High-impact-strength transparent PVC/MBS alloy material and preparation method thereof

A high-impact, PVC resin technology, applied in the field of high-impact transparent PVC/MBS alloy material and its preparation, can solve problems such as surface fogging, poor low-temperature brittleness, and failure to pass the test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

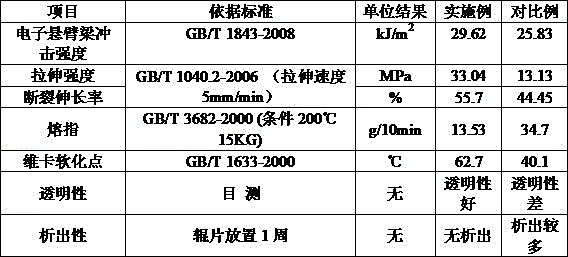

Examples

Embodiment 1

[0028] A high-impact transparent PVC / MBS alloy material and a preparation method thereof, comprising mixing the following materials and proportions in parts by mass:

[0029] PVC resin 100 parts

[0030] MBS resin 100 parts

[0031] Environmental stabilizer 5 parts

[0032] Impact modifier 5 parts

[0033] Processing aid 4 parts

[0034] Weathering agent 2 parts

[0035] 10 parts of inorganic filler.

[0036] Further, the environment-friendly stabilizer is a calcium-zinc composite stabilizer.

[0037] Further, the impact modifier is an acrylate impact modifier.

[0038] Further, the processing aid is compounded by ACR-201 and EBS wax in a weight ratio of 8:2.

[0039] Further, the weather resistance agent is compounded by antioxidant 1010, hindered amine light stabilizer 770, and ultraviolet absorber UV-531 in a weight ratio of 5:2:3.

[0040] Further, the inorganic filler is nanometer calcium carbonate with a particle size of 50nm.

[0041] Further, the PVC resin can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com