Screw rod of single screw extruder

A single-screw extruder and screw technology, applied in the field of extruder parts, can solve the problems of high crystal point and bubbles in plastic products, increased temperature of plastic materials, low viscosity of plastic materials, etc. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

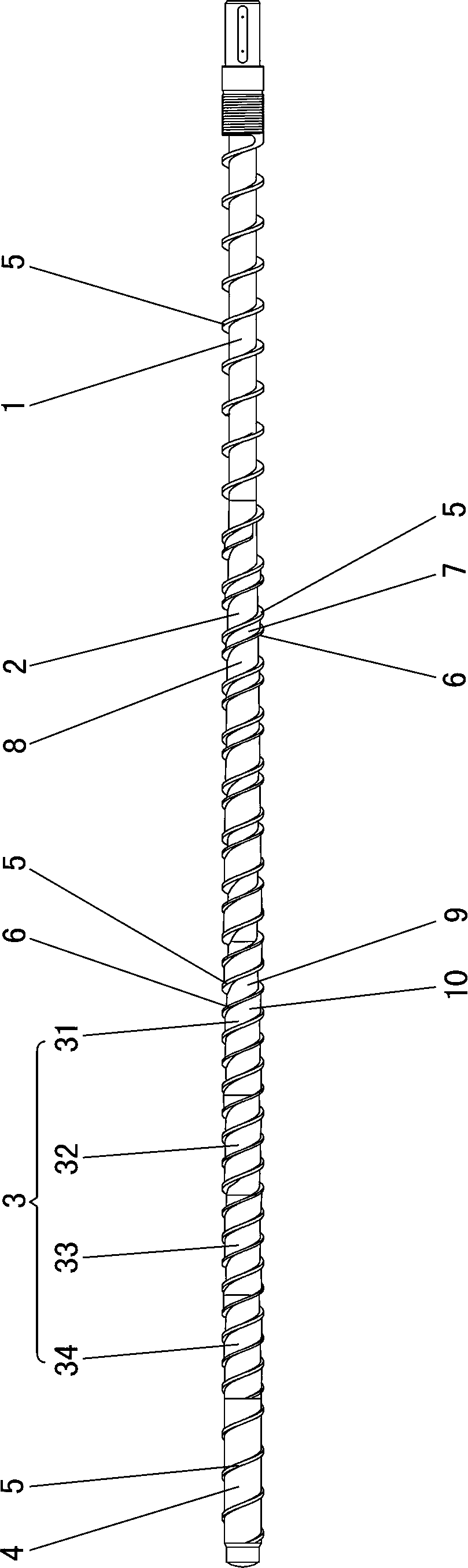

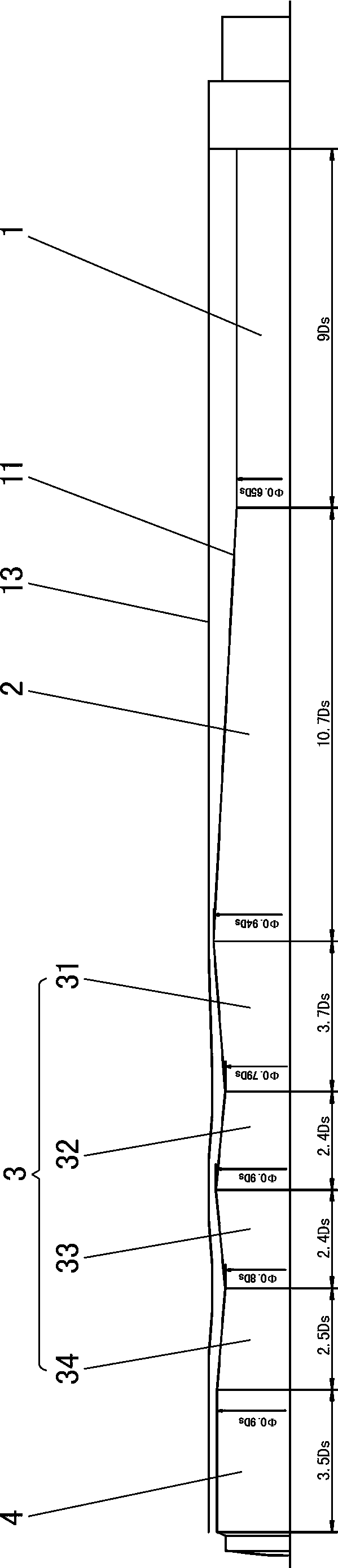

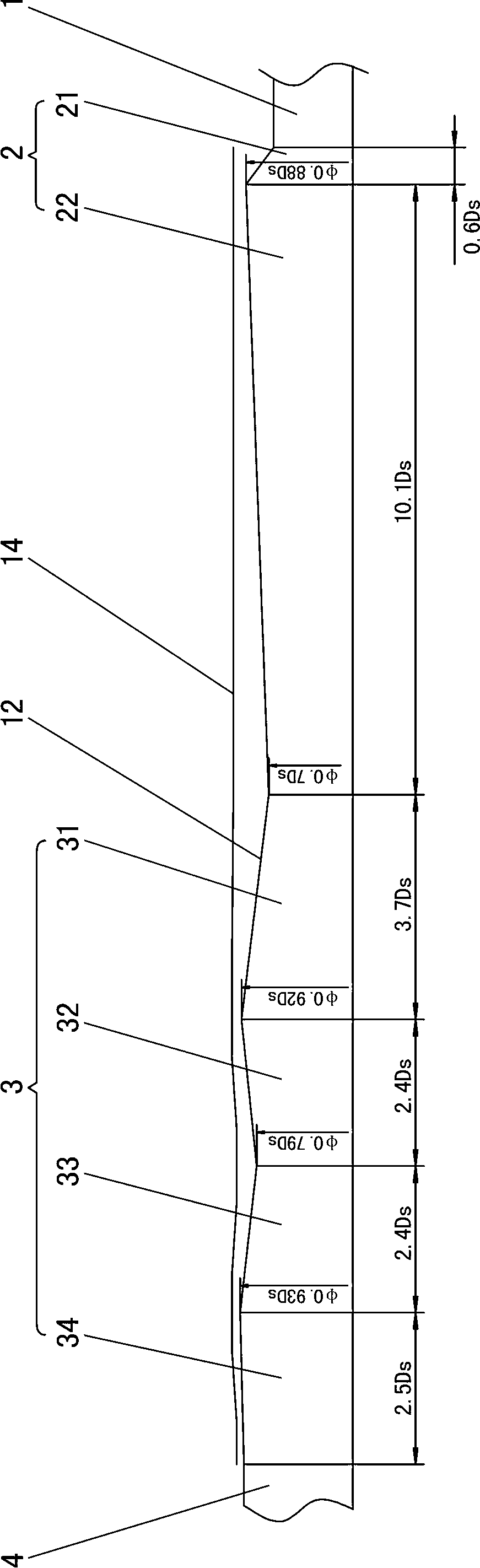

[0018] Such as figure 1 - image 3 As shown, the screw of this single-screw extruder includes a feed section 1, a compression separation section 2, a mixing section 3, and a metering section 4 from front to back. The feed section 1 is provided with a main thread 5, and the compression separation section 2 The main thread 5 and the secondary thread 6 are provided on the top, the main thread 5 and the secondary thread 6 are provided on the mixing section 3 , and the main thread 5 is provided on the metering section 4 . In this embodiment, the feed section 1 includes the front section of the feed section 1 and the rear section of the feed section 1, wherein the pitches of the main threads 5 of each part on the front section of the feed section 1 are consistent, and the main threads 5 on the rear section of the feed section 1 are the same. The pitch of the thread 5 gradually increases from front to back, and the pitch of the main thread 5 at the rear end of the feed section 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com