Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "To achieve the purpose of toughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-permeable paving material and preparation method and application thereof

The invention discloses a water-permeable paving material and a preparation method and application thereof. The water-permeable paving material comprises, by weight, 60-90 parts of quartz sand, 10-40 parts of Portland cement, 2-10 parts of hydrophilic epoxy resin binders, 0.5-5 parts of curing agents and 1-10 parts of water. The curing agents include one or more of aliphatic polyamine and cycloaliphatic polyamine curing agents or aromatic ring polyamine curing agents. The hydrophilic epoxy resin binders comprise, by weight, 500-950 parts of bisphenol A epoxy resin, 1-200 parts of surfactant span, 1-200 parts of surfactant tween and 0.001-0.005 part of catalysts, wherein the catalysts can be tetraethylammonium chloride, butyl triphenyl phosphorus bromide, benzyl triethyl ammonium bromide, benzyl triethyl ammonium chloride, 2- methylimidazole or optional combination of the above substances. The water-permeable paving material is prepared by uniformly stirring the quartz sand, the Portland cement, the water, the hydrophilic epoxy resin binders and the curing agents; and then placing the stirred mixture into a mould for molding and curing for 24 hours at the normal temperature prior to demolding. The water-permeable paving material is used for preparing pavement bricks, pavement slabs and sewage filtering prefabricated members by means of molding.

Owner:杭锦旗亿嘉环境治理有限公司

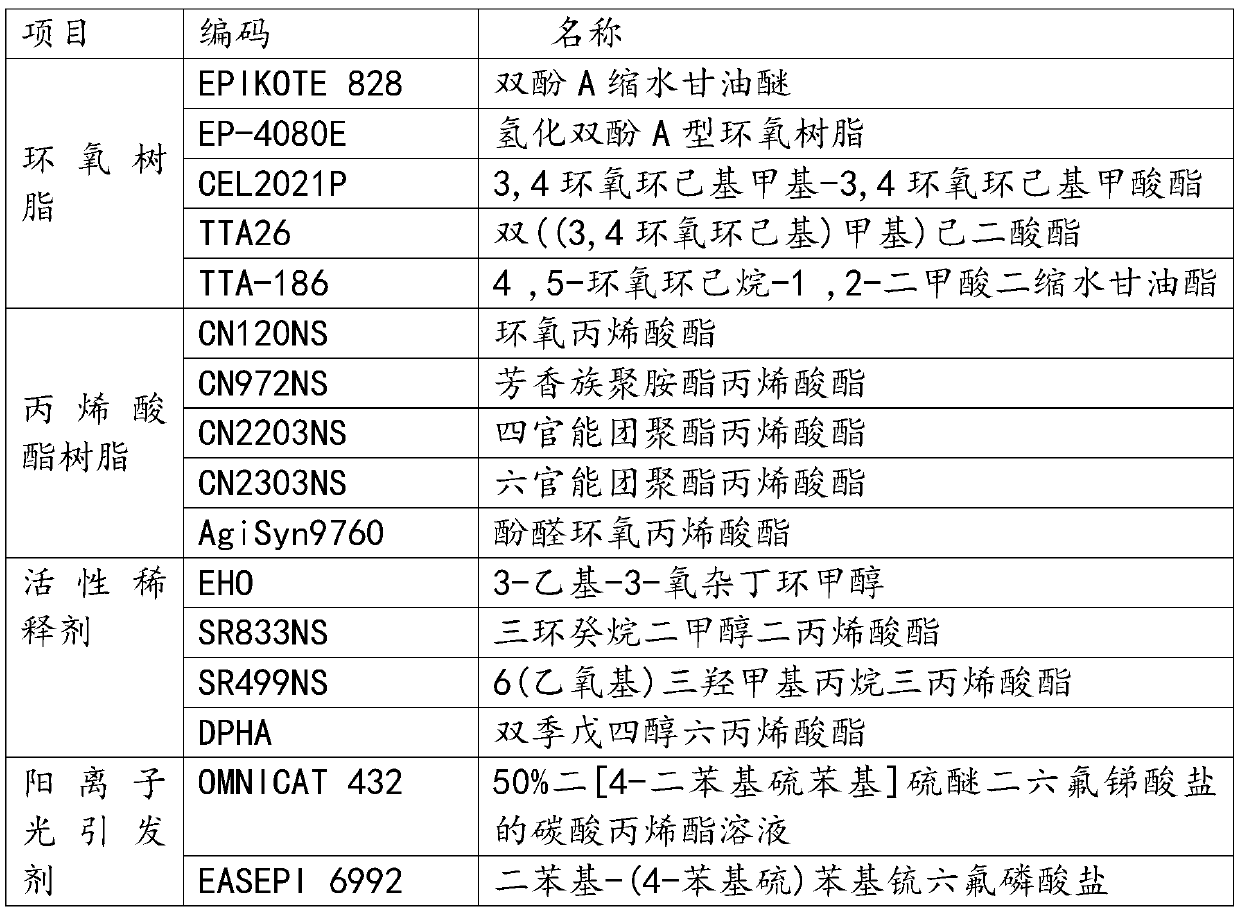

High-temperature-resistant light-cured resin and preparation method thereof

InactiveCN110724236APlay a synergistic roleLight curing reaction speed is fastAdditive manufacturing apparatusEpoxyPolymer science

The invention provides high-temperature-resistant light-cured resin and a preparation method thereof. The light-cured resin comprises the following components in percentage by mass: 40%-70% of epoxy resin, 5%-20% of acrylic resin, 10%-20% of an active diluent, 3%-6% of a cationic photoinitiator, 1%-3% of a free-radical photoinitiator, 5%-20% of a flexibilizer and 0.1%-3% of an inorganic filler. The high-temperature-resistant light-cured resin is high in curing reaction rate and has both toughness and strength.

Owner:威斯坦(厦门)实业有限公司

Modified PLA (polylactic acid) material for 3D printers

The invention discloses a modified PLA (polylactic acid) material for 3D printers, which comprises the following components in parts by mass: 30-88 parts of PLA, 2-25 parts of toughener, 0.5-18 parts of nano oxide, 5-30 parts of lignin, 4-35 parts of polyacrylate, 1-12 parts of crosslinking agent, 2-20 parts of filler and 1-10 parts of coupling agent. The lignin can form a network structure to be dispersed inside the PLA structure, thereby enhancing the strength of the PLA through the network structure. The coupling agent is used for enhancing the dispersity of the filler in the PLA, thereby further enhancing the impact resistance of the filler reinforcing material. The nano oxide is fine particles (nanoparticles) with high rigidity, and the crack in the molecular structure derivates when meeting the nanoparticles in the expansion process, so that the energy is absorbed, thereby achieving the goal of toughening.

Owner:CHANGZHOU HANBANG ENG PLASTIC

Insulating heat conducting cable material and preparation method thereof

InactiveCN105837911AImprove heat resistanceImprove cold resistancePlastic/resin/waxes insulatorsElastomerPolyolefin

The invention discloses an insulating heat conducting cable material. The insulating heat conducting cable material comprises the following raw materials in parts by weight: 60 to 70 parts of high-density polyethylene, 20 to 30 parts of modified polypropylene, 15 to 25 parts of heat conducting filler, 6 to 10 parts of polyolefin elastomers, 5 to 8 parts of glass fibres, 3 to 5 parts of a compatilizer, 3 to 8 parts of modified zinc borate, and 10 to 15 parts of ethylene-vinyl acetate copolymer. The insulating cable material is high in heat conductivity, high in insulating property, high in tensile strength, high in toughness, and convenient to process.

Owner:STATE GRID HENAN SHEQI POWER SUPPLY CO

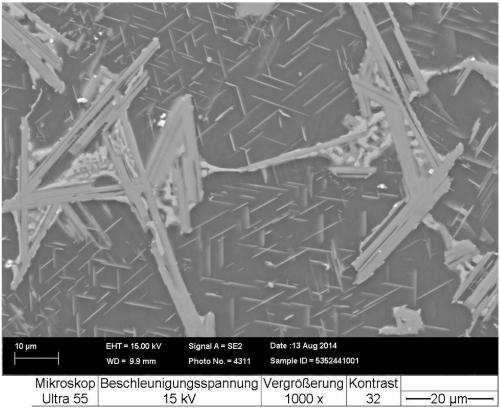

Laser cladding metal-ceramic coating material based on ZrO2 doping

ActiveCN108707893AReduce generationLow extensionMetallic material coating processesStress concentrationAlloy substrate

The invention discloses a laser cladding metal-ceramic coating material based on ZrO2 doping. The laser cladding metal-ceramic coating material based on ZrO2 doping is prepared by mixing 5-20 wt% of Ti powder, 70-92 wt% of TiBCN ceramic powder and 3-10 wt% of ZrO2 powder. The coating material is clad on the surface of a titanium alloy substrate by a laser cladding technology. The coating materialcan absorb strain energy of residual thermal stress of laser cladding, reduce crack generation and extension caused by stress concentration, improve fracture toughness of the cladding coating, and increase strength and corrosion resistance of the cladding coating to form a toughened metal-ceramic cladding coating.

Owner:ZHONGBEI UNIV

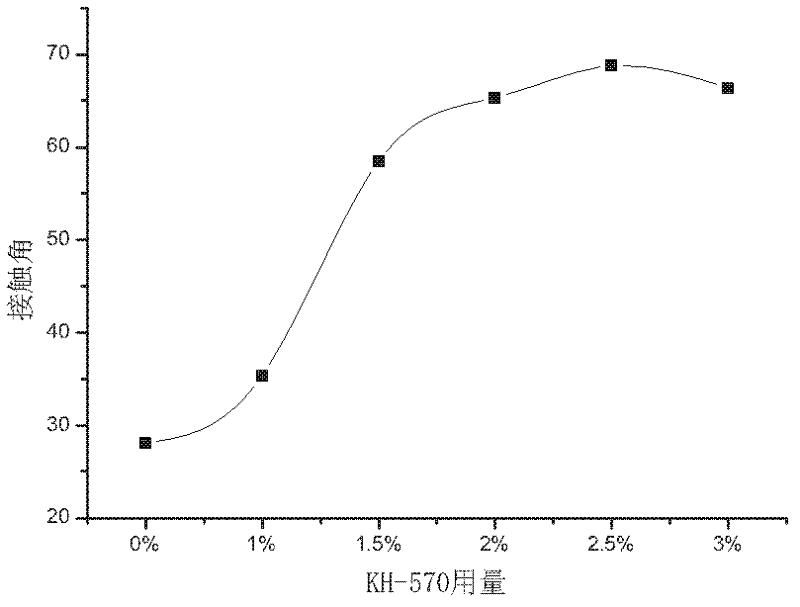

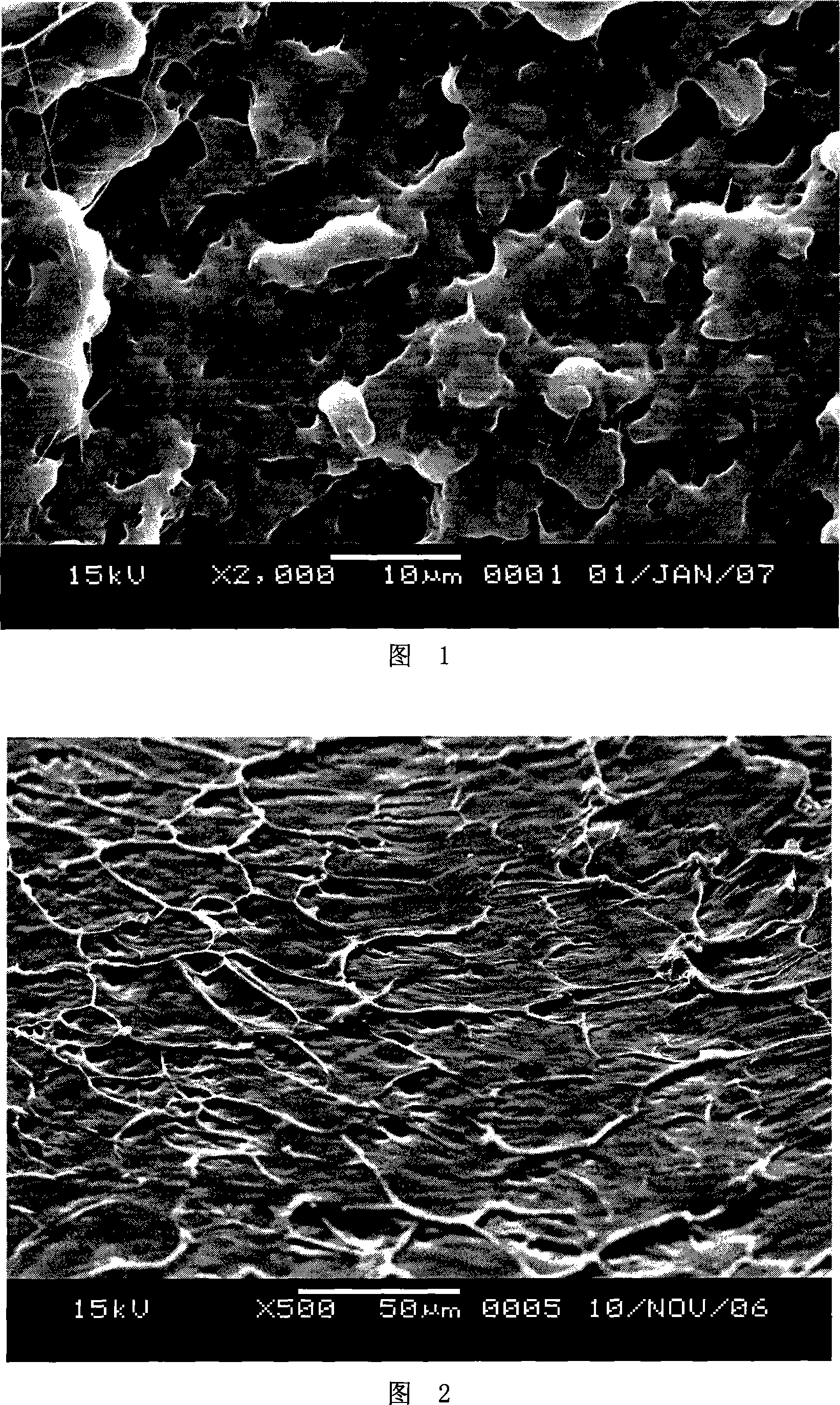

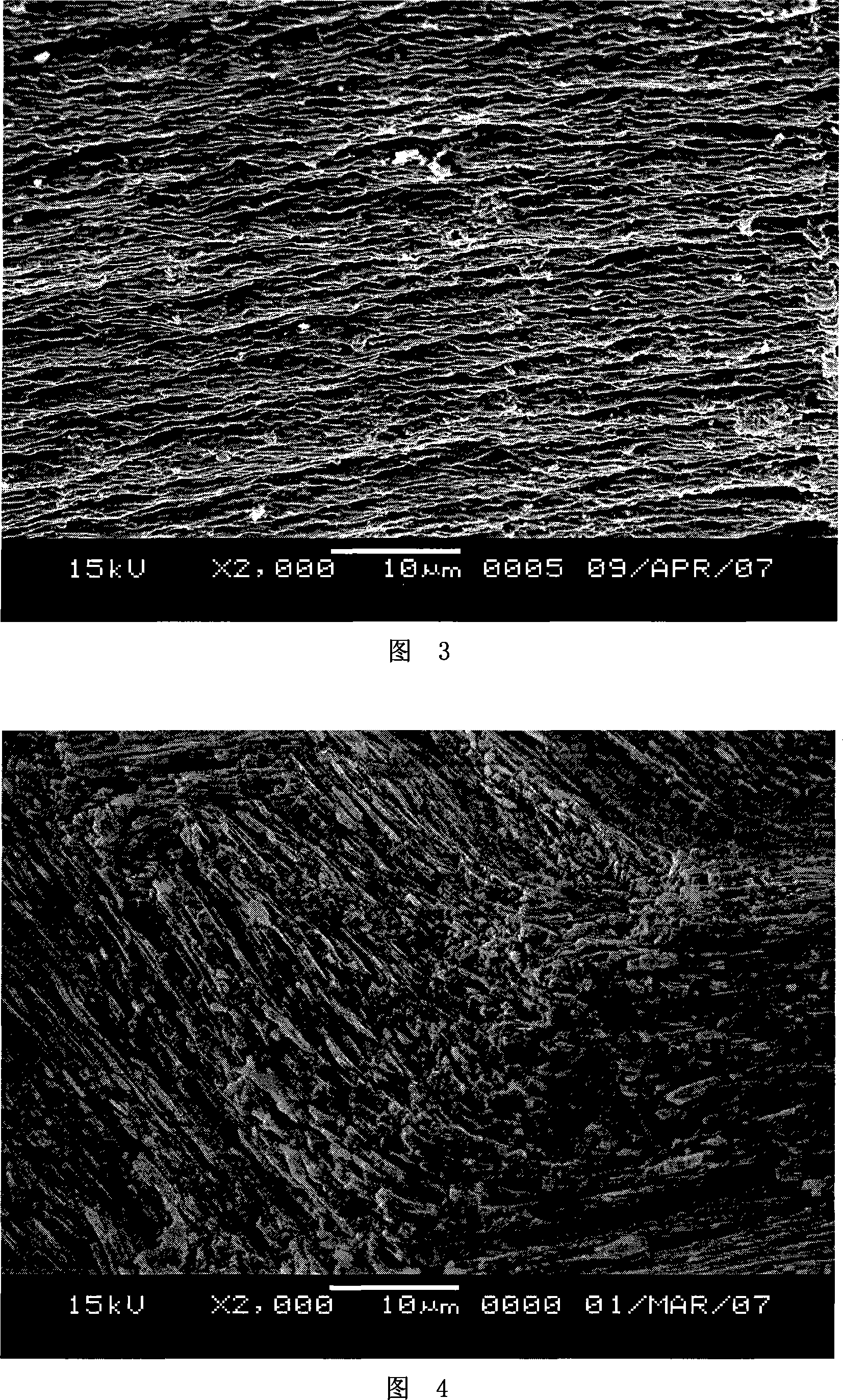

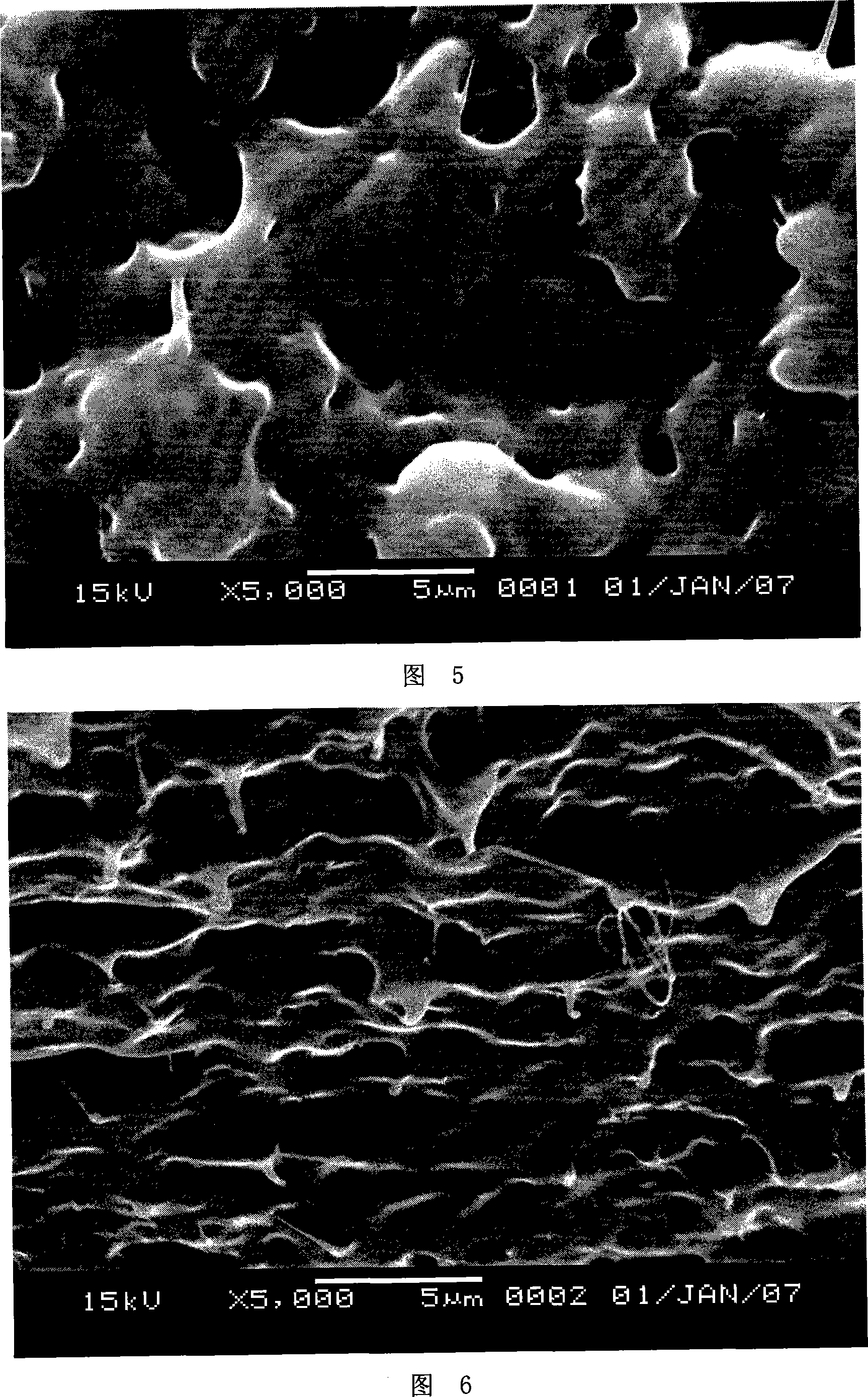

Method for toughening epoxy resin by adopting modified wollastonite

InactiveCN102532951ATake advantage ofHigh modulusPigment treatment with organosilicon compoundsPigment physical treatmentEpoxyWollastonite

The invention relates to a method for toughening epoxy resin by adopting modified wollastonite. The method is characterized by comprising the following steps: stirring the wollastonite for 30 minutes at the temperature of 80 DEG C so as to improve reaction activity; carrying out wet modification on the wollastonite with a silane coupling agent KH-570; and then toughening the epoxy resin by utilizing the modified wollastonite, wherein the tensile strength and the impact strength of the modified epoxy resin are greatly improved. According to the invention, the wollastonite is subjected to surface treatment and then the epoxy resin is subjected to toughening modification with the modified wollastonite, thus the process is simple and convenient for operation, thereby reaching the toughening purpose, reducing production cost and sufficiently utilizing the wollastonite so as to improve the additional value of the wollastonite.

Owner:EAST CHINA UNIV OF SCI & TECH

Fine-grained cubic boron nitride blade and preparation method thereof

The invention relates to a fine-grained cubic boron nitride blade. The blade is prepared from, by weight, 60%-80% of micro cubic boron nitride powder and 20%-40% of nano-binder, wherein the nano-binder is prepared from, by weight, 25%-45% of TiN powder, 17%-20% of NbC powder, 12%-15% of Al2O3 powder, 12%-15% of HfC powder, 6%-10% of Be powder, 6%-10% of WC powder and 2%-5% of Mo power. By adding the nano-binder, formation of a tough sintering body is promoted, the toughness of the cubic boron nitride blade is increased, and the service life is prolonged. According to the fine-grained cubic boron nitride blade prepared through the preparation method, the technical indexes can reach the conditions that the grain size is smaller than or equal to 1 micrometer, the abrasive ratio ranges from 7,000 to 7,500, the microhardness HV ranges from 6,000 to 6,500, and the bending strength ranges from 850 MPa to 900 MPa, and the requirements of precise machining can be met.

Owner:ZHONGNAN DIAMOND CO LTD

A method for forming concba lamellar structure with degradable plastics PLA

InactiveCN101157273AImprove application versatilityFlat surfaceInjection pressureMechanical property

The invention discloses a method, by which the biodegradable plastic PLA can form a shell-like samdwich structure; the method includes the following steps: firstly, under the temperature of 150-200 DGE C and the injection pressure of 60 bar -160 bar, the sample of the biodegradable plastic PLA can be molded; secondly, the molded sample of the biodegradable plastic PLA can be cut into a rectangular block of 35 mm * 10mm * 4mm; thirdly, the prepared sample of the biodegradable plastic PLA is put in the cavity of a module, under the temperature of 0-170 DGE C, the pressure of 0-1000 MPa, and the time of 0-150 min, the polymer begins to flow induced by low temperature and pressure to form the PLA with the micro shell-like samdwich structure. The method improves the appearance performance of the products and the mechanical properties of the material, such as the ability of impacting, stretching and bending, and fully enhances the application of PLA used as material.

Owner:DONGHUA UNIV

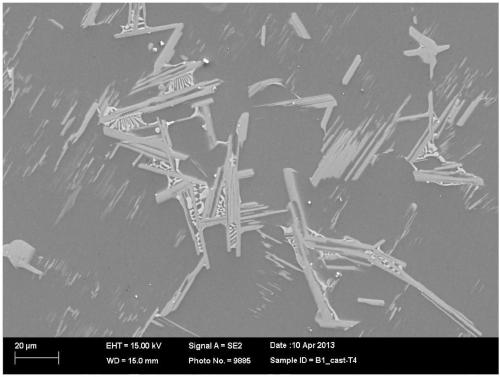

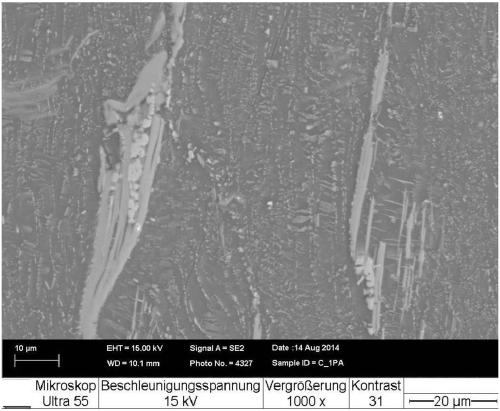

Toughening-strengthening heat treatment method of high nitrogen austenitic stainless steel

ActiveCN105624376AToughen or enhance propertiesImprove performanceAustenitic stainless steelLamellar structure

The invention belongs to the field of heat treatment technics or high nitrogen austenitic stainless steel material processing, and particularly relates to a toughening-strengthening heat treatment method of high nitrogen austenitic stainless steel. The method comprises the following steps: conducting the solid-solution treatment on a high nitrogen austenitic stainless steel material at a high-temperature area, conducting the ageing treatment on the solid-solution treated high nitrogen austenitic stainless steel material at a medium-temperature area, and conducting the spheroidizing heat treatment on the ageing-treated high nitrogen austenitic stainless steel material at a higher-temperature area, so as to dissolve and spheroidize a laminar nitride to obtain a granular nitride distributed in an austenite matrix. The toughening-strengthening heat treatment method has the advantages that the laminar structure of a cellular reaction nitride is changed, and the formed granular nitride is distributed in the austenite matrix, so that the high nitrogen austenitic stainless steel is strengthened or toughened, and the performance is improved or increased.

Owner:CHANGCHUN SHIYUE ENERGY SAVING MATERIAL CO LTD

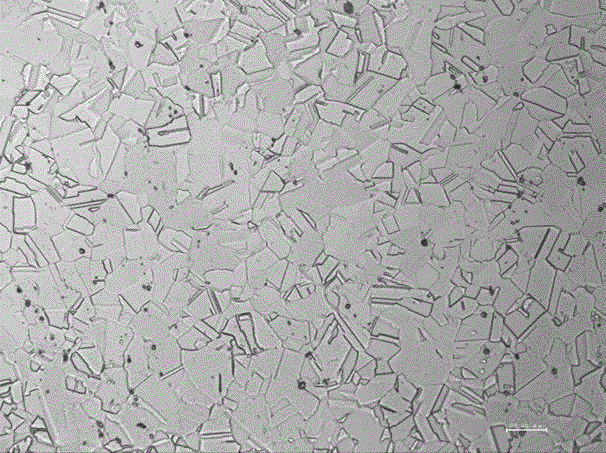

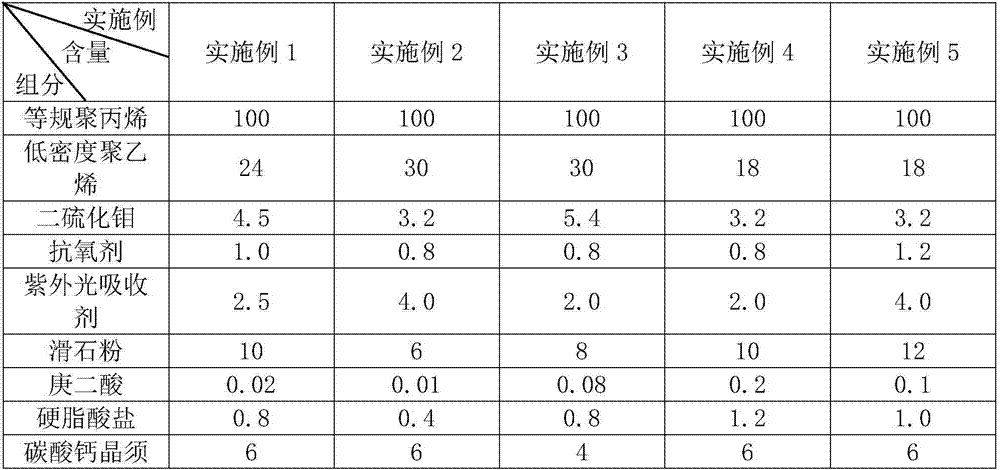

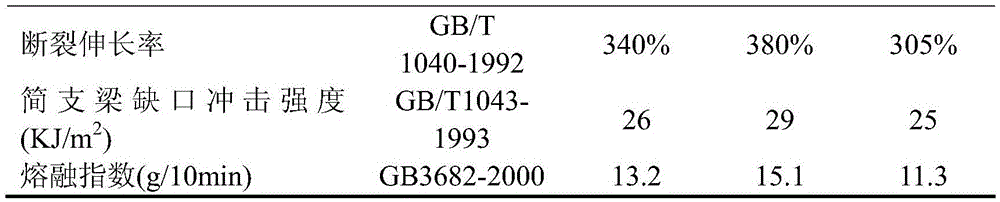

Material for reinforced plastic woven bag

The invention discloses a material for a reinforced plastic woven bag. The material is characterized by being prepared from the following raw materials in parts by weight: 100 parts of isotactic polypropylene, 18 to 30 parts of low density polyethylene, 3.2 to 5.4 parts of molybdenum disulfide, 0.8 to 1.2 parts of an antioxidant, 2 to 4 parts of an ultraviolet absorbent, 6 to 12 parts of talcum powder, 0.01 to 0.2 part of pimelic acid, 0.4 to 1.2 parts of stearate and 2 to 10 parts of calcium carbonate whiskers, wherein stearate comprises calcium stearate. The material has the advantages of high tensile strength and high toughness.

Owner:浙江海威包装有限公司

Cyanate resin modified by polyether imide

InactiveCN1480490AImprove impact resistanceGood mechanical propertiesCoatingsAdhesivesCyanate esterImide

Owner:FUDAN UNIV

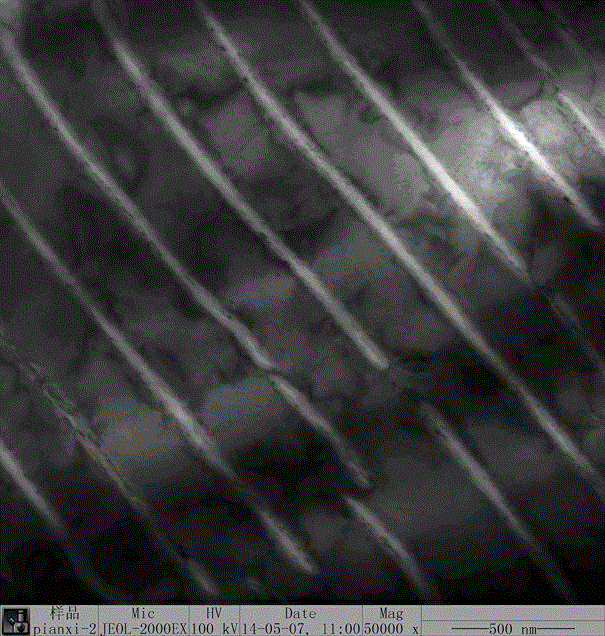

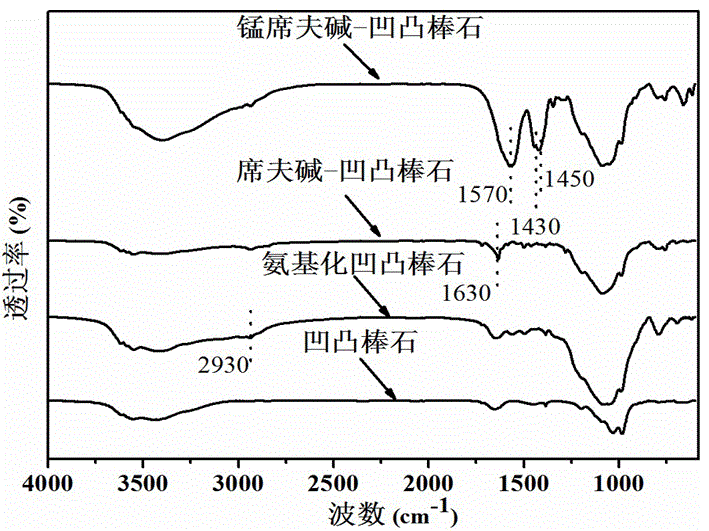

Modified attapulgite and preparing method thereof

ActiveCN104877394AGood dispersionPrevent crack growthPigment treatment with non-polymer organic compoundsPolymer scienceSalicylaldehyde

The invention discloses modified attapulgite and a preparing method thereof. The modified attapulgite is composed of attapulgite and manganese Schiff base. The preparing method of the modified attapulgite includes the steps that the attapulgite and hydrochloric acid are reacted to obtain acidulated attapulgite, and then the acidulated attapulgite is reacted with methylbenzene and gamma-aminopropyltriethoxysilane to obtain amination attapulgite; the amination attapulgite is added into mixed liquid composed of salicylaldehyde and ethyl alcohol for reaction to obtain attapulgite with Schiff base grafted to the surface; then the attapulgite is mixed with manganous acetate tetrahydrate, backflow, stirring and reacting are carried out in the N2 atmosphere, and the modified attapulgite is obtained after suction filtering, washing and drying are carried out. By means of the modified attapulgite, cyanate ester resin can be remarkably catalyzed and toughened at the same time, and the heat resistance of the resin is improved. The preparing method of the modified attapulgite has the advantages of being simple in technology, easy to control, wide in raw material source, low in cost and the like.

Owner:SUZHOU UNIV

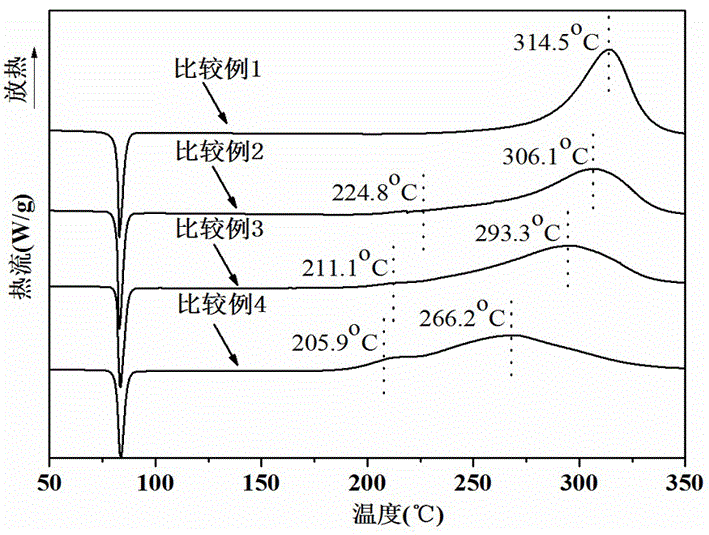

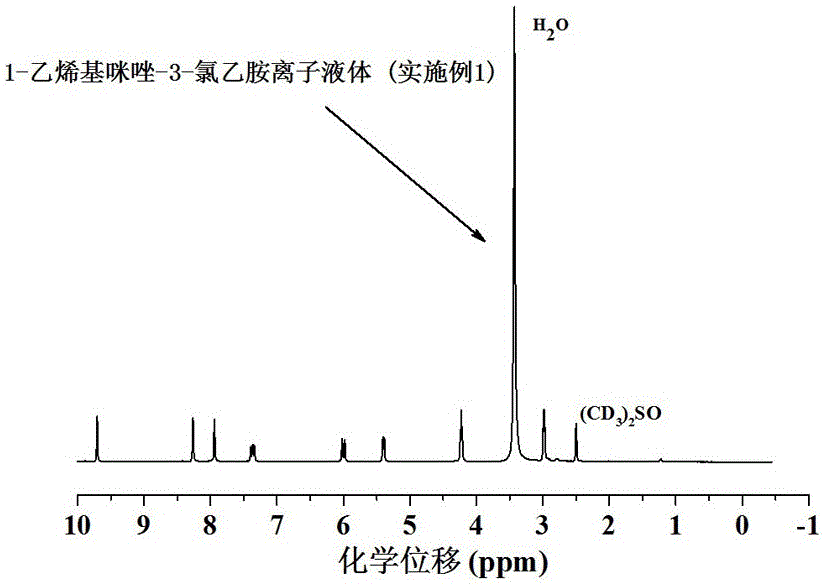

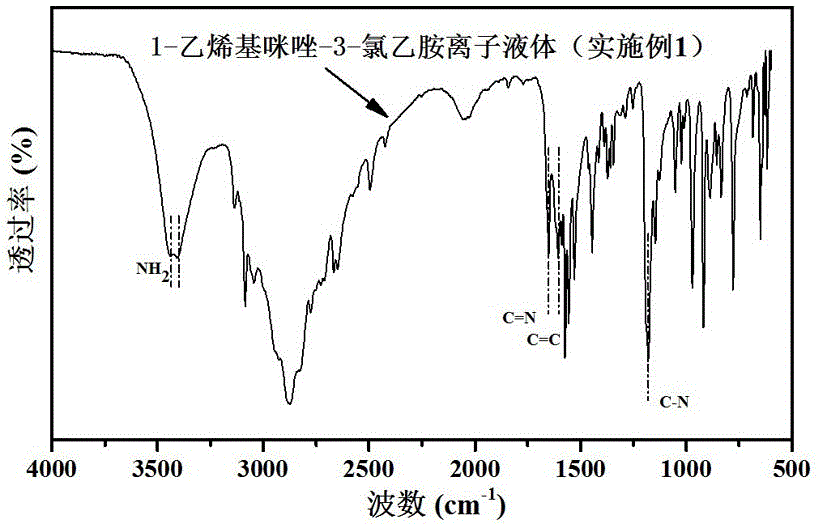

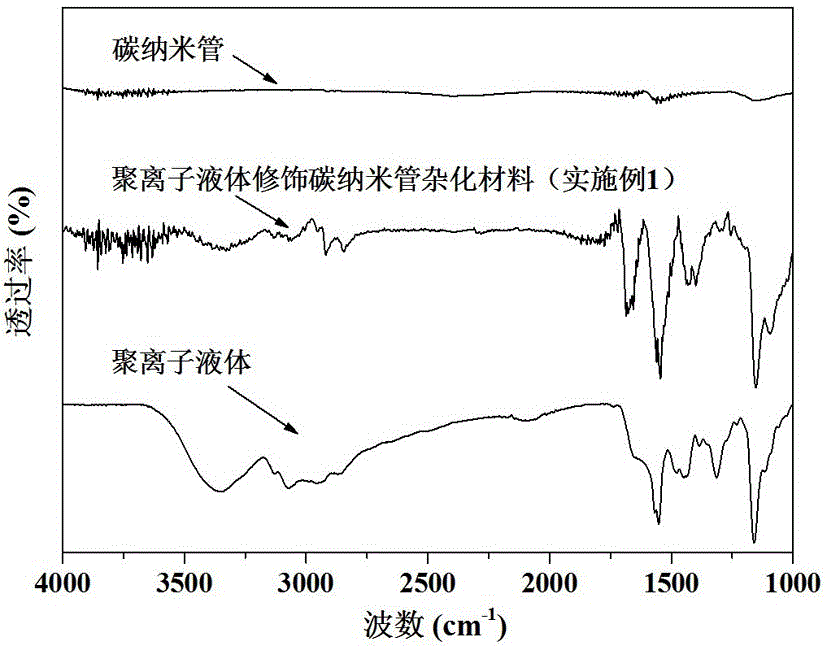

Polyion liquid-modified carbon nano-tube hybrid material and preparation method thereof

The invention discloses a polyion liquid-modified carbon nano-tube hybrid material and a preparation method thereof. The preparation method comprises the following steps: under the protection of nitrogen, mixing and heating vinyl N-heterocycle and 2-chloroethylamine hydrochloride; performing Menshutkin reaction to obtain an ionic liquid hydrochloride; neutralizing to obtain ion liquid monomers; reacting a certain ratio of monomers and a metal salt under a heating condition to obtain an ion liquid which contains an amino end group and a transition metal; dissolving obtained ion liquid in water, adding a fixed amount of carbon nano-tubes, performing ultrasonic dispersing, adding an initiator to perform surface-initiated polymerization, and filtering and drying a product to obtain the polyion liquid-modified carbon nano-tube hybrid material. According to the polyion liquid-modified carbon nano-tube hybrid material and the preparation method thereof, the hybrid material is prepared by coating the carbon nano-tubes with polyion liquid; the hybrid material has toughening and catalyzing functions; the preparation method has the characteristics of simple process and easiness in control.

Owner:SUZHOU UNIV

Hydrophilic epoxy resin binder and preparation method and application thereof

ActiveCN102775948AReduce pollutionImprove mechanical propertiesNon-macromolecular adhesive additivesEpoxy resin adhesivesHigh intensitySurface-active agents

The invention discloses a hydrophilic epoxy resin binder and a preparation method and an application thereof. The hydrophilic epoxy resin binder consists of the following components according to parts by weight: bisphenol A type epoxy resin, a surface active agent Span, a surface active agent Tween and a catalyst, wherein the catalyst can be tetraethyl ammonium chloride, butyl triphenyl phosphonium bromide, benzyl triethyl ammonium bromide, benzyl triethyl ammonium chloride, 2-methyl imidazole or any combination thereof; the bisphenol A type epoxy resin can be bisphenol A type epoxy resin E-44, E-42, E-35, E-31, E-20, E-14, E-12, E-06, E-03 or any combination thereof; the surface active agent Span can be S-20, S-40, S-60, S-80, S-85 or any combination thereof; and the surface active agent Tween can be T-20, T-40, T-60, T-80, T-85 or any combination thereof. The hydrophilic epoxy resin binder is applied in the preparation process of water permeable pavement materials and high-strength cement products.

Owner:杭锦旗亿嘉环境治理有限公司

High-toughness phenolic resin adhesive for abrasive paper, and preparation method and application method thereof

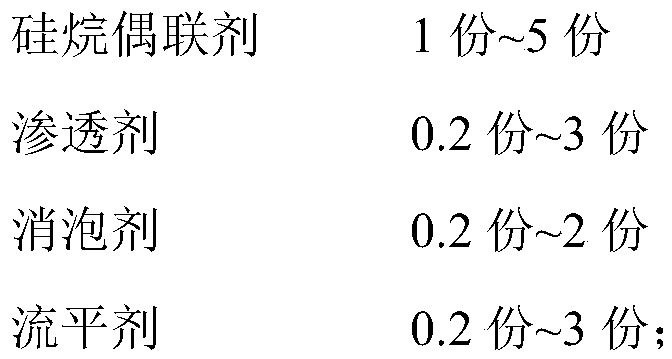

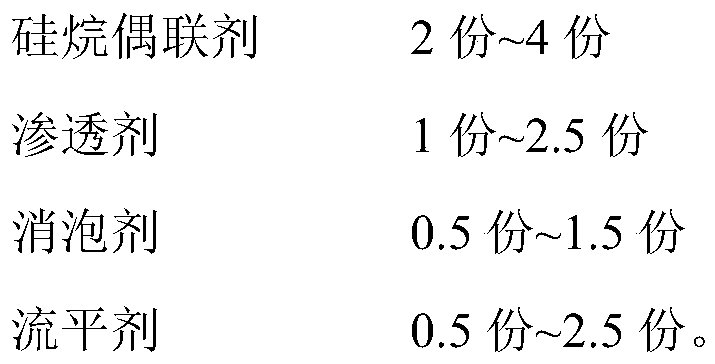

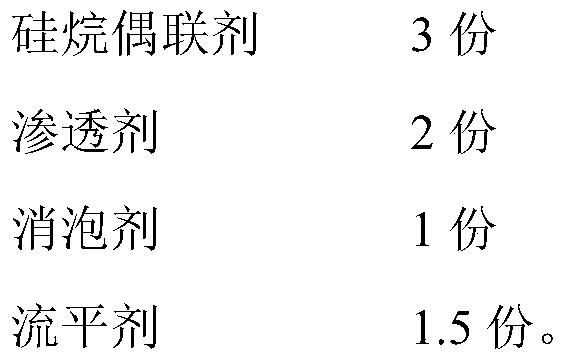

ActiveCN110938399AReduce pollutionImprove brittlenessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceOrganosolv

The invention relates to the technical field of abrasive tools and particularly relates to a high-toughness phenolic resin adhesive for abrasive paper, and a preparation method and application methodthereof. The abrasive paper is prepared by blending four components A, B, C and D, wherein the A component includes phenolic resin, polyurethane, and multifunctional amine additive, the B component iswater, the C component includes a silane coupling agent, a permeating agent, a defoaming agent, and a leveling agent, and the D component is filler. Compared with an abrasive paper adhesive in the prior art, the high-toughness phenolic resin adhesive only employs water as a solvent without any other organic solvents, so that during a curing process, volatilization of organic solvents is avoided and environmental pollution is greatly reduced. The preparation method is simple in process and low in production cost, and is suitable for large scale production. The adhesive is used for manufacturing the abrasive paper for abrasive, wherein an abrasive test result proves that compared with the adhesives in the prior art, the abrasive paper employing the adhesive in the invention is better in flexibility and is higher in abrasive efficiency.

Owner:DONGGUAN GOLDEN SUN ABRASIVES

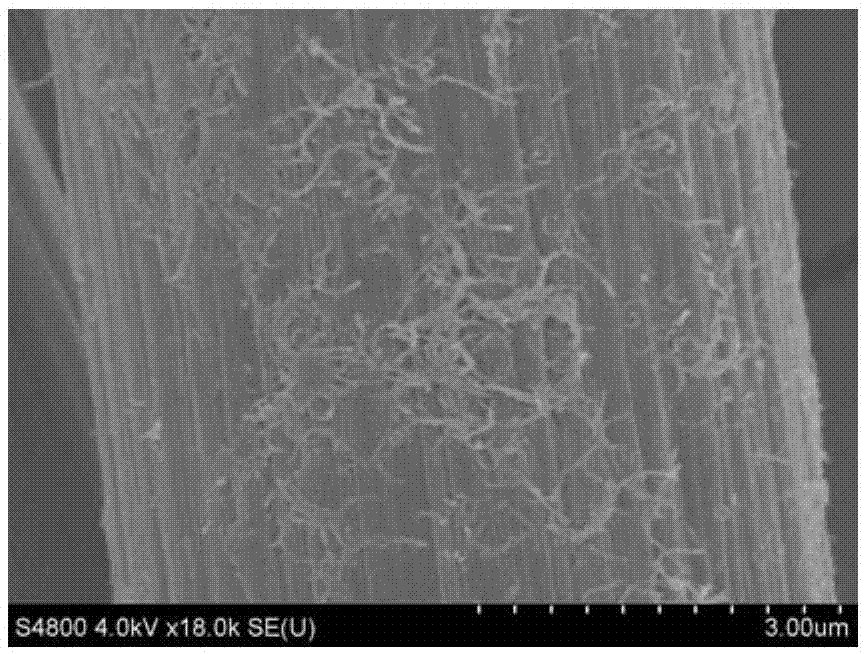

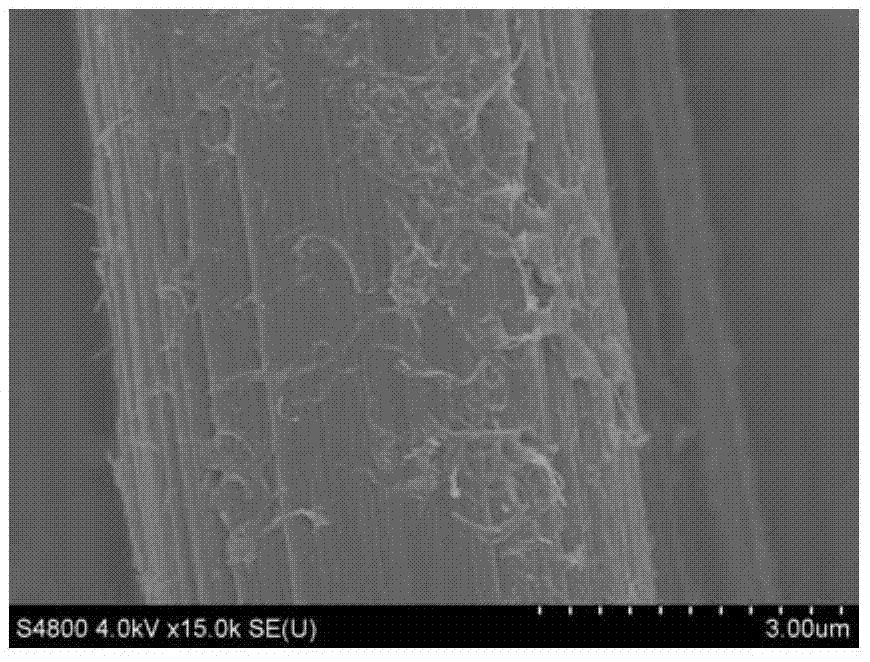

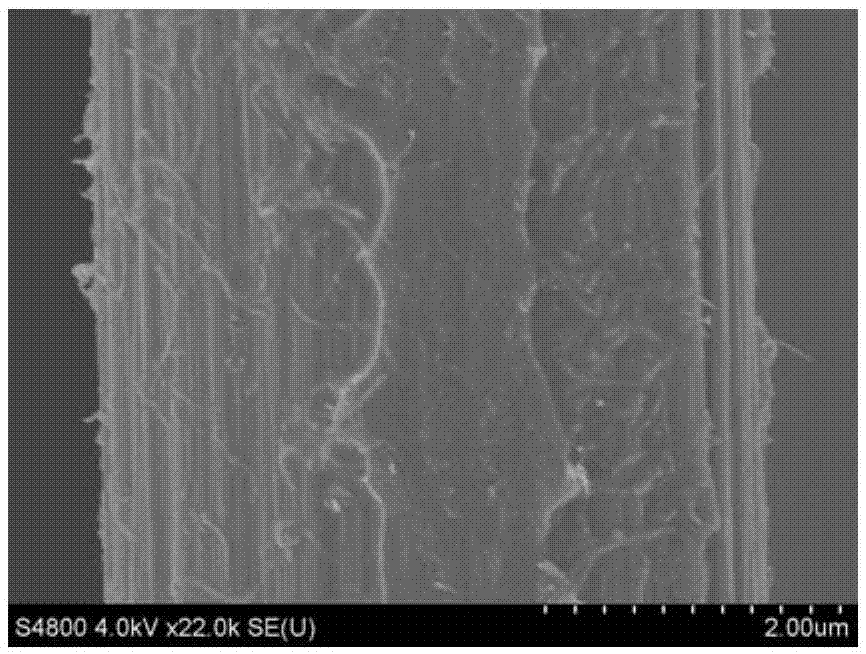

Method for preparing carbon fiber composite material interface layer

The invention provides a method for preparing a carbon fiber composite material interface layer. The method comprises the following steps: coating the surface of a carbon fiber by using a sizing agent with carbon nanotubes, phenolic resin, a curing agent and a solvent, curing, and performing high temperature thermal treatment, thereby obtaining a pyrolytic carbon coated layer with the carbon nanotubes. Effects of strengthening and toughening can be achieved in a composite material with the carbon fiber as a reinforcing part. The method is simple and feasible and low in cost, the process complexity of the method is greatly reduced as compared with those of conventional CVD and EPD, in addition, process conditions are easy to control, the carbon fiber self is not damaged in the preparation process, and the influence upon the performance of the carbon fiber self is reduced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

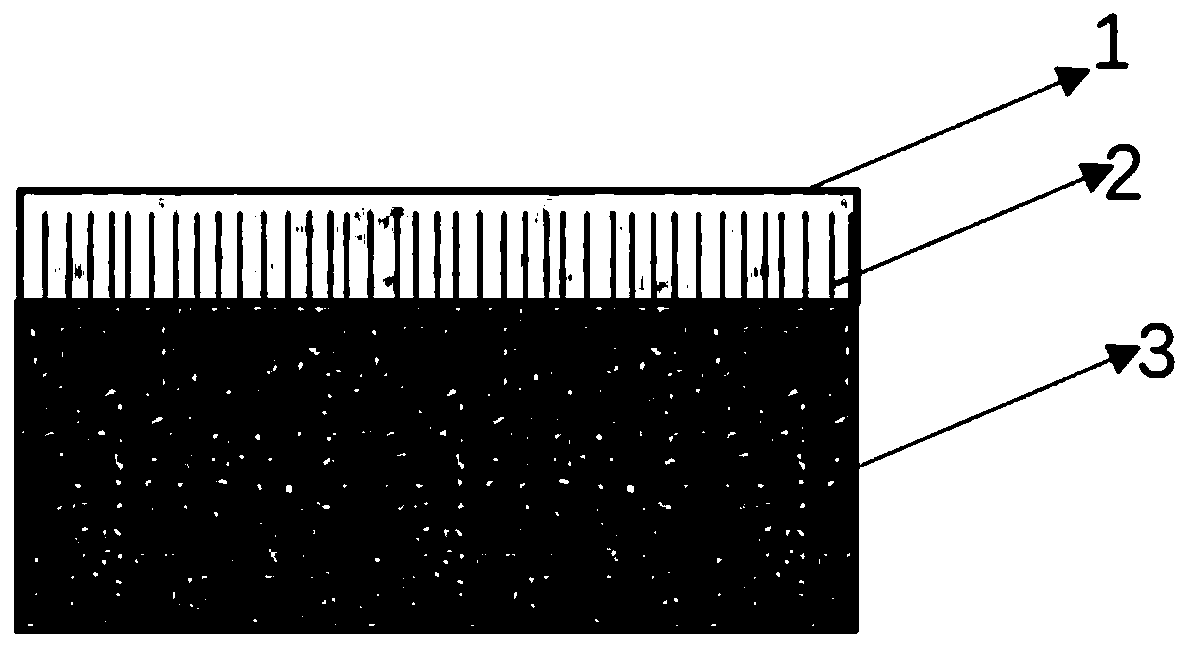

Preparation method for polyimide three-layer composite film with electromagnetic shielding function

InactiveCN106939518AWith electromagnetic shielding functionReduce agglomeration effectFilament/thread formingNon-woven fabricsComposite filmElectrospinning

The invention provides a preparation method for a polyimide three-layer composite film with an electromagnetic shielding function. When carbon nanotubes are employed for modification of a polyimide film, the resistivity of the polyimide film can be effectively reduced; however, with increase of the content of the carbon nanotubes, the carbon nanotubes are substantially agglomerate in polyimide, which leads to drastic decrease of the mechanical properties of the polyimide film. The preparation method provided by the invention comprises the following steps: (1) preparation of a carbon nanotube-modified polyamide acid solution; (2) preparation of a carbon nanotube-modified polyamide acid microporous film by using an electrostatic spinning method; (3) preparation of a polyamide acid solution; (4) coating of two sides of the microporous film with the polyamide acid solution; and (5) thermal imidization of a prepared carbon nanotube-modified polyimide acid three-layer composite film. The polyimide three-layer composite film prepared in the invention is mainly applied to broaden the application scope of polyimide films in the field of electromagnetic shielding materials.

Owner:HARBIN UNIV OF SCI & TECH

Polypropylene/polyethylene/wood fiber composite and preparation method thereof

The invention provides polypropylene / polyethylene / wood fiber composite and a preparation method thereof. The composite comprises 30%-70% of polypropylene, 10%-50% of polyethylene, 10%-25% of wood fiber, 0.1%-2% of a lubricant, 0.1%-1% of an antioxidant and 3%-10% of a compatibilizer. Polypropylene, polyethylene and wood fiber as well as the lubricant, the antioxidant and the compatibilizer are added to a blender mixer separately, stirred and mixed, and a mixed material is obtained; the mixed materials are further mixed uniformly and pelletized by a double-screw extruder, and the pelletized mixed materials are dried. On one hand, the polypropylene, polyethylene and wood fiber composite prepared with the method overcomes defects of poor rigidity and notch sensitivity of polypropylene; on the other hand, the cost of the composite is substantially reduced due to use of the resourceful and recyclable wood fiber with low price, and the environment protection performance is also improved.

Owner:SHAANXI UNIV OF SCI & TECH

Deformation heat treatment method for toughening high-performance deformation rare-earth magnesium alloy

The invention relates to a deformation heat treatment method for toughening high-performance deformation rare-earth magnesium alloy, and belongs to the technical field of the alloy. The method comprises the following steps that 1) homogenizing heat treatment is performed; 2) pre-annealing heat treatment before deformation is performed, wherein pre-aging treatment is performed on an ingot blank needing to be extruded to deform at an extrusion temperature for 0.1h to 9h; 3) reverse extrusion deformation treatment is performed, wherein extrusion deformation treatment is performed on the pre-agedsample, the extrusion temperature is 400 DEG C to 450 DEG C, the extrusion ratio is 10:1 to 20:1, and the extrusion speed is 1 mm / s; and 4) aging heat treatment is performed, wherein T6 aging heat treatment is performed on the sample obtained after extrusion deformation. According to the deformation heat treatment method, the purposes that the toughness of the alloy can be obviously enhanced whilethe high strength is kept can be achieved, and the problem that the deformed magnesium alloy is high in strength and low in toughness is solved.

Owner:BEIJING UNIV OF TECH

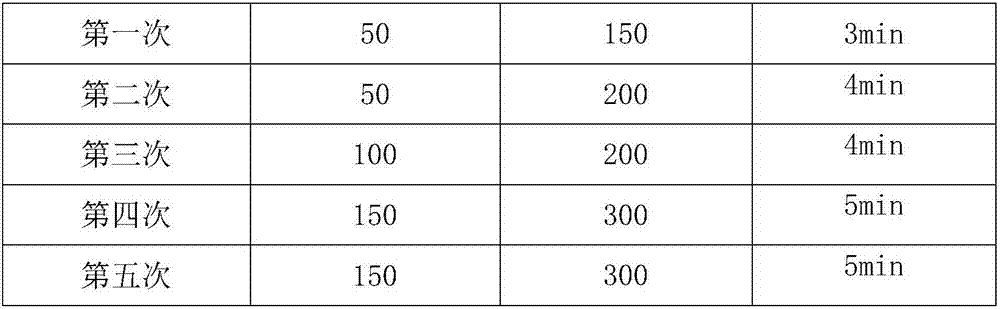

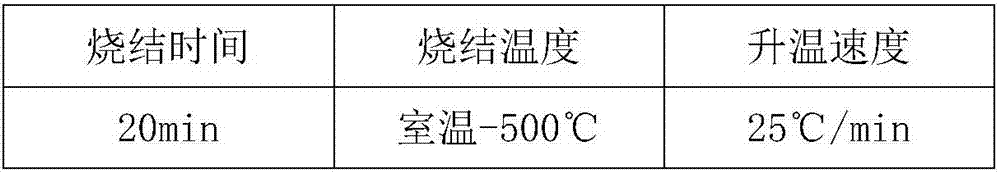

Preparation method of toughened aluminum oxide ceramic

The invention belongs to the technical field of preparation of ceramic materials, and particularly relates to a preparation method of toughened aluminum oxide ceramic. The preparation method comprisesthe following steps: by taking sludge of an aluminum profile factory as an aluminum source and taking an impurity in the sludge as a first additive, performing acid and alkali treatment and then suction filtration, thus obtaining additive impurity-containing aluminum sediments, adding the aluminum sediments into an ethyl alcohol aqueous solution, adding nano aluminum powder serving as a second additive, and performing aeration reaction and reduced pressure distillation, thus obtaining slurry; finally, performing grouting solidification in a microwave reaction manner, and after solidification,performing sintering, thus obtaining the toughened aluminum oxide ceramic. According to the preparation method, the sludge of the aluminum profile factory is used as the aluminum source, and the impurity in the sludge is used as a toughening additive and a stabilizer, so that the problem on environmental protection treatment of the sludge of the aluminum profile factory is solved, and the production cost of the aluminum oxide ceramic is also reduced.

Owner:无锡特科精细陶瓷有限公司

A kind of insulating and heat-conducting cable material and preparation method thereof

InactiveCN105837911BImprove heat resistanceImprove cold resistancePlastic/resin/waxes insulatorsElastomerPolymer science

The invention discloses an insulating heat conducting cable material. The insulating heat conducting cable material comprises the following raw materials in parts by weight: 60 to 70 parts of high-density polyethylene, 20 to 30 parts of modified polypropylene, 15 to 25 parts of heat conducting filler, 6 to 10 parts of polyolefin elastomers, 5 to 8 parts of glass fibres, 3 to 5 parts of a compatilizer, 3 to 8 parts of modified zinc borate, and 10 to 15 parts of ethylene-vinyl acetate copolymer. The insulating cable material is high in heat conductivity, high in insulating property, high in tensile strength, high in toughness, and convenient to process.

Owner:STATE GRID HENAN SHEQI POWER SUPPLY CO

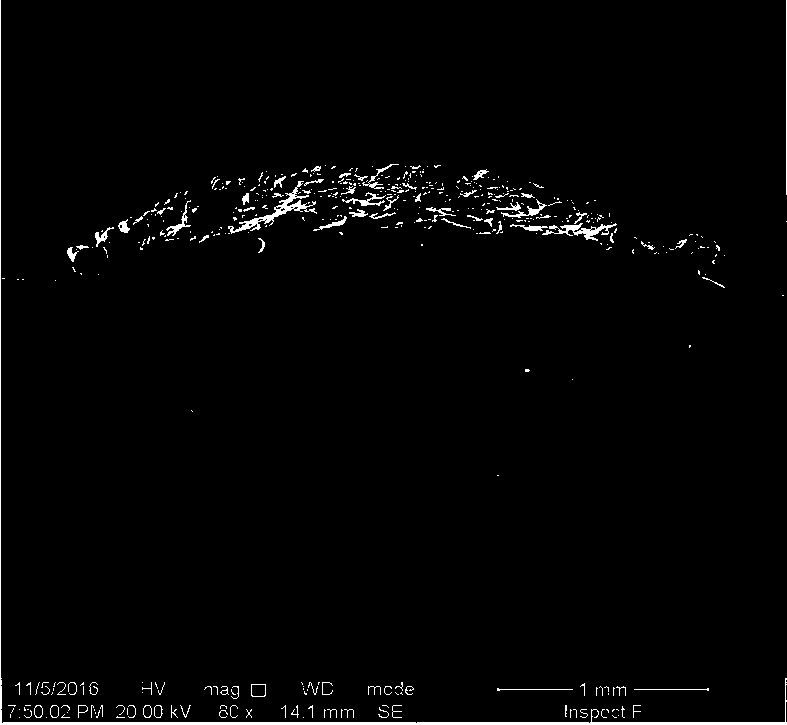

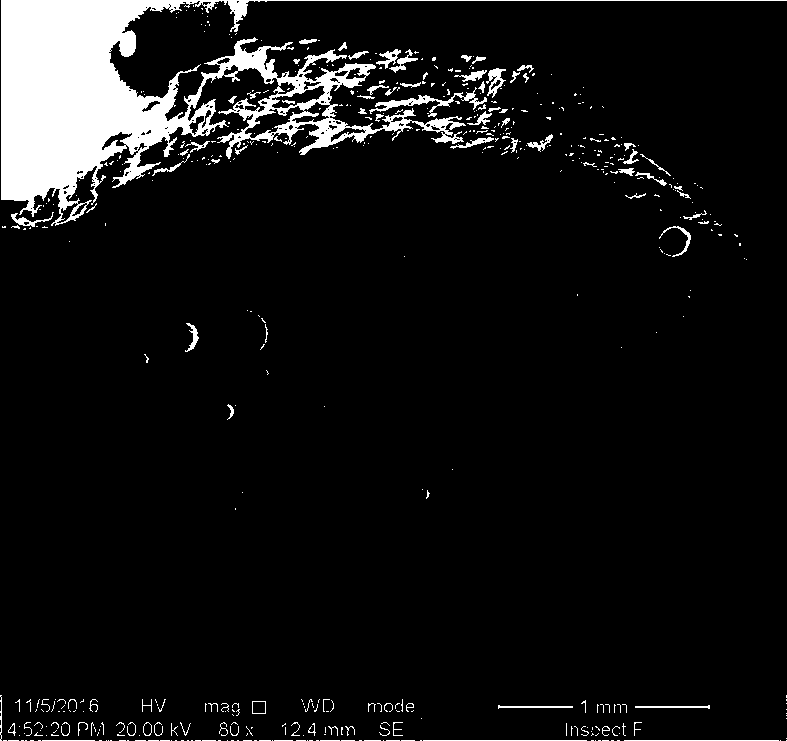

Fiber-reinforced Cf/SiC composite material welded joint

The invention discloses a fiber-reinforced Cf / SiC composite material welded joint and belongs to the field of connection of composite materials and heterogeneous metals. A carbon fiber reinforced phase on the surface of the joint disclosed by the invention is 500-1500[mu] m. The joint is prepared by the following steps: placing a Cf / SiC composite material in a NaOH solution, performing heating corrosion, performing ultrasonic cleaning, and drying the material for later use; setting a scanning speed, a scanned surface distance and laser power in software, and processing the material so as to obtain a final product. The welded joint disclosed by the invention adopts a carbon fiber reinforced structure, the carbon fiber reinforced phase exists between the Cf / SiC composite material and the metal welded joint, the carbon fiber reinforced phase at the joint is one part of a fiber woven inside the Cf / SiC composite material, the carbon fiber reinforced phase at the joint and the metal solder are wetted, the carbon fiber reinforced phase is connected with the composite material and the metal solder, and by virtue of a fiber toughening effect and a pullout effect, the purpose of toughening the welded joint is achieved.

Owner:DALIAN UNIVERSITY

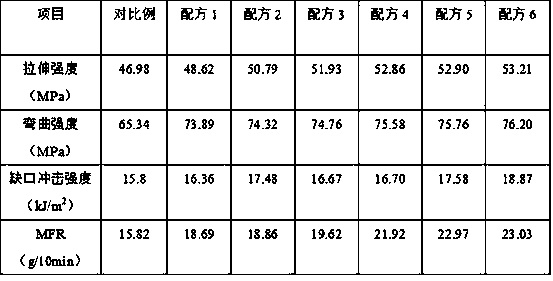

Preparation method of reinforcing and toughening lubricant specially used for ABS

The invention belongs to the technical field of lubricants, and in particular relates to a preparation method of a reinforcing and toughening lubricant specially used for ABS. The method comprises thefollowing steps: firstly nano powder is added into ethanol, a treating agent is added to modify the surface of the powder, the obtained treated nano powder is added into ethylenediamine to obtain aminated nano powder, the aminated nano powder and stearic acid are subjected to a reaction at high temperature to obtain a waxy substance, glass cellulose modified by glyceryl monostearate can be addedinto the waxy substance, extrusion granulation is performed, and therefore the reinforcing and toughening lubricant specially used for the ABS can be obtained. According to the method provided by theinvention, the prepared lubricant is added into the ABS resin, and the lubricant has good compatibility with the ABS resin, and improves the impact strength and bending strength of the ABS resin whileimproving the fluidity of the ABS resin.

Owner:常州可赛成功塑胶材料有限公司

Metal anticorrosive material, and preparation method thereof

InactiveCN107099222AGood leveling performanceGood surface toughnessAnti-corrosive paintsEpoxy resin coatingsSolventMetal

The invention provides a metal anticorrosive material, and a preparation method thereof, and belongs to the field of anticorrosive material. The metal anticorrosive material comprises following raw materials, by weight, 70 to 80 parts of epoxy resin, 20 to 30 parts of a mixed solvent, 0.5 to 3 parts of a flexibilizer, 0.2 to 0.5 part of an antifoaming agent, 4 to 16 parts of a phenolic amine epoxy hardener, 1.2 to 3.2 parts of an anti-aging agent, 0.1 to 1.5 parts of an anti-oxidant, 0.1 to 0.8 part of a lubricant, 0.5 to 1.3 parts of a thixotropic agent, 1 to 3 parts of a pigment, and 15 to 25 parts of a filling material. The preparation method comprises following steps: 1, raw material weighing; 2, dissolving; 3, blending; 4, defoaming; and 5, impurity removing. The metal anticorrosive material is excellent in levelability, thixotropy, and impervious performance, high in surface toughness and adhesive force, is more friendly to the environment, is longer in service life; and no pin hole is formed.

Owner:合肥市晨雷思建筑材料科技有限公司

Preparation method of modified dicyclopentadiene type cyanate ester resin with low hygroscopicity

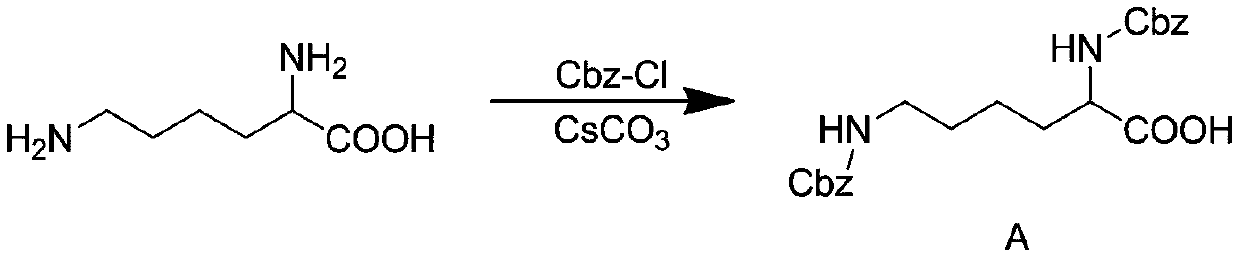

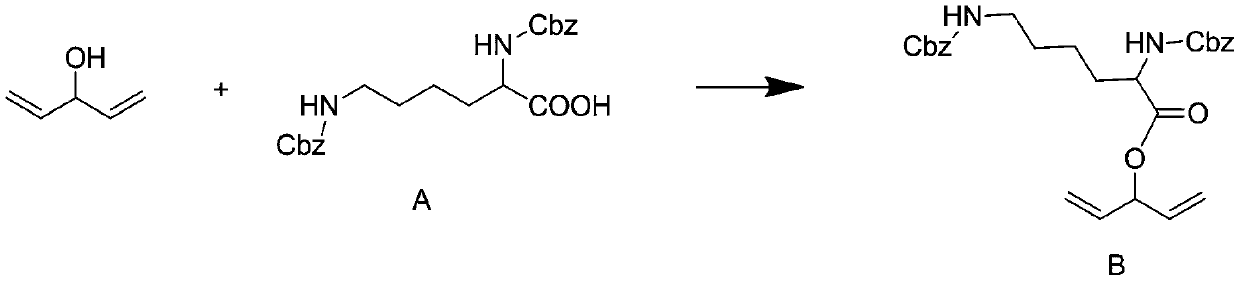

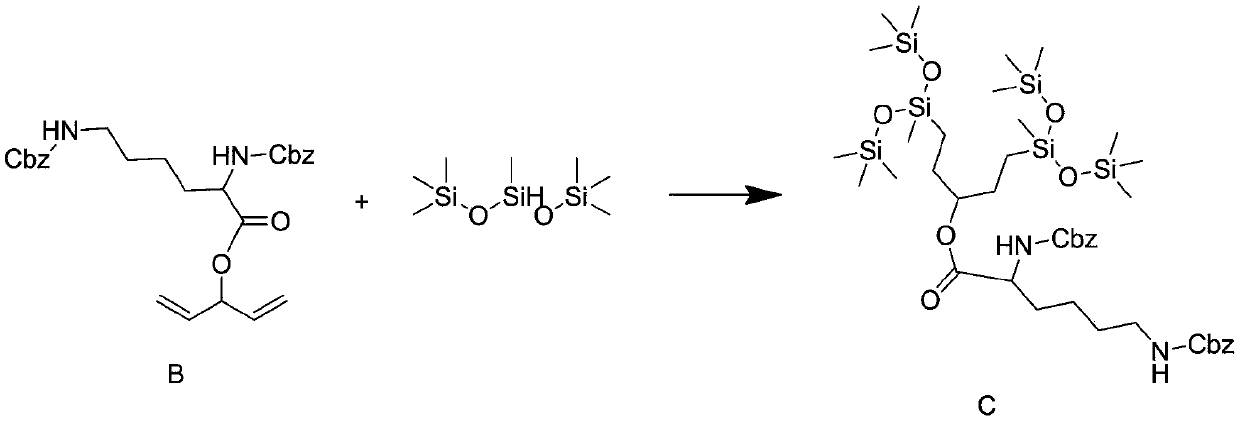

ActiveCN110372861AWater resistantTo achieve the purpose of tougheningSilicon organic compoundsBulk chemical productionWater resistantToughening

The invention discloses a preparation method of a modified dicyclopentadiene type cyanate ester resin with low hygroscopicity. Firstly, a modifier with toughening and water-resistant properties is prepared, the modifier has two amino groups, and can react with -OCN groups of a dicyclopentadiene type cyanate ester to carry out front-end polymerization, a soft segment is introduced to achieve the purpose of toughening, and at the same time, the modifier contains a large amount of organosilicone, the organosilicone is introduced by a block bonding manner, the organosilicone has a stable dielectric constant and dielectric loss in a relatively wide temperature range, has relatively high flexibility, and can greatly improve toughness of the cyanate ester, and at the same time, the organosiliconehas good oxidation resistance and low surface energy, the organosilicone is embedded in a space networking resin, and when the resin is cured, silicon atoms are released to the surface of the resin due to low surface energy of the organosilicone, so that the modified cyanate ester resin has good water resistance, and the problem that hygroscopicity is increased during a resin toughing process issolved.

Owner:YANGZHOU TECHIA MATERIAL CO LTD

Surface coating for aluminum template as well as preparation method and application method of surface coating

InactiveCN112795270AImprove impact performanceImprove tensile propertiesEpoxy resin coatingsFirming agentEthyl acetate

The invention relates to the technical field of aluminum template surface coatings, and in particular, relates to a surface coating for an aluminum template as well as a preparation method and an application method of the surface coating. The surface coating comprises the following raw materials in parts by weight: 100-200 parts of ethyl acetate, 100-200 parts of modified epoxy resin, 50-100 parts of organic silicon resin, 20-40 parts of alumina powder, 10-30 parts of a dispersing agent, 10-15 parts of a flatting agent, 10-20 parts of silicone oil, 5-10 parts of an organic silicon defoaming agent, 5-10 parts of dipropylene glycol butyl ether and 10-20 parts of a curing agent. The surface coating disclosed by the invention can prevent concrete from chemically reacting with the aluminum template, has a good protection effect on the surface of the aluminum template, can improve the smoothness of a wall surface, is easy to clean and reuse the aluminum template, and improves the use frequency of the aluminum template.

Owner:重庆新久融科技有限公司

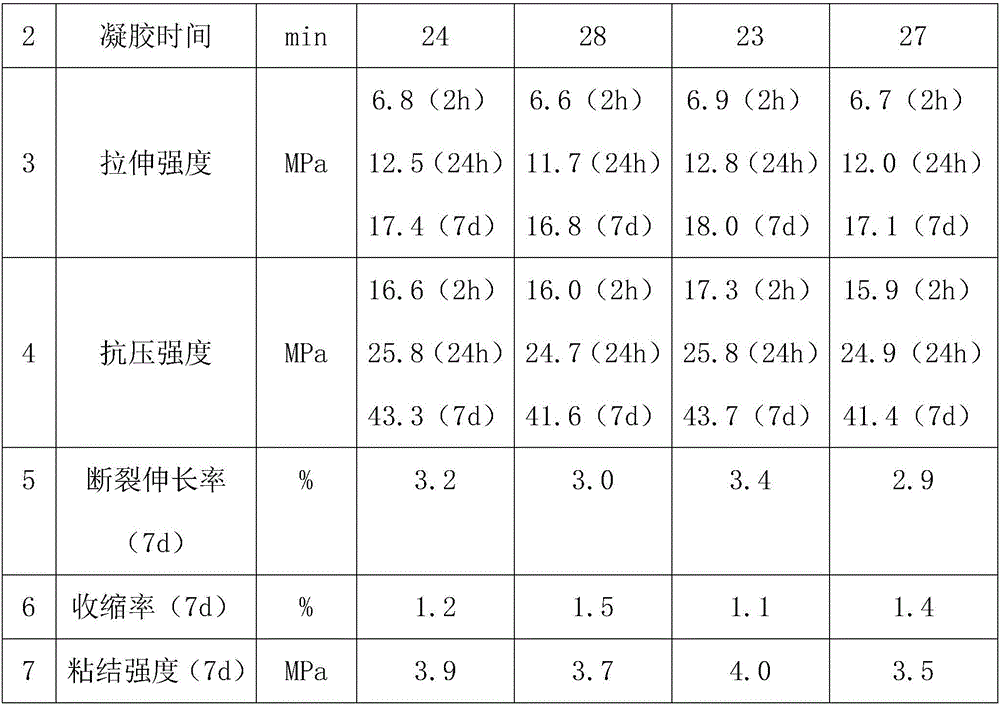

Ballastless track CA (cement and asphalt) mortar layer damage repair resin material and preparation method thereof

The invention relates to a ballastless track CA (cement and asphalt) mortar layer damage repair resin material and a preparation method thereof, belonging to the field of high-speed railway engineering materials. The resin material is prepared from the following raw materials in parts by weight: 100 parts of epoxy resin, 30-60 parts of furfural, 20-40 parts of acetone, 0.1-0.3 part of saturated ammonia water, 3-10 parts of toughener, 1-3 parts of accelerator, 0.5-2 parts of coupling agent, 0.5-2 parts of surfactant and 20-50 parts of composite amine curing agent. The obtained product has the characteristics of high binding force and high corrosion resistance in the common epoxy-furfural-acetone resin grouting material, also has the advantages of high permeability, environment friendliness, low toxicity, higher glass transition temperature, low shrinkage, high normal-temperature curing rate and the like, and is applicable to wet basal plane construction.

Owner:北京中德新亚建筑技术有限公司

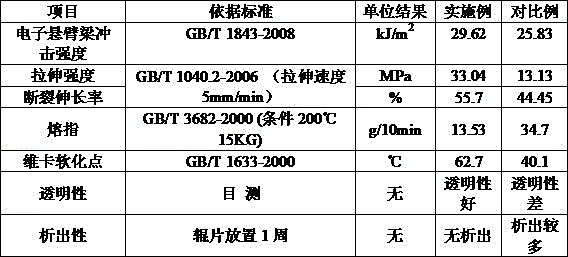

High-impact-strength transparent PVC/MBS alloy material and preparation method thereof

InactiveCN106589690ATo achieve the purpose of tougheningLower glass transition temperatureProcedure AgentsPlasticizer

The invention discloses a high-impact-strength transparent PVC / MBS alloy material and a preparation method thereof. The alloy material comprises, by mass, 100 parts of PVC resin, 50-120 parts of MBS resin, 4.0-6.0 parts of stabilizer, 4.0-8.0 parts of impact modifier, 3.0-5.0 parts of processing auxiliary, 1.0-3.0 parts of weather-resistant agent and 5.0-25.0 parts of inorganic filler. Being mixed evenly according to a certain process by means of a high cooling mixing unit, the raw materials are extruded through a conical dual-screw extruder and granulated. The formula is further optimized, impact resistance of PVC is greatly improved, and transparency is also improved. The situation that a plasticizer is used in the prior art for changing the plasticity of PVC is abandoned, MBS and PVC are mixed to adjust the plasticity of PVC, and the prepared PVC / MBS alloy material can be used in the aspect of transparent PVC profiles, sheets, PVC transparent environment-friendly hoses, transparent packages, daily stationery plastic and the like.

Owner:WUHU TIANXIONG NEW MATERIAL TECH

Thermo-mechanical treatment method for toughening high-performance wrought rare earth aluminum alloy

InactiveCN110952049AImprove alloy elongationImprove high strength and low toughnessAusformingMechanical Treatments

The invention provides a thermo-mechanical treatment method for toughening a high-performance wrought rare earth aluminum alloy, and mainly relates to the technical field of alloys. The thermo-mechanical treatment method for toughening the high-performance wrought rare earth aluminum alloy is characterized in that the aluminum alloy comprises 0.6wt%-0.7wt% of magnesium, 0.6wt%-0.7wt% of silicon, 0wt%-0.8wt% of erbium and the balance of aluminum and inevitable impurities. The heat treatment method comprises the steps of (1) homogenizing heat treatment; (2) preheating treatment; and (3) hot extrusion deformation treatment. The beneficial effects of the invention are that related elements are selected, the wrought rare earth aluminum alloy mainly containing high-solid-solubility elements (Er,Mg, Si and the like) is subjected to preheating treatment and hot extrusion treatment, the elongation of the alloy is remarkably improved on the premise that the yield strength and the tensile strength of the alloy are not reduced, and the current situation that the existing conventional rare earth aluminum alloy is high in strength and low in toughness is improved.

Owner:SHANDONG NANSHAN ALUMINUM

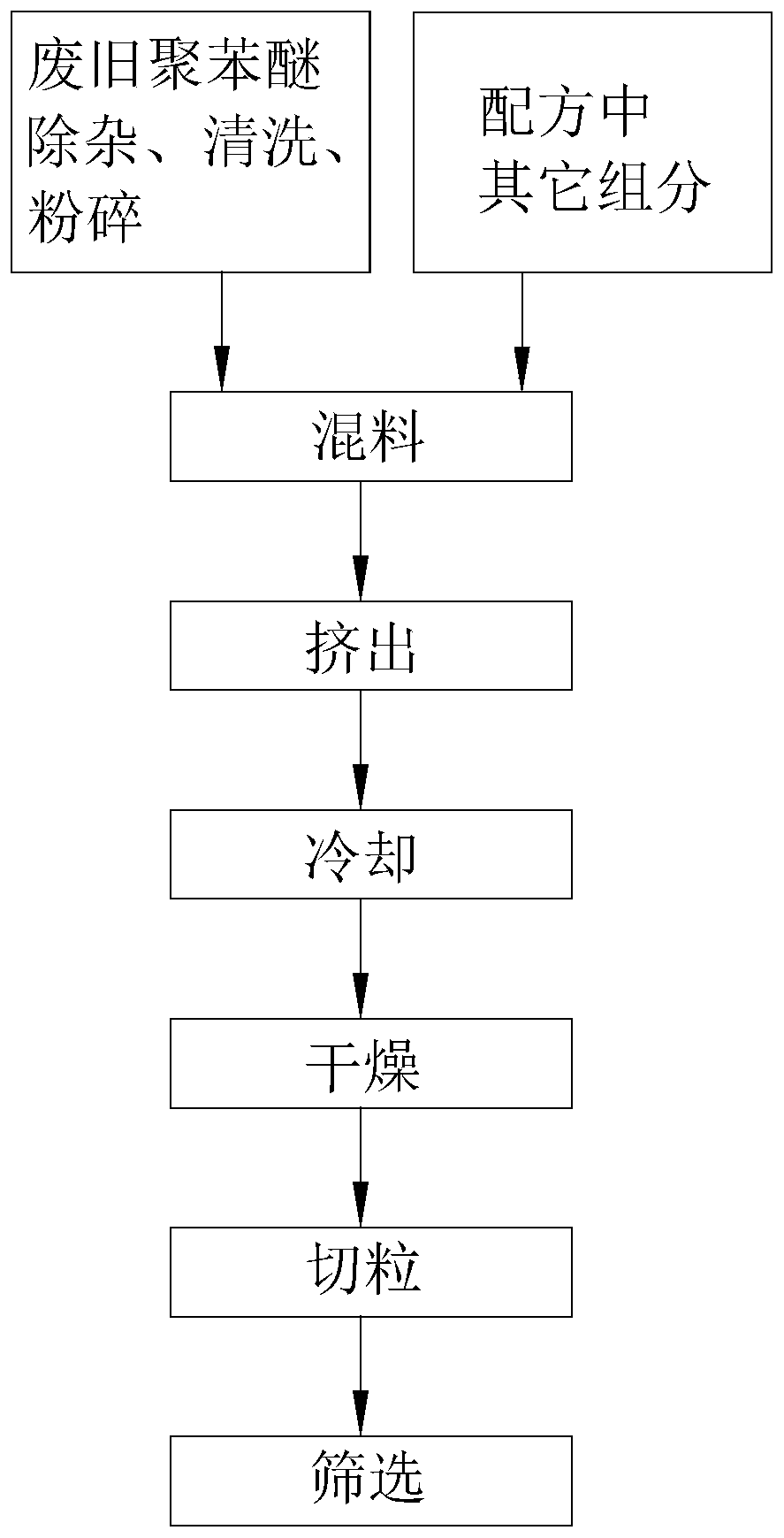

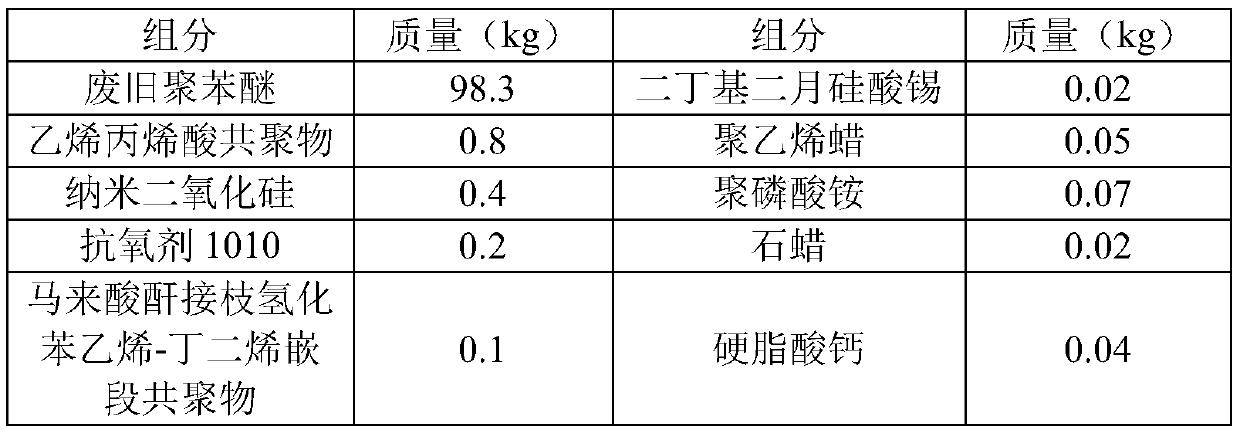

Polyphenyl ether reclaimed material and preparation process thereof

The invention relates to a polyphenyl ether reclaimed material and a preparation process thereof, and relates to the technical field of reclaimed materials. The polyphenyl ether reclaimed material comprises the following components in percentages by mass: 97.1-98.3% of waste polyphenyl ether, 0.8-1.2% of an ethylene-acrylic acid copolymer, 0.4-0.6% of nanometer silicon dioxide, 0.2-0.5% of an antioxidant, 0.1-0.3% of a toughening agent, 0.02-0.05% of a heat stabilizer, 0.03-0.06% of a lubricating agent, 0.05-0.1% of a flame retardant, 0.01-0.03% of paraffin and 0.03-0.05% of calcium stearate.The polyphenyl ether reclaimed material prepared by using the method provided by the invention is excellent in mechanical properties, and the service life of a product prepared from the polyphenyl ether reclaimed material can be prolonged. The preparation process disclosed by the invention has the following advantages: the prepared polyphenyl ether reclaimed material is stable in performance; andthe preparation process is simple and convenient to operate.

Owner:日彩复合塑料(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com