Hot melt adhesive for high-performance polypropylene barrier film as well as preparation method and application of hot melt adhesive

A polypropylene and barrier film technology, applied in chemical instruments and methods, adhesives, grafted polymer adhesives, etc., can solve problems such as poor adhesion, many crystal points, and large odor, and achieve excellent adhesion performance , the effect of less crystal point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

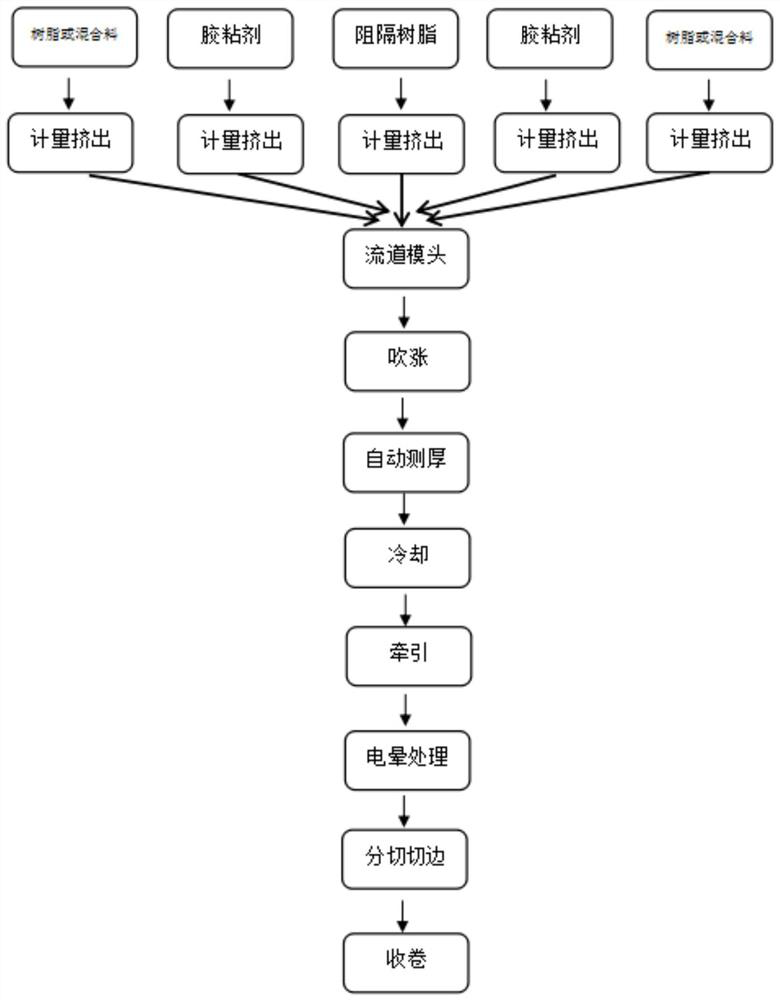

Method used

Image

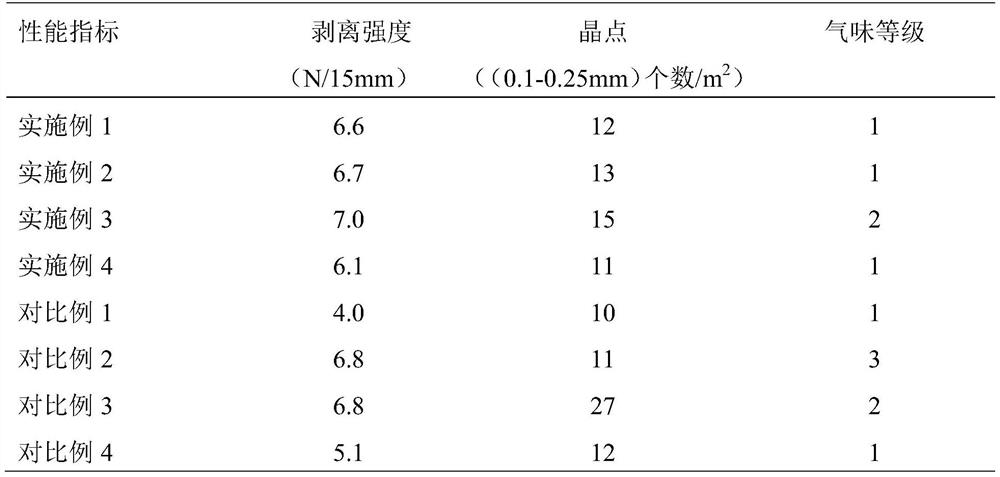

Examples

Embodiment 1

[0027] Maleic anhydride (MAH) grafted polypropylene (maleic anhydride graft rate 2.5%, density 0.900g / cm 3 , under the conditions of 230°C and 2.16kg, the melt flow rate is 6g / 10min) 20 parts by mass, random copolymerized polypropylene (density 0.905g / cm 3 , under the conditions of 230°C and 2.16kg, the melt flow rate is 3g / 10min) 52 parts by mass, low-density polyethylene (density 0.910g / cm 3 10 parts by mass of metallocene polyolefin plastomer (melt flow rate of 1.0 g / 10min at 190 °C and 2.16 kg) 15 parts by mass , PP grafted maleic anhydride wax (density 0.940g / cm 3, maleic anhydride content 7.5%, viscosity is 300cps) 3 mass parts under the condition of 190 ℃, antioxidant 1010 (BASF company) 0.1 mass part and antioxidant 168 (BASF company) 0.2 mass part join high-speed mixer together After mixing evenly, blend and granulate through a twin-screw extruder. The processing temperature of the twin-screw extruder is 190°C, the speed of the screw is 350rpm, the vacuum degree of ...

Embodiment 2

[0029] Maleic anhydride (MAH) grafted polypropylene (maleic anhydride graft rate 2.5%, density 0.900g / cm 3 , under the conditions of 230°C and 2.16kg, the melt flow rate is 6g / 10min) 20 parts by mass, random copolymerized polypropylene (density 0.905g / cm 3 , under the conditions of 230°C and 2.16kg, the melt flow rate is 3g / 10min) 42 parts by mass, low-density polyethylene (density 0.910g / cm 3 10 parts by mass of metallocene polyolefin plastomer (melt flow rate of 1.0 g / 10min at 190 °C and 2.16 kg) 25 parts by mass , PP grafted maleic anhydride wax (density 0.940g / cm 3 , maleic anhydride content 7.5%, viscosity is 300cps) 3 mass parts under the condition of 190 ℃, antioxidant 1010 (BASF company) 0.1 mass part and antioxidant 168 (BASF company) 0.2 mass part join high-speed mixer together After mixing evenly, blend and granulate through a twin-screw extruder. The processing temperature of the twin-screw extruder is 190°C, the speed of the screw is 350rpm, the vacuum degree of...

Embodiment 3

[0031] Maleic anhydride (MAH) grafted polypropylene (maleic anhydride graft rate 2.5%, density 0.900g / cm 3 , under the conditions of 230°C and 2.16kg, the melt flow rate is 6g / 10min) 20 parts by mass, random copolymerized polypropylene (density 0.905g / cm 3 , under the conditions of 230°C and 2.16kg, the melt flow rate is 3g / 10min) 50 parts by mass, low-density polyethylene (density 0.910g / cm 3 10 parts by mass of metallocene polyolefin plastomer (melt flow rate of 1.0 g / 10min at 190 °C and 2.16 kg) 15 parts by mass , PP grafted maleic anhydride wax (density 0.940g / cm 3 , maleic anhydride content 7.5%, viscosity is 300cps) 5 mass parts under the condition of 190 ℃, antioxidant 1010 (BASF company) 0.1 mass part and antioxidant 168 (BASF company) 0.2 mass part join high-speed mixer together After mixing evenly, blend and granulate through a twin-screw extruder. The processing temperature of the twin-screw extruder is 190°C, the speed of the screw is 350rpm, the vacuum degree of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com