Self-adhering protecting film and application thereof in adhering protecting smooth-surfaced PC board

A technology of self-adhesive protective film and adhesive layer, which is applied in the direction of film/sheet adhesives and adhesives, which can solve the problems of difficult to tear, residual glue, and inability to tear, and achieve uniform thickness, good flexibility, easy to tear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

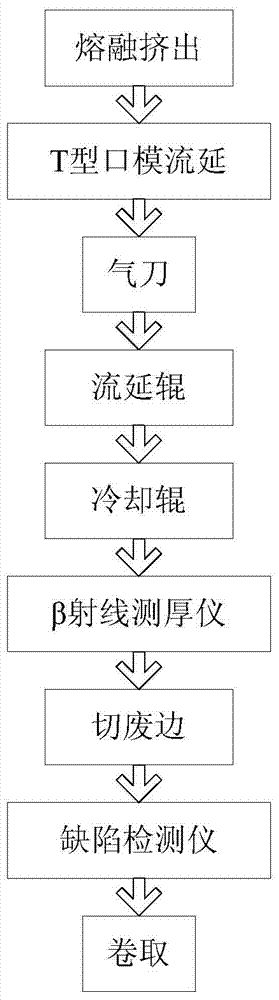

[0051] The present invention preferably adopts the method for heating cast film to prepare self-adhesive protective film, and the preparation method of described self-adhesive protective film preferably comprises the following steps:

[0052] Melting and co-extruding the components included in the skin layer, core layer and adhesive layer;

[0053] The extruded material is cast into a film to obtain a self-adhesive protective film.

[0054] The present invention melts and co-extrudes the components included in the surface layer, core layer and adhesive layer described in the above technical solution. The present invention does not have special limitation to the equipment that described melt coextrusion adopts, adopts the equipment of melt coextrusion well-known to those skilled in the art and gets final product, as can adopt German W&H model to be 568 cast extruders to carry out melt coextrusion .

[0055] After melt co-extrusion, the present invention casts the material of ...

Embodiment 1

[0071] Adhesive layer components: MPE and SEBS with a mass ratio of 95:5, wherein the density of MPE is 0.90g / cm 3 , The melt index is 4.5g / 10min; the density of SEBS is 0.92g / cm 3 , The melt index is 8.0g / 10min.

[0072] Core layer component: PP)LDPE with a mass ratio of 60:40, where the density of PP is 0.90g / cm 3 , The melt index is 5.0g / 10min; the density of LDPE is 0.925g / cm 3 , The melt index is 4.0g / 10min.

[0073] Surface layer components: HDPE and LDPE with a mass ratio of 20:80, where the density of HDPE is 0.957g / cm 3 , The melt index is 6.0g / 10min; the density of LDPE is 0.925g / cm 3 , The melt index is 4.0g / 10min.

[0074] The German W&H model 568 casting machine is used for the heating and casting process, and the components of the adhesive layer, core layer and surface layer are prepared to obtain a self-adhesive protective film. The heating and casting process is: extruder extrusion → T Die casting→air knife→casting roll→cooling roll→β-ray thickness gauge→...

Embodiment 2

[0081] Adhesive layer components: MPE and LDPE with a mass ratio of 80:20, wherein the density of MPE is 0.90g / cm 3 , The melt index is 4.5g / 10min; the density of LDPE is 0.925g / cm 3 , The melt index is 4.0g / 10min.

[0082] The core layer component and the surface layer component are the same, HDPE and LDPE with a mass ratio of 40:60, and the density of HDPE is 0.957g / cm 3 , The melt index is 6.0g / 10min; the density of LDPE is 0.925g / cm 3 , The melt index is 4.0g / 10min.

[0083] The self-adhesive protective film was prepared according to the heating casting process and parameters in the examples.

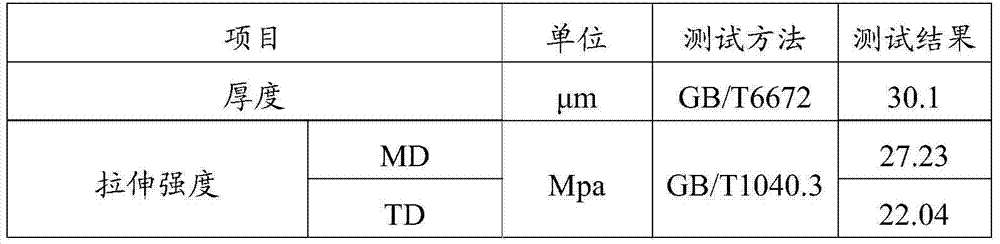

[0084] In the present invention, the obtained self-adhesive protective film is tested for physical properties, and the results are shown in Table 2. Table 2 shows the physical property test results of the self-adhesive protective film obtained in Example 2 of the present invention.

[0085] The physical property test result of the self-adhesive protective film that table 2 embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com