Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2833 results about "Anti-Static Agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An antistatic agent is a compound used for treatment of materials or their surfaces in order to reduce or eliminate buildup of static electricity.

Explosion prevention PVC sheath material for mine cable and preparation method thereof

InactiveCN101159174AImprove antistatic performanceImprove flame retardant performancePlastic/resin/waxes insulatorsOther chemical processesPlasticizerPolyvinyl chloride

The invention relates to an anti-explosion polyvinyl chloride sheath material for mining cables and a preparation method thereof. The preparation method comprises mixing evenly polyvinyl chloride resin 100 parts by weight, plasticizer 30-80 parts by weight, stuffing 0-60 parts by weight, high-conductivity carbon black 10-40 parts by weight, anti-static agent 0-10 parts by weight, and other auxiliary agent 3-20 parts by weight by a high-speed mixer, extruding at 130-170 DEG C by a single- or double-screw extruder after being melted, water-cooling drawing bar or wind-cooling die-surface hot cutting and granulating, oven-drying, and packaging to obtain the finished product. Compared with the prior art, the invention has the advantages of excellent durable anti-static property and flame retardant property.

Owner:SURREY HI TECH INC

High-cleanness environment-friendly alcohol ether fuel for car

ActiveCN103275769AHigh chemical activityImproves resistance to phase separationLiquid carbonaceous fuelsFuel additivesMechanical engineeringMethanol

The invention provides a high-cleanliness environment-friendly alcohol ether fuel for a car. The fuel provided by the invention consists of the following raw materials: 600-800 parts of methanol, ethanol or a mixture of methanol and ethanol, 100-350 parts of an ether stabilizer, 1-6 parts of an anti-oxygen and anti-gum inhibitor, 2-5 parts of a metal deactivator, 1-3 parts of a corrosion inhibitor, 1-40 parts of a catalytic combustion improver, 2-4 parts of an antistatic agent, 10-100 parts of an antiknock stabilizer, 1-6 parts pf a purification dispersant, 1-6 parts of an anti-wear repair agent, 1-6 parts of a metal corrosion inhibitor, 2-6 parts of a rubber and plastic part corrosion and swelling inhibitor, 10-50 parts of a modified alcohol cosolvent, 0.2-0.8 part of a bactericide and 0.04-0.1 part of a recognition agent. The fuel provided by the invention has the advantages of stable performance, strong power, sufficient combustion, good seismic performance, good acceleration, easiness for starting up, no air lock, no separated layer, reduced fuel consumption, cleaner tail gas emission and no need of changing the structure of a spark ignition engine in the prior art and can be separately used, used instead of regular gasoline or used together with regular gasoline by co-combustion.

Owner:鲁家政

Natural-like multifunctional color batch and use thereof

The present invention features that the color concentrate is prepared with main carrier resin A, matched carrier resin X, compatizer, pigment, inorganic stuffing, antistatic agent, light stabilizer, antioxidant and pigment lubricating dispersant. The main carrier resin an and the matched carrier resin X, which has obviously different compatibility and smelting behavior from that of the basic resin B in the product, may constitute alloy carrier resin. The said materials may be altered to result in various decoration effects.

Owner:GUANGDONG SHENGHENGCHANG CHEM IND

Terylene FDY oil and preparation method thereof

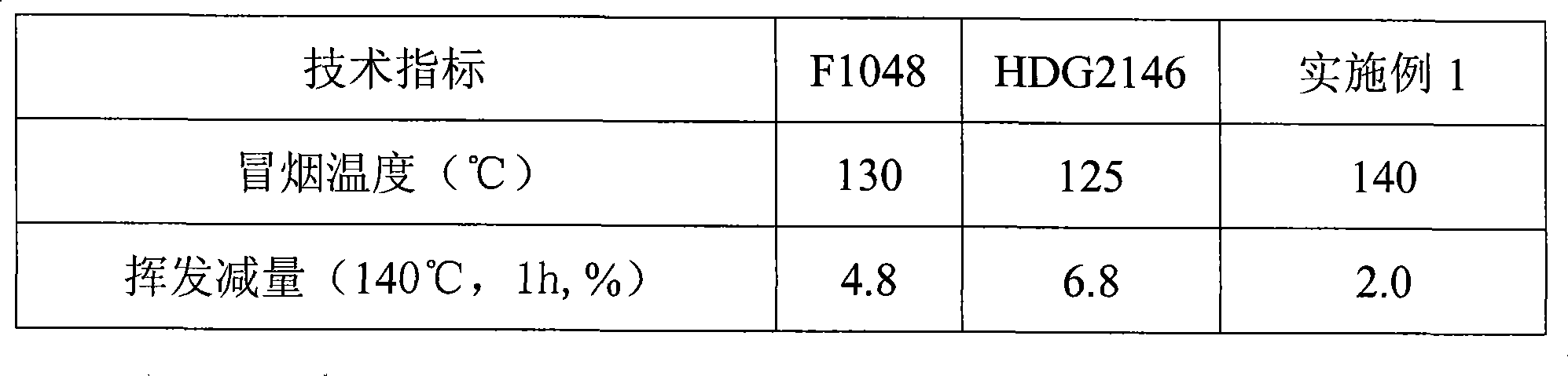

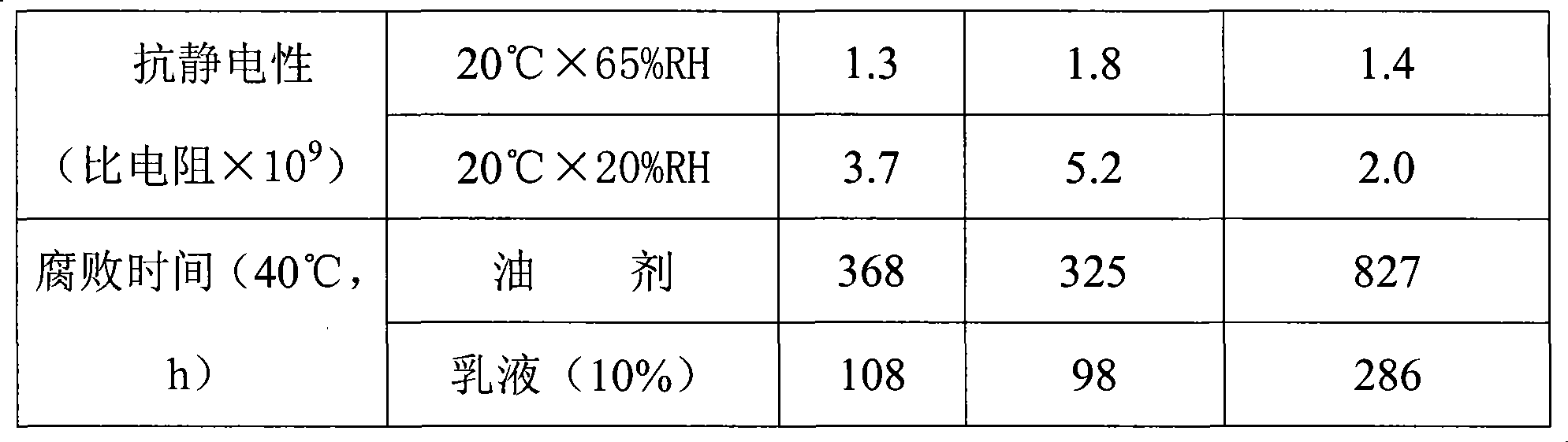

The invention discloses a polyester FDY oil agent and a preparation method thereof. The heat resistance of the existing oil agent is poor with serious volatilization, which results in heavy smog in the workshop and seriously affects the working environment and the body health of the workers; also the oil agent has serious coking phenomena and causes yarn waste and broken ends. The ingredients of the invention and the weight percentages are as follows: 55-65% of high-temperature smoothing agent, 15-25% environment-friendly emulsifying agent, 3-10% binder, 5-8% compound anti-static agent and the rest is additive; and the high-temperature smoothing agent contains special polyether. The invention has good heat resistance and is suitable for the high-speed spinning technique of various polyester fibers (including the high denier); and the oil agent provided by the invention does not generate smoke and does not coke on the hot roll.

Owner:HANGZHOU TRANSFAR CHEM LTD

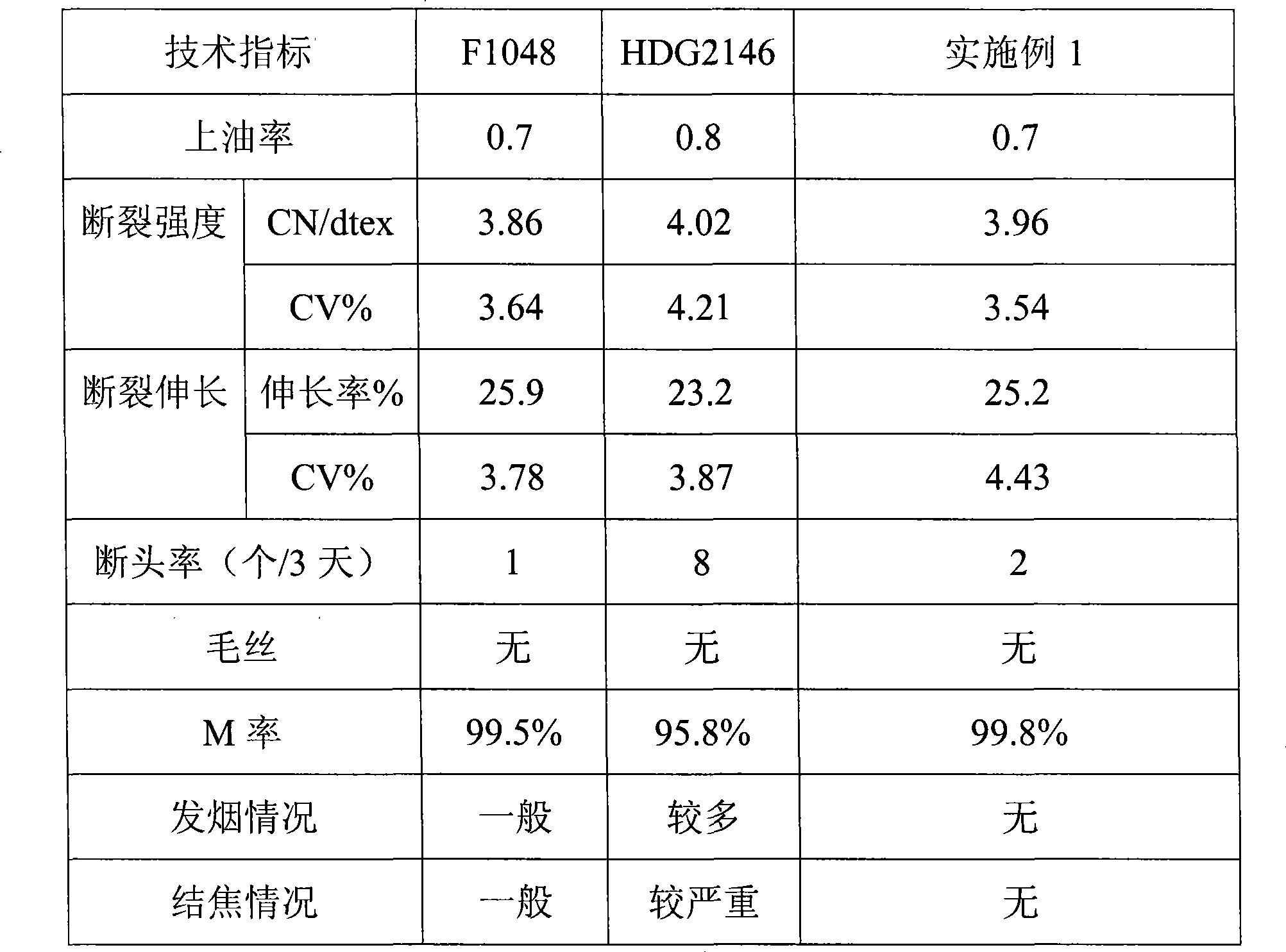

A kind of pressure-sensitive adhesive for PET protective film and preparation method thereof

ActiveCN102260478AAdaptableSlightly viscousFilm/foil adhesivesEster polymer adhesivesEthylene HomopolymersSolvent

The invention relates to a pressure-sensitive adhesive for a PET protective film and a preparation method thereof. The pressure-sensitive adhesive provided by the invention is made from the following raw materials of: by weight, 1-20 parts of a (methyl)acrylate monomer which is used for preparing homopolymers and whose glass transition temperature ranges from minus 45 DEG C to 10 DEG C, 60-90 parts of a (methyl)acrylate monomer which is used for preparing homopolymers and whose glass transition temperature ranges from minus 90 DEG C to minus 50 DEG C, 1-20 parts of a acrylic acid monomer containing functional groups, 0.01-15 parts of a cross-linking agent, 0.01-1 part of an initiator, 0.001-5 parts of a silane coupling agent, 0.001-5 parts of a plasticizer, 0.001-5 parts of an antistatic agent, and 70-100 parts of a solvent. The pressure-sensitive adhesive for the PET protective film in the invention has characteristics of strong adaptability to the PET basement film, microviscosity, repeelable performance, high temperature resistance and antistatic property, and can be widely applied in the production of the PET protective film. The invention also provides a preparation method ofthe above pressure-sensitive adhesive.

Owner:上海绘兰材料科技有限公司

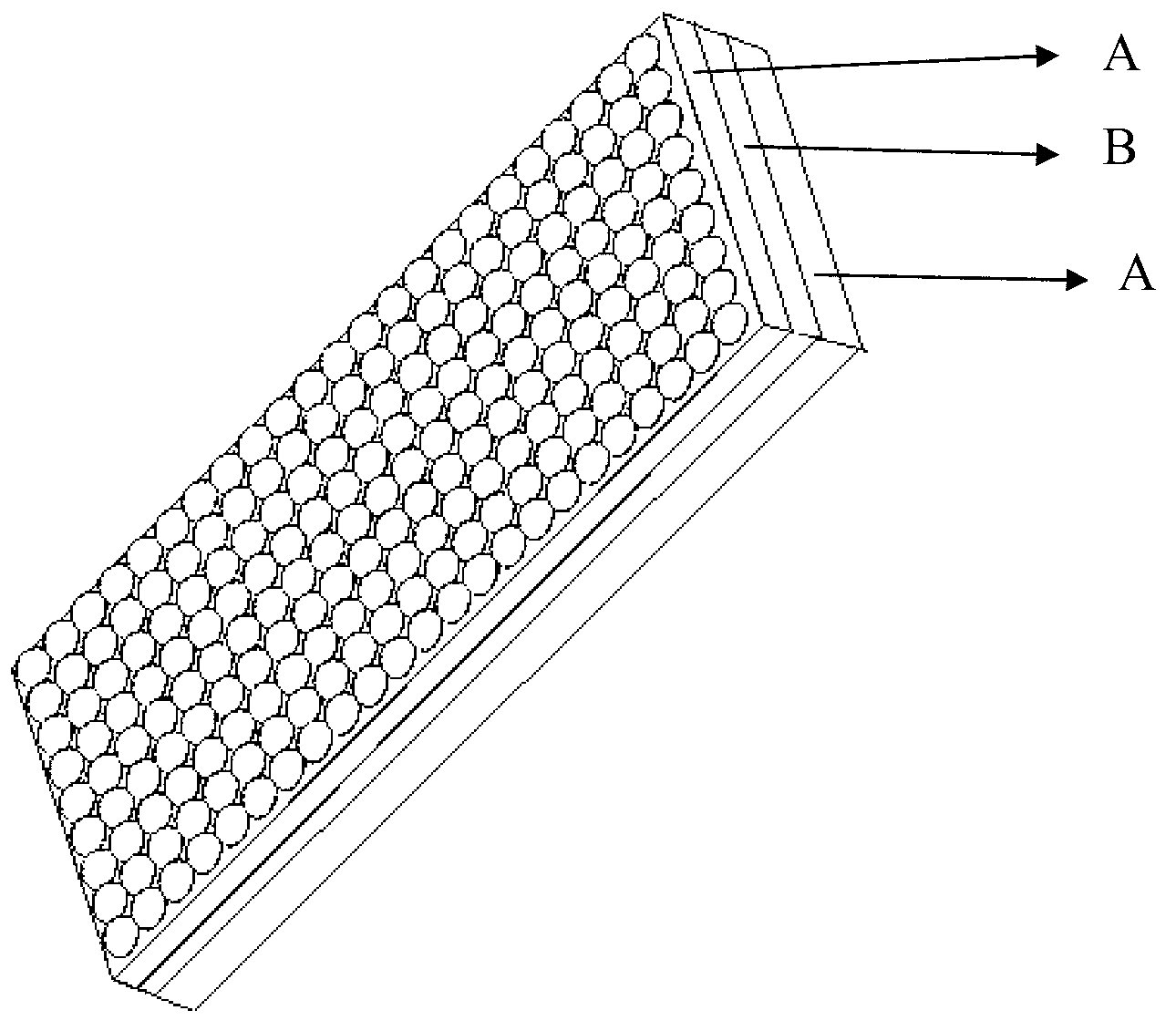

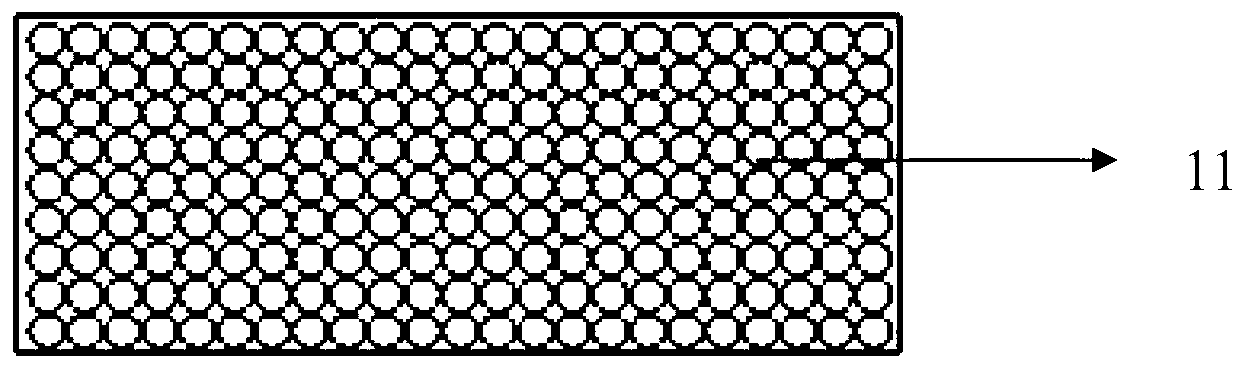

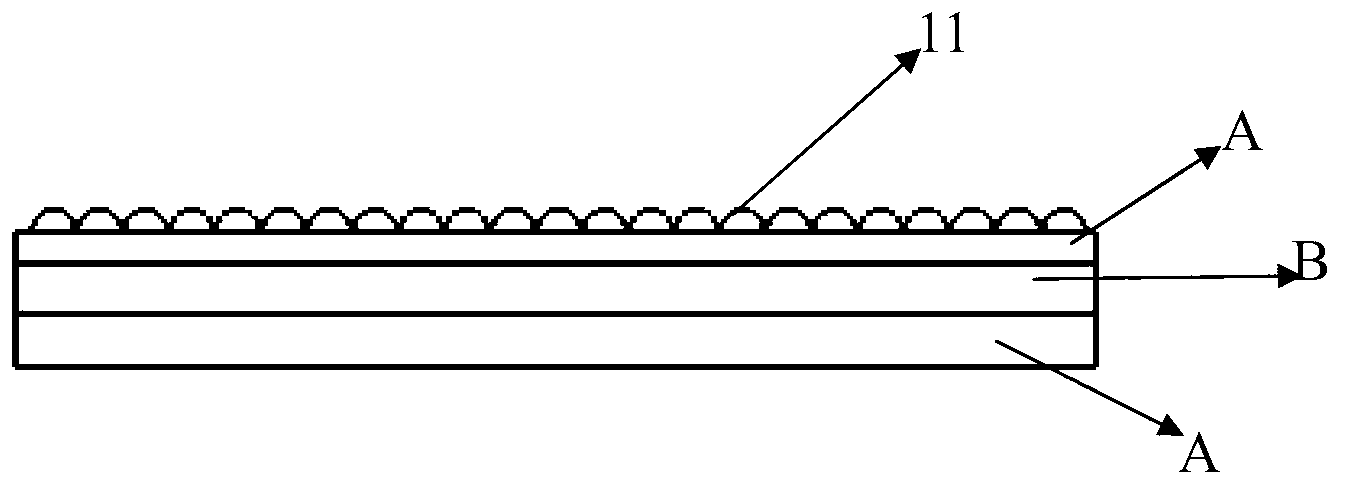

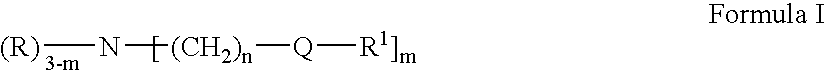

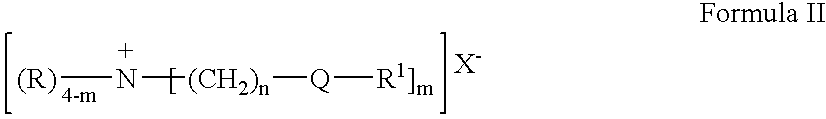

Antistatic polyester film and antistatic film laminate

InactiveUS6103368AIncrease resistanceIncrease productivityRecord carriersMagnetic materials for record carriersCarbon numberPolyester

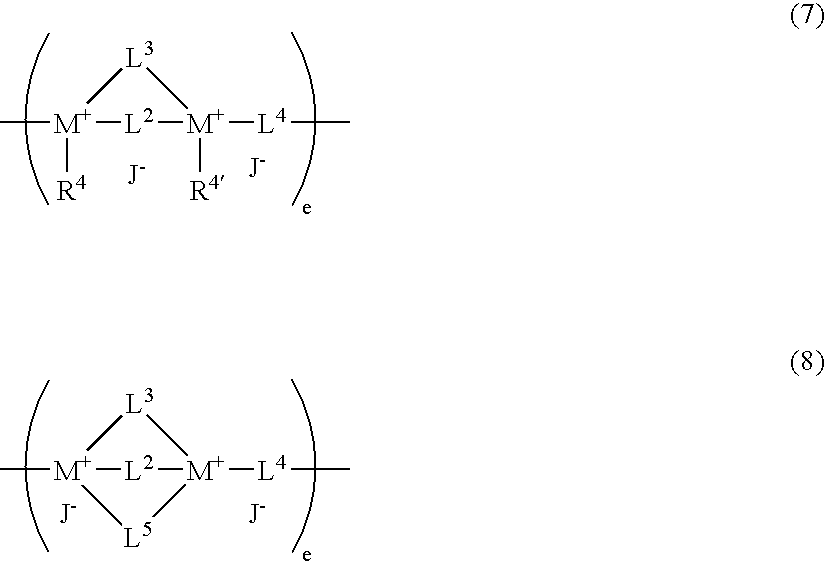

PCT No. PCT / JP97 / 02341 Sec. 371 Date Feb. 27, 1998 Sec. 102(e) Date Feb. 27, 1998 PCT Filed Jul. 7, 1997 PCT Pub. No. WO98 / 02308 PCT Pub. Date Jan. 22, 1998The present invention provides an antistatic polyester film having an antistatic layer formed of an antistatic agent (A) composed mainly of a polymer having a recurring unit of a structure expressed by the following formula (I) on at least one surface of a polyester film wherein R1 and R2 are each H or CH3, R3 is an alkylene group having a carbon number of 2 to 10, R4 and R5 are each a saturated hydrocarbon group having a carbon number of 1 to 5, R6 is an alkylene group having a carbon number of 2 to 5, n is a number of 0 to 40, m is a number of 1 to 40, and Y- is a halogen ion, a mono- or polyhalogenated alkyl ion, nitrate ion, sulfate ion, an alkylsulfate ion, sulfonate ion or an alkylsulfonate ion.

Owner:TEIJIN LTD

Environment-protection flame-proof electrostatic resistance polypropylene material and method for producing the same

The invention relates to an environmental-friendly polypropylene material with flame resistance and antistatic capacities, which comprises parts by weight of components that: 100pbw of pp resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers and 10-30 portions of antistatic agent. The PP resin is high fluidity homopolymerization PP; the flame retardant is deca-diphenylethane; the flame-retardant synergist is antimony trioxide; the filler is 2000 meshes talcum powder; the antistatic agent is conductive carbon black; lubrication dispersing agent is aethylenum double fatty acid amide TAS-2A. The preparation method of the material is that: according to the part by weight, 100 portions of PP resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers, 10-30 portions of antistatic agent and 1-10 portions of lubrication dispersant are weighted and mixed in a high-speed mixer for 3 to 5 minutes, and after mixing, the mixed raw materials are molten, squeezed and made into particles in a parallel twin-screw extruder. The polypropylene material of the invention has the advantages of good mechanical intensity, antistatic effect, flame resistance and being environment-friendly.

Owner:ANHUI KEJU NEW MATERIALS

Flame-retardant polycarbonate resin composition and its injection moldings

InactiveUS6150443AImprove antistatic performanceImprove stabilityPlastic/resin/waxes insulatorsDomestic articlesElastomerAntistatic agent

Provided are a flame-retardant polycarbonate resin composition capable of being formed into moldings having good impact resistance, high strength and good thermal stability that are intrinsic to polycarbonate resins and having good antistatic properties and good flame retardancy, and also injection moldings of the composition. The composition comprises 100 parts by weight of a resin or resin mixture of (A) from 50 to 100% by weight of a polycarbonate resin and (B) from 0 to 50% by weight of a styrenic resin, from 1 to 50 parts by weight of (C) a flame retardant, and from 0.1 to 5 parts by weight of (D) an anionic antistatic agent, and has a sodium sulfate content of at most 0.05% by weight. Optionally, the composition may contain (F) a fluoro-olefinic resin, (G) a rubber-like elastomer, and (H) an inorganic filler.

Owner:IDEMITSU KOSAN CO LTD

Multiple-effect type water-based synthesized cutting solution and preparation thereof

InactiveCN101323813AExtended service lifeImprove extreme pressure and anti-wearLubricant compositionWater basedCleansing Agents

The invention relates to a multi-effect water-based composite cutting / grinding fluid which consists of water-soluble oil, cleaning agent, extreme pressure antiwear agent, antirust, antibacterial agent, complexant, solubilizer and anstatic agent. The water-soluble oil is the mixture of aminoethyl alcohol and triethanolamine oleate, the cleaning agent is anionic surfactant or nonionic surfactant, the extreme pressure antiwear agent is one or two of additives A, B, C, D, E and F, the antirust is benzotriazole and sodium benzoate, the antibacterial agent is boric acid and borax, the complexant is EDTA and the solubilizer is urea. The cutting / grinding fluid with various improved performances is non-toxic and tasteless, is an environment-friendly product and has no harm to human body and the skin of users; the operating cycle is normally more than 6 months.

Owner:大连弘瑞化工有限公司

Label for in-mold decorating and labeled resin molded article

InactiveUS20020050319A1High bonding strengthImprove adhesion strengthStampsSynthetic resin layered productsAntistatic agentShell molding

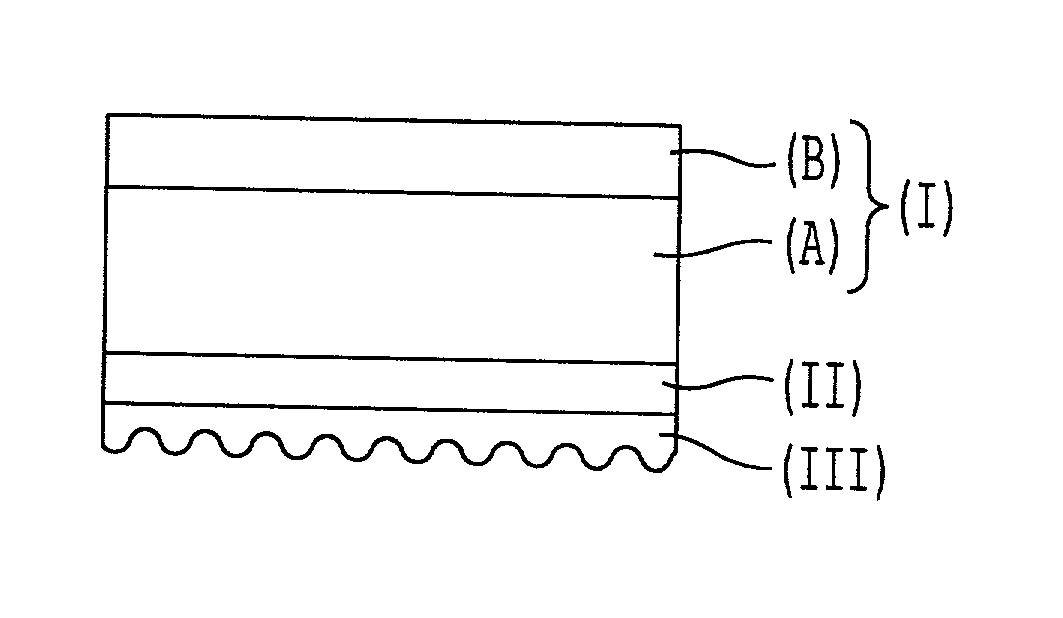

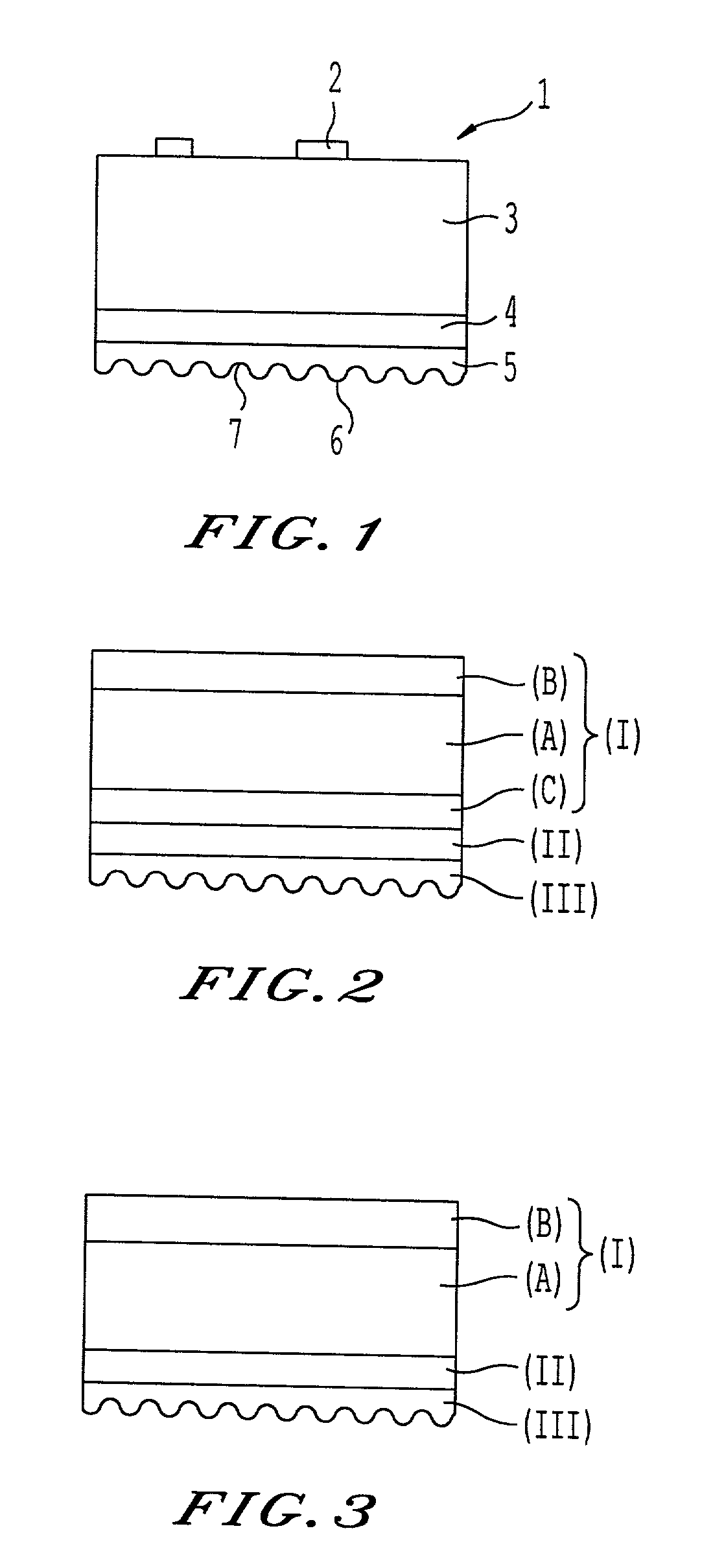

The label includes (I) a thermoplastic resin film base layer, (II) an interlayer, and (III) a heat-sealable resin layer, wherein the interlayer (II) contains a thermoplastic resin and an antistatic agent.

Owner:YUPO CORP

Thermoplastic elastomer material, preparation thereof and method for manufacturing medicinal bottle stopper by using the same

InactiveCN101376730ACreate pollutionWon't releasePharmaceutical containersMedical packagingRubber materialAntistatic agent

The invention provides thermoplastic elastomer materials used for a bottle cork for manufacturing medicines, a preparation method thereof and a method for applying the bottle cork for manufacturing medicines thereof. The materials are prepared by the following components: styrene copolymer or rubber materials as well as polyolefine matters. The styrene copolymer is PP or PE; besides, the materials also contain a plasticizer and a loading agent, contain or do not contain a compatibilizer, contain or do not contain an antioxidant, contain or do not contain an antistatic agent, contain or do not contain adhesion preventives. The preparation method thereof includes the steps of drying the materials, fusing a reaction kettle, using a plastic extruding machine to extrude the materials, using a cooling water slot to cool and shape the materials, using a hauling machine to haul and cut off the materials, and the like. The thermoplastic elastomer materials provided by the invention have the advantages of stable chemical property, no poison, low polarity and good rebound resilience.

Owner:谷其昌

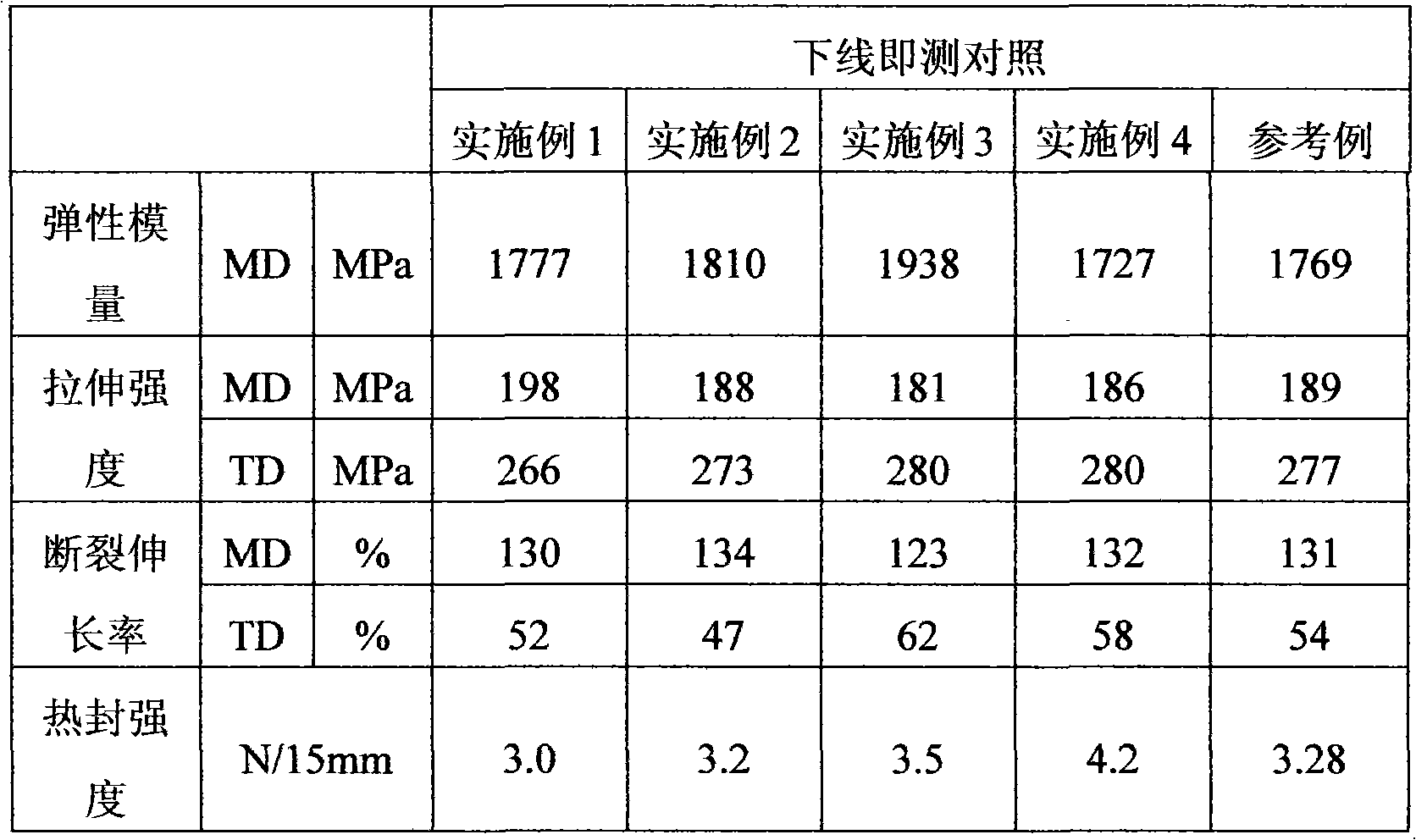

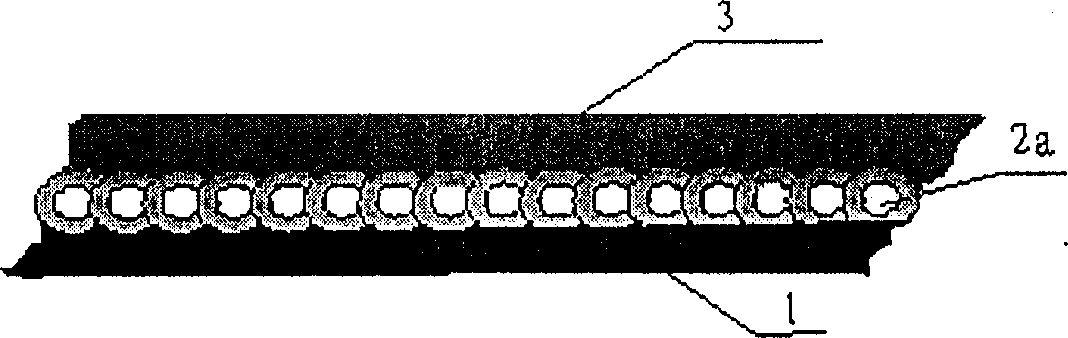

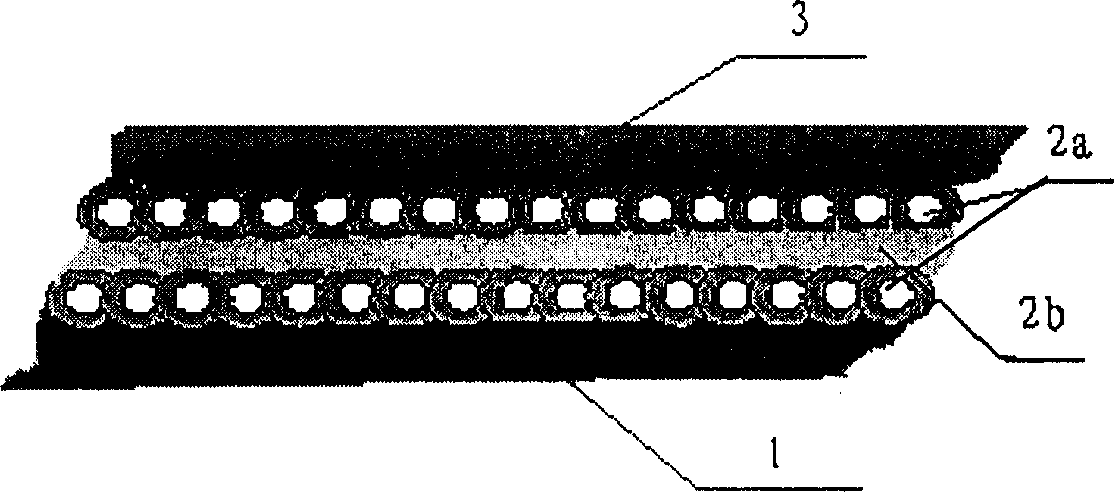

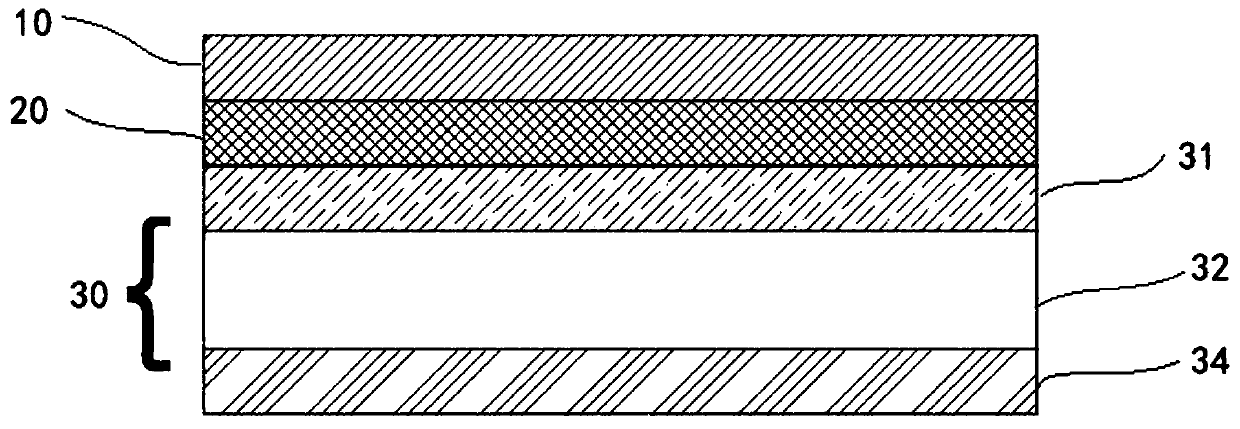

Barrier heat sealing type biaxial tensile composite thin film and preparation method thereof

InactiveCN102501511ASimple production processLow costSynthetic resin layered productsLinear low-density polyethyleneLow-density polyethylene

The invention discloses a barrier heat sealing type biaxial tensile composite thin film and a preparation method thereof. The thin film comprises two surface layers, and at least a barrier layer, wherein the surface layer and the barrier layer are connected through bonding layers. The thin film is characterized in that the two surface layers comprise the following components, by weight, 90-99% of metallocene linear low density polyethylene resin with a characteristic of bimodal molecular weight distribution, 0-5% of an antistatic agent, 0-5% of an anti-adhering agent, 0-5% of a smoothing agent, and 0-5% of an antioxidant; the barrier layer is a barrier polymer, and the bonding layer is a high strength and high temperature resistance adhesive. The preparation method adopts a multi-layer co-extruding successive biaxial tensile process or a multi-layer co-extruding simultaneous biaxial tensile process. The composite thin film has excellent gas and moisture barrier property, and the mechanical properties of the thin film are further improved. The thin film has characteristics of high tensile strength, low temperature high heat sealing strength, and high puncture resistance strength.

Owner:FSPG HI TECH

Thermal shrinkage biaxially oriented film

InactiveCN102059836ACrystallization perfectHigh heat shrinkageSynthetic resin layered productsTime changesAcrylic resin

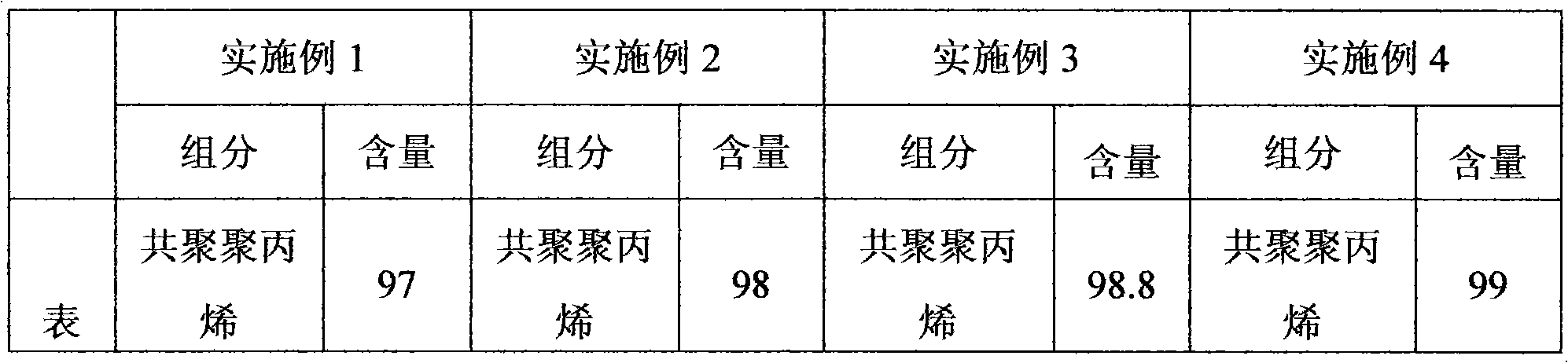

The invention discloses a thermal shrinkage biaxially oriented film which is composed of a surface layer, a sandwich layer and an inner layer, wherein the thickness of the surface layer is 0.5-1.5 micrometers, the thickness of the sandwich layer is 19-22 micrometers, the thickness of the inner layer is 0.5-1.5 micrometers, and the total thickness of the three layers is 20-23 micrometers. The surface layer comprises the following components in percentage by weight: 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The sandwich layer comprises 80-93% of acrylic resin homopolymer, 0.3-3% of anti-static agent, 0.1-0.5% of crystal regulator, 1-2% of surfactant, 5-18% of stiffening agent and 0.5-1% of lubricant. The inner layer comprises 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The film has a stable thermal shrinkage factor which slightly changes as the storage time changes.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

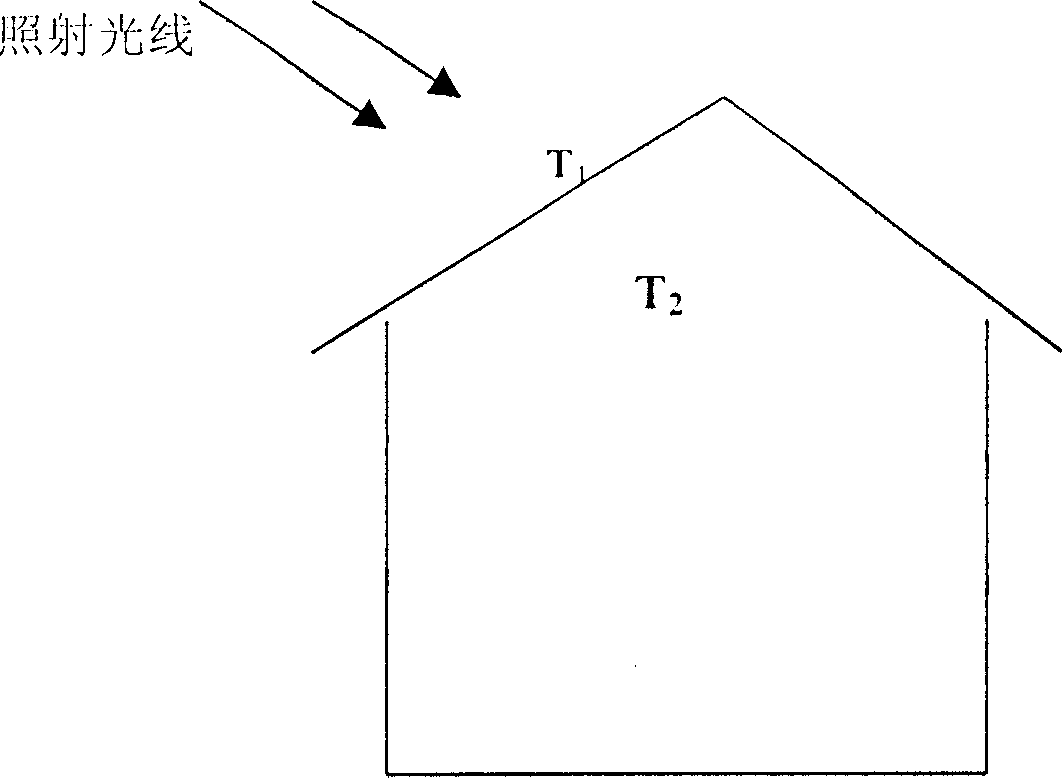

Themally insulating and reducing composite paint and its preparing process and application

InactiveCN1396219AGood heat insulation and heat reduction effectConjugated diene hydrocarbon coatingsSpecial surfacesAntistatic agentThermal radiation

A composite coated layer for thermal insulating and heat reflecting is composed of a thermal insualting layer on the surface of a substrate and a heat reflecting layer on the said thermal insulating laye. The thermal insulating layer contains filming agent, hollow microbeads arranged by one or more layers, thermal insulating filler and / or stress reducing material. The reflecting layer contains filming agent, antiageing agent, antistatic agent and reflecting pigment.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of antistatic and flame-retardant silicon rubber foam material

InactiveCN104387776AImprove antistatic performanceImprove flame retardant performanceVulcanizationPtru catalyst

The invention discloses a preparation method of an antistatic and flame-retardant silicon rubber foam material. The antistatic and flame-retardant silicon rubber foam material is prepared from raw materials including silicon rubber, a foaming agent, a crosslinking agent, a catalyst and thermal reduced graphene oxide. The preparation method comprises the following steps of (1) stirring and dispersing the silicon rubber into a solvent to obtain a silicon rubber dispersing solution; (2) placing the thermal reduced graphene oxide into the same solvent to carry out ultrasonic dispersion, stirring the thermal reduced graphene oxide and a coupling agent under heating, then, adding the liquid obtained through stirring under heating into the silicon rubber dispersing solution to secondarily stir, and removing the solvent in vacuum; and (3) sequentially adding the crosslinking agent, the catalyst and the foaming agent, uniformly stirring the crosslinking agent, the catalyst and the foaming agent to obtain a mixture, then, placing the mixture into a mould to foam and cure to prepare a silicon rubber / graphene composite silicon rubber foam sheet with the thickness of 3mm. According to the preparation method, graphene is simultaneously used as an antistatic agent, a flame retardant and a reinforcing agent, so that the antistatic and flame-retardant silicon rubber foam material has favorable antistatic performance, flame retardance and mechanical property.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

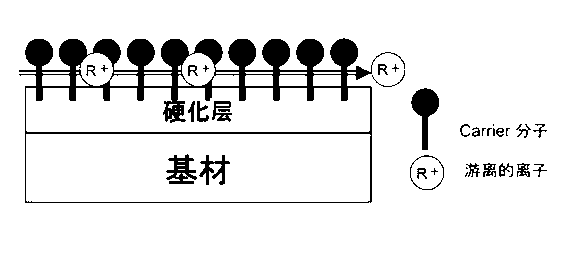

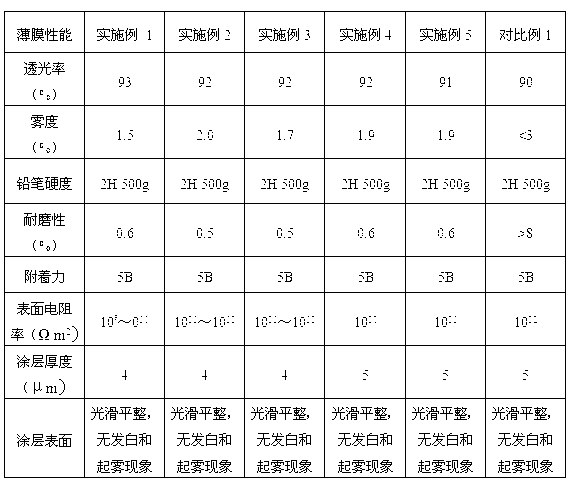

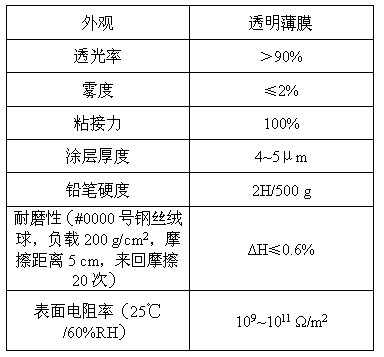

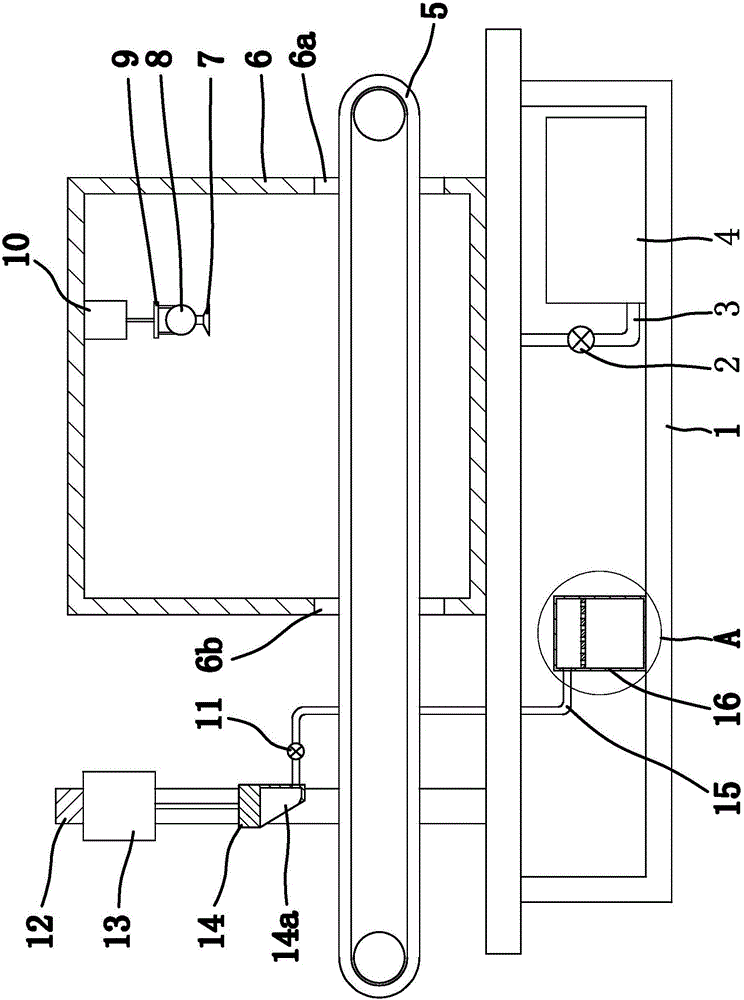

Anti-static hardened film

ActiveCN102786875AOvercoming the problem of light transmittance dropGood compatibilityPolyurea/polyurethane coatingsElectrically-conductive paintsFilm basePolymethyl methacrylate

The invention provides an anti-static hardened film, which comprises a film base material and an ultraviolet-curing anti-static hardened paint layer coated on the film base material, wherein the film base material is selected from a PET (polyethylene glycol terephthalate) film, a PC (polycarbonate) film or a PMMA (polymethyl methacrylate) film; and the ultraviolet-curing anti-static hardened paint layer is prepared from the following components by weight: 20-40% of multifunctional polyurethane acrylates, 50-70% of alcohol and / or ether reagent, 5-10% of UV (ultraviolet) curing active monomer, 1-20% of organic surfactant anti-static agent, 1-10% of photoinitiator and 0.1-0.5% of paint assistant which are subjected to ultraviolet-curing. The film provided by the invention has a good anti-static effect, high transmittance, high hardness and good wear resistance, and has no whitening and fogging phenomena on the surface.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

High-modulus flame-retardant antistatic safe protection belt and preparation method thereof

InactiveCN105064024AEasy to adjustAdjustable thicknessFibre typesTextile treatment machine arrangementsCross-linkAntistatic agent

The invention provides a high-modulus flame-retardant antistatic safe protection belt and a preparation method thereof, and solves the problems that when the conventional protection belt is used in a complex environment, the personnel safety of a user cannot be protected effectively as the conventional protection belt is not flame-retardant and antistatic, the safety is poor and no preparation methods is available. The high-modulus flame-retardant antistatic safe protection belt comprises a base cloth layer, wherein reinforcing layers are fixed on both sides of the base cloth layer; the reinforcing layers comprise the following ingredients by weight: 40 to 60 parts of polyvinyl chloride, 20 to 30 parts of polycarbonate, 6 to 10 parts of a solvent, 3 to 6 parts of magnesium oxide, 3 to 6 parts of zinc oxide, 5 to 10 parts of calcium carbonate, 2 to 4 parts of a cross-linking agent, 3 to 8 parts of a plasticizing agent, 5 to 8 parts of an antistatic agent, and 0.1 to 0.3 part of an anti-oxidant. The high-modulus flame-retardant antistatic safe protection belt and the preparation method have the advantages that the safety is high; the production is fast.

Owner:HAINING JINGDA FABRIC

Antistatic, halogen-free, and fire-retardant enhanced master batch dedicated for polyamide and preparation method thereof

InactiveCN103351618AGood modification effectImprove antistatic performanceZinc borateAntistatic agent

The invention relates to an antistatic, halogen-free, and fire-retardant enhanced master batch dedicated for polyamide and a preparation method thereof. The fire-retardant master batch is composed of following components in parts by weight: 25 to 50 parts of PA, 15 to 30 parts of alkyl phosphinate fire-retardant, 15 to 30 parts of melamine polyphosphate fire retardant, 8 to 15 parts of zinc borate fire retardant, 4 to 6 parts of CTI improver, 1 to 1.5 parts of antistatic agent, 3 to 8 parts of flexibilizer, 0.5 to 1 part of coupling agent, 0.7 to 1.5 parts of lubricant, and 0.3 to 1 part of anti-oxidant. The sum of the weight ratio of components mentioned above is 100 wt%. The fire-retardant master batch is used to produce fire-retardant enhanced and modified nylon, meets standards of the United States underwriters laboratories (UL)-941.6mm and a higher V-0 grade, simultaneously achieves that glowing wire temperature (GWIT) is equal to or larger than 750 DEG C and the CTI value is equal to or larger than 600 V, also has a antistatic performance, meets European Union RoHS, International Electrotechnical Commission (IEC) halogen-free and Reach rule requirements, is easy to use and excellent in comprehensive performance, and does not affect color matching.

Owner:GUANGDONG WAYLAM ENG PLASTICS

Surface treating agent and surface treating process of glass fiber filter cloth

ActiveCN102776777AUniform surface colorHigh folding resistanceFibre treatmentDry-cleaning apparatus for textilesGlass fiberPolymer science

The invention relates to a surface treating agent and a surface treating process of a piece of glass fiber filter cloth, belonging to the technical field of the surface treating agent of the glass fiber. The surface treating agent disclosed by the invention comprises 8-15% of PTFE (Polytetrafluoroethylene) dispersing agent, 5-10% of emulsion type high-temperature softening agent, 1-2% of inorganic antistatic agent, 0.5-1% of penetrating agent, 1-2% of silane coupling agent, 0.5-1% of fluorocarbon surfactant and the balance of softened water. The glass fiber filter cloth produced after the treatment of the surface treating agent solves the problems that the corrosion resistance is poor and the air permeability is large in the prior art, and has the advantages that the surface colors are uniform, the flexibility is good, the folding number is large, the air permeability is moderate, and the service life is long.

Owner:SICHUAN FIBERGLASS GRP

Antistatic resin composition

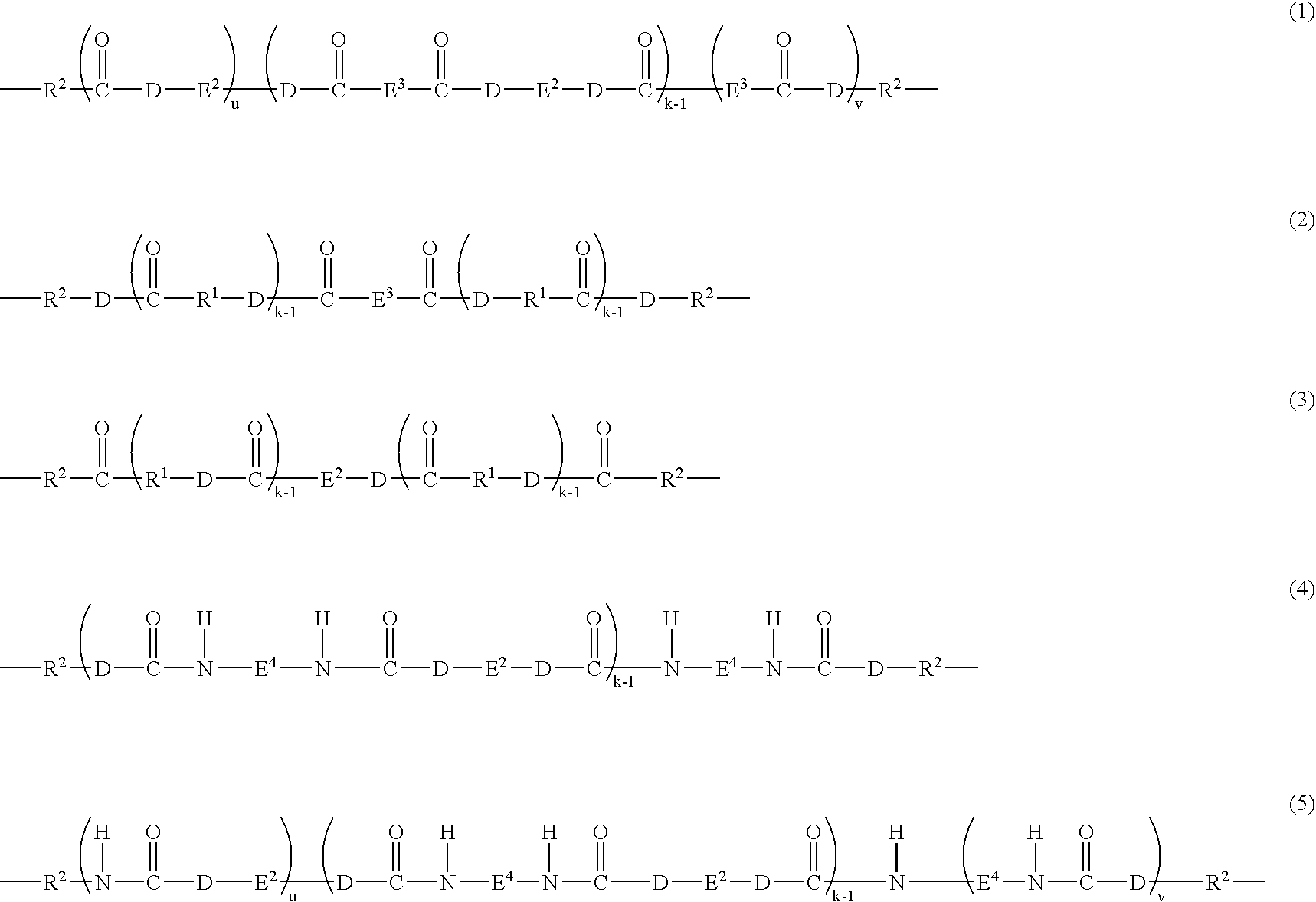

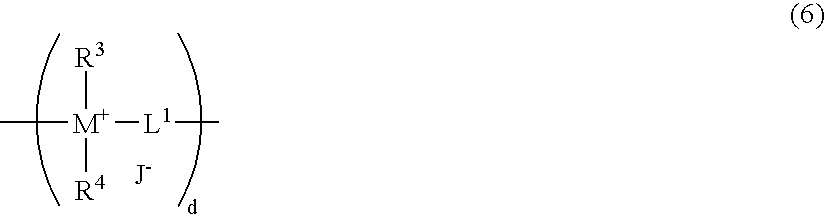

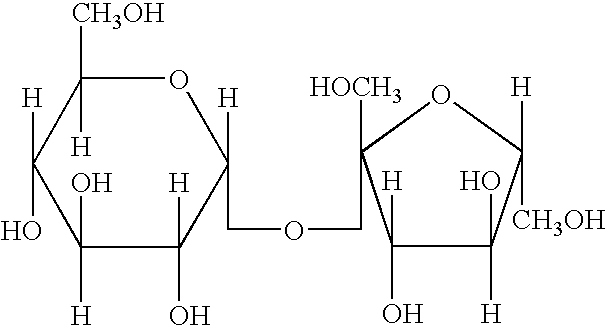

ActiveUS20050049360A1Excellent in permanent antistatic effect and mechanical strengthExcellent permanent effectFibre treatmentChemistryPolyamide

An antistatic resin composition and molded products therefrom are described, having good antistatic effect and mechanical strength regardless the type of the molding method. The composition includes a thermoplastic resin (A) and an antistatic agent (B), wherein a refractive index difference between (A) and (B) is not more than 0.02. The antistatic agent (B) includes at least one material selected from the group consisting of (B1) and (B2). (B1) is a polyetheresteramide derived from a polyamide having a Mn of 200-5000 and an alkyleneoxide adduct of bisphenol having a Mn of 300-5000. (B2) is a block polymer having a structure such that blocks of a polyolefin and blocks of a hydrophilic polymer having an volume resistivity of 105-1011 Ω·cm are bonded together alternately and repeatedly via at least one bonding mode selected from the group consisting of ester bonding, amide bonding, ether bonding, imide bonding and urethane bonding.

Owner:SANYO CHEM IND LTD

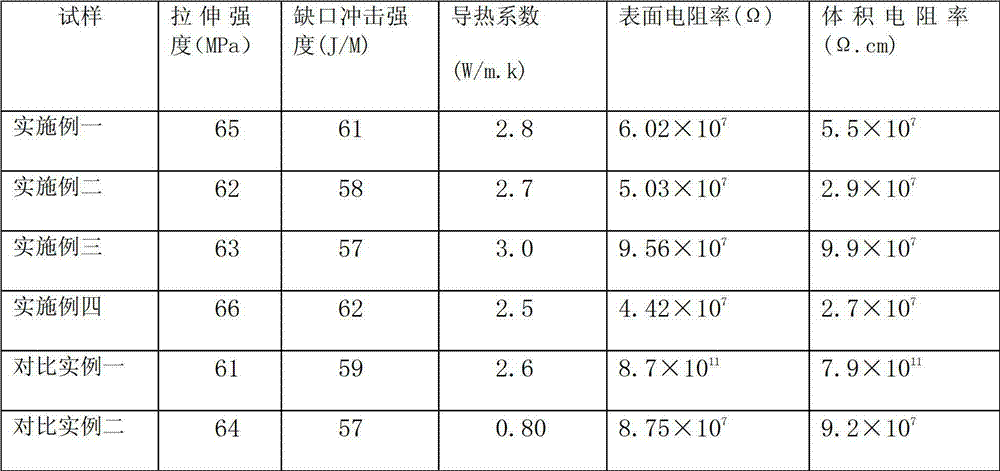

Nylon 66 composite material, preparation method thereof and electronic device

The invention is suitable for the technical field of high polymer materials and provides a nylon 66 composite material, a preparation method thereof and an electronic device. the nylon 66 composite material comprises the raw materials in percentage by weight as follows: 40%-65% of PA 66 resins, 8%-12% of a roughening agent, 20%-35% of heat conduction powder; 10%-15% of an antistatic agent, 2.5%-5.5% of a compatilizer, 0.1%-0.5% of a lubricating agent, 0.1%-1% of an antioxidant agent, 0.1%-2% of a coupling agent and 0.2%-0.5% of a nucleating agent, wherein the heat conduction powder is processed by the coupling agent. According to the invention, when the nylon 66 composite material is prepared, the coupling agent is used for processing the heat conduction powder, and two fillers of the heat conduction powder and a conductive agent are mutually matched and coordinated, so that the excellent heat conductivity and antistatic property can be obtained with low filler consumption, and simultaneously the prepared nylon 66 composite material has excellent physical and mechanical properties.

Owner:SHENZHEN YATAIXING IND

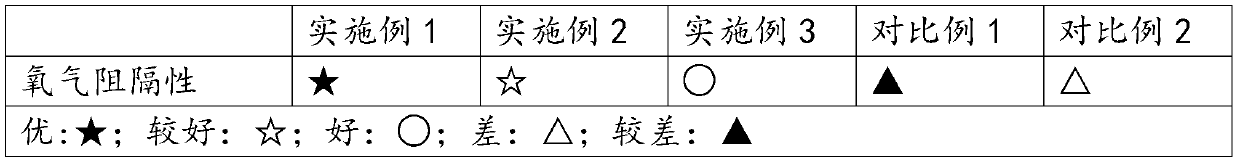

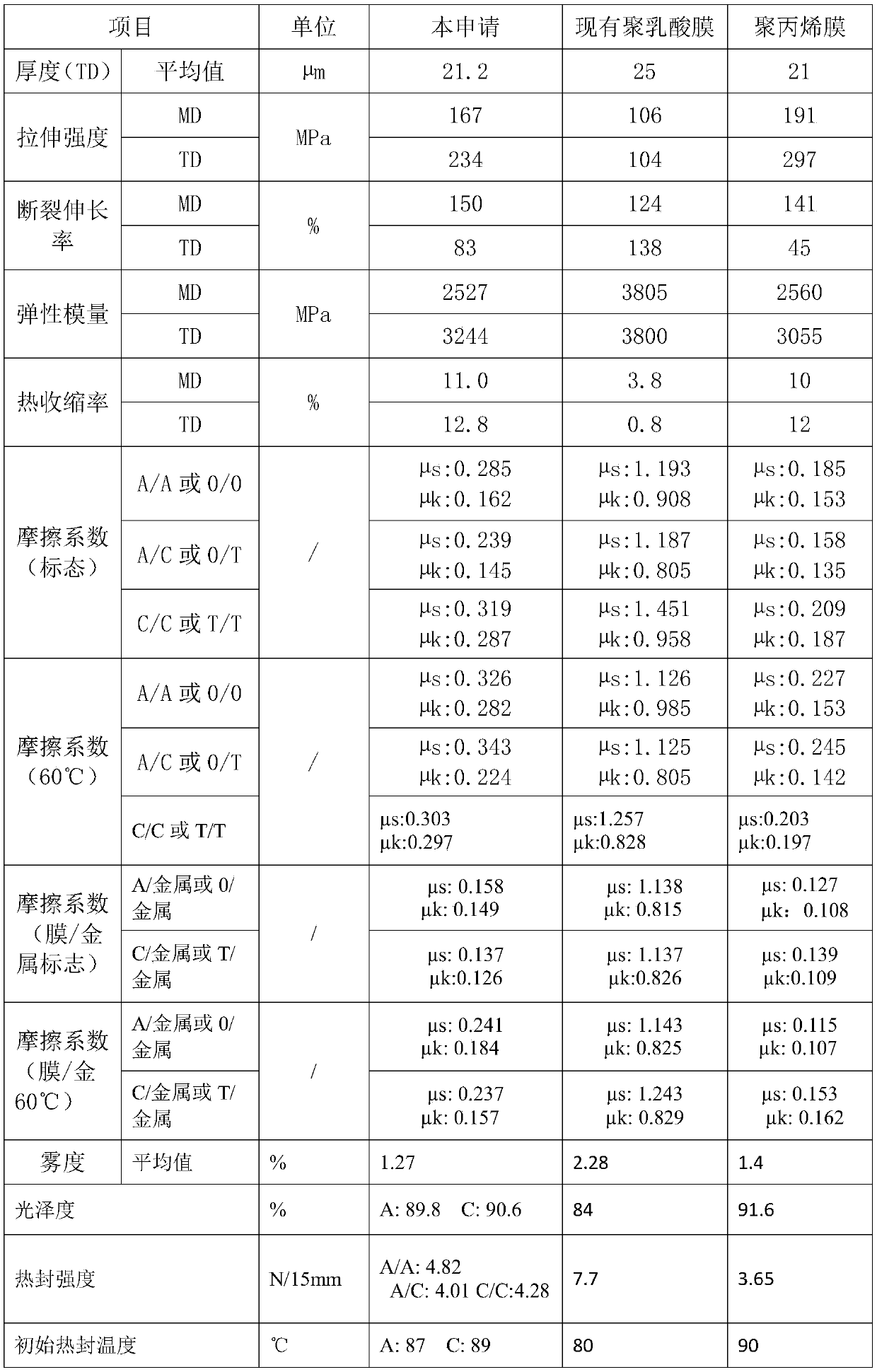

Coated high-barrier biaxially stretched polylactic acid film and preparation method thereof

ActiveCN110774713ASimple processImprove performanceSynthetic resin layered productsPolyurea/polyurethane coatingsPolymer scienceBoPET

The invention relates to a coated high-barrier biaxially stretched polylactic acid film and a preparation method thereof. The coated high-barrier biaxial tensile polylactic acid film structurally comprises a high-barrier coating, a bottom coating and a substrate layer from inside to outside in sequence, wherein the substrate layer is composed of three layers of a co-extruded biaxially stretched PLA (polylactic acid) film, namely a layer A, a layer B and a layer C; the layer A and the layer C comprise the following components in parts by mass: 68-93.2 parts of PLA, 5-20 parts of a toughening agent, 1-3 parts of a compatibilizer, 0.2-1 part of a chain extender, 0.2-1 part of an antioxidant, 0.5-3 parts of an antistatic agent, 0-1 part of an open agent and 0-1 part of a smoothening agent; thelayer B comprises the following components in parts by mass: 76-93.8 parts of PLA, 5-20 parts of a toughened resin, 1-3 parts of a compatibilizer and 0.2-1 part of a chain extender; and the high barrier coating is a water-resistant modified PVA coating. Production procedures are simple, green and environmental protection materials are used, and the film is excellent in performance, and still hasa good barrier effect in case of a very thin high-barrier coating.

Owner:中仑新材料股份有限公司 +1

A kind of epe pearl cotton

The invention relates to an EPE pearl cotton which is melted and kneaded by an extruder and extruded to form the following materials. The parts by weight of the components are: low-density polyethylene 100, filler 0.08-0.12, color masterbatch 0-0.004 , Antistatic agent 1-3%, foaming agent 0.4-0.6, surfactant 0.6-0.9. The EPE pearl cotton produced by this formula has smooth appearance, shockproof, sound insulation and better thermal insulation performance.

Owner:LANGXI TIANCHENG PACKAGE MATERIALS

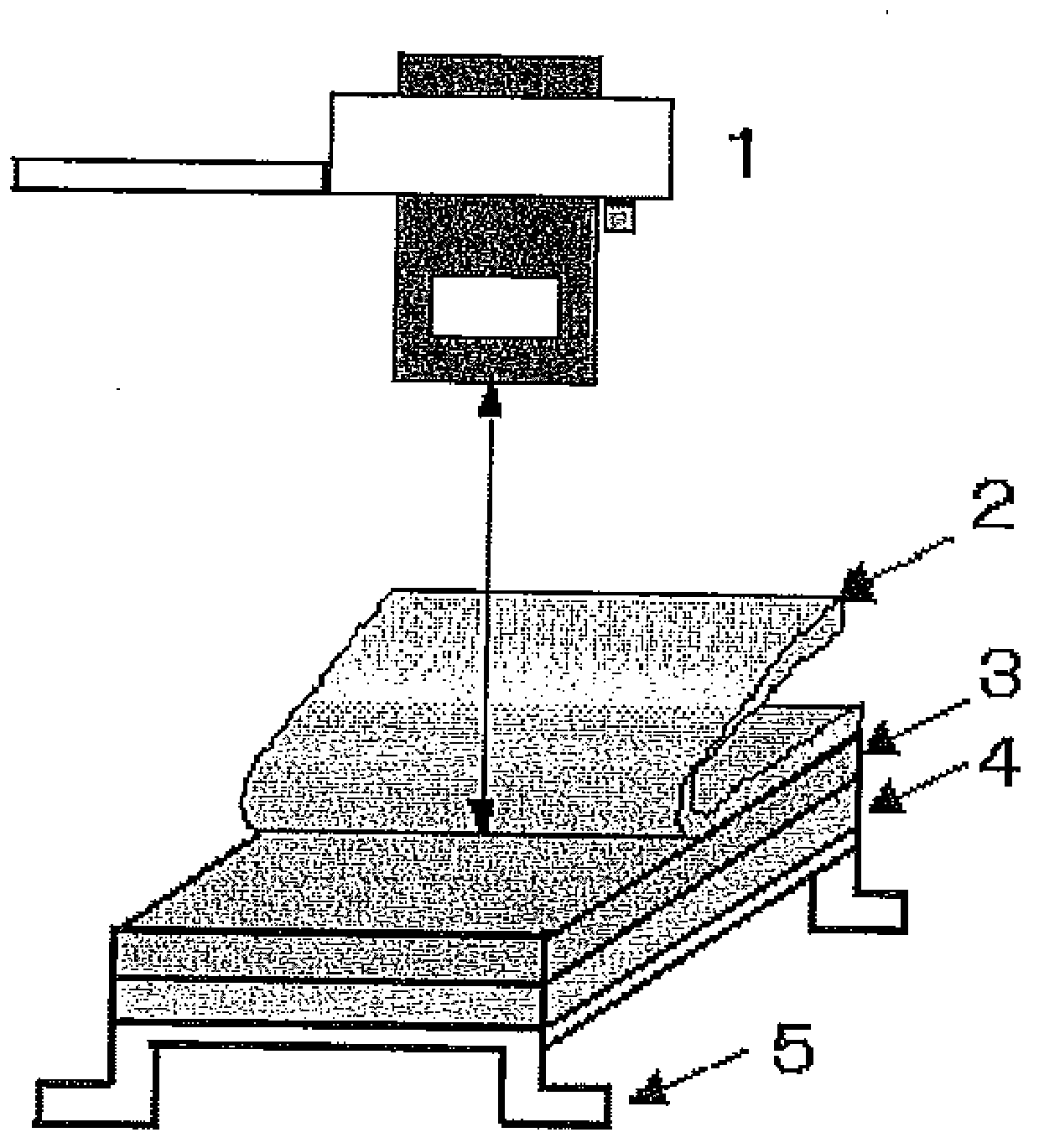

Antistatic material, self-cleaning light diffusion plate prepared therefrom, and preparation method of self-cleaning light diffusion plate

ActiveCN103242593ARaw materials are easy to getReduce manufacturing costOptical elementsAntioxidantAntistatic Materials

The invention relates to an antistatic material, a self-cleaning light diffusion plate prepared therefrom, and a preparation method of the self-cleaning light diffusion plate. The antistatic material comprises a matrix resin, a light diffusing agent, an antistatic agent, an antioxidant, a light stabilizer and a dispersing agent; the antistatic material has the resistivity up to 107 to 1011 and is remarkable in antistatic performance; the light diffusion plate prepared from such an antistatic material has high light transmission performance and high antistatic self-cleaning performance, effectively improves the light transmission performance and has long-term stability; in addition, raw materials are easy to obtain, the preparation cost is low, and the light diffusion plate is suitable for being applied to related fields of products requiring antistatic prevention and improvement of self-cleaning performance. The preparation method of the self-cleaning light diffusion plate, provided by the invention, is optimal in process, simple in operation, suitable for continuous production and manufacturing, low in economic cost, and suitable for popularization and application.

Owner:BEIJING UNIV OF CHEM TECH

Pressure-sensitive adhesive compositions, pressure-sensitive adhesive layers, and pressure-sensitive adhesive sheets

ActiveCN102911629AReduce pollutionReduce adhesionEster polymer adhesivesThin material handlingAntistatic agentAlkoxy group

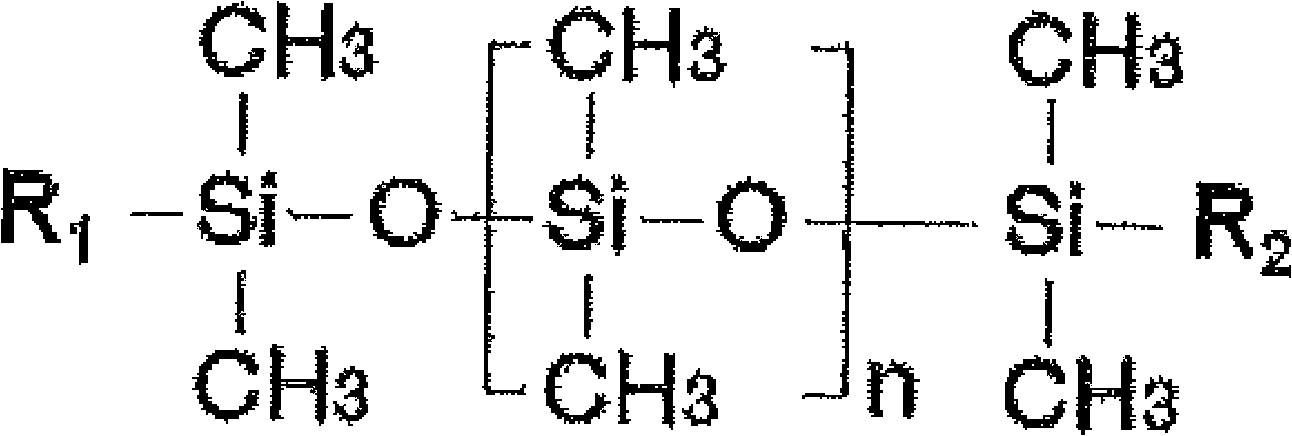

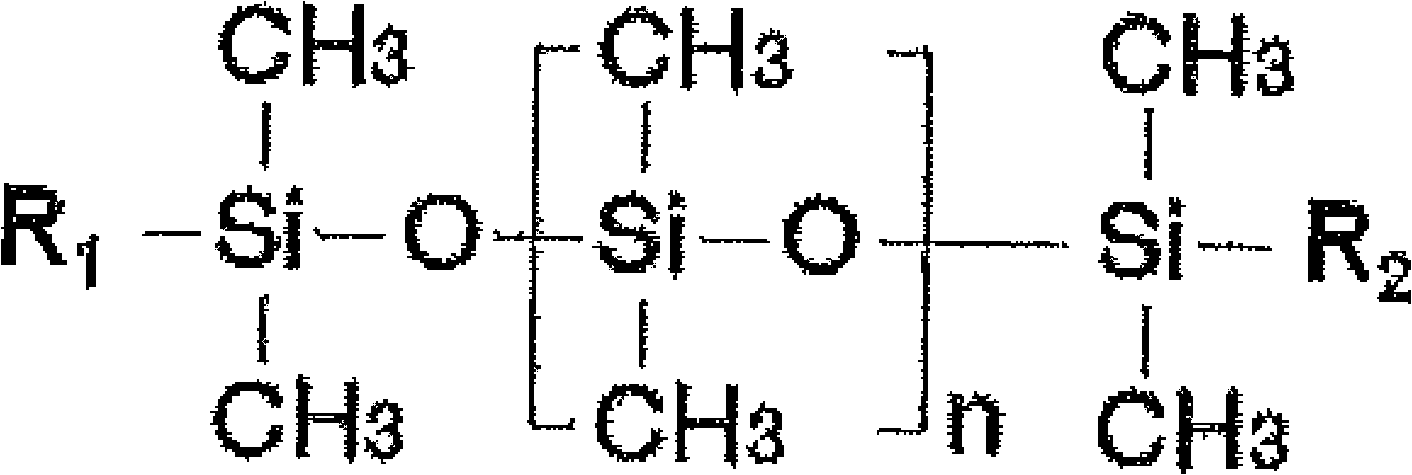

The present invention provides a pressure-sensitive adhesive composition which is excellent in removability, peel adhesive power temporal stability and staining properties; a pressure-sensitive adhesive layer produced with the same; and a pressure-sensitive adhesive sheet. The present invention also provides a pressure-sensitive adhesive composition which can prevent electrification of a non-antistatic protected adherend when peeled off using an ionic compound which is an antistatic agent, and is less likely to cause lifting and is also excellent in removability; a pressure-sensitive adhesive layer produced with the same; and a pressure-sensitive adhesive sheet.A pressure-sensitive composition comprising a (meth)acryl-based polymer containing, as a main component, a (meth)acryl-based monomer having an alkyl group of 1 to 14 carbon atoms and an organopolysiloxane having a oxyalkylene chain, wherein the organopolysiloxane is represented by the following formula: wherein R 1 and / or R 2 have / has an oxyalkylene chain of 1 to 6 carbon atoms, an alkylene group in the oxyalkylene chain may be a straight or branched chain and the oxyalkylene chain may have an alkoxy group or a hydroxyl group at the end, and any one of R 1 or R 2 may be a hydroxyl group or an alkyl group or an alkoxy group, and a part of the alkyl group and alkoxy group may be a functional group substituted with a hetero atom; and n is an integer of 1 to 300.

Owner:NITTO DENKO CORP

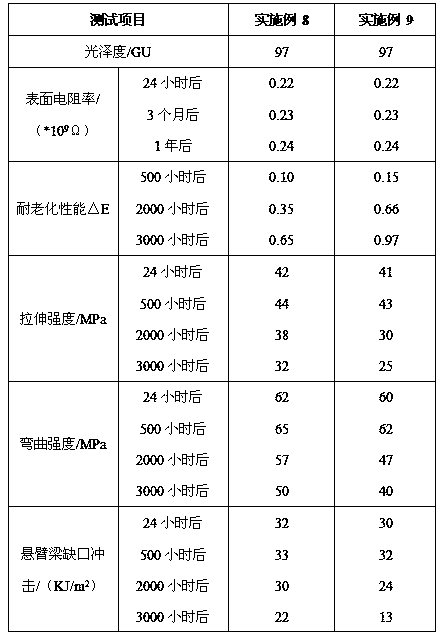

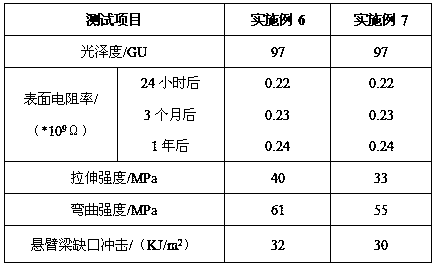

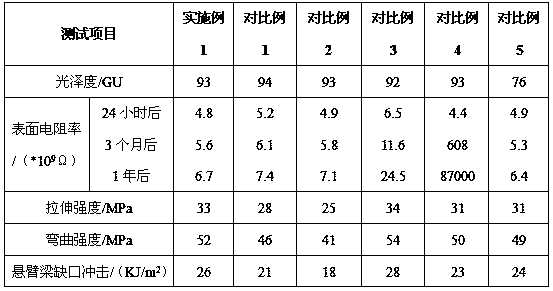

Antistatic high-luster polypropylene composite material and preparation method thereof

The invention discloses an antistatic high-luster polypropylene composite material and a preparation method thereof. The composite material is prepared by using 100 parts of polypropylene, 50-100 parts of acrylonitrile-butadiene-styrene copolymer, 9-30 parts of an antistatic agent, 4-10 parts of a compatilizer, 10-20 parts of a modification filler, 1-2 parts of an antioxidant and 0.5-1 part of a processing assistant, wherein the antistatic agent is composed of a permanent high-molecular antistatic agent and a low-molecular antistatic agent; and the compatilizer is a polypropylene grafted maleic anhydride and acrylonitrile-butadiene-styrene copolymer grafted maleic anhydride mixture. The preparation method improves the antistatic performance, the comprehensive performances and the cost performance of the polypropylene composite material, so the composite material has the characteristics of permanent antistatic performance, high luster and workability, and can be widely used in the field of electronic apparatuses, the field of household electrical appliances, the fields of aviation and aerospace, the national defense field and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Preparation method of two-component waterborne polyurethane antistatic floor coating

InactiveCN105368292AWith antibacterial disinfectionPermanent antistaticPolyurea/polyurethane coatingsElectrically-conductive paintsChemistryAntistatic agent

The invention discloses a preparation method of a two-component waterborne polyurethane antistatic floor coating. The coating is composed of a base coat and a face coat. A base coat component A is composed of polyether polyols polyurethane, filler, silver-plated conductive materials, conductive mica powder, an additive and the like. A face coat component A is composed of polyester polyol or polycarbonate glycol polyurethane, titanium dioxide, filler, silver-plated conductive materials, a polymer antistatic agent, an additive and the like. A curing agent component B is composed of polyether polyol and diisocyanate. The ratio of A to B is 1:0.3-0.7 (W / W). The antistatic floor coating obtained through the preparation method meets the technical requirements of GB / T 22374-2008, HG / T 3829-2006 and SJ / T 11294-2003 standards, has the excellent waterproof, weatherproof, anti-aging, acid and alkali resisting and oil contamination resisting performance and the excellent impact resistance, friction resistance and skid resistance, and meets the antistatic requirements of top-grade plants, hospitals, ultra-clean plants and the like.

Owner:GUANGDONG HUALONG COATING IND

Fabric care compositions for softening, static control and fragrance benefits

InactiveUS20080132437A1Perfume longevityCationic surface-active compoundsSoftening compositionsNeutral phAntistatic agent

A fabric care composition containing non-ionic softening compounds, antistatic agents and perfume. Particularly, the fabric care composition is suitable for use in the rinse cycle of a textile laundering operation to provide excellent fabric softening / static control benefits, and surprisingly improved perfume freshness and longevity. The fabric care composition is preferably at a neutral pH.

Owner:THE PROCTER & GAMBLE COMPANY

Degradable biaxially-oriented polylactic acid cigarette film and preparation method thereof

ActiveCN110774714AReduce coefficient of frictionReduce the possibility of static electricityFlexible coversWrappersPolymer scienceBoPET

The invention relates to the technical field of polylactic acid films, especially to a degradable biaxially-oriented polylactic acid cigarette film and a preparation method thereof. The invention overcomes the problems that an existing polypropylene cigarette film is non-degradable and an existing degradable polylactic acid film is difficult to be applied to cigarette films. According to a technical scheme, the degradable biaxially-oriented polylactic acid cigarette film is composed of a layer A, a layer B and a layer C which are co-extruded and stretched. The layer A comprises, by mass, 80%-90% of heat-seal I-type PLA, 8%-15% of a slipping agent and 2%-5% of an anti-blocking agent, wherein the heat-seal I-type PLA is composed of 70%-80% of crystalline PLA and 20%-30% of non-crystalline PLA. The layer B comprises 90-95% of crystalline PLA, 1-5% of an antistatic agent, 1-2% of a stiffening agent and 1-5% of a toughening agent. The layer C comprises 94-97% of heat-seal II-type PLA, 2-3%of a slipping agent and 1-3% of an anti-blocking agent, wherein the heat-seal II-type PLA is composed of 75-85% of crystalline PLA and 15-25% of non-crystalline PLA. The preparation method comprises the following steps: drying the above components according to the use amounts, carrying out melt extrusion, performing biaxially stretching, carrying out corona treatment, and then successively conducting rolling, aging, and slitting.

Owner:JIANGYIN ZHONGDA FLEXIBLE PLASTIC NEW MATERIALS CO LTD

Antistatic and anti-aging white masterbatch for polypropylene (PP) resin and preparation method thereof

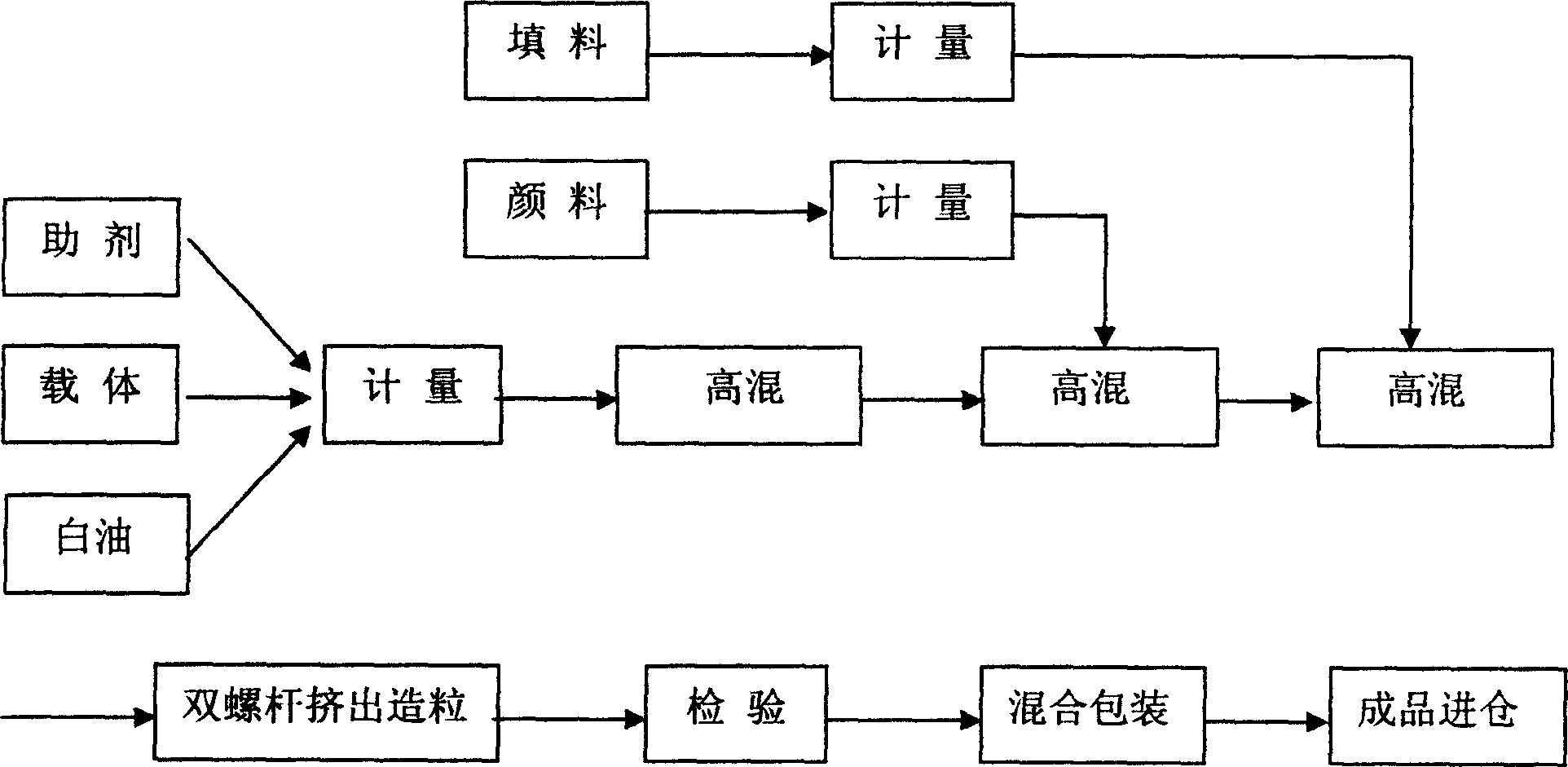

The invention provides antistatic and anti-aging white masterbatch for polypropylene (PP) resin. The white masterbatch comprises the following components in weight percentage: 8-12% of antistatic agent, 1-3% of compatilizer, 8-12% of antiager, 10-14% of pigment, 4-8% of dispersion lubricant and 51-69% of carrier resin, wherein, components of the antiager have good synergistic effect, thus effectively preventing PP and polyoxyethylene ether from being aged and meeting the requirements for coloration, color retention, light retention and dust pollution prevention of a one-time-molded external PP decorating part for white appliances. The preparation method of the white masterbatch comprises the following steps: mixing the antiager, the pigment, the dispersion lubricant and the carrier resin in a high-speed mixer; adding the antistatic agent and the compatilizer, stirring, and then adding the obtained mixed material to a double screw extruder for extrusion; and cooling, drying, granulating and packaging to obtain the needed masterbatch. The antistatic and anti-aging white masterbatch has the characteristics of less consumption of the carrier resin, low consumption of an antioxidant during the masterbatch forming process, and simple added materials in a forming process of downstream materials, and the masterbatch can be widely applied to coloring the PP resin.

Owner:中山市铁鹰塑胶有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com