Laser cladding metal-ceramic coating material based on ZrO2 doping

A technology of laser cladding and ceramic coating, applied in the field of metal-ceramic coating materials and toughened metal-ceramic coating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

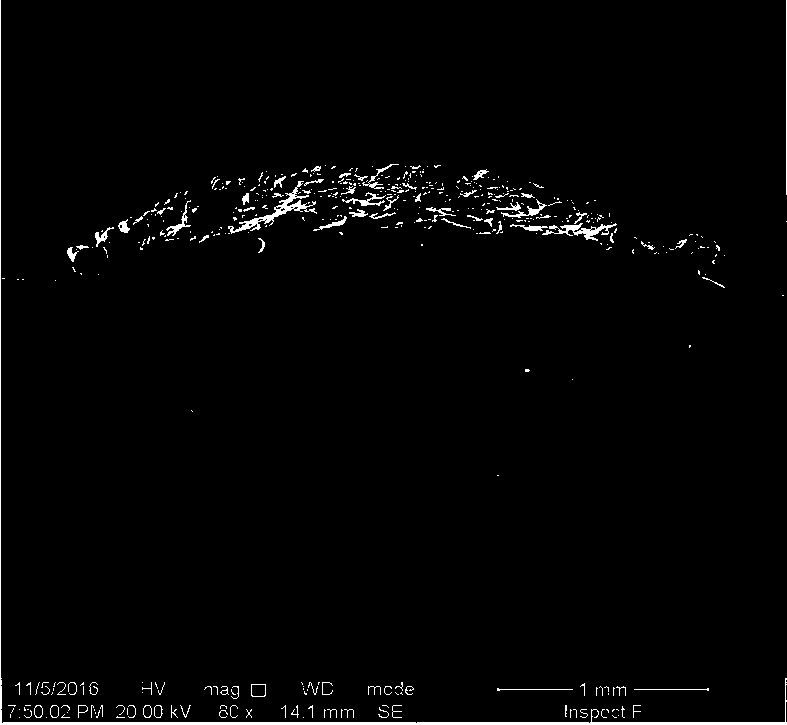

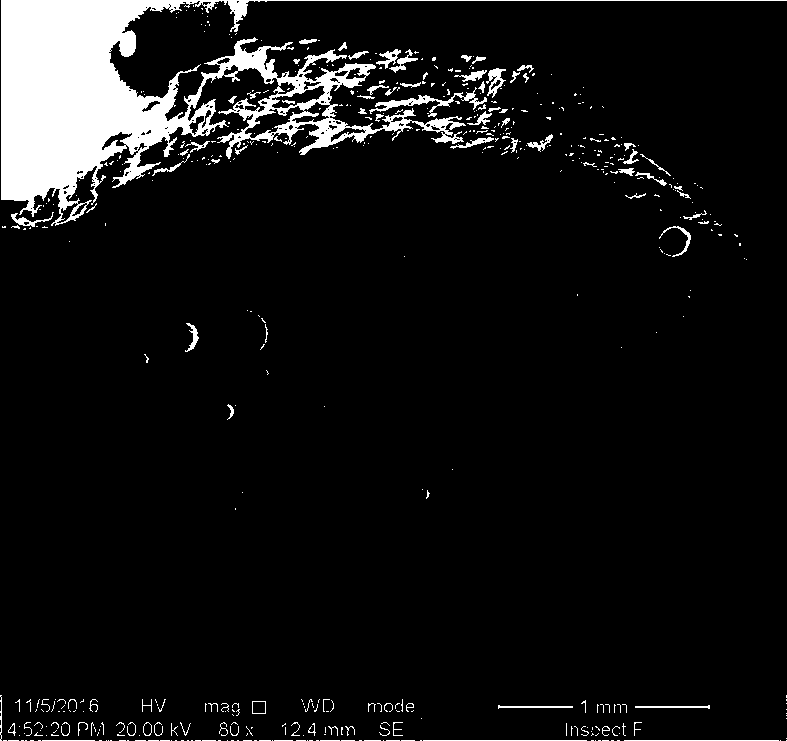

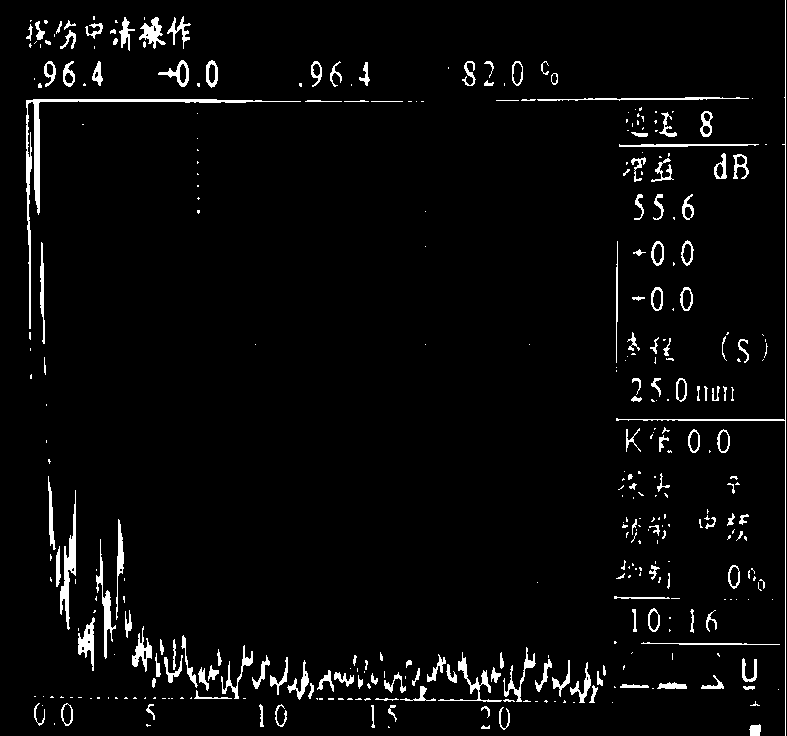

Image

Examples

Embodiment 1

[0031] Cut the titanium alloy matrix sample into a cuboid with a size of 5.0cm×1.5cm×1.5cm, and grind the surface to a surface roughness of 5Ra. After cleaning and degreasing with acetone, dry it in the air, and place it in a vacuum furnace for pretreatment. Heat to 150°C.

[0032] Weigh 15g of 80-150 mesh titanium powder, 80-150 mesh ZrO 2 9g of powder and 276g of TiBCN powder of 150-200 mesh were mixed, dried in a vacuum furnace at 100°C for 1.5h, cooled naturally, and mixed in a planetary ball mill for 3h to obtain a laser cladding metal-ceramic coating material.

[0033] The titanium alloy sample is placed on the laser cladding workbench, and the metal-ceramic coating material is loaded into the powder chamber of the automatic powder feeder of the laser cladding device. Using the coaxial powder feeding method, using the German LDF-4000-100 semiconductor laser as the light source, laser cladding is carried out on the titanium alloy sample to form a toughened metal-ceramic ...

Embodiment 2

[0044] Cut the titanium alloy matrix sample into a cuboid with a size of 5.0cm×1.5cm×1.5cm, and grind the surface to a surface roughness of 7Ra. After cleaning and degreasing with acetone, dry it in the air, and place it in a vacuum furnace for pretreatment. Heat to 100°C.

[0045] Weigh 10g of 80-150 mesh titanium powder, 80-150 mesh ZrO 2 Mix 6g of powder and 284g of 150-200mesh TiBCN powder, dry in a vacuum furnace at 100°C for 1.5h, cool naturally, and mix in a planetary ball mill for 3h to obtain a laser cladding metal-ceramic coating material.

[0046] The titanium alloy sample is placed on the laser cladding workbench, and the metal-ceramic coating material is loaded into the powder chamber of the automatic powder feeder of the laser cladding device. Using the coaxial powder feeding method, using the German LDF-4000-100 semiconductor laser as the light source, laser cladding is carried out on the titanium alloy sample to form a toughened metal-ceramic cladding coating....

Embodiment 3

[0052] Cut the titanium alloy matrix sample into a cuboid with a size of 5.0cm×1.5cm×1.5cm, and grind the surface to a surface roughness of 10Ra. After cleaning and degreasing with acetone, dry it in the air, and place it in a vacuum furnace for pretreatment. Heat to 300°C.

[0053] Weigh 20g of 80-150 mesh titanium powder, 80-150 mesh ZrO 2 Mix 12g of powder and 268g of 150-200mesh TiBCN powder, dry in a vacuum furnace at 100°C for 1.5h, cool naturally, and mix in a planetary ball mill for 3h to obtain a laser cladding metal-ceramic coating material.

[0054] The titanium alloy sample is placed on the laser cladding workbench, and the metal-ceramic coating material is loaded into the powder chamber of the automatic powder feeder of the laser cladding device. Using the coaxial powder feeding method, using the German LDF-4000-100 semiconductor laser as the light source, laser cladding is carried out on the titanium alloy sample to form a toughened metal-ceramic cladding coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com