Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1139results about How to "Improve anti-static effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

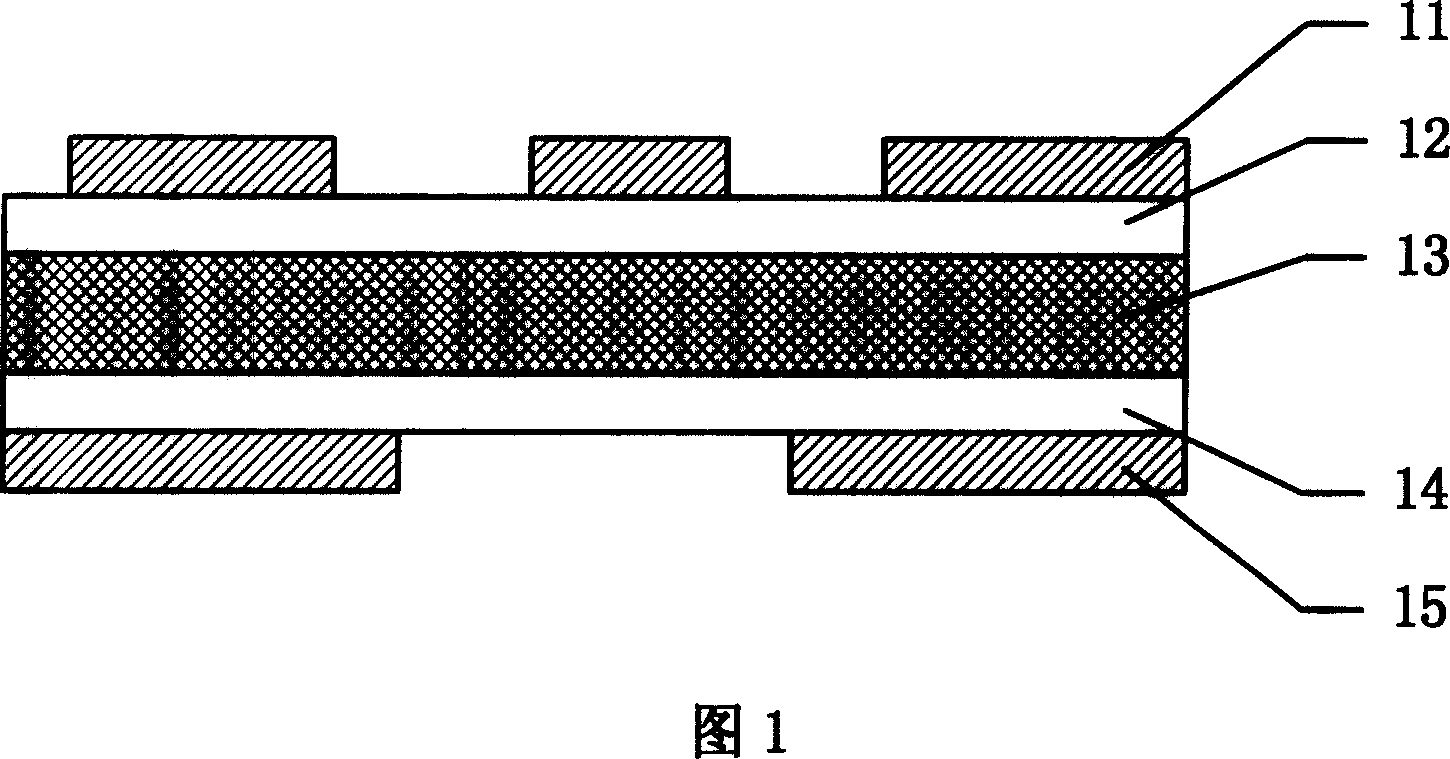

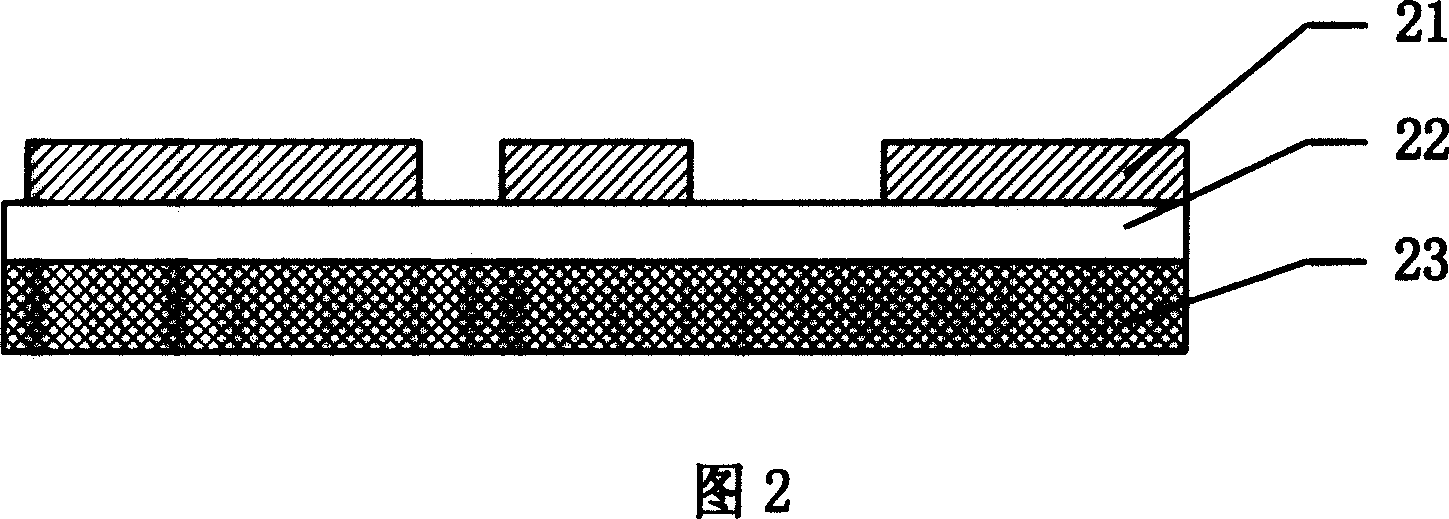

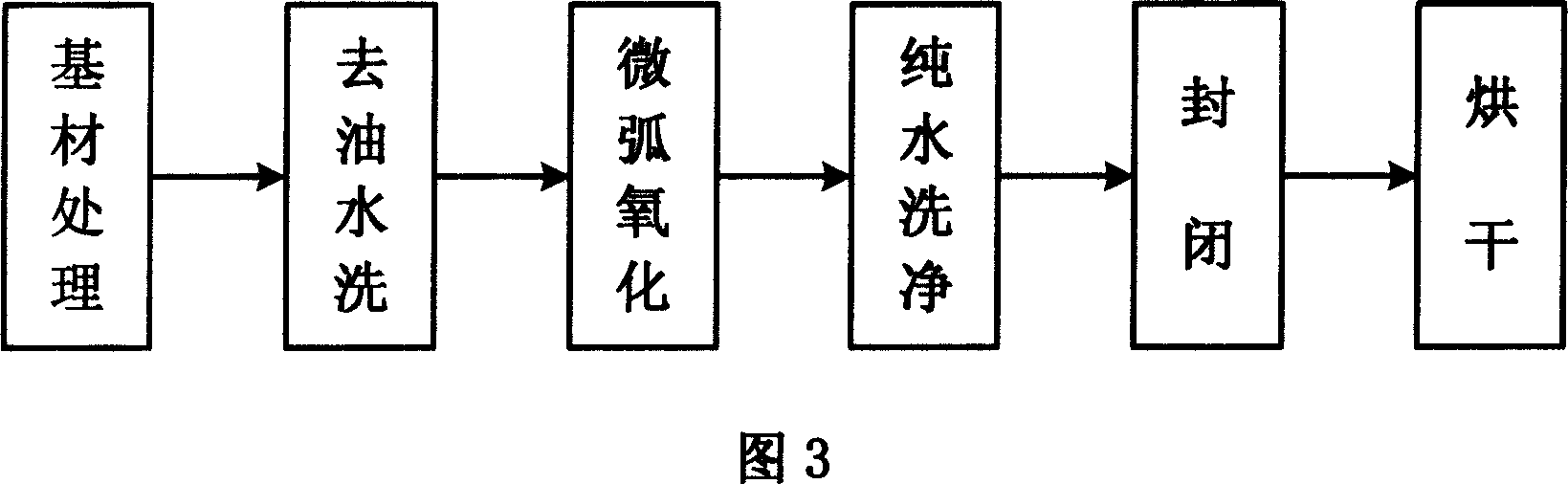

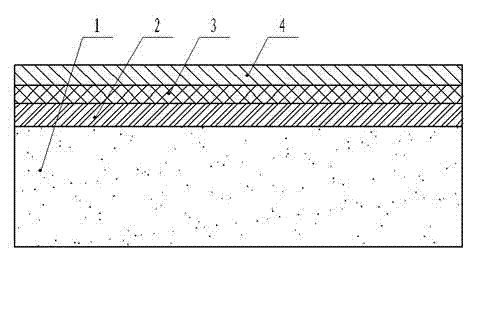

Aluminum-base printing circuit board and its production

InactiveCN101076224AReliable workmanshipSimple processing equipmentPrinted circuit manufactureCircuit susbtrate materialsInsulation resistanceMicro arc oxidation

The bottom layer of invention uses aluminium baseboard; the intermediate layer is a heat conduction insulation layer; the surface layer is an electric conduction layer. It features the following: the heat insulation layer is a ceramic-like thin film layer with 10-400 micron thick and >=100Momega insulation resistance, which chemical composition is aluminium oxide. The preparation method comprises: making pretreatment, de-oiling and washing for the surface of the aluminium baseboard using mechanical method or chemical method to form a clean workpiece plane; using the microarc oxide treatment and the microplasma surface ceramic method to make a heat conduction insulation layer on the workpiece surface; finally, overlapping an electric conduction layer on the heat conduction insulation layer; etching circuit pattern.

Owner:JIANGSU HANDSON INTELLIGENT TECH CO LTD

Electrostatic-resisting rubber board and its production

ActiveCN101074301AWill not polluteWon't change colorOther chemical processesEngineeringPolymer science

An anti-electrostatic rubber plate (desk pad and floor mattress) and its production are disclosed. The anti-electrostatic rubber plate consists of anti-electrostatic layer and conducting layer. It is prepared by preparing anti-electrostatic layer, preparing conducting layer film and vulcanizing to obtain final product.

Owner:浙江一远静电科技有限公司

Nano technology modified ultraviolet solidified woodware paint

InactiveCN1554717AImprove wear resistanceHigh surface hardnessPaints with biocidesPolyurea/polyurethane coatingsEpoxyUltraviolet

The modified ultraviolet cured woodenware paint consists of one or several of nano silica, zirconia, titania, zinc oxide, negative ion powder, antibiotic material, far infrared powder, antistatic powder and alumina in 0.3-20 wt% and active oligomer comprisnig acrylic epoxy resin, acrylic polyurethane and acrylic amino resin in 30-76 wt%. The modified ultraviolet cured woodenware paint has the small size effect, surface effect, quantum size effect and macroscopic quantum tunnel characteristic of nano material, so that it has high antiwear property, hgih surface hardness, high toughness, high cracking resistance and many other advantages.

Owner:南京海泰纳米材料有限公司

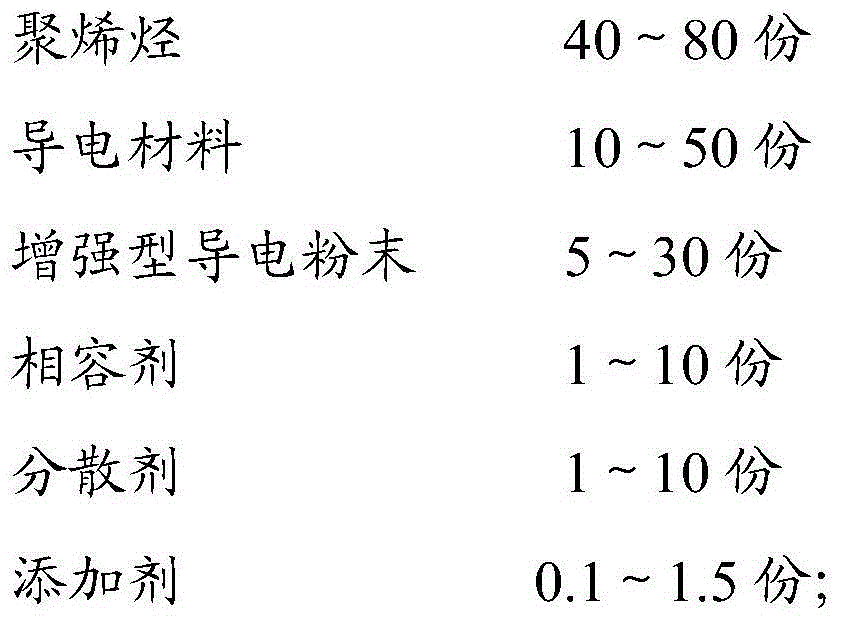

Permanently anti-static polyolefin master batch and preparation method thereof

The invention belongs to the technical field of high polymer materials, and particularly relates to a permanently anti-static polyolefin master batch and a preparation method thereof. The polyolefin master batch is prepared from the following components in parts by weight: 40-80 parts of polyolefin, 10-50 parts of conductive polymer or a composite material thereof, 5-30 parts of reinforcing conductive powder or fiber, 1-10 parts of a compatilizer, 1-10 parts of a dispersing agent, and 0.5-1.5 parts of other additives; the preparation method comprises the following steps: mixing the materials uniformly, then adding the mixture into a co-rotating twin screw extruder with a length to diameter ratio of 36-48, and extruding and pelletizing to obtain the product. The polyolefin master batch is good in dispersibility and compatibility; the good appearance, mechanical properties and stability of polyolefin can be maintained while the excellent anti-static effect can be achieved; the polyolefin master batch can be widely applied to membrane blowing, extrusion, blow molding and injecting molding products, and promotes the high-speed development of the electronic industry, the petroleum industry, the weapon industry and the military field in China.

Owner:DONGGUAN DICOLORS PLASTIC & METAL

Release film with high anti-static property and method for manufacturing the same

InactiveCN102582174AGood release propertiesGood anti-static performanceSynthetic resin layered productsLaminationStatic performanceAnti-Static Agents

The invention relates to a release film with a base film and a release film. The release film of an anti-static layer including binder and anti-static agent and the manufacturing method thereof are provided. The release film possesses excellent release force and, remaining binder ratio and other release characteristics, the anti-static performance is excellent, and the release can be effectively applied in products in IT field.

Owner:YOULCHON CHEM

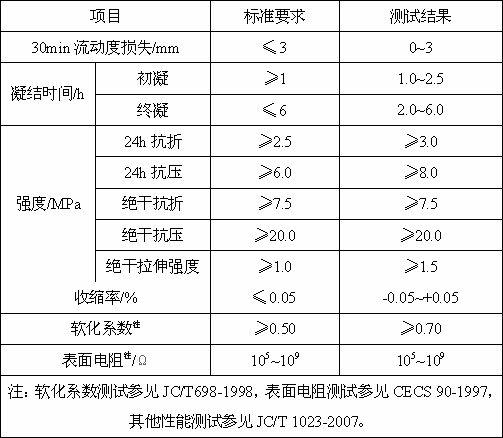

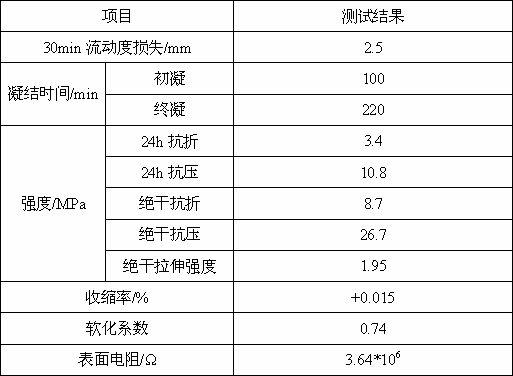

Desulfurized gypsum based antistatic self-leveling mortar and its preparation method

The invention relates to desulfurized gypsum based antistatic self-leveling mortar and its preparation method. Adopting calcined desulfurized gypsum as the main raw material, the desulfurized gypsum based antistatic self-leveling mortar comprises the following components by weight: 25-45 of desulfurized gypsum, 5-10 of slag powder, 3-10 of fly ash, 5-12 of portland cement, 15-25 of quartz sand, 15-25 of steel slag sand, 0.03-0.2 of modified carbon fiber, 0.5-2.0 of redispersible emulsion powder, 0.02-0.07 of cellulose ether, 0.10-0.25 of a water reducer, 0.1-0.4 of an antifoaming agent, 1.2-2.5 of an early strength agent, 0.02-0.06 of a retarder, and 0.002-0.005 of a carbon nanotube. The desulfurized gypsum based antistatic self-leveling mortar has good antistatic performance, bonding property, wear resistance, as well as high compressive strength, and overcomes the defect of poor water proofness of gypsum based materials. By utilizing a lot of industrial solid waste, the self-leveling mortar of the invention has the advantages of environmental protection, energy saving, and low cost, etc., and can be applied in various building ground projects with requirements for electrostatic protection and levelability.

Owner:TONGJI UNIV

Ultra-clean antistatic resin composition, preparing method thereof, product containing the same and application thereof

InactiveCN101016406AImprove anti-static effectShieldingOther chemical processesMagnetic/electric field screeningAntioxidantElectromagnetic field

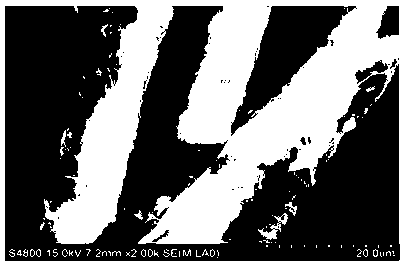

The invention discloses a super clean antistatic resin composition, preparing method and product through utilizing this composition and application in barrier electromagnetic field, which comprises the following parts: 63-98% plastic base material; 1-30% nanometer grade carbon pipe and / or nanometer grade carbon black; 0.1-0.5% coupling agent; 0.1-5% dispersing agent; 0.5-1.5% oxidation resistance agent. This product possesses good electrostatic resistance property and super clean property.

Owner:东莞市问鼎静电科技有限公司

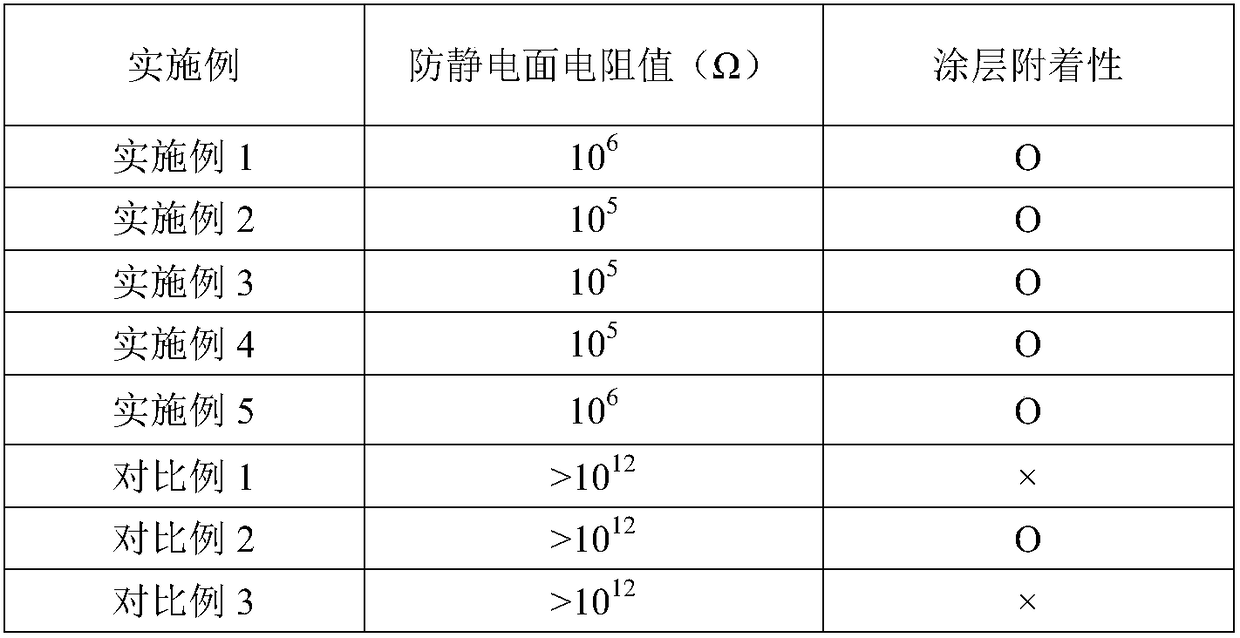

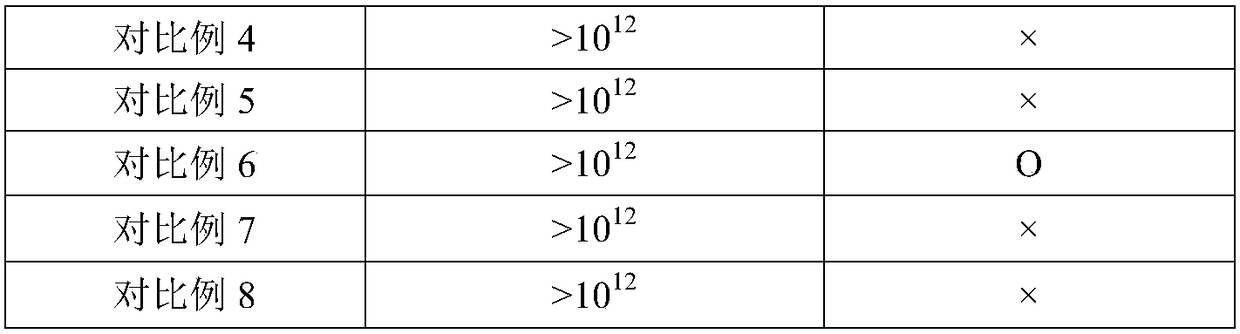

Antistatic protective film and manufacturing method thereof

InactiveCN107312471AReduce surface resistanceImprove adhesionFilm/foil adhesivesElectrically-conducting adhesivesTectorial membraneAdhesive

The invention provides an antistatic protective film. The antistatic protective film comprises a release film layer, an adhesive layer and a base material layer; the antistatic protective film is characterized in that the adhesive layer is prepared from the following components in parts by weight: 100 parts of an organosilicone adhesive, 1.0 to 10.0 parts of a curing agent, 0.1 to 10.0 parts of an anchoring agent, 0.2 to 2.0 parts of a catalyst and 0.1 to 3.0 parts of a conductive assistant; one surface or two surfaces of the base material layer is or are coated with an antistatic coating layer. The invention also provides a manufacturing method of the antistatic silica gel protective film. The antistatic protective film provided by the invention has low surface resistance, good static conduction performance and excellent adhesion, and the requirements of a market on the antistatic protective film can be met.

Owner:宁波启合新材料科技有限公司

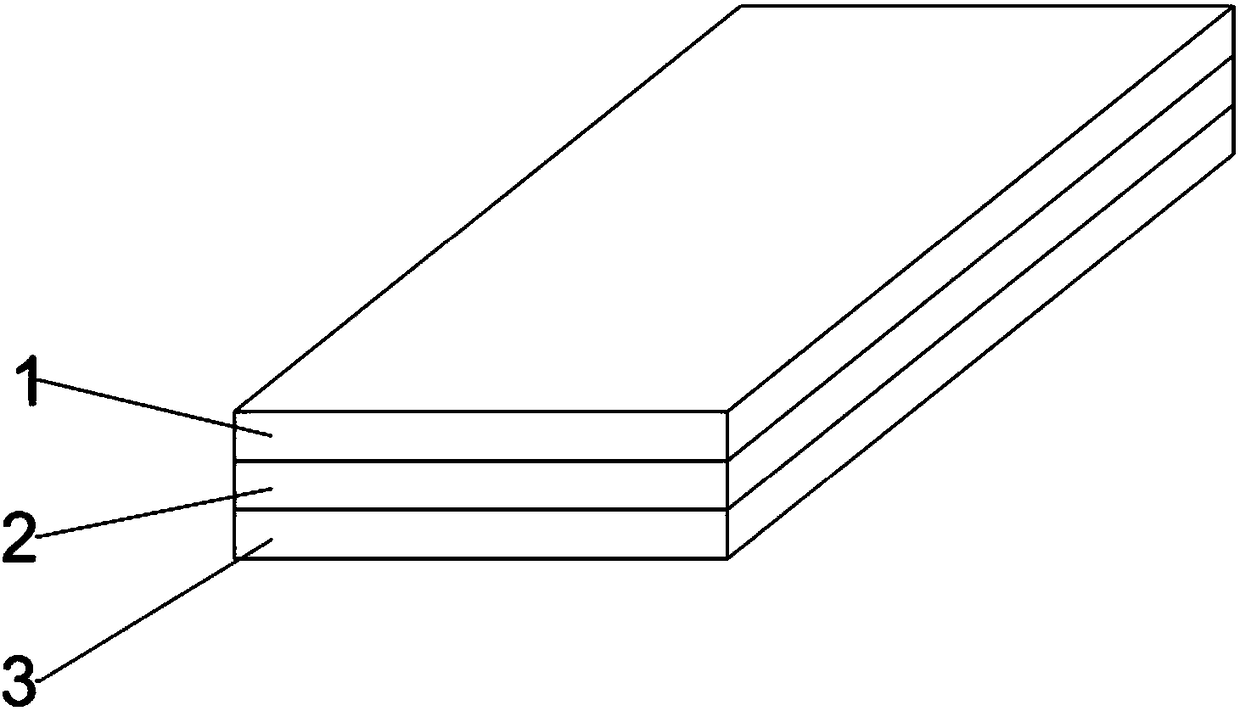

Antistatic composite material, electronic device shell and electronic device

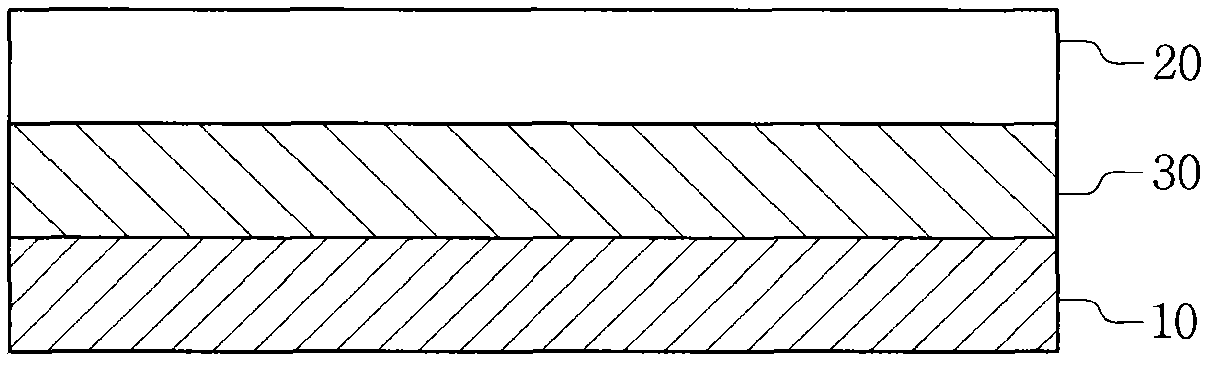

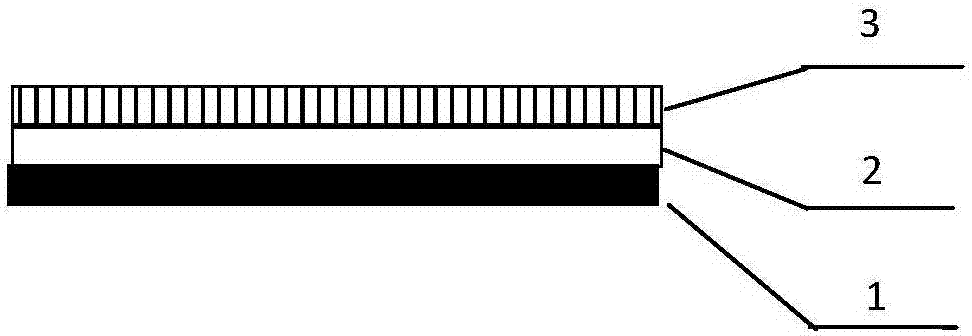

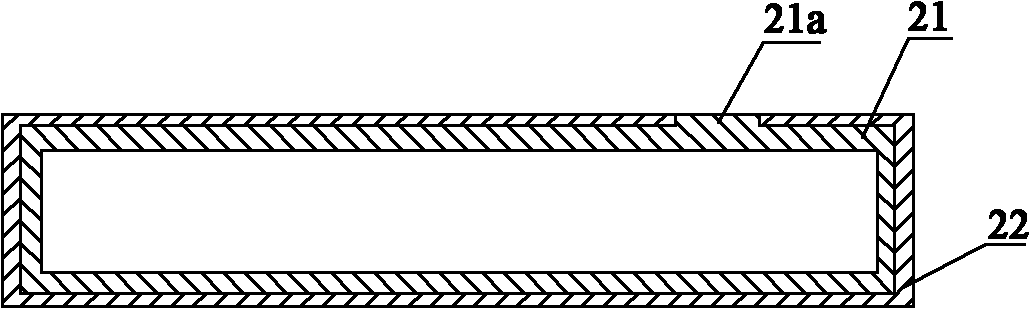

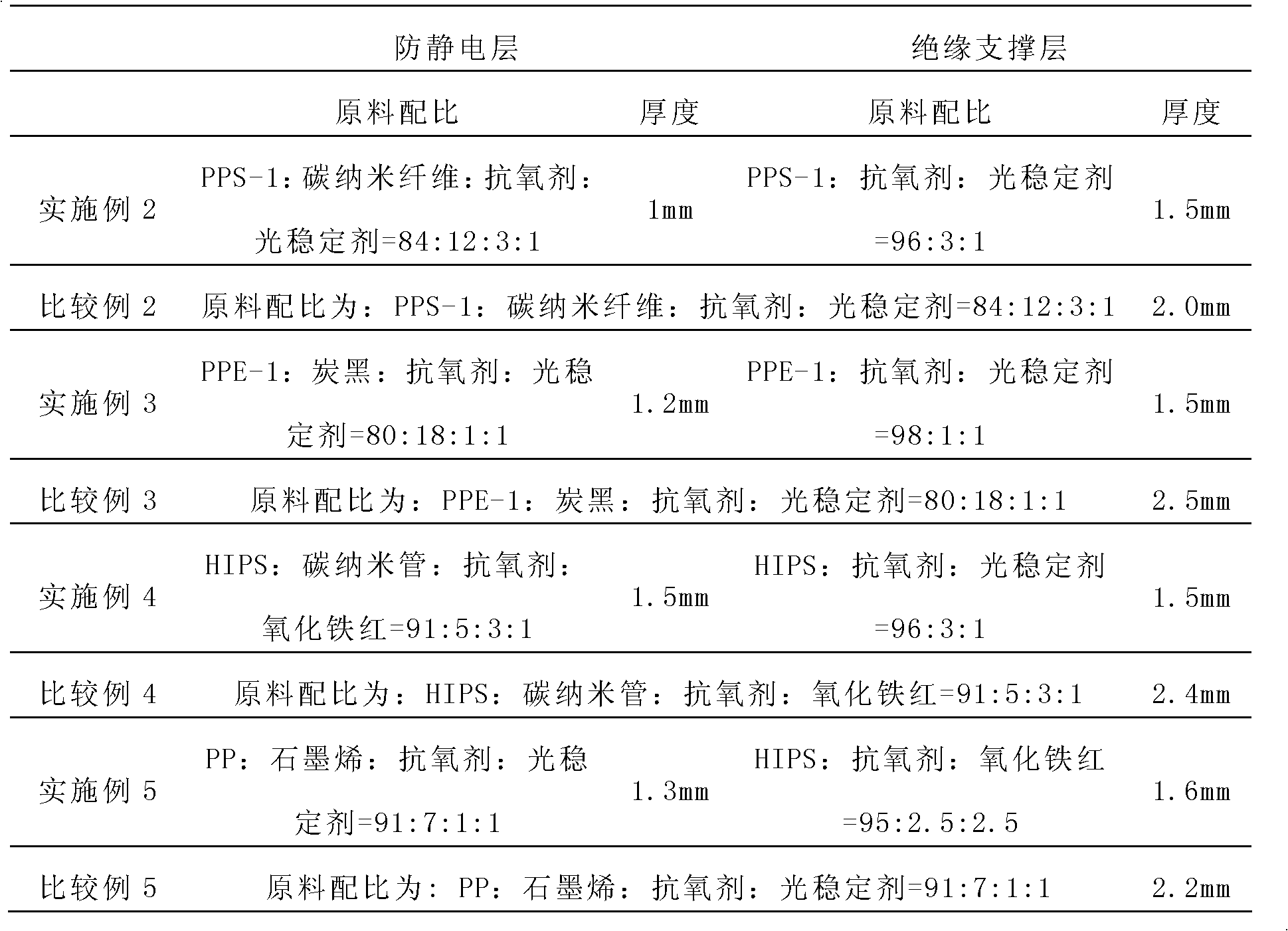

InactiveCN102173157AGood anti-static effectImprove mechanical propertiesSynthetic resin layered productsElectrical apparatus casings/cabinets/drawersAntistatic agentMechanical property

The invention provides an antistatic composite material which comprises an antistatic layer and an insulating support layer, wherein the antistatic layer is prepared by curing a first resin composition, and the first resin composition contains conductive fillers; and the insulating support layer is connected with the antistatic layer, and prepared by curing a second resin composition. Compared with the prior art, the antistatic layer of the composite material provided by the invention can enable the composite material to achieve a good antistatic effect, and the insulating support layer can enable the composite material to have good mechanical properties, namely, by using the composite material provided by the invention, the good mechanical properties of the composite material are guaranteed, and the composite material is endowed a good antistatic property.

Owner:HYTERA COMM CORP

Anti-corrosion antistatic coating made of waterborne acrylate grafted epoxy resin and preparation method thereof

ActiveCN103173087ANovel structureImprove conductivityAnti-corrosive paintsElectrically-conductive paintsEpoxyEmulsion

The invention discloses an anti-corrosion antistatic coating made of waterborne acrylate grafted epoxy resin and a preparation method thereof and relates to the technical field of production of a coating. According to the invention, carbon nano tube is selected as an antistatic additive; and a film forming matter is waterborne acrylate grafted epoxy resin emulsion. The characteristics of the acrylate resin and epoxy resin can be effectively integrated into a whole; the prepared anti-corrosion antistatic coating is good in storage stability, good in construction property, fast to dry after being coated, smooth in dried film, and excellent in mechanical behavior, antistatic property, acid resistance, alkali resistance, salt water resistance and the like.

Owner:扬州市伊丽特高分子材料科技有限公司

Anti-static film

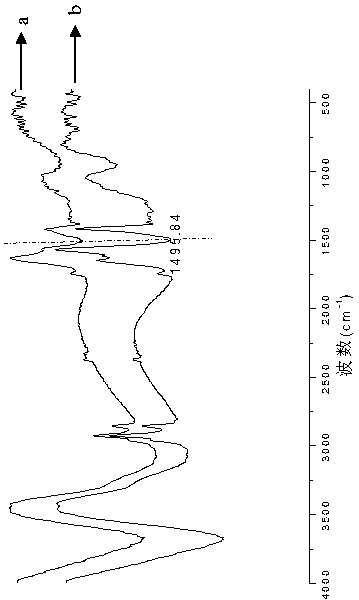

ActiveCN108192121AImprove anti-static effectGood adhesionPolyurea/polyurethane coatingsElectrically-conductive paintsWater basedCarbon nanotube

The invention provides an anti-static film. The anti-static film comprises a base material and at least one surface of anti-static layer of the base material; the anti-static layer is formed by dryingraw materials, carrying out transverse tensile on the dried raw materials with the base material synchronously, and then carrying out sizing, wherein the raw materials are the follows in percentage by weight: 2-10% of a water-based carbon nanotube dispersing agent, 2-15% of waterborne polyurethane resin, 0.5-2% of a cross-linking agent, 0.5-5% of an assistant and 68-95% of deionized water. The surface resistance value of the anti-static film provided by the invention can reach 10<5>-10<6>, and the adhesive force is stable.

Owner:HEFEI LUCKY SCI & TECH IND

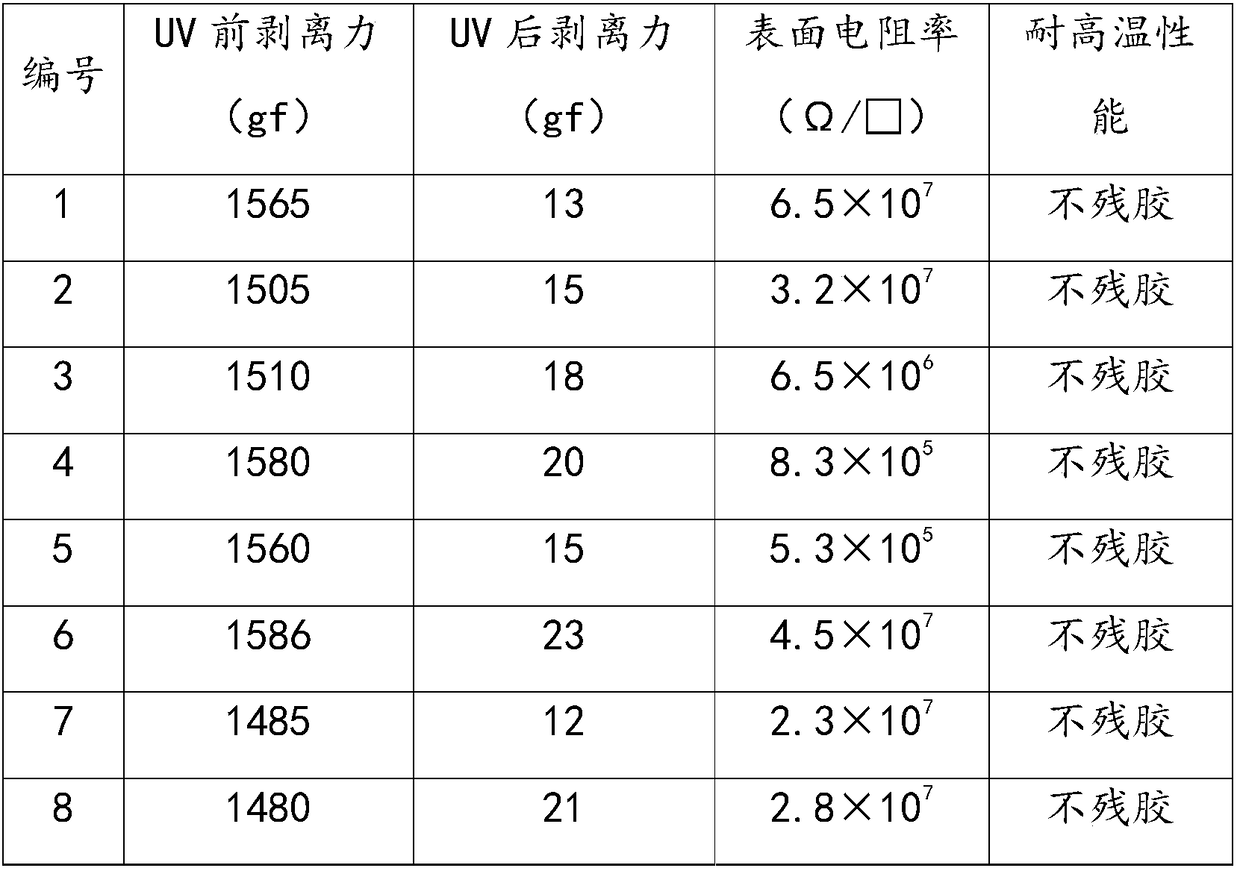

UV viscosity reducing composition, UV viscosity reducing film and preparation method thereof

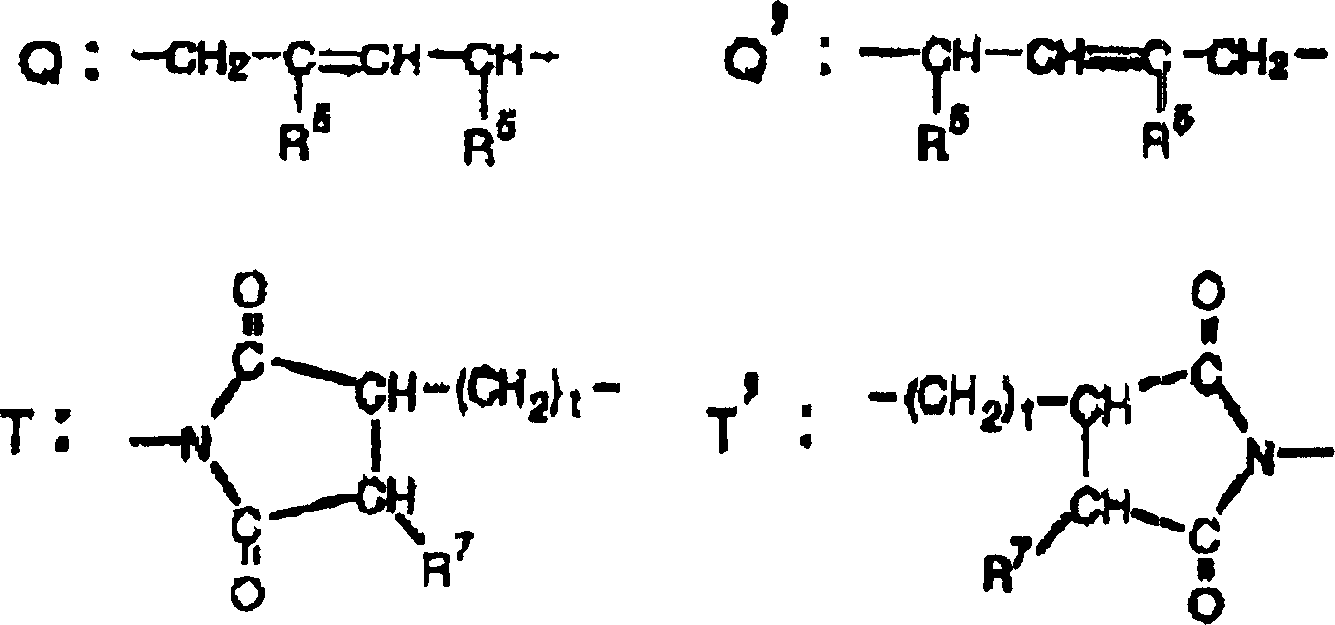

InactiveCN108300336AImprove adhesionReduce adhesionFilm/foil adhesivesOrganic non-macromolecular adhesiveTectorial membraneOligomer

The invention relates to the technical field of protective films, in particular to an UV viscosity reducing composition, an UV viscosity reducing film and a preparation method thereof. The UV viscosity reducing composition is prepared from the following main raw materials in percent by weight: 20-50% of high temperature-resistant acrylate pressure-sensitive adhesive resin, 1-30% of a polyfunctional oligomer and / or polyfunctional monomer, 0.3-2% of a crosslinking agent, 0.1-5% of an antistatic agent, 0-2% of a dispersant, 0.2-2% of a leveling agent, 0.5-5% of a photoinitiator and 25-60% of a solvent. The UV viscosity reducing film comprises a substrate layer, an UV viscosity reducing layer coated thereon and a release film layer. The UV viscosity reducing composition has an excellent adhesive force, has a high adhesive force and a high release force before UV irradiation, has a low adhesive force, a low release force and a good antistatic effect after UV irradiation, and can resist 120DEG C high temperature for 30 minutes without an adhesive residue.

Owner:SUZHOU CHENGBANG DALI MATERIAL TECH

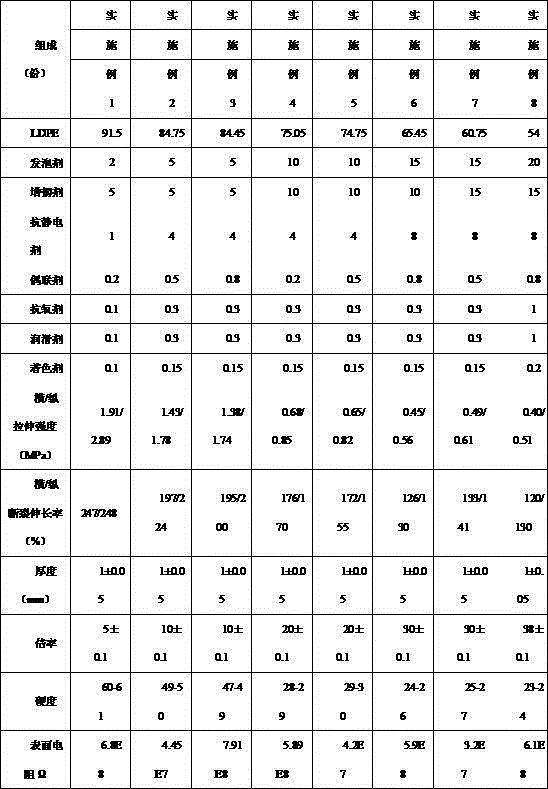

Colored high-performance and anti-static radiation cross-linked polyethylene foam material and preparation method thereof

InactiveCN104610632AExcellent impact resistanceGood anti-static performanceCross-linked polyethylenePolymer chemistry

The invention discloses a colored high-performance and anti-static radiation cross-linked polyethylene foam material and a preparation method thereof. Low-density polyethylene and a foaming agent are adopted, a toughening agent, an antistatic agent, a coupling agent, an antioxidant, a lubricating agent and a coloring agent are added for process optimizing treatment, a product has excellent impact resistance, excellent anti-static performance and a dazzling surface vision effect, changes the condition that most anti-static radiation cross-linked polyethylene foam cotton is black, fills up the blank, can completely meet the demand of the current market for the anti-static cross-linked polyethylene foam material, improves the market competitiveness, is important improvement of common anti-static foaming polyethylene materials and overcomes the defects of high cost, difficulty in process and low mechanical property of conventional anti-static polyethylene foam cotton.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

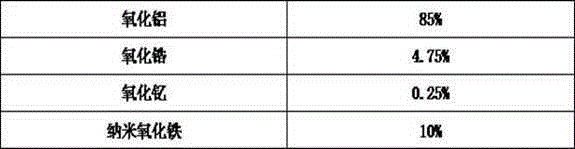

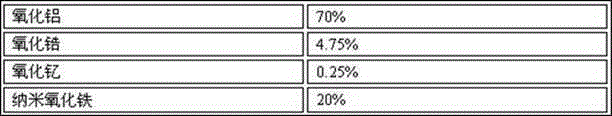

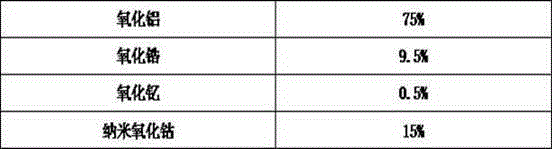

Aluminum oxide anti-static ceramic material and preparation method thereof

The invention relates to a ceramic material and a preparation method. The ceramic material has the electrostatic dissipation characteristic of safe discharge of electrostatic charges. The aluminum oxide anti-static ceramic material comprises the following components: aluminum oxide, a nanometer second conductive phase and 3Y-zirconium oxide. Thus, the obtained aluminum oxide anti-static ceramic material has the characteristics of excellent antistatic performance, wear resistance, corrosion resistance, high toughness and high compactness. The invention also provides a simple, ageing-free and low-cost preparation method for the aluminum oxide anti-static ceramic material.

Owner:NINGBO TOPTEK ADVANCED CERAMICS CO LTD

Anti-static polyurethane material for manufacturing shoe soles, shoe sole manufacturing method and manufacturing method of dual-density polyurethane safety shoe soles

ActiveCN102504519AImprove anti-static performanceGood anti-static performanceSolesDefoaming AgentsIsocyanate compound

The invention discloses an anti-static polyurethane material for manufacturing shoe soles, a shoe sole manufacturing method and a manufacturing method of dual-density polyurethane safety shoe soles. The anti-static polyurethane material consists of a component A and a component B which are mixed and poured, the component A includes polyatomic alcohol, catalyst, foaming agent, anti-static agent, carbon fiber powder, chain extender and defoaming agent; and the component B is isocyanate. The shoe sole manufacturing method includes steps of baking and drying the polyatomic alcohol and the isocyanate, mixing the rest compositions in the component A and the baked polyatomic alcohol uniformly to form material A, and mixing the material A with the isocyanate of the component B to obtain shoe soles made of anti-static polyurethane materials by pouring forming. The dual-density polyurethane safety shoe soles can be manufactured by secondary pouring by selecting foaming agents in different quantity. The polyurethane materials are high in anti-static performance, and the manufactured shoe soles are proper in hardness. Shoe soles manufactured by the manufacturing methods are fine in demouldingand high in production efficiency.

Owner:深圳市新纶超净科技有限公司

Self-cleaning layer with photocatalysis and anti-static compounding functions and production method thereof

InactiveCN103112231AImprove superhydrophilicityOvercoming the weakness of self-cleaning functionLayered productsSpecial surfacesEngineeringPhoto catalysis

The invention relates to a self-cleaning layer with photocatalysis and anti-static compounding functions and a production method of the self-cleaning layer, and particularly relates to a method of combining photocatalytic materials capable of enabling visible light to respond and anti-static materials on a base material surface in an adhering manner. According to the self-cleaning layer, the anti-fouling, anti-dust and photocatalysis self-cleaning functions can be realized on external decorative material surfaces of different buildings. The self-cleaning layer is formed by a sealing layer, an anti-static layer and a photocatalysis layer, wherein the sealing layer is coated on the base material surface, the anti-static layer is compounded on the sealing layer, and finally, the photocatalysis layer is compounded on the anti-static layer. The self-cleaning layer is a novel self-cleaning layer capable of being automatically cleaned under visible light and preventing dust. The self-cleaning layer is mainly applied on building roofs, building curtain walls, wall decorations and glass surfaces and is also applied in the municipal traffic engineering construction and modification engineering projects.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

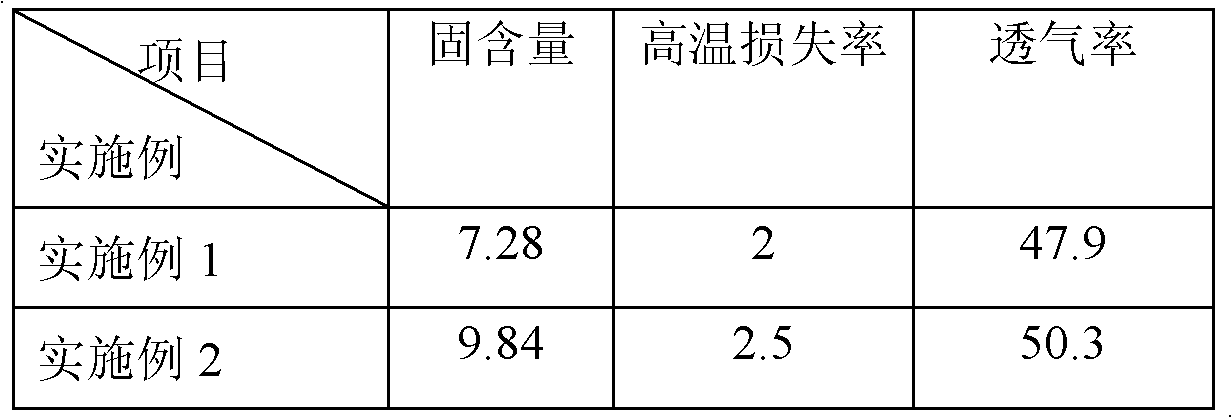

Impregnating compound for basalt fiber filter felt

ActiveCN102002855AHigh temperature loss rate reductionImprove high temperature resistanceFibre treatmentEmulsionWorking environment

The invention relates to a high-temperature filter felt impregnating compound with high temperature resistance and antistatic property, which is particularly suitable for a basalt fiber filter felt. The invention aims to provide a high temperature-resistant and antistatic impregnating agent for the basalt fiber filter felt to solve the problem that the working environment of the basalt fiber filter felt is severe. The technical scheme is that: the impregnating agent for the basalt fiber filter felt comprises the following components in percentage by weight: 5 to 6 percent of graphite emulsion with the solid content of 20 percent, 8 to 10 percent of PTFE solution with the solid content of 60 percent, 4 to 6 percent of silicone emulsion with the solid content of 60 percent, 3 to 5 percent of polyacrylate with the solid content of 30 percent, and the balance of water. After the impregnating compound is coated on the basalt fiber filter felt, the basalt fiber filter felt has good high temperature resistance and antistatic property. Actual detection proves that the heat loss of the basalt fiber filter felt produced by the formula is greatly reduced, and the product performance is greatly improved.

Owner:SHANDONG XINLI ENVIRONMENTAL PROTECTION MATERIAL

Luminous diode device structure and its manufacture method

ActiveCN101212000AImprove performanceImprove crystal qualitySemiconductor devicesCrystal structureNucleation

The invention discloses a structure of a light-emitting diode device, which includes the following layers from the upper part to the lower part in sequence: a sapphire substrate, a buffer nucleation layer, an undoped GaN layer, an N-type GaN layer, a multiple quantum well layer, a GaN layer doped with Al and Mg as well as a GaN layer doped with the Mg. The N-type GaN layer is respectively arranged on a lower first GaN layer doped with Si and an upper second GaN layer doped with the Si. An AlGaN layer doped with the Si is contained between the first GaN layer doped with the Si and the second GaN layer doped with the Si. The invention also discloses a method for manufacturing the light-emitting diode device. When the N-type layer is manufactured, the following steps are included: at first, the first GaN layer doped with the Si grows; then, the AlGaN layer doped with the Si grows; at last, the second GaN layer doped with the Si grows. The light-emitting diode device is manufactured by the method provided by the invention and the method has simple steps and easy realization. Furthermore, the manufactured light-emitting diode device has good static-proof capacity and a crystal structure, thus greatly facilitating the performance of the light-emitting diode.

Owner:EPILIGHT TECH

UV visbreaking composition, UV visbreaking film, and production method of film

InactiveCN108441135AImprove adhesionReduce adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntistatic agentOligomer

The invention relates to the technical field of protection films, and especially to a UV visbreaking composition, a UV visbreaking film, and a production method of the film. The UV visbreaking composition is mainly prepared from, by weight, 20-50% of acrylate pressure-sensitive adhesive resin, 1-30% of a multifunctional oligomer and / or a multifunctional monomer, 0.3-2% of a cross-linking agent, 0.1-5% of an antistatic agent, 0-2% of a dispersant, 0.2-2% of a leveling agent, 0.5-5% of a photoinitiator and 25-60% of a solvent. The UV visbreaking film comprises a substrate layer, a UV visbreakinglayer and a release film layer which are sequentially bonded, and the UV visbreaking layer is obtained by coating the surface of the substrate layer with the UV visbreaking composition, and drying and curing the UV visbreaking composition. The UV visbreaking composition has excellent adhesion, has high adhesion and high peel strength before UV irradiation, has low adhesion and low UV peel strength after the UV irradiation, and also has a good antistatic effect.

Owner:SUZHOU CHENGBANG DALI MATERIAL TECH

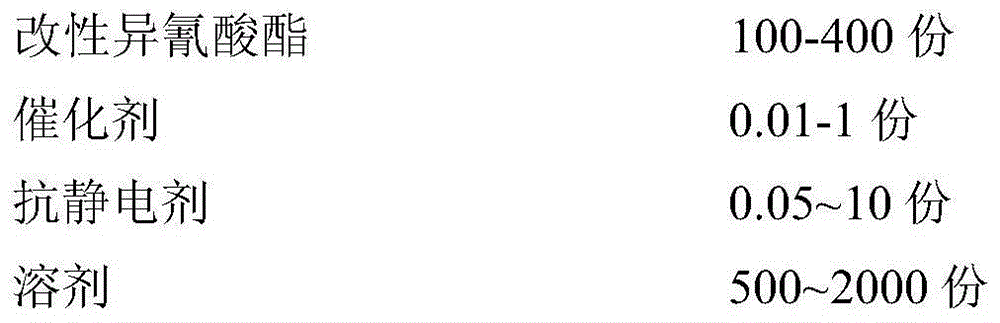

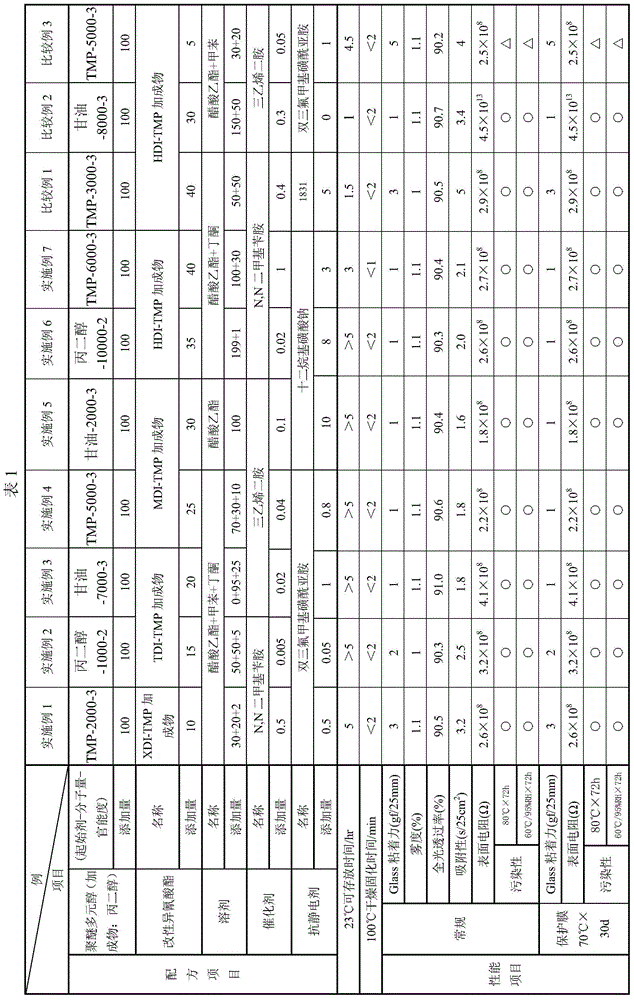

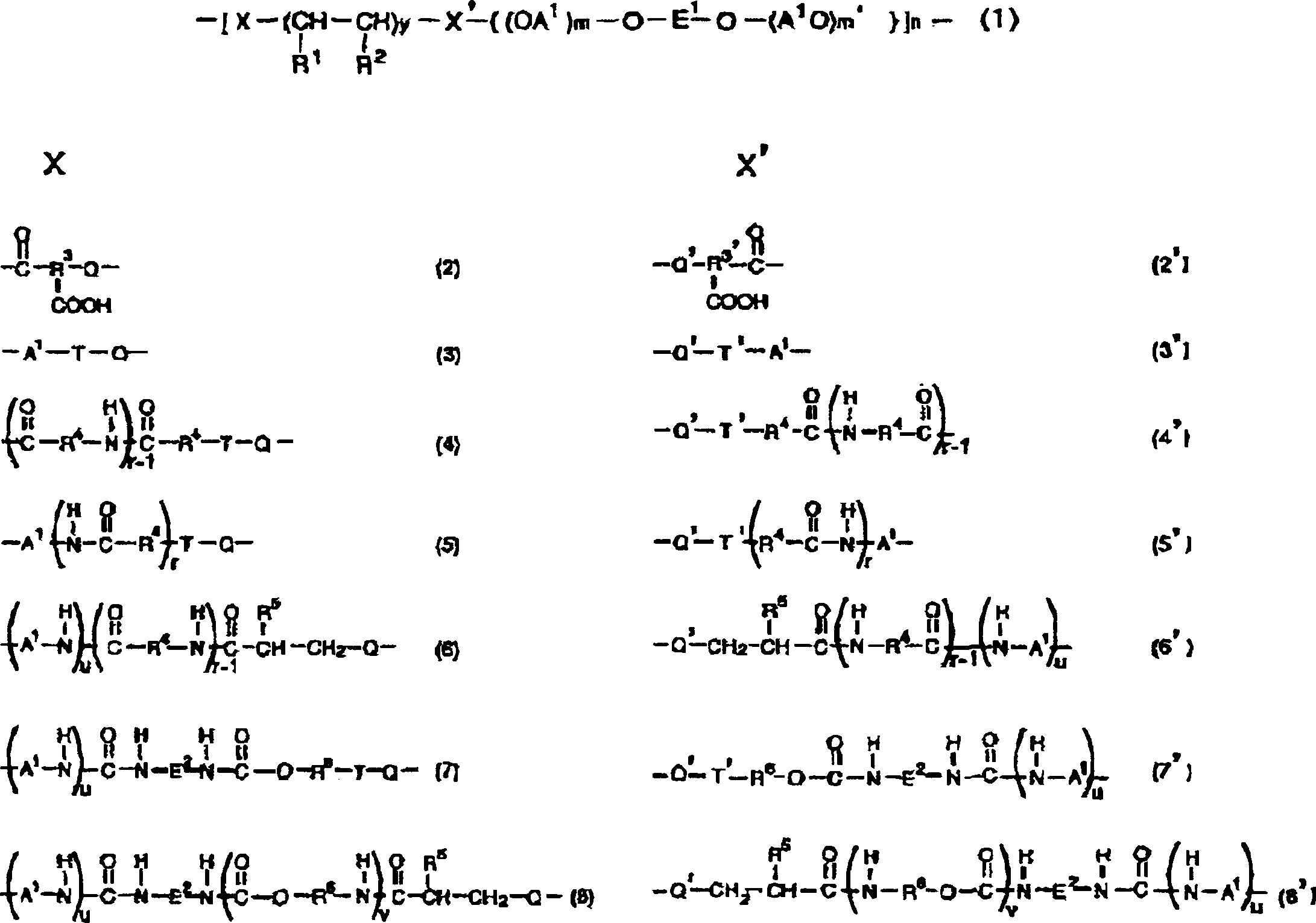

Preparation method of polyurethane pressure-sensitive adhesive composition and polyurethane protective film

ActiveCN104531039AInhibitory activityLow anti-static effectNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkTectorial membrane

The invention relates to a preparation method of polyurethane pressure-sensitive adhesive composition and a polyurethane protective film. The preparation method is characterized by including 1000 parts of polyether polyol, 100-400 parts of modified isocyanate, 0.01-1 part of a catalyst, 0.05-10 parts of an antistatic agent and 500-2000 parts of solvent. The above mentioned components are mixed and coated on a substrate, and the polyurethane protective film with good performance can be obtained through first-step reaction at a temperature of 60 DEG C-130 DEG C. The provided preparation method of a polyurethane formula and the polyurethane protective film saves the previous prepolymerization process, raw material monomer is directly used in the process of catalytic reaction polymerization, cross-linking and soliding and forming, the rate of film formation is 100%, a large number of cost and time are saved, accuracy control of the protective film with stable quality is achieved, a configured tackiness agent mixed liquor can be stored at room temperature for a long time and certainly can be used immediately, and the operable time in a coating process is greatly extended.

Owner:NINGBO SOKEN CHEM

Polyolefin resin foam and manufacturing method thereof

The present invention provides a manufacturing method of a polyolefin resin foamed body which, when used as a packaging material, has least possibility of contaminating the surface of a contacting material, which excels in appearance and which shows antistatic characteristics uniform over the entire surface, and provides the polyolefin resin foamed body. The present invention comprises a specific mount of a polymer type antistatic agent whose apparent density may be 15 to 65 g / L, whose specific surface inherent resistance rate is 1 X 108 to 1 X 1013 (ohm), and whose average foamed body diameter meets a specific relationship.

Owner:JSP CORP

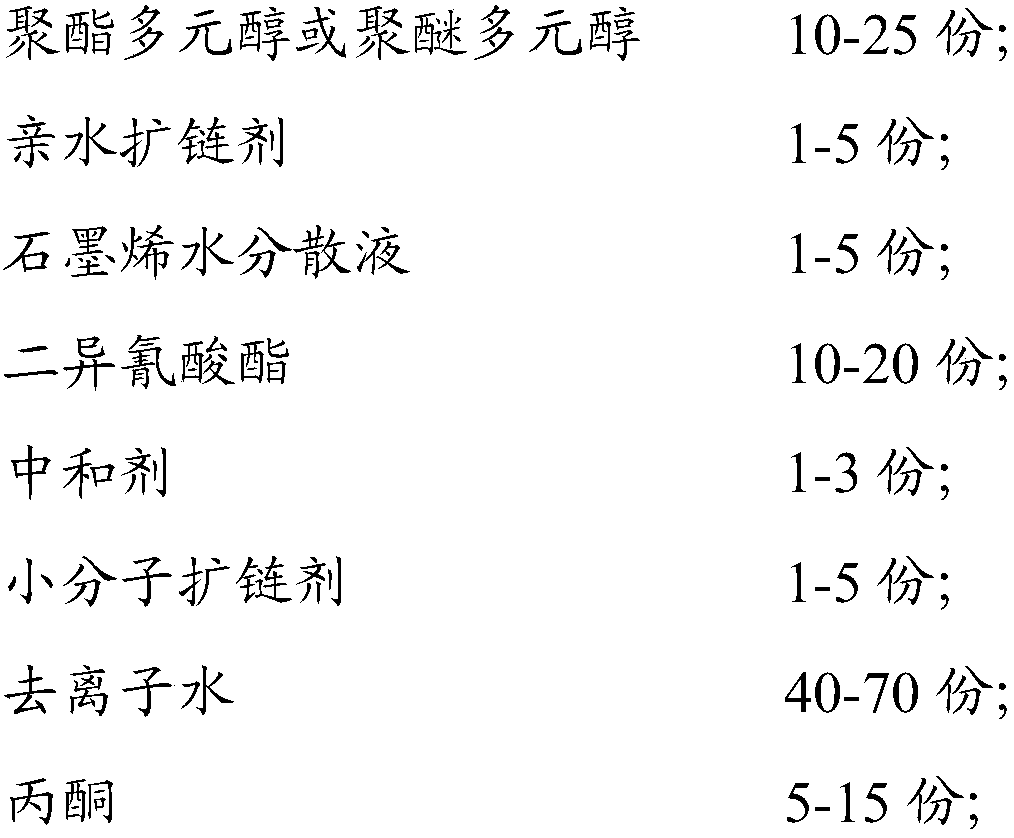

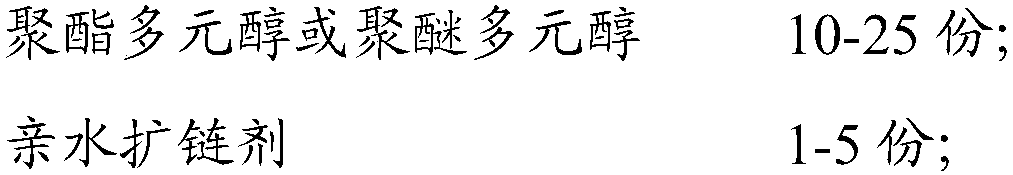

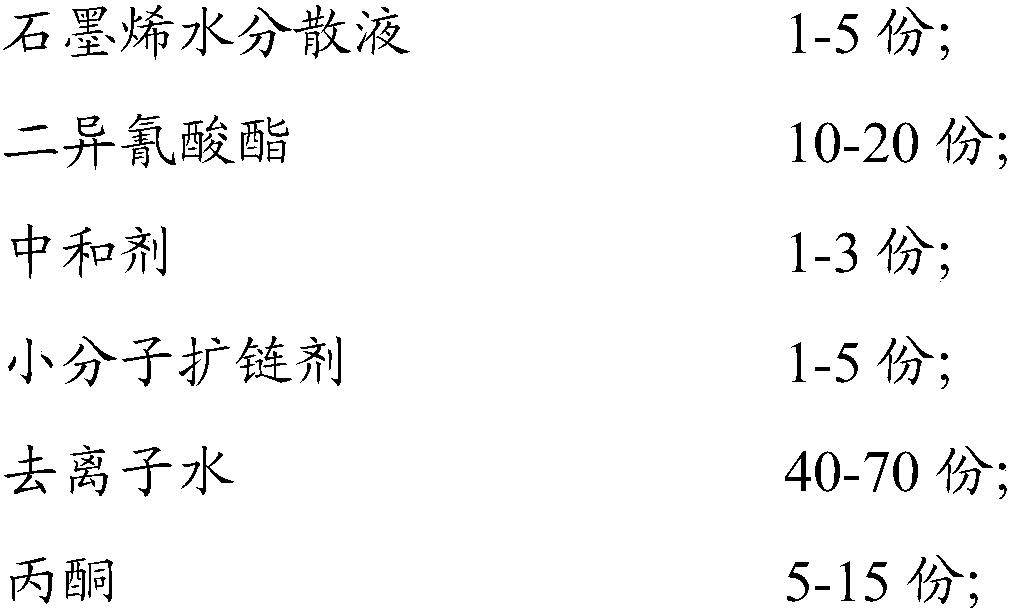

Graphene modified waterborne polyurethane resin and preparation method thereof

InactiveCN107778449AHigh hardnessImprove anti-static effectAntifouling/underwater paintsPaints with biocidesPolyesterHigh concentration

The invention discloses graphene modified waterborne polyurethane resin and a preparation method thereof. The preparation method specifically includes: subjecting graphene oxide obtained through a Hummers method to functional modification and dispersing to obtain a high-concentration graphene aqueous dispersion; adding polyester polyol (or polyether polyol) and a hydrophilic chain extender which are of formula ratio into the graphene aqueous dispersion, evenly stirring, and removing moisture under a vacuum condition; feeding nitrogen immediately after the vacuum condition is ended, adding diisocyanate of formula ratio, performing heating and stirring reaction for a certain time, then stopping nitrogen feeding, and adding a neutralizing agent; adding deionized water, performing high-speed dispersing for a certain time, then adding a small-molecule chain extender to perform reaction, and discharging. The preparation method has the advantages that the method is simple and controllable inoperation and capable of easily preparing and synthesizing the graphene modified waterborne polyurethane resin in a large-batch manner; the graphene modified waterborne polyurethane resin prepared bythe method is good in adhesive force, corrosion resistance and impact resistance and widely applicable to fields such as the marine field, steel structures, anti-static coating, conductive coating andantifouling and waterproof coating.

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

Production formula and production process for fiberglass-reinforced plastic container equipment

InactiveCN102212261AExcellent corrosion resistanceGood anti-static performanceChemistryAging property

The invention provides a production formula and a production process for fiberglass-reinforced plastic container equipment. The preparation raw materials include a surface mat, a chopped strand mat, base-free fiberglass, spray yarns, resins, a curing agent, an accelerator, an anti-static agent and an anti-UV absorbent, wherein the weight ratio of the resins to the accelerator to the curing agent is 100: (1-3): (1-3), and the optimal weight ratio of the resins to the accelerator to the curing agent is 100: 1: 1. The lining forming process adopts an injection molding process; the demoulding process adopts a pneumatic ejection demoulding method; the inner lining butting process is performed by trimming, affixing of a support plate and precise alignment treating; the inner lining in the winding process is subjected to charging supporting and pressing; and the winding process uses 360-degree all-round three-dimensional envelope winding. The fiberglass-reinforced plastic container equipment provided by the invention has the advantages of excellent corrosion resistance, good anti-static property, excellent anti-aging property, long service life and so on.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

Polyvinyl chloride electrostatic film and preparation method thereof

InactiveCN106046626AHigh static resistanceImprove anti-static effectFlat articlesPlasticizerPolyvinyl chloride

The invention relates to the technical field of electrostatic film, and in particular, relates to a polyvinyl chloride electrostatic film and a preparation method thereof, wherein the polyvinyl chloride electrostatic film comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 46-73 parts of a plasticizer, 1-3 parts of a heat stabilizer, 3-7 parts of an anti-electrostatic agent, 0.3-0.7 part of a gelatinizing agent, 0.02-0.03 part of a pigment powder, and 0.1-0.3 part of other auxiliary agents. The polyvinyl chloride electrostatic film has high electrostatic resistance, has high anti-electrostatic effect and protection functions, has high self-adhesive performance, and has excellent stable performance under high temperature conditions; the polyvinyl chloride electrostatic film also has the advantages of being ultra thin, tough, transparent, self-adhesive, good in transparency, small in watermarks and the like, has fewer crystal points and low-temperature resistance, and has excellent comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Graphene coating fabric and preparation process thereof

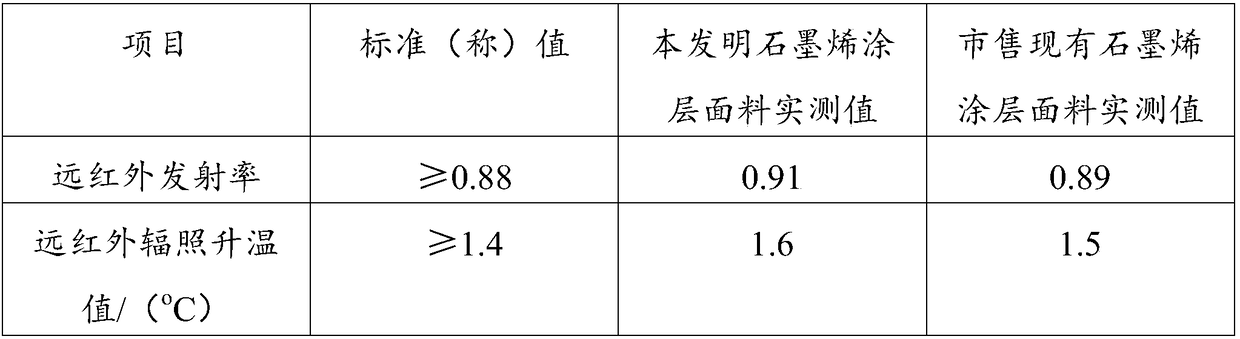

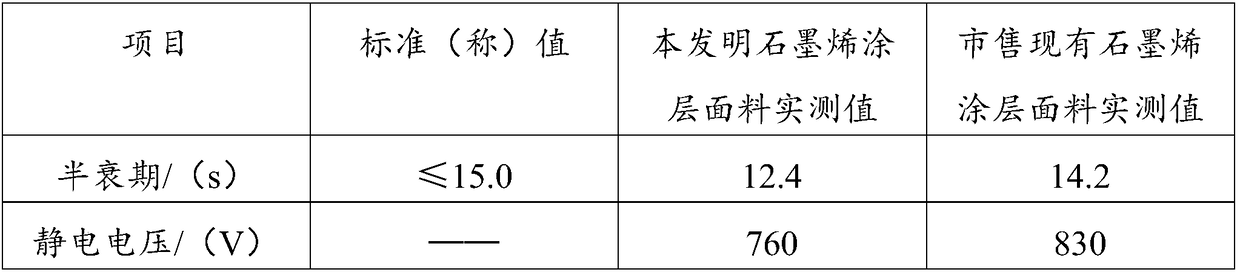

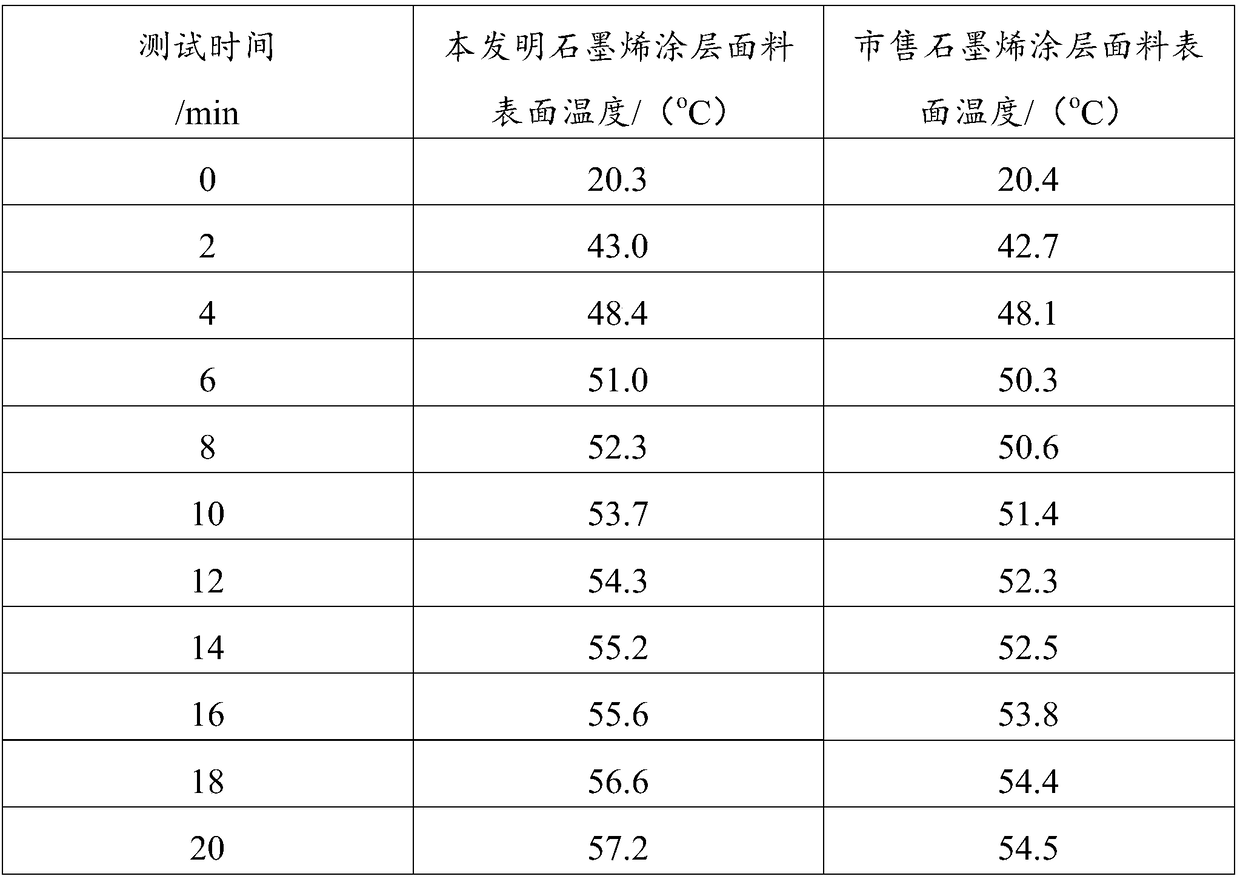

InactiveCN109457499ASimple preparation processImprove efficiencyTextiles and paperCvd grapheneGraphene coating

The invention relates to a graphene coating fabric and a preparation process thereof. The preparation process includes the steps: (1) uniformly mixing graphene powder and adhesives to obtain mixture a; (2) transferring the mixture a to prepare a film, and coating a fabric substrate with the film to obtain a graphene coating fabric. The preparation method is free from pollution emission, simple andeasy to operate and high in efficiency, and the acquired graphene coating fabric has better far infrared, heat storage and warm retention and anti-static performance as compared with a current graphene coating fabric.

Owner:昆山联盛达纺织品有限公司

Antistatic PVC (polyvinyl chloride) modified material and preparation method thereof

The invention relates to the technical field of PVC (polyvinyl chloride) materials, particularly an antistatic PVC modified material and a preparation method thereof. The antistatic PVC modified material is prepared from the following raw materials in parts by weight: 80-120 parts of PVC resin, 35-55 parts of plasticizer, 10-15 parts of filler, 2-3 parts of heat stabilizer, 2-4 parts of antistatic agent and 0.6-1.0 part of lubricant. By adopting the raw materials and strictly controlling the weight parts of the raw materials, all the properties of the prepared antistatic PVC modified material exceed the national standard; and the antistatic PVC modified material has the advantages of favorable effect, environment friendliness, favorable temperature and weather resistance, high strength, excellent impact resistance, favorable flame-retardant effect, favorable processability and excellent comprehensive properties.

Owner:广东祺龙科技有限公司

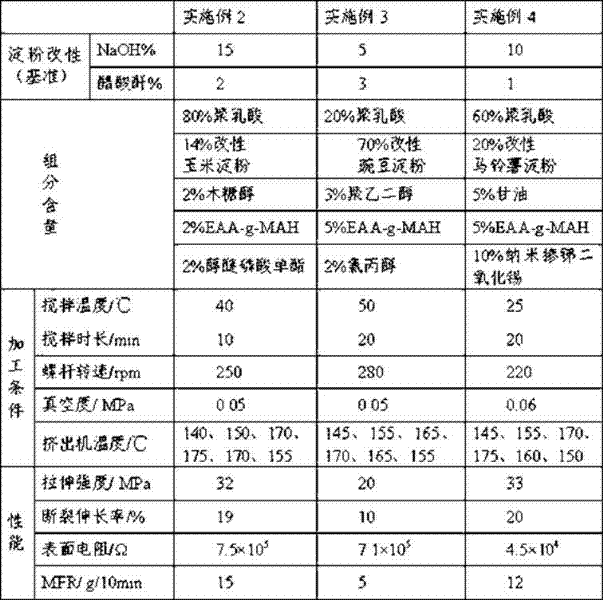

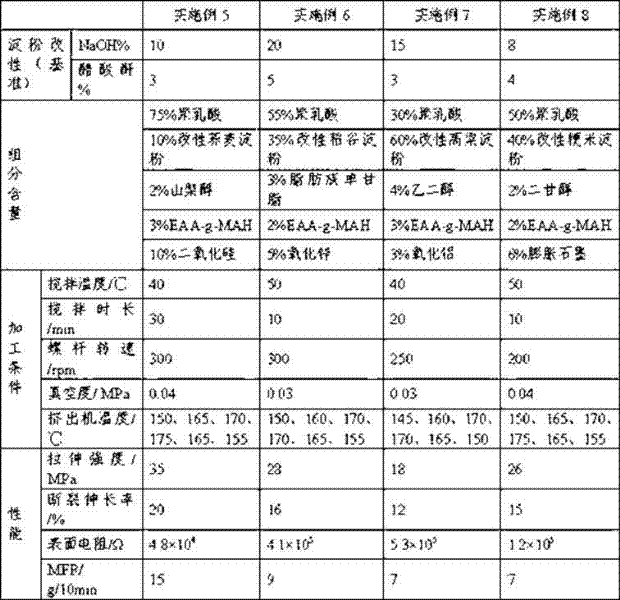

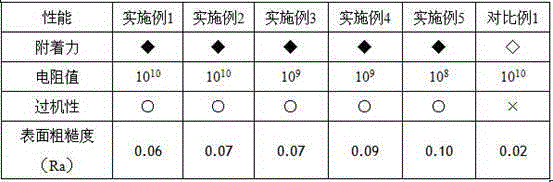

Biodegradable anti-static macromolecule composite material and preparation method of the same

InactiveCN102391631AImprove anti-static effectImprove mechanical propertiesPolymer scienceProcess equipment

The invention relates to a biodegradable anti-static macromolecule composite material which is prepared by mixing the following components by weight: 20-80% of polylactic acid; 10-70% of modified starch; 1-10% of anti-static agent; 1-5% of plasticizer and 1-5% compatilizer. The biodegradable anti-static macromolecule composite material achieves surface resistance of being lower than or equal to 106 ohm, tensile strength of 20-35Mpa and breaking elongation percent of 10-20% and has excellent anti-static and mechanical properties; simultaneously the biodegradable anti-static macromolecule composite material has good environmental degradation property and after 12-week composting, the biological decomposition is above 90%; and the forming processing property is remarkable, therefore the biodegradable anti-static macromolecule composite material can form various products by methods of extrusion, injection molding, hot pressing and the like on processing equipment of common plastics.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

Tent fabrics and preparation method thereof

InactiveCN104859231AKeep warmGood dyeing effectSynthetic resin layered productsVegetal fibresHemp fiberPolyester

The invention discloses tent fabrics and a preparation method of the tent fabrics. The tent fabrics comprise base cloth and waterproof coating. The base cloth comprises, by weight 50-65% of polyester fiber, 15-25% of hemp fiber is, 10-20% of bamboo fiber and 5-10% of wool fiber. The tent fabrics adopt special waterproofing treatment and dyeing processing, not only ensure the waterproof washing color fastness, the color fastness to light and the waterproof effect, but also ensure the wearability to the largest extent through the fiber blending weaving, and enable the blending fibers to have good-strength, anti-bacteria, heat-insulation, uvioresistant and anti-static effects.

Owner:湖州丝葳纺织有限公司

Pressure-sensitive adhesive composition, pressure-sensitive adhesive sheets, and surface protecting film

ActiveCN1696230AReduce static peeling voltageImprove anti-static effectNon-macromolecular adhesive additivesFilm/foil adhesivesCarbon numberMeth-

An object of the present invention is to provide a surface protecting film which reduces staining on an adherend (subject to be protected) when applied to a surface protecting film of plastic products, and prevents electrification on an adherend (subject to be protected) which has not been electrification-prevented when a surface protecting film is peeled. There is provided a pressure-sensitive adhesive composition, which comprises a (meth)acryl-based polymer containing, as a main component, a (meth)acryl-based monomer having an alkyl group of a carbon number of 6 to 14, a polyether polyol compound and an alkali metal salt, wherein an acid value of the (meth)acryl-based polymer is 1.0 or lower, and the alkali metal is contained at an amount of less than 0.1 part by weight relative to 100 parts by weight of the (meth)acryl-based polymer.

Owner:NITTO DENKO CORP

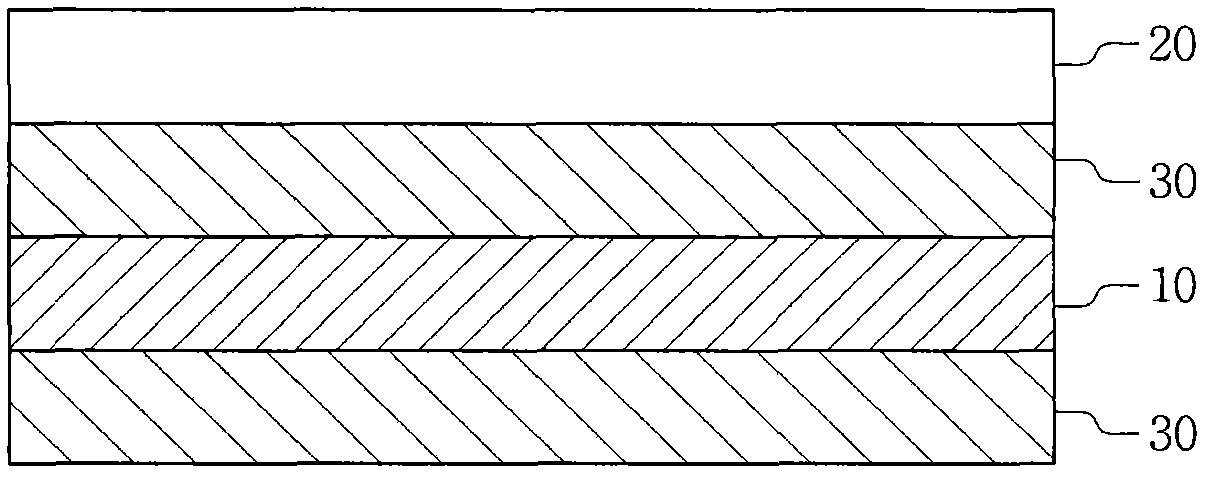

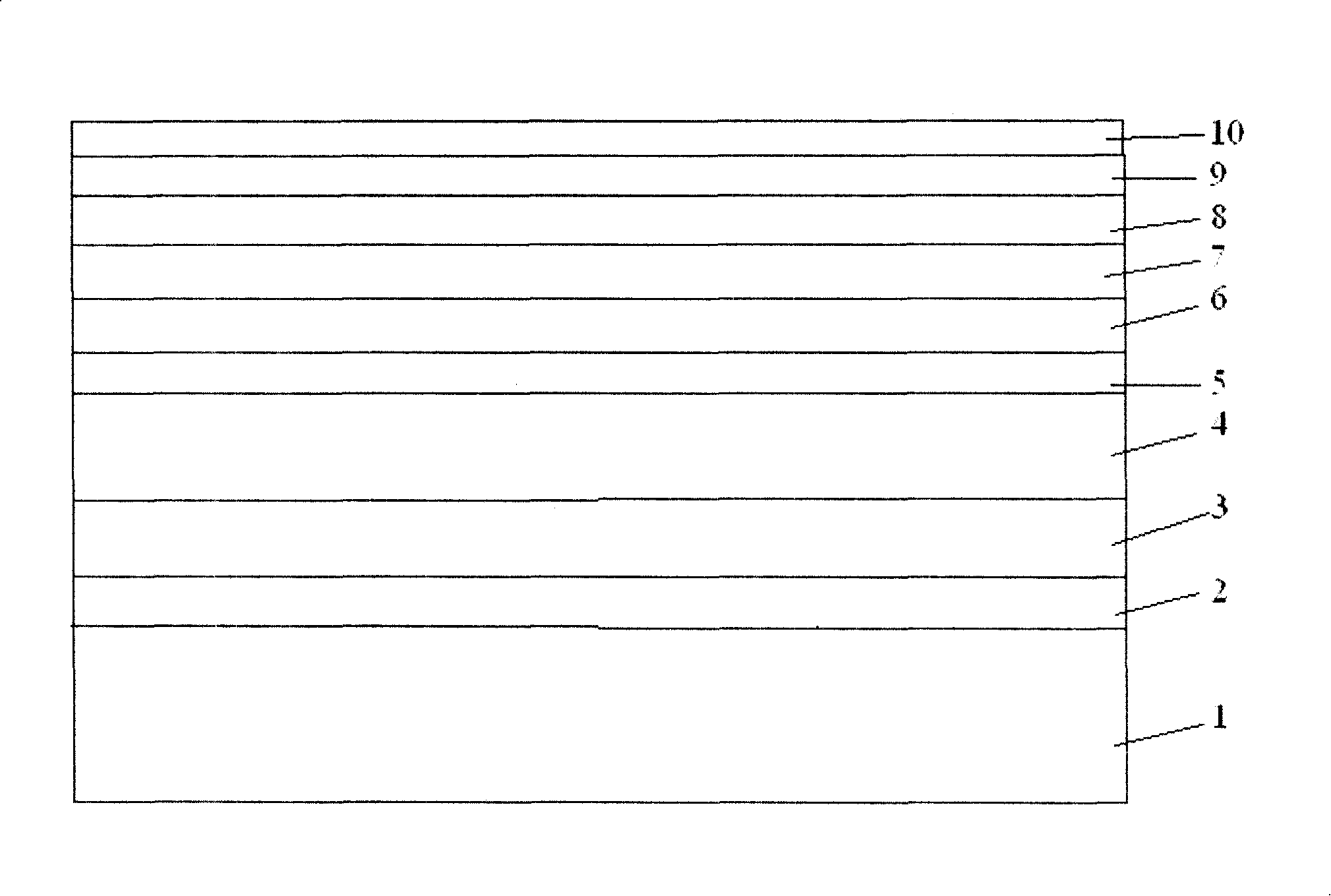

Polyester film base for dry type medical film

ActiveCN105216472ARealize the combinationSimple production processSynthetic resin layered productsCoatingsPolyesterFilm base

The invention provides a polyester film base for a dry type medical film. The polyester film base comprises a back layer, a thin film supporter and a bottom layer, wherein the bottom layer and the back layer are coated on two sides of the thin film supporter respectively through online coating; the bottom layer of the polyester film base improves the adhesive force between the film base and a thermo-sensitive imaging layer; at the same time, the back layer of the film base has excellent smoothness and anti-static function, so that an electrostatic phenomenon and an adhesion phenomenon of the film are kept not to occur; and excellent laminating performance is achieved. The polyester film base is simple in production technology, low in manufacturing cost and excellent in overall performance.

Owner:HEFEI LUCKY SCI & TECH IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com