Bonding resin for aluminum-plastic board, preparation method thereof, and aluminum-plastic board

A technology for bonding resin and aluminum-plastic panels, which is applied in the field of aluminum-plastic panels and adhesive resins for aluminum-plastic panels, and can solve the problems of unstable quality of aluminum-plastic panels, reduction of bonding strength and bonding durability, etc. Reduced time, stable bonding effect, and reduced steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing the adhesive resin for aluminum-plastic panels, the method comprising: calculating the raw material formula by weight percentage to include the following components: 10% to 20% linear low-density polyethylene (LLDPE), 20%~30% functionalized modified polyethylene masterbatch, 20%~30% ethylene-vinyl acetate copolymer (EVA), 10%~30% low density polyethylene (LDPE), 2%~10% polyolefins Elastomer (POE), 5%-15% impact-resistant polystyrene (HIPS), 0.08%-0.15% thermal oxygen stabilizer, after mixing evenly, it is granulated by a reactive twin-screw extruder. The rotation speed is 250-450rpm, the length-to-diameter ratio of the twin-screw extruder is L:D≥40:1, and the extrusion processing temperature range is 150-230°C.

[0046] The preparation method of the adhesive resin for aluminum-plastic panels of the present invention, the corresponding limitations of the specific implementation methods are as described above.

...

Embodiment 1-3

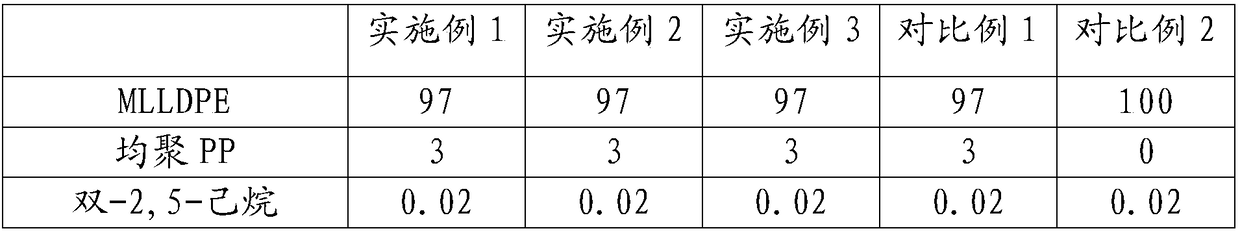

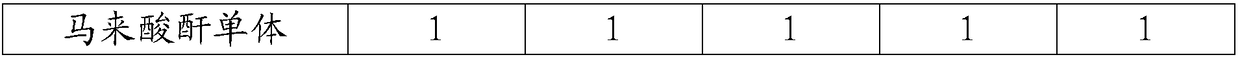

[0049] Embodiment 1-3, comparative example 1-2

[0050] Preparation of functionalized modified polyethylene:

[0051] For the functionalized modified polyethylene of Examples 1-3 and Comparative Example 1-2, after the raw materials were uniformly mixed according to the formula ratio (weight percentage) in Table 1, they were extruded through a reactive twin-screw extruder to implement a plasticized blending process. It is prepared by granulation, the length-to-diameter ratio of the twin-screw extruder is L:D≥40:1, and the extrusion processing temperature range is 160-220°C.

[0052] Table 1 embodiment 1-3 and comparative example 1-2 the raw material formula ratio of functionalized modified polyethylene

[0053]

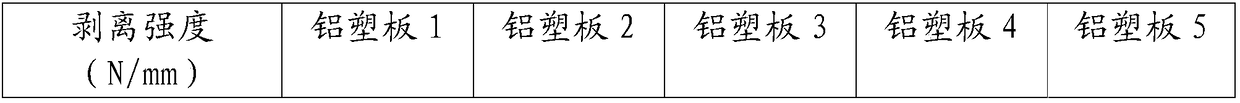

[0054]

[0055] Preparation of Adhesive Resin for Aluminum Composite Panel

[0056] For the adhesive resins for aluminum-plastic panels of Examples 1-3 and Comparative Examples 1-2, after mixing the raw materials uniformly according to the formula ratio (weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com