A low temperature impact resistant glass fiber reinforced polypropylene composite material and its preparation and application

A technology of composite materials and polypropylene, applied in the field of vehicle underbody protection panels, can solve the problems of low output and achieve the effect of improving reinforcement, low cost, and increasing the degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

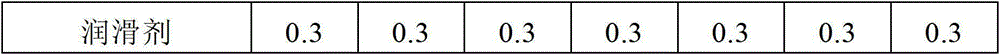

Embodiment 1

[0043] As shown in Table 1, weigh Qilu Petrochemical Copolymer SP179 (notched impact strength ≥ 45kJ / m 2 ), 68.5 parts by weight, 5 parts by weight of multi-branched polyethylene LLDPE7042 (Yangzi Petrochemical), 5 parts by weight of maleic anhydride grafted polypropylene compatibilizer CMG5001 (MAH grafting rate ≥ 1%) of Shanghai Rizhisheng Company, no Alkali continuous long glass fiber 988A (glass fiber diameter 9-13 μm) 21 parts by weight, antioxidant 1010 (tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester) And antioxidant 168 (tris [2,4-di-tert-butylphenyl] phosphite) 0.1 parts by weight each, processing aid calcium stearate 0.3 parts by weight, mix each component except glass fiber evenly Finally, put it into the hopper of the extruder, and melt and blend through the twin-screw extruder. The continuous long glass fiber is added from the exhaust port or the short fiber is added from the side feeding port. By adjusting the main engine speed, ...

Embodiment 2

[0050] As shown in Table 1, weigh Qilu Petrochemical Copolymer SP179 (notched impact strength ≥ 45kJ / m 2 ) 56.5 parts by weight, multi-branched polyethylene LLDPE7042 (Yangzi Petrochemical) 7 parts by weight, Rizhisheng maleic anhydride grafted polypropylene compatibilizer CMG5001 (MAH grafting rate ≥ 1%) 5 parts by weight, non-alkali continuous long 31 parts by weight of glass fiber 988A (diameter of glass fiber is 9-13 μm), 0.1 parts by weight of each of antioxidant 1010 and 168, 0.3 parts by weight of processing aid calcium stearate, after mixing all components except glass fiber evenly , into the hopper of the extruder, melted and blended through the twin-screw extruder, the continuous long glass fiber is added from the exhaust port or the short fiber is added from the side feed port, by adjusting the speed of the main engine, the main feed and the long glass fiber root The number or side feeding speed can adjust the glass fiber content; extruded strands are cooled, air-dr...

Embodiment 3

[0053] As shown in Table 1, weigh Qilu Petrochemical Copolymer SP179 (notched impact strength ≥ 45kJ / m 2 ) 43.5 parts by weight, multi-branched polyethylene LLDPE7042 (Yangzi Petrochemical) 10 parts by weight, Rizhisheng maleic anhydride grafted polypropylene compatibilizer CMG5001 (MAH grafting rate ≥ 1%) 5 parts by weight, non-alkali continuous long 41 parts by weight of glass fiber 988A (diameter of glass fiber is 9-13 μm), 0.1 parts by weight of each of antioxidant 1010 and 168, 0.3 parts by weight of processing aid calcium stearate, after mixing all components except glass fiber evenly , into the hopper of the extruder, melted and blended through the twin-screw extruder, the continuous long glass fiber is added from the exhaust port or the short fiber is added from the side feed port, by adjusting the speed of the main engine, the main feed and the long glass fiber root The number or side feeding speed can adjust the glass fiber content; extruded strands are cooled, air-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com