Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Improve low temperature brittleness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength steel sheet excellent in workability and cold brittleness resistance, and manufacturing method thereof

InactiveCN102828106AEasy to processImprove low temperature brittlenessFurnace typesHeat treatment furnacesMartensiteAustenite

The invention relates to a steel sheet having a tensile strength of 1180 MPa or more, the steel sheet excels in workability and cold brittleness resistance. The high-strength steel sheet contains 0.10% to 0.30% of C, 1.40% to 3.0% of Si, 0.5% to 3.0% of Mn, 0.1% or less of P, 0.05% or less of S, 0.005% to 0.20% of Al, 0.01% or less of N, 0.01% or less of O, as well as Fe and inevitable impurities. The steel sheet has: (i) a ferrite volume fraction of 5% to 35% and a bainitic ferrite and / or tempered martensite volume fraction of 60% or more; (ii) a MA constituent volume fraction of 6% or less (excluding 0%); and (iii) a retained austenite volume fraction of 5% or more.

Owner:KOBE STEEL LTD

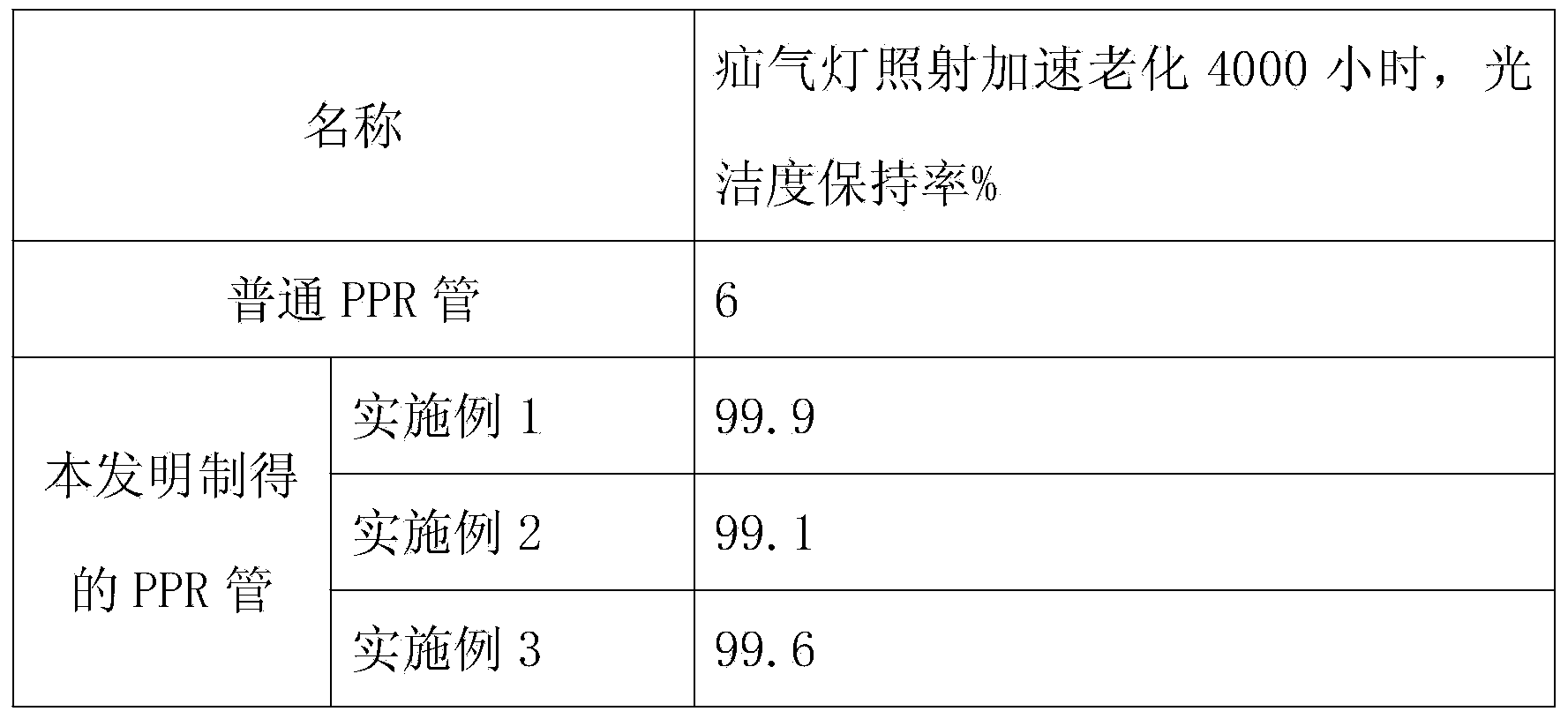

RRP (polypropylene random) temperature-resistant water pipe

InactiveCN104059300AImprove creep performanceGood weather resistanceGeneral water supply conservationFlexible pipesLinear low-density polyethyleneWeather resistance

The invention relates to the technical field of plastic product processing, particularly a RRP (polypropylene random) temperature-resistant water pipe. The RRP temperature-resistant water pipe is prepared from the following raw materials in parts by weight: 60-80 parts of carrier resin, 10-30 parts of LLDPE (linear low-density polyethylene), 1-6 parts of butyl rubber and 3-8 parts of special coloring master batch for RRP pipes. The temperature-resistant pipe has the advantages of high toughness, favorable weather resistance, wide application range and high safety, and can be used as both a cold-water pipe and a hot-water pipe.

Owner:BLUESTAR CHENGDU NEW MATERIALS

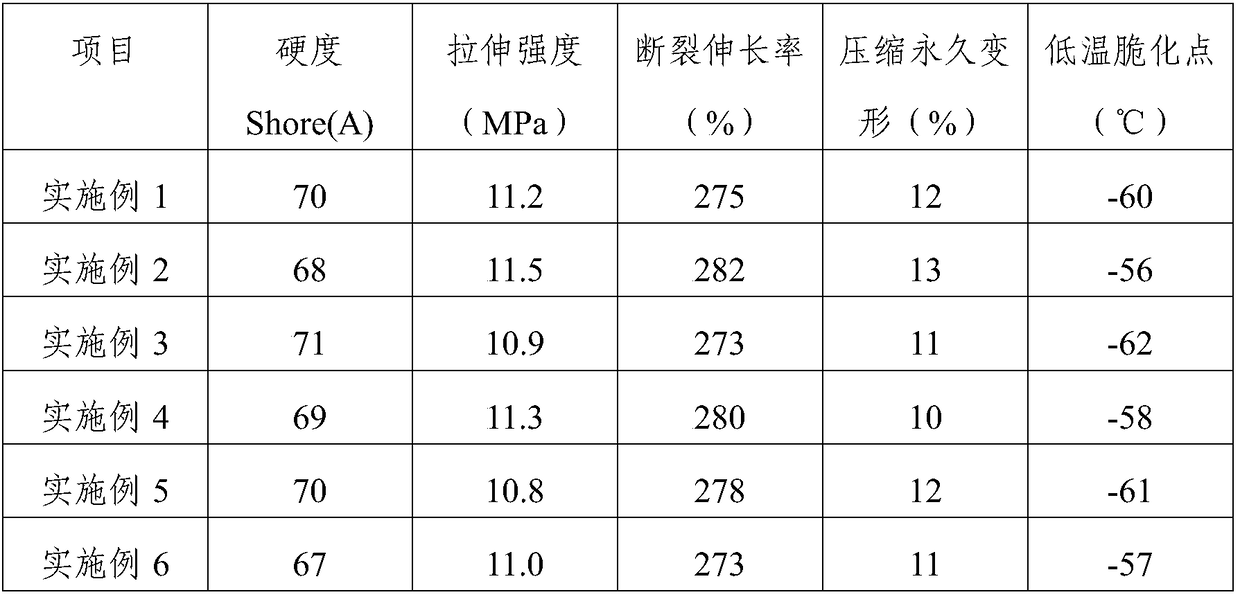

Self-lubricating high-wear resistance oil seal and production method thereof

InactiveCN102061046AImprove wear resistanceReduce coefficient of frictionEngine sealsDomestic articlesPhysical agingWeather resistance

The invention provides a self-lubricating high-wear resistance oil seal and a production method thereof. The self-lubricating high-wear resistance oil seal is characterized by being prepared from 60-80 parts by weight of fluorous rubber, 20-40 parts by weight of polytetrafluoroethylene, 1.5-2.5 parts by weight of p-phenylenediamine aging resister, 1.5-2.5 parts by weight of dihyaroquinoline aging resister, 3-6 parts by weight of physical aging resister, 5-10 parts by weight of plasticizing agent, 35-48 parts by weight of strengthening agent, 2-6 parts by weight of slipping agent, 2-4 parts of dispersion agent, 1.5-2.5 parts by weight of vulcanizing agent, 5-8 parts by weight of activating agent, 1-2 parts by weight of stearic acid and 1.6-2.0 parts by weight of accelerating agent. The self-lubricating high-wear resistance oil seal obtained by the invention can be adapted to the high speed of an engine and a crankshaft, has the advantages of high wear resistance, small friction coefficient, high-low temperature resistance, weather resistance, favorable heat resistance and long service life and ensures that the oil seal does not leak oil when an automobile is driven for at least 0.3 million kilometer.

Owner:SHANGHAI ZHONGLI AUTO PARTS

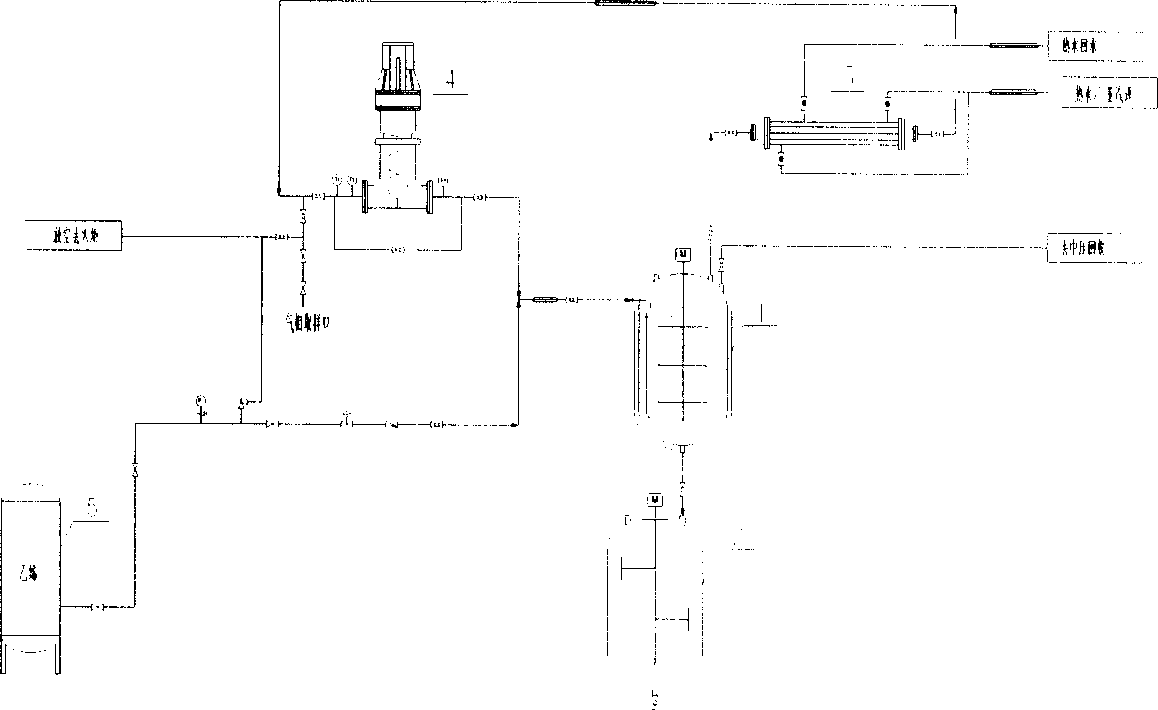

Production and reactor for polypropylene

Production of polypropylene and its reactor are disclosed. The process is carried out by propylene homopolymerization reacting for some time in polymerizer, and inducing ethane gas from external-circulation system into polymerizer to have copolymerization reaction. The external-circulation system consists of steam heat exchanger, circulation fan and related pipeling sluice valve. It costs low, has better impact strength and quality, more variety and can improve low-temperature brittleness. It can be used for small and moderate intermittent polypropylene producer.

Owner:南京金陵塑胶化工有限公司

Environment-friendly asphalt reclaiming agent and preparing method and using method thereof

The invention relates to asphalt reclaiming agents and particularly discloses an environment-friendly asphalt reclaiming agent and a preparing method and a using method thereof. The environment-friendly asphalt reclaiming agent is prepared from, by mass, 15-30% of waste engine oil, 15-25% of waste rubber powder, 45-55% of aromatic light oil, 0.1-1% of a petizing agent, 3-8% of petroleum resin and 0.1-0.5% of an anti-ageing agent. The preparing method of the environment-friendly asphalt reclaiming agent comprises the steps that the waste engine oil, the waste rubber powder and the aromatic light oil are mixed, the petizing agent is added after swelling is achieved at the normal temperature, the mixture is stirred evenly, and a mixed solution is obtained; the mixed solution is subjected to microwave irradiation, and a thick solution is obtained; finally, the petroleum resin and the anti-ageing agent are added into the thick solution, the mixture is mixed evenly, and the environment-friendly asphalt reclaiming agent is obtained. The adding quantity of the environment-friendly asphalt reclaiming agent accounts for 7-9% of waste asphalt by mass when the environment-friendly asphalt reclaiming agent is used for reclaiming waste asphalt pavements. The raw material ingredients are low in price, cost of the raw materials is reduced, and environment production is facilitated.

Owner:CHANGAN UNIV

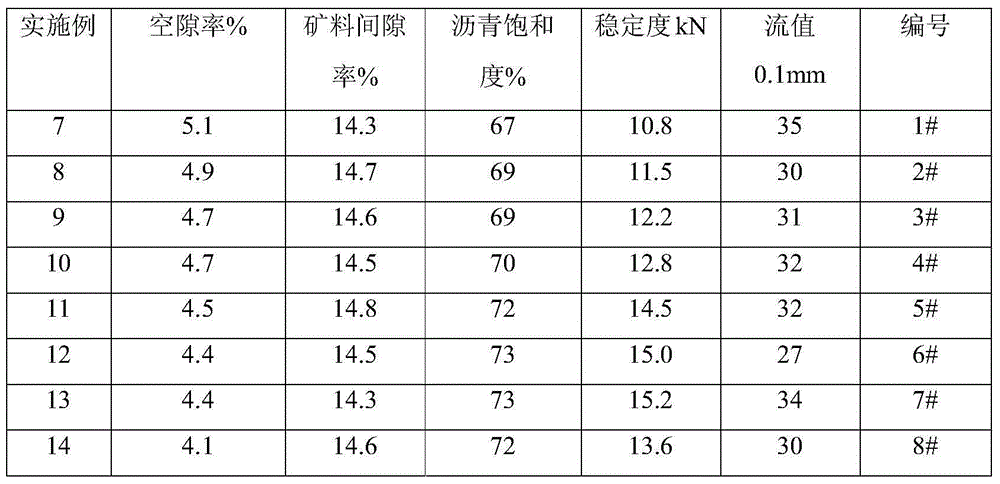

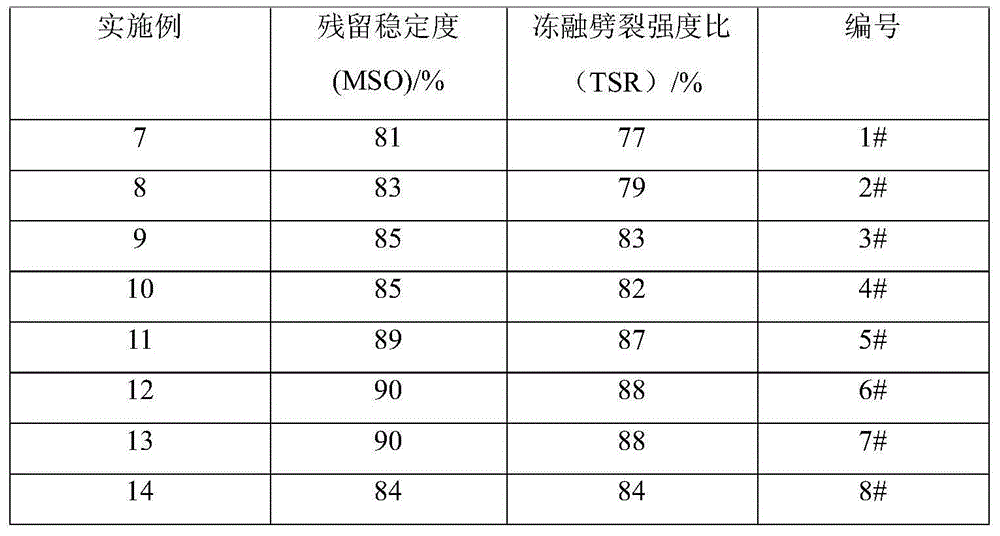

Bituminous mixture using DVS (direct vat set) high-adhesion modifier and preparation method thereof

ActiveCN104693821AControl "Secondary Pollution"Low costBuilding insulationsBulk chemical productionCrack resistancePolymer science

The invention relates to a bituminous mixture using a DVS (direct vat set) high-adhesion modifier and a preparation method thereof. The bituminous mixture is prepared from aggregates, a DVS high-adhesion bituminous mixture modifier and matrix asphalt by mixing, wherein the modifier is prepared from high-desulfurization-degree reclaimed rubber, modified high-temperature coal tar pitch and a skeleton proppant by stirring and extruding. Waste rubber is deeply activated under the high temperature and high shearing action of a twin screw extruder, so that the high-desulfurization-degree reclaimed rubber is obtained; then, the mixture of the modified high-temperature coal tar pitch modified by rubber pyrolysis oil, the high-desulfurization-degree reclaimed rubber and the skeleton proppant is fully mixed by using a screw, and then extruded and granulated so as to obtain the DVS high-adhesion bituminous mixture modifier; and finally, the modifier, the aggregates and the matrix asphalt are mixed so as to obtain a DVS high-adhesion bituminous mixture. The bituminous mixture disclosed by the invention has excellent water damage resistance, good high-temperature rutting resistance and low-temperature crack resistance.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

Heating-processing technology for improving mechanical property of high-intensity extra-thick plate

ActiveCN102061373AImprove mechanical propertiesHigh strengthFurnace typesHeat treatment furnacesMechanical propertyMaterials science

The invention provides a heating-processing technology for improving the mechanical property of a high-intensity extra-thick plate, and the heating-processing technology can be used for improving the mechanical property of a normalizing high-intensity extra-thick plate and improving the normalizing qualification rate of the extra-thick plate. A water-cooling working procedure is added in the normalizing process of the extra-thick plate and is used for replacing air cooling for normalizing; the normalizing cooling speed is quickened, the phase-transition temperature of a steel plate is lowered, and the growth of microalloy element carbonitride can be inhibited, so that a small quantity of ferrite and a large quantity of thinner perlite structure can be obtained, and intensity, plasticity, low temperature brittleness and the like can be improved so as to guarantee the intensity of the steel plate and improve the qualification rate of the steel plate.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Method for preparing low-temperature cross-linked emulsified SBS pitch modifier

InactiveCN103965492AReduce pollutionImprove low temperature brittlenessBuilding insulationsCross-linkMaterials preparation

The invention discloses a method for preparing a low-temperature cross-linked emulsified SBS pitch modifier. The method comprises the following steps: material preparation, sol preparation, liquid soap preparation, latex preparation, finished product preparation and the like. The low-temperature cross-linked emulsified SBS pitch modifier obtained according to the method has the advantages that the high-temperature flexibility and low-temperature fragility of pitch can be effectively improved; the softening point and low-temperature ductility of pitch can be improved.

Owner:安徽路达泰克沥青新材料有限公司

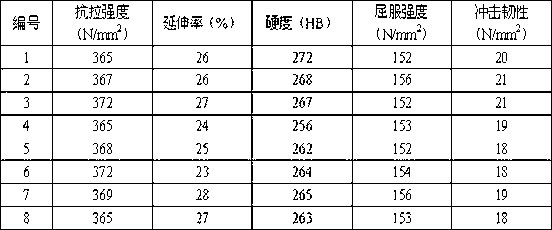

Casting method of low temperature resistant iron cushion plate for high speed railway buckling part

The invention discloses a casting method of a low temperature resistant iron cushion plate for a high speed railway buckling part. The method comprises smelting, spheroidizing inoculation and casting, a smelting material is made of cast iron and low-carbon steel which meets requirements that P: <=0.04% and S: <=0.03%, smelted iron water is subjected to nodulizing and inoculation and then is subjected to casting molding, and hot processing is conducted to obtain the required iron cushion plate. According to the casting method, the quantity of ferrites can be increased, the low-temperature toughness is improved, and the anti-impact performance of the iron cushion plate can be improved further.

Owner:中原利达铁路轨道技术发展有限公司

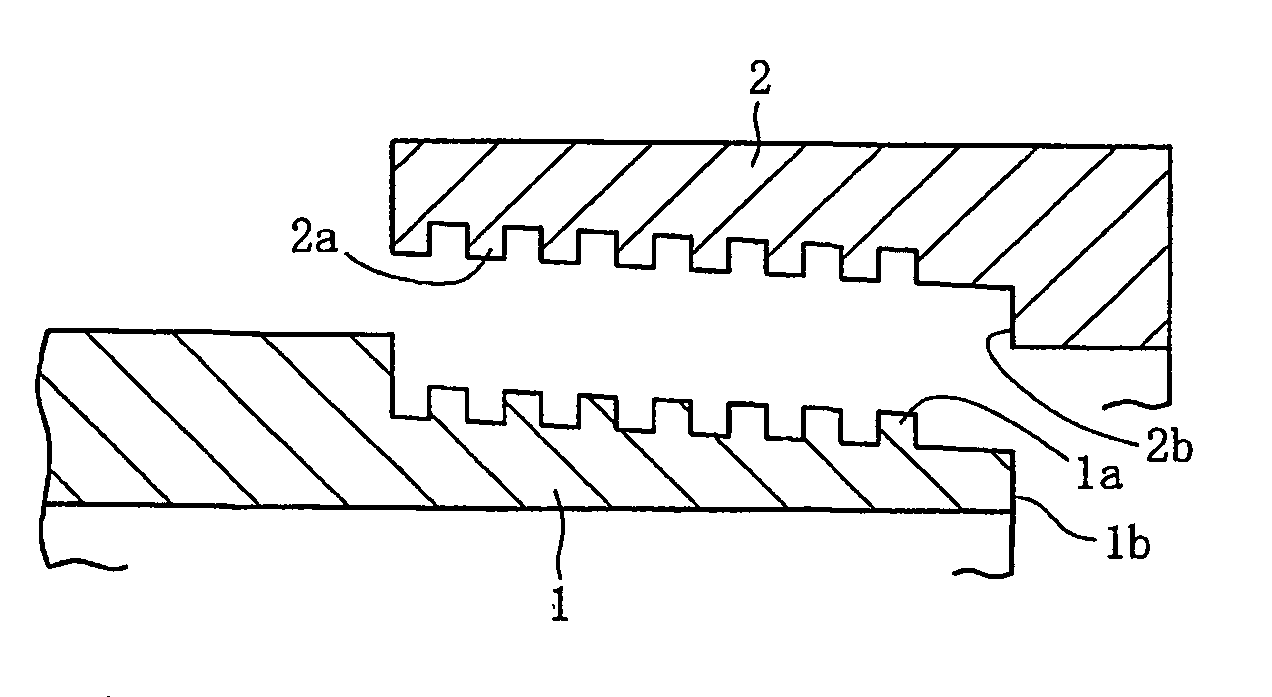

Threaded joint for steel pipes

InactiveUS20080217916A1Solve the lack of resistanceImprove low temperature brittlenessSleeve/socket jointsPipe supportsCopper platingAlloy

A threaded joint for steel pipes comprised of a pin 1 and a box 2 each having a threaded portion (1a, 2a) and an unthreaded metal contact portion (1b, 2b) exhibits adequate leakage resistance and galling resistance when used for makeup of oil country tubular goods with application of a green dope or even without any dope. The threaded joint has a first plating layer of Sn—Bi alloy plating or Sn—Bi—Cu alloy plating formed on the contact surface of at least one of the pin 1 and the box 2. The first plating layer may have a second plating layer selected from Sn plating, Cu plating, and Ni plating on its lower side and at least one layer of a lubricating coating, and particularly a solid lubricating coating, on its upper side.

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

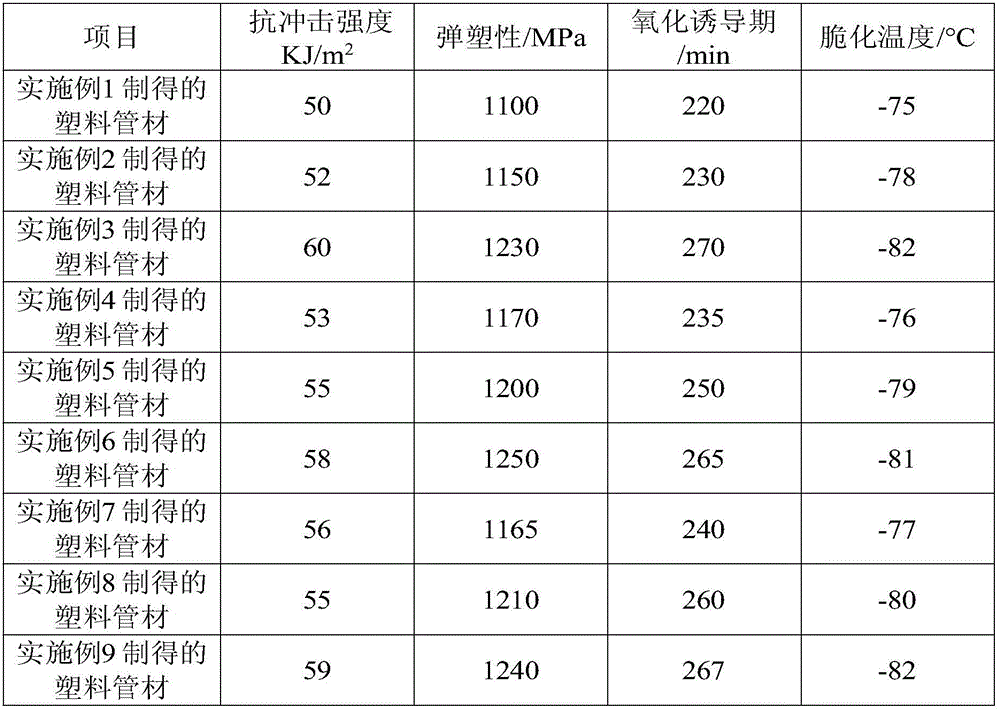

Steel wire mesh framework reinforced polypropylene composite pipe and preparation method and application of steel wire mesh framework reinforced polypropylene composite pipe

ActiveCN112096973AImprove low temperature impact resistanceSolve the problem of low temperature brittlenessCoatingsRigid pipesPolypropylene compositesElastomer

The invention relates to a steel wire mesh framework reinforced polypropylene composite pipe and a preparation method and application of the steel wire mesh framework reinforced polypropylene composite pipe. A polypropylene core pipe, a steel wire reinforced layer, a first adhesive resin layer, a second adhesive resin layer and a polyethylene outer layer are sequentially arranged from inside to outside. The first adhesive resin layer is composed of maleic anhydride grafted polypropylene, polypropylene, a flexibilizer, an adhesive force regulator and an anti-aging auxiliary agent. The second adhesive resin is composed of an elastomer, polypropylene, polyethylene and an anti-aging auxiliary agent. The problems that the low-temperature brittleness is large when polypropylene is independentlyused as a base body pipe and the heat resistance is poor when polyethylene is independently used as a base body are solved, the using temperature of a conveying medium is increased, and the technicalrisk that lantern damage is caused by bulging and wire drawing when an existing polypropylene steel wire mesh framework composite pipe conveys a medium at the temperature of 40 DEG C or above is reduced.

Owner:SHANDONG DONGHONG PIPE IND

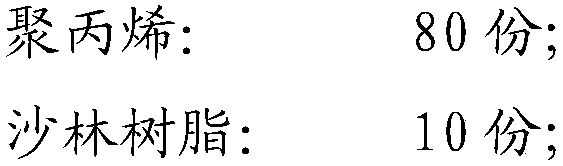

Metal appearance-imitated polypropylene-surlyn composite material and preparation method thereof

InactiveCN108342015AGood low temperature impact propertiesImprove low temperature brittlenessPolypropyleneSpecial effects

The invention relates to a metal appearance-imitated polypropylene-surlyn composite material and a preparation method thereof. The metal appearance-imitated polypropylene-surlyn composite material isprepared from the following components in parts by weight: 55-85 parts of polypropylene, 5-25 parts of surlyn, 0-10 parts of flexibilizer, 0-15 parts of enhancer, 0.3-0.8 part of antioxidant, 0.2-1 part of lubricant, 0.2-0.4 part of light stabilizer, and 1-3 parts of special effect toners. The surlyn has high low temperature impact resistance, and can remarkably improve the low temperature brittleness of a PP material after being added, the composite material has transparency and high gloss, and can remarkably improve the surface gloss of the composite material, so that the visual effect of metal is more outstanding; and the composite material has high scratch resistance, and can be remarkably improved in scratch resistance.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Annealing process for polypropylene random copolymer (PP-R) pipes

ActiveCN105252793ASolve the deformationEliminate or reduce internal stressTubular articlesTemperature differencePolypropylene

The invention discloses an annealing process for polypropylene random copolymer (PP-R) pipes. The process includes the following steps of five times of heating treatments and cooling treatment, wherein the temperature of the first and second times of heating treatments is controlled to be lower than 100 DEG C, and the heating treatment time is controlled to be about two hours, so that the problem of pipe deformation caused by excessively high temperature and too long time is prevented; the temperature of the third and fourth times of heating treatments is controlled to be lower than 125 DEG C, the heating treatment time is controlled to be about one hour, and internal stress caused by PP-R interior molecular crystallization during pipe production is eliminated or reduced; the temperature of the fifth time of heating treatment is controlled to be lower than 100 DEG C, the heating treatment time is controlled to be about 0.5 hour, the secondary internal stress caused during annealing is avoided or reduced, the problems of pipe contraction, bending and deformation caused by too large temperature difference are reduced, the problem that low-temperature brittle cracking and the like are prone to happen to existing PP-R pipes is solved, and the production quality of the PP-R pipes is improved.

Owner:浙江中财管道科技股份有限公司

High strength boat deck with low-temperature strain aging brittleness resistant property and production method thereof

InactiveCN103882305AHigh strengthReduce offline heat treatment stepsChemical compositionLaminar cooling

The invention provides a high strength boat deck with a low-temperature strain aging brittleness resistant property and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.04% to 0.08% of C, 0.15% to 0.45% of Si, 0.8% to 1.2% of Mn, 0.005% to 0.15% of P, not more than 0.005% of S, 0.02% to 0.08% of Al, and not more than 0.005% of N, and also comprises at least two components selected from the following components in percentage by weight: 0.05% to 0.50% of Cu, 0.05% to 0.40% of Ni, 0.02% to 0.10% of V, 0.005% to 0.05% of Nb, 0.005% to 0.05% of Ti, and 0.0005% to 0.006% of Ca. The deck base heating temperature is 1100 to 1150 DEG C, the rolling temperature in the recrystallization area is 1050 to 1100 DEG C, the finishing temperature is 880 to 940 DEG C, the accumulated deformation is not less than 60%, then the deck base is cooled in the air until the temperature of the deck base reaches 810 to 840 DEG C and then is rolled in the recrystallization area, the finishing temperature is 780 to 820 DEG C, the accumulated deformation is larger than or equal to 50%; the deck base is subjected to a laminar cooling treatment after the rolling process, the cooling speed is 8 to 15 DEG C per second, and the re-reddening temperature is 550 to 640 DEG C. The obtained high strength steel is used to manufacture ship structure, has a low strain aging sensitivity index, and can be used in an extremely cold climate.

Owner:ANGANG STEEL CO LTD

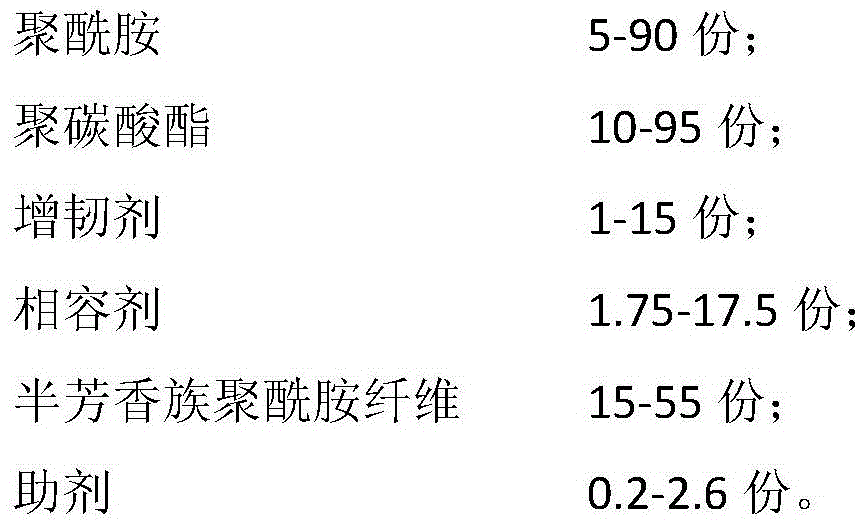

Polyamide polycarbonate alloy material and preparation method and applications thereof

The invention provides a polyamide polycarbonate alloy material and a preparation method and applications thereof. The polyamide polycarbonate alloy material comprises the following components in parts by weight: 5 to 90 parts of polyamide, 10 to 95 parts of polycarbonate, 1 to 15 parts of toughening agent, 1.75 to 17.5 parts of compatilizer, 15 to 55 parts of semi-aromatic polyamide fibers, and 0.2 to 2.6 parts of auxiliary agent. The preparation method comprises the following steps: evenly mixing polyamide, polycarbonate, a toughening agent, a compatibilizer, and an auxiliary agent, adding the mixture into the main feed hopper of a double-screw extruder; adding the semi-aromatic polyamide fibers into the lateral feed hopper of the double-screw extruder, and carrying out extruding, pulling, and cutting to obtain the polyamide polycarbonate alloy material. The provided polyamide polycarbonate alloy material has the advantages of good interfacial compatibility, good particle dispersing property, and high strength, can be used to prepare parts of electronic and electrical products, and has a wide application range.

Owner:上海昶勤实业有限公司

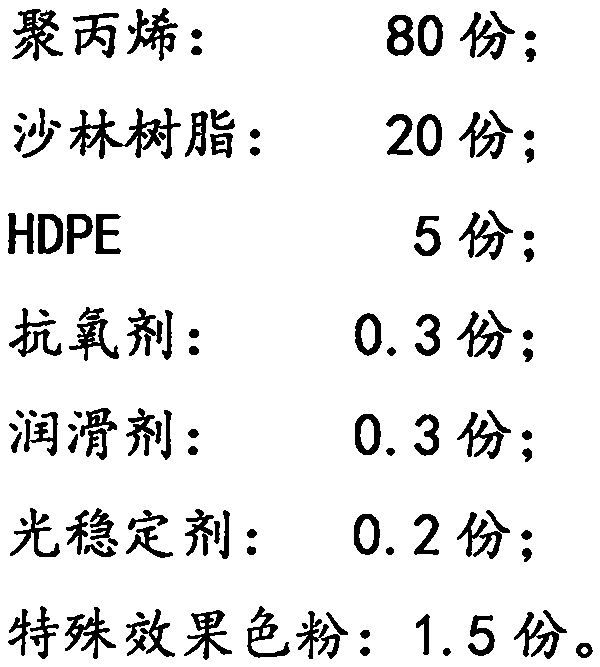

Polypropylene-surlyn resin composite material

The invention relates to a polypropylene-surlyn resin composite material. The composite material comprises, by weight, 55-85 parts of polypropylene, 5-25 parts of surlyn resin, 3-5 parts of HDPE, 0-10parts of a toughening agent, 0-15 parts of an enhancer, 0.3-0.8 part of an antioxidant, 0.2-1 part of a lubricant, 0.2-0.4 part of a light stabilizer and 1-3 parts of special effect color powder. Thesurlyn resin has excellent low-temperature impacting performance, the low temperature brittleness of a PP material can be significantly improved, the surlyn resin is transparent and has high glossiness, the surface gloss level of the composite material can be significantly improved after the surlyn resin is added, a metal imitation visual effect is more outstanding, the surlyn resin has higher scratching resistance, and therefore the scratching resistance of the material can be significantly improved.

Owner:严静儿

Heating-processing technology for improving mechanical property of high-intensity extra-thick plate

ActiveCN102061373BImprove mechanical propertiesHigh strengthFurnace typesHeat treatment furnacesMechanical propertyHeat treated

The invention provides a heating-processing technology for improving the mechanical property of a high-intensity extra-thick plate, and the heating-processing technology can be used for improving the mechanical property of a normalizing high-intensity extra-thick plate and improving the normalizing qualification rate of the extra-thick plate. A water-cooling working procedure is added in the normalizing process of the extra-thick plate and is used for replacing air cooling for normalizing; the normalizing cooling speed is quickened, the phase-transition temperature of a steel plate is lowered, and the growth of microalloy element carbonitride can be inhibited, so that a small quantity of ferrite and a large quantity of thinner perlite structure can be obtained, and intensity, plasticity, low temperature brittleness and the like can be improved so as to guarantee the intensity of the steel plate and improve the qualification rate of the steel plate.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

High-temperature-resistant and wear-resistant fluororubber sealing element and preparation method thereof

InactiveCN108504004AHigh strengthImprove performanceOther chemical processesCalcium silicateWear resistant

The invention provides a high-temperature-resistant and wear-resistant fluororubber sealing element and a preparation method thereof. The high-temperature-resistant and wear-resistant fluororubber seal element is prepared from the following raw materials in parts by weight: 50-70 parts of 26 type fluororubber, 20-45 parts of 23 type fluororubber, 12-20 parts of medium-particle pyrolysis carbon black, 5-8.5 parts of organic modified attapulgite, 1-1.8 parts of calcium silicate, 0.5-1 part of a talc powder, 1.5-2.5 parts of hydroxyl fluorosilicone oil, 1.5-2.5 parts of magnesium oxide, 0.3-0.5 part of a silane coupling agent, 2-3 parts of perfluoromethyl phenyl hydroxyl peroxide, 0.4-0.7 part of triallyl isocyanurate, and 0.5-1 part of a processing aid. The prepared sealing element has excellent high-temperature resistance and wear resistance and high strength, and the service life of the sealing element can be effectively prolonged.

Owner:ANHUI PROPELLENT HEAT TRANSFER TECH CO LTD

Toughened and modified PVC (polyvinyl chloride) plastic pipe and preparation method thereof

ActiveCN105837996AImprove impact resistanceImprove low temperature brittlenessPolyvinyl chlorideInjection moulding

The invention discloses a toughened and modified PVC (polyvinyl chloride) plastic pipe and a preparation method thereof. The toughened and modified PVC plastic pipe is prepared from the following raw materials in parts by weight: 100 parts of PVC resin, 15 to 35 parts of high-cis butadiene rubber, 0.5 to 1.5 parts of coupling agents and 0.2 to 0.6 part of inorganic fillings. The toughened and modified PVC plastic pipe is obtained by using an extrusion forming or injection molding forming preparation process. By using a molecular structure design method, the high-cis butadiene rubber is used as toughening materials to be uniformly added into the PVC resin, so that the low-temperature brittleness of the polyvinyl chloride plastic pipe is improved, and the mechanical intensity and the heat-resistant performance are enhanced.

Owner:河北宇天通信器材有限公司

Threaded joint for steel pipes

InactiveUS7740285B2Solve the lack of resistanceImprove low temperature brittlenessSleeve/socket jointsPipe supportsEngineeringScrew thread

A threaded joint for steel pipes comprised of a pin (1) and a box (2) each having a threaded portion (1a, 2b) and an unthreaded contact portion (1b, 2a) exhibits adequate leakage resistance and galling resistance when used for makeup of oil country tubular goods with application of a green dope or even without any dope. The threaded joint has a first plating layer of Sn—Bi—Cu alloy plating formed on the contact surface of at least one of the pin (1) or the box (2). The first plating layer may have a second plating layer selected from Sn plating, Cu plating, and Ni plating on its lower side and at least one layer of a lubricating coating, and particularly a solid lubricating coating on its upper side.

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

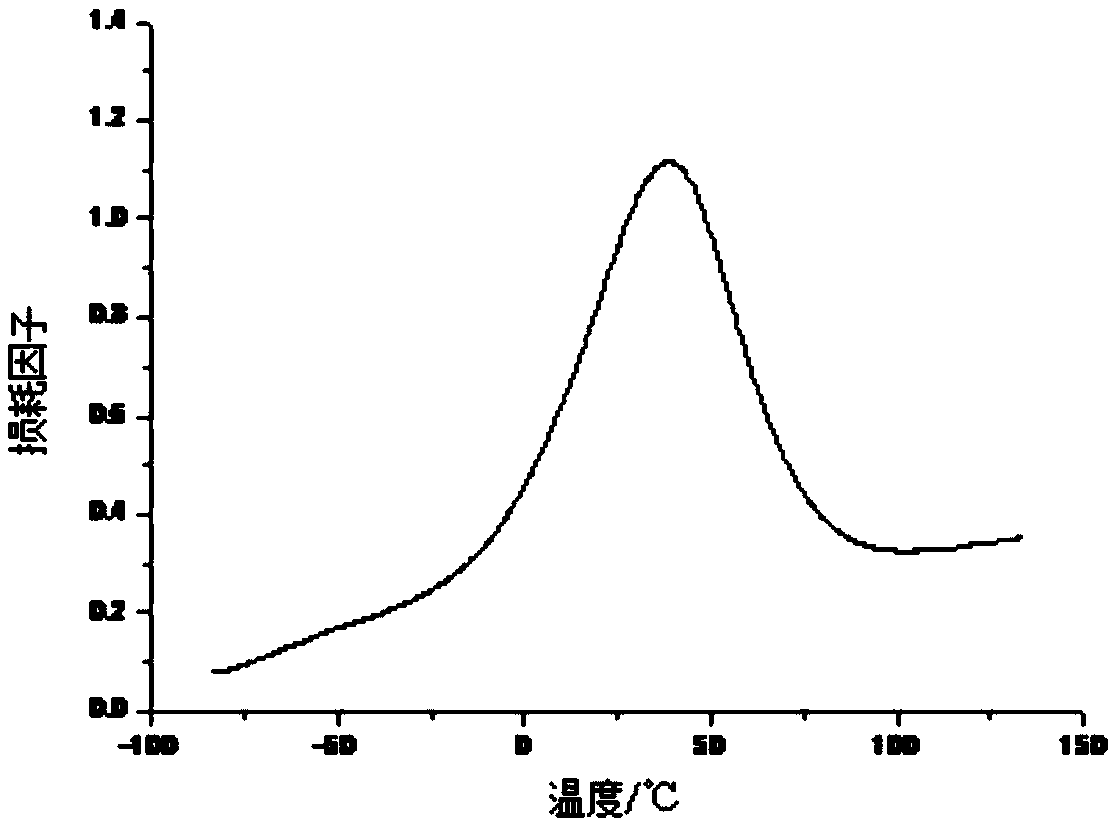

Organosilicon-type polyurethane damping material and preparation method thereof

ActiveCN109021196AHigh damping loss factorImprove low temperature brittlenessHydrolysisMechanical property

The invention provides an organosilicon-type polyurethane damping material and a preparation method thereof. The damping material is synthesized by methyl propylene oxide, a molecule main chain has ahomo-carbon dimethyl structure and a homo-silicon dimethyl structure, and terminal alkenyl ether alcohol is synthesized by using enol and isobutylene oxide, the diol having the homo-carbon dimethyl structure and the homo-silicon dimethyl structure is synthesized with the double-end hydrogen silicone oil having the homo-silicon dimethyl, a polyurethane prepolymer is synthesized by the raw materialand the diisocyanate, the prepolymer is reacted with a chain extender, and the organosilicon-type polyurethane damping material is obtained. The damping material prepared by the invention has good mechanical properties and damping properties, and at the same time, the low temperature brittleness, heat resistance and hydrolysis resistance of the material are improved by the introduction of the organosilicon, and the application of the material in the fields of sophisticated weapons, spaceflight aircrafts, navigation, construction, and environmental protection and the like.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

Multielement alloy based on tungsten-potassium alloy and preparation method thereof

The invention belongs to the field of metal material, and relates to a preparation method of a multielement alloy based on a tungsten-potassium alloy. The method comprises the following process steps: (1) in an argon atmosphere with the oxygen content of less than 0.1 ppm and the water content of less than 0.1 ppm, weighing a tungsten-potassium alloy powder, a metal X powder and grinding balls, together adding into a ball milling tank, vacuumizing the ball milling tank, then filling the ball milling tank with mixed gas of hydrogen gas and argon gas, and carrying out ball milling for 20-60 h, wherein the metal X is at least one of Ti and Y; and (2) loading the mixed powder obtained in the step (1) into a mould, then putting the mould loaded with the mixed powder into a spark plasma sintering furnace, sintering for 1-6 min under the pressure of 40-100 MPa and the temperature of 1600-1900 DEG C, then cooling to the room temperature along with the furnace, next reducing the pressure to the normal pressure, and thus obtaining the product. The multielement alloy prepared by the method has excellent irradiation resistance and thermal shock resistance.

Owner:SICHUAN UNIV

Preparing method of PS (polystyrene) composite

InactiveCN104927220AImprove rigidityImproves toughness and impact resistancePolymer chemistryButadiene-styrene rubber

The invention discloses a preparing method of PS (polystyrene) composite. The PS composite comprises, by weight, 65% to 89% of PS, 10% to 34% of modified resin filler, 0.3% to 0.4% of antioxidant, 0.3% to 0.4% of lubricant, and 0.4% to 1.2% of aid. According to the preparing method, styrene butadiene transparent impact resin is used as modified resin filler for PS, rigidity of PS resin can be effectively improved, impact resistance and toughness of the PS resin can be enhanced, and products of the PS composite are protected from stress cracking during using; by the use with other aids, the thermal stability, weatherability and cold brittleness of the PS resin are effectively improved, and thus, the PS resin excellent in comprehensive performance is prepared.

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

Modified epoxy resin and preparation method thereof

The invention relates to modified epoxy resin and a preparation method thereof, which belong to the technical field of modified epoxy resin and solve the technical problem of utilizing furfuryl alcohol waste efficiently and achieving fine compatibility to bitumen after epoxy resin is modified. The technical scheme includes that the modified epoxy resin comprises the following raw materials: by weight parts, 3-9 parts of epoxy resin, 2-8 parts of furfuryl alcohol mud, 0.5-3 parts of polyester and 0.5-3 parts of furfuryl alcohol. Usage of the epoxy resin is reduced since part of epoxy resin is substituted, and accordingly cost is reduced. The modified epoxy resin has excellent compatibility with the bitumen, can react with the epoxy resin under a certain condition, is simple in preparation process due to the fact that most reaction is completed at the normal temperature. Cost of epoxy bitumen can be reduced and waste is utilized, energy resources are saved for the country, environment pollution is reduced and excellent social benefits are brought.

Owner:山西永力实业有限公司

Novel optical cable outer sheath material and preparation method thereof

The invention discloses a novel optical cable outer sheath material and a preparation method thereof. The optical cable outer sheath material is prepared from the following raw materials in parts by weight: 30 to 40 parts of polypropylene, 15 to 25 parts of modified lignin, 10 to 20 parts of modified cellulose, 10 to 20 parts of ABS plastic, 2 to 4 parts of interface compatibilizers, 1 to 2 parts of heat stabilizers, 2 to 3 parts of anti-ultraviolet agents, 1 to 2 parts of lubricant, 2 to 3 parts of antioxidant and 2 to 3 parts of fillers. According to the optical cable outer sheath material provided by the invention, the polypropylene is used as a main raw material, compared with an existing polypropylene sheath, the novel optical cable outer sheath material has the advantages of ultrahigh elasticity modulus, low-temperature brittleness resistance, high tensile strength, good glossiness, smooth effect and ageing resistance and mildew resistance, the defect of high water absorption of general polar materials after mixing is overcome, and compared with the prior art, obvious substantial characteristics and remarkable progress are achieved.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

Low-temperature-brittleness-resistant PVC pipe material and preparation method thereof

InactiveCN104558945AImprove impact resistanceImprove cold resistanceWeather resistanceCold resistance

The invention discloses a low-temperature-brittleness-resistant PVC pipe material. The PVC pipe comprises the following raw material components in parts by weight: 100 parts of PVC, 1-15 parts of polyacrylate, 15-30 parts of toughening agent, 10-20 parts of active nanometer calcium carbonate, 2-7 parts of stabilizing agent and 4-10 parts of APAO. PVC pipes prepared by using the PVC pipe material disclosed by the invention have good impact resistance, cold resistance and weather resistance, and have remarkably better low temperature brittleness than that of the PVC pipes in the prior art; the PVC pipe material disclosed by the invention is easily processed, and the homogeneity between the components of the PVC pipe material is good; and the material cost and production cost of the PVC pipe material are low.

Owner:SHANGHAI BANZAN MACROMOLECULE MATERIAL

PPR pipe having high ageing resistance and manufacturing method thereof

The invention discloses a PPR pipe having high ageing resistance and a manufacturing method thereof. The manufacturing method includes selecting a PPR raw material, and adding a certain quantity of zinc powder and mixing uniformly; adding a DOP liquid into the uniform mixture of the PPR and the zinc powder; putting the mixture, to which the DOP liquid is added, into a forming machine, heating to 200-230 DEG C, maintaining the temperature for 1-3 min until the mixture is prepared into a colloidal raw material; putting the colloidal raw material into a double-screw extruder, extruding and sorting granules; and then extruding a pipe and forming by using a single-screw pipe extruder. By addition of the zinc powder, a ZnO layer can be formed both on the surface and internal of the pipe, thus enhancing the ageing resistance property of the pipe, and improving the hardness and low-temperature brittleness of the pipe. The PPR pipe has a broad market prospect.

Owner:ANHUI ZHONGHONG PIPE IND TECH

Production method for big-thickness ultrawide DIWA353 steel plates

InactiveCN110499458AImprove low temperature toughnessGuaranteed StrengthSheet steelTreatments procedures

The invention discloses a production method for big-thickness ultrawide DIWA353 steel plates, and belongs to the technical field of metallurgy. The production method comprises the procedures of smelting, casting, heating, rolling, water cooling and heat treatment. The smelting procedure comprises electric furnace initial smelting, LF furnace refining and VD furnace vacuum treatment; the heat treatment procedure adopts normalization and tempering treatment processes; the normalization temperature is 950+-10 DEG C; the heating time is 4.5-5 h; the insulation time is 0.8-1 min / mm; the furnace iscooled to 910+-10 DEG C; the insulation time is 1.2-1.5 min / mm; the water cooling is performed by 6-8 min after normalization; and the red returning temperature of steel plates is not higher than 600DEG C. The produced steel plates are higher in purity, uniform in component, compact in internal, smooth in surface, free of recess and excellent in mechanical performance, and can be used for manufacturing high-pressure boiler drums, nuclear energy containers and other high-pressure resisting containers.

Owner:WUYANG IRON & STEEL

Modified PP-R material

The invention provides a modified PP-R material for reducing low-temperature brittleness of PP-R and improving rigidity of PP-R material without influencing the toughness. The modified PP-R material comprises PP-R and dicumyl peroxide and is characterized in that the modified PP-R material contains 90 to 97wt percent of PP-R and 3 to 10wt percent of dicumyl peroxide. In the modified PP-R material, micro-cross-linking technology is utilized to influence the sequence structure of random polymer as well as the sequence structure of homo-polymerization section, so that the isotactic structure of PP main chain is reduced to influence the regularity of the chain and enhance the randomness of the main chain, thus enhancing the rigidity of PP-R and improving the mechanical strength of PP-R. Because the dicumyl peroxide belongs to thermoplastic material, the modified PP-R is recoverable and environment-friendly, and causes no pollution to the environment.

Owner:浙江爱康实业有限公司

A low temperature impact resistant glass fiber reinforced polypropylene composite material and its preparation and application

ActiveCN103087429BImprove low temperature impact resistanceGood yieldPolypropylene compositesGlass fiber

The invention provides a low temperature impact resisting glass fiber reinforced polypropylene composite material as well as preparation and application thereof. The composite material provided by the invention comprises 40-90 parts of co-polypropylene, 2-10 parts of compatilizer, 5-45 parts of glass fiber and 2-10 parts of highly branched chain polyethylene in parts by weight. According to the composite material based on high impact co-polypropylene as a base material and highly branched chain polyethylene with hexane and octylene as branched chains as a crack propagation inhibitor, the good yield is ensured by a common twin screw device, so that the cost is lower. The composite material has better low temperature impact resistance.

Owner:中广核俊尔(上海)新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com