Polyphenyl ether reclaimed material and preparation process thereof

A preparation process and polyphenylene ether technology are applied in the field of polyphenylene ether recycled material and its preparation process, and can solve the problems of reduced impact strength, tensile strength and elongation at break mechanical properties, reduced service life, and wide molecular weight distribution. , to achieve the effect of increased toughness, reduced pollution and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

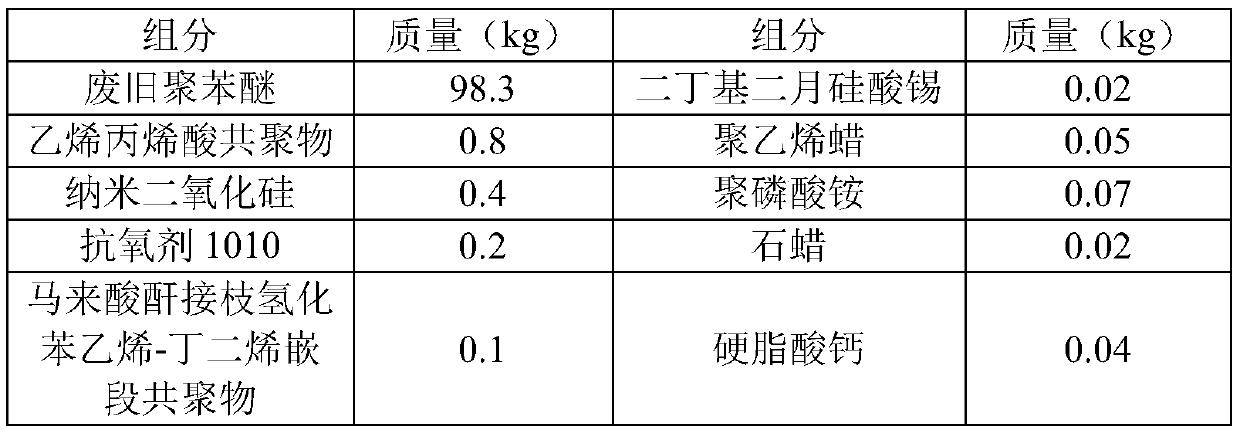

[0039] Table 1 is each component and its quality of a kind of polyphenylene ether recycled material of embodiment 1

[0040]

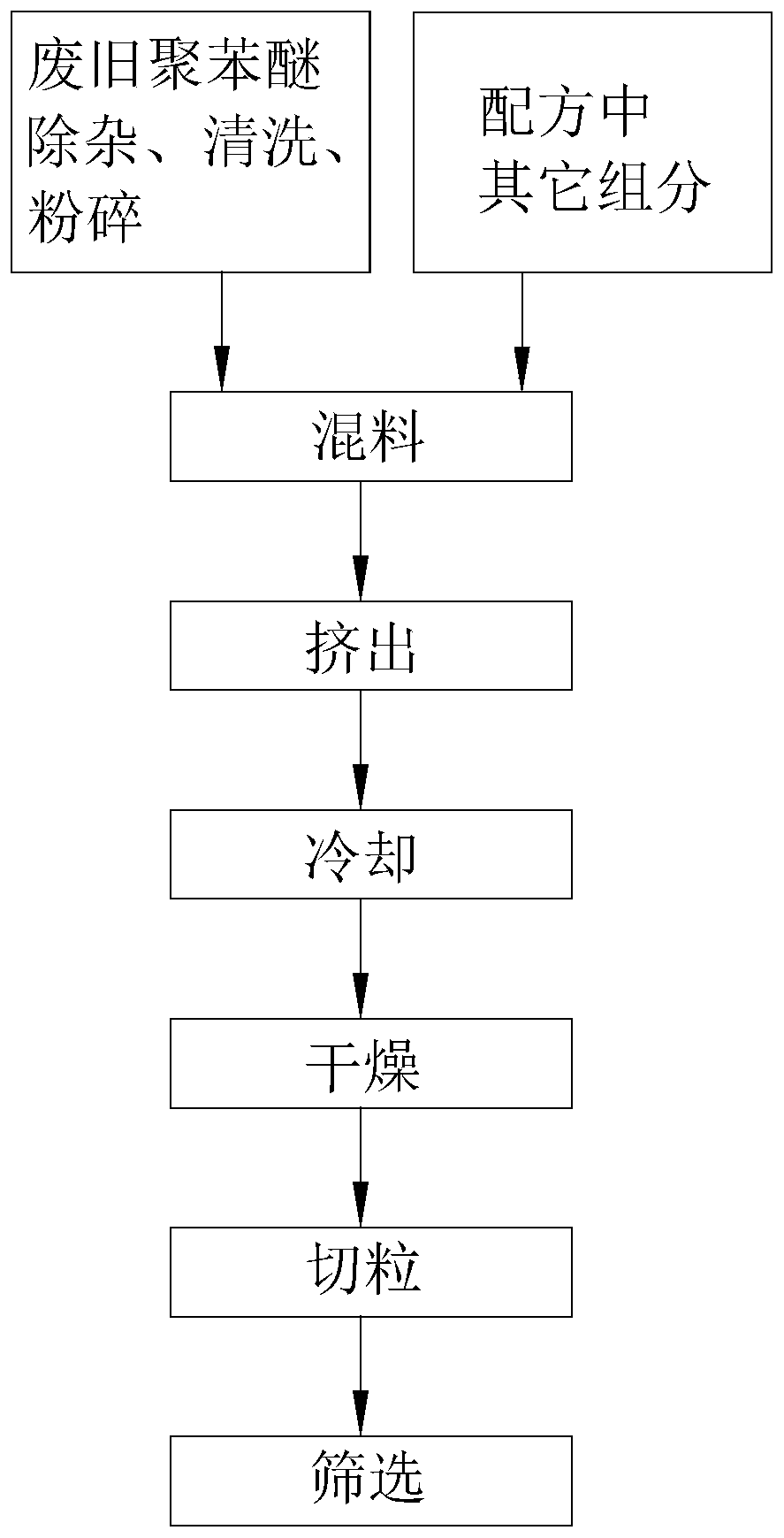

[0041] A preparation process of polyphenylene ether regenerated material, specifically comprising the steps of:

[0042] Step 1, mixing materials: waste and old polyphenylene ether is removed and cleaned, then pulverized and mixed with other substances in the formula of Example 1 in a mixer for 5 minutes to obtain a mixed material;

[0043] Step 2. Extrusion: Transport the uniformly mixed mixture in step 1 to the extruder for uniform mixing, and then extrude. The temperature of the extruder is set to 245°C in the first zone, 250°C in the second zone, and 260°C in the third zone. The fourth zone is 265°C, the fifth zone is 270°C, the sixth zone is 275°C, the seventh zone is 275°C, the eighth zone is 280°C, and the head temperature is 285°C;

[0044] Step 3. The cooled and extruded product is cooled by a water tank, the temperature of the front end o...

Embodiment 2

[0048] Table 2 is each component and its quality of a kind of polyphenylene ether recycled material of embodiment 2

[0049]

[0050]

[0051] A preparation process of polyphenylene ether regenerated material, specifically comprising the steps of:

[0052] Step 1, mixing materials: waste and old polyphenylene ether was removed, cleaned, and then pulverized and mixed with other substances in the formula of Example 2 in a mixer for 15 minutes to obtain a mixed material;

[0053] Step 2. Extrusion: Transport the mixed material uniformly mixed in step 1 to the extruder for uniform mixing, and then extrude. The fourth zone is 255°C, the fifth zone is 255°C, the sixth zone is 255°C, the seventh zone is 260°C, the eighth zone is 260°C, and the head temperature is 265°C;

[0054] Step 3. The cooled and extruded product is cooled by a water tank, the temperature at the front end of the water tank is 40°C, and the back end is 30°C, and then the water on the surface of the extrude...

Embodiment 3

[0058] Table 3 is each component and its quality of a kind of polyphenylene ether regenerated material of embodiment 3

[0059]

[0060] A preparation process of polyphenylene ether regenerated material, specifically comprising the steps of:

[0061] Step 1. Mixing: waste polyphenylene ether is removed and cleaned, then pulverized and mixed with other substances in the formula of Example 3 in a mixer for 10 minutes to obtain a mixed material;

[0062] Step 2. Extrusion: Transport the uniformly mixed material in step 1 to the extruder for even mixing, and then extrude. The fourth zone is 275°C, the fifth zone is 275°C, the sixth zone is 275°C, the seventh zone is 280°C, the eighth zone is 280°C, and the temperature of the machine head is 285°C;

[0063] Step 3. The cooled and extruded product is cooled in a water tank, the temperature at the front end of the water tank is 35°C, and the back end is 25°C, and then the moisture on the surface of the extruded product is removed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com