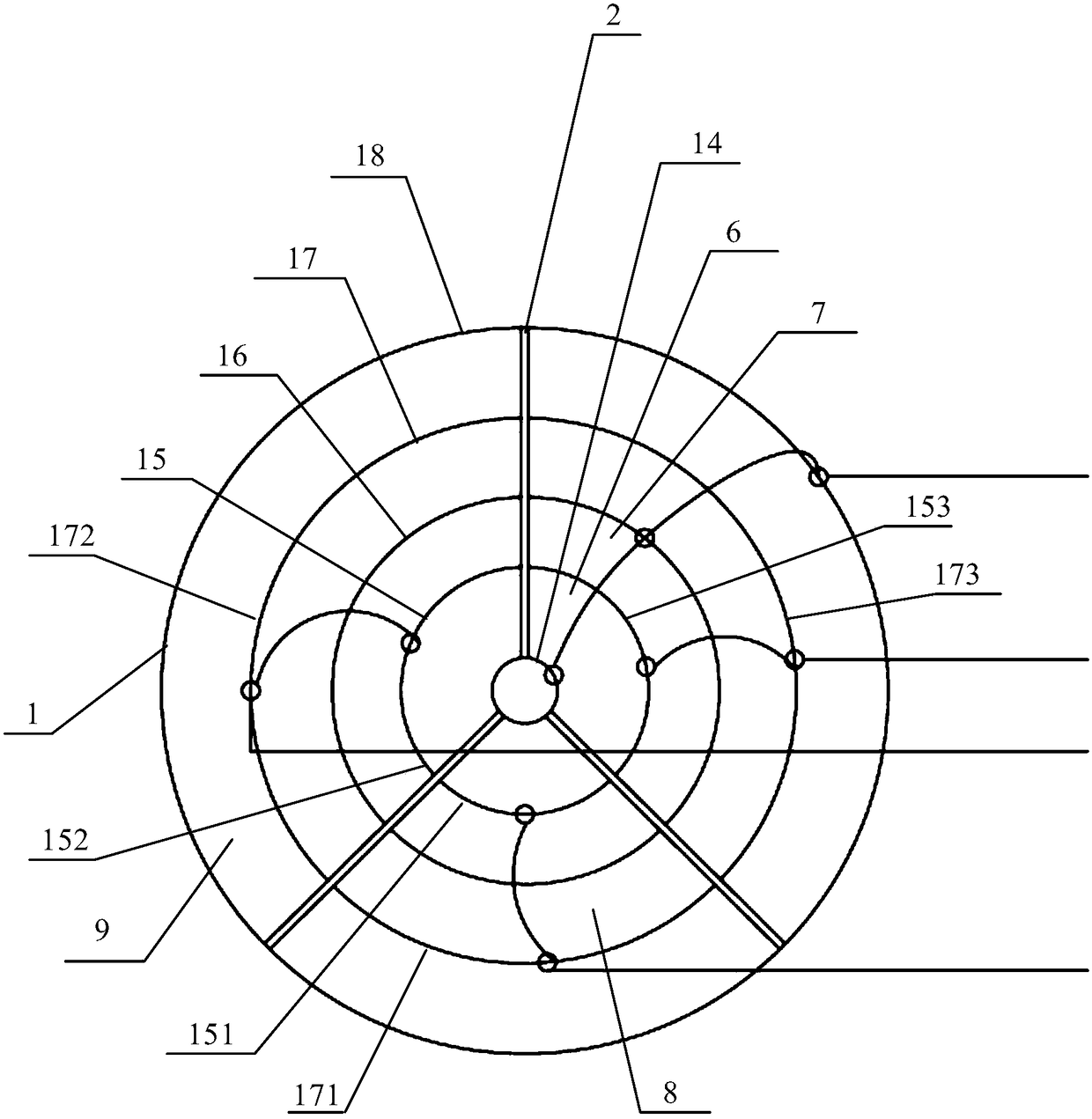

[0035] Such as figure 2As shown, an electrode for activated carbon electrothermal regeneration equipment includes a third power-out electrode 14, a first power-in electrode 15, a fourth power-out electrode 16, a second power-in electrode 17 and The corresponding diameters of the fifth electrical outlet electrode 18 are 370 mm, 560 mm, 850 mm, 1300 mm and 2000 mm in sequence. The electrodes are evenly filled with 700kg of activated carbon, and three insulating plates are arranged at intervals of 120° on the circumference of the cylindrical electrode group, and the first feed electrode 15 is divided into the first feed section 151 and the first feed section 151 which are not connected to each other. The second feed section 152 and the third feed section 153 divide the second feed electrode 17 into a first feed section 171 , a second feed section 172 and a third feed section 173 which are not connected to each other.

[0036] Wherein the carbon bed between the first power-in el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com