Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Polysiloxane polycarbonate copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant thermoplastic polycarbonate compositions, use, and method of manufacture thereof

Owner:SABIC INNOVATIVE PLASTICS IP BV

Flame retardant thermoplastic compositions having EMI shielding

ActiveUS20070105994A1Good physical propertiesConductive materialNon-conductive material with dispersed conductive materialPolysiloxane polycarbonate copolymerMetal fibers

A flame retardant thermoplastic composition having excellent physical properties that includes 20 to 90 wt. % of a polycarbonate resin; from 1 to 35 wt. % of an impact modifier; from 0.5 to 30 wt. % of a polysiloxane-polycarbonate copolymer including from 8 to 30 wt. % polydimethylsiloxane units or the equivalent molar amount of other diorganosiloxane units; from 0.5 to 20 wt. % of a phosphorus-containing flame retardant, and from 3 to 30 wt. % of metal fiber, each based on the total combined weight of the thermoplastic composition, exclusive of any filler. In one embodiment, a molded sample of the thermoplastic composition having a thickness of 3.0 mm (±10%) has an EMI shielding of at least 20 dB. In addition, a molded sample of the thermoplastic composition is capable of achieving UL94 V0 or V1 rating at a thickness of 1.5 mm (±10%). The compositions are useful in forming flame retardant articles having EMI shielding characteristics.

Owner:SHPP GLOBAL TECH BV

Flame retardant thermoplastic polycarbonate compositions, use and method thereof

InactiveUS20060074156A1Plastic/resin/waxes insulatorsDyeing processThermoplasticPolysiloxane polycarbonate copolymer

A thermoplastic composition contains about 20 to about 90 wt. % of a polycarbonate resin; up to about 35 wt. % of an impact modifier; about 0.5 to about 30 wt. % of a polysiloxane-polycarbonate copolymer; and about 0.5 to about 20 wt. % of a phosphorus-containing flame retardant, each based on the total combined weight of the thermoplastic composition, exclusive of any filler. An article of manufacture having a wall having a thickness of 3 mm or less may be made using the composition, e.g., by molding, extruding, or shaping the above-described composition into an article. Alternatively, an article may be made by ultrasonically welding a first part comprising the foregoing composition a second part.

Owner:SHPP GLOBAL TECH BV

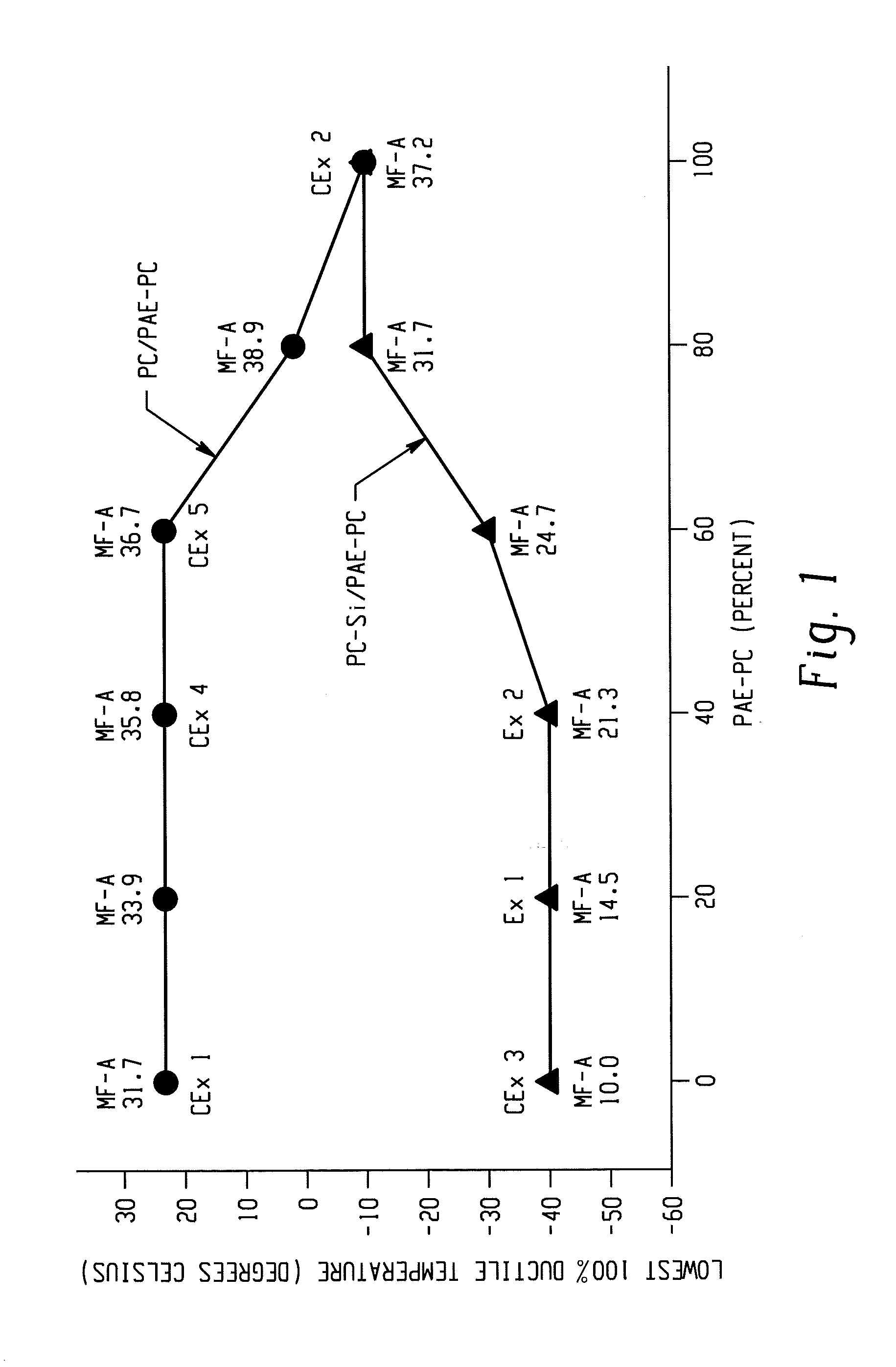

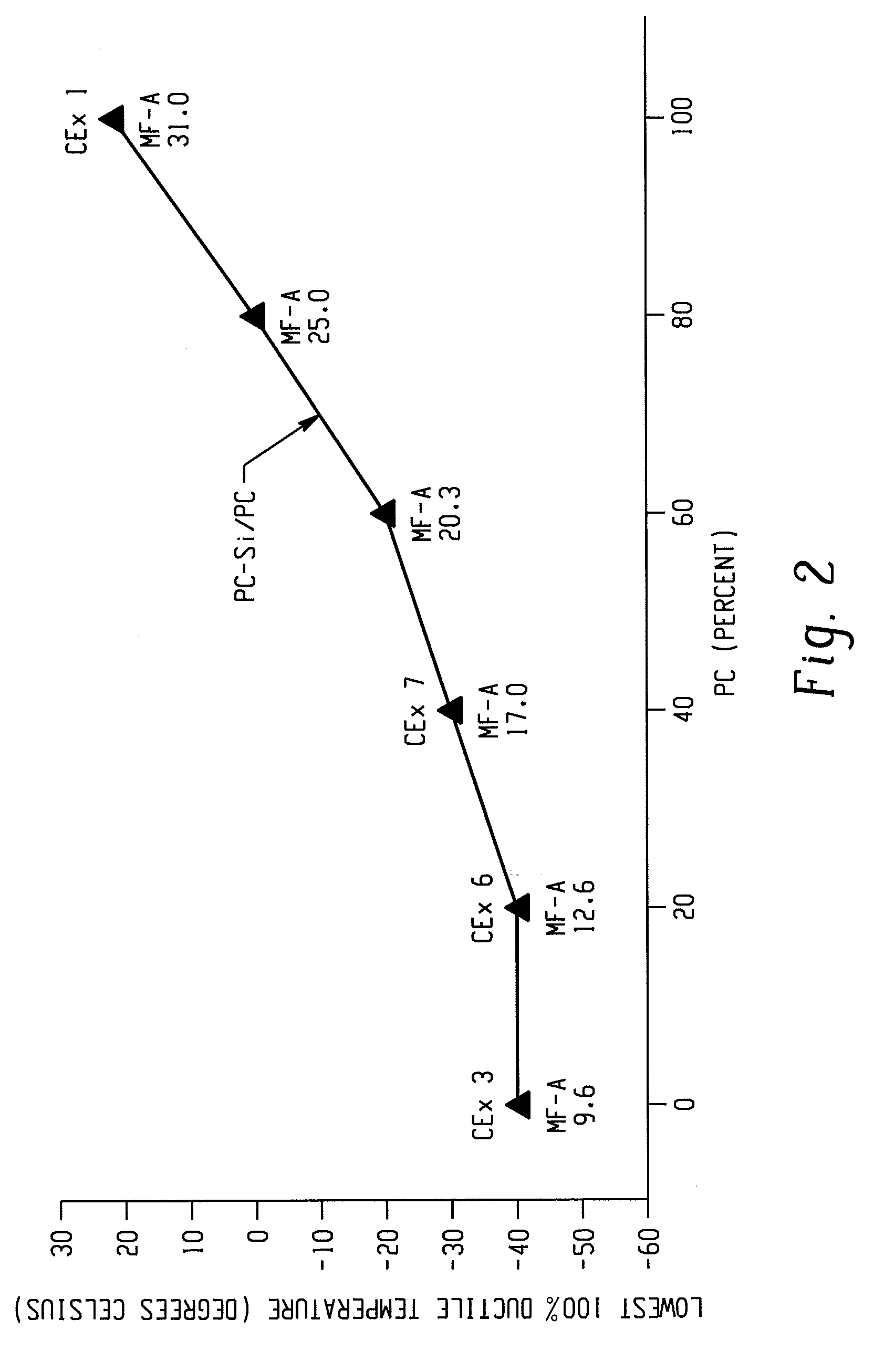

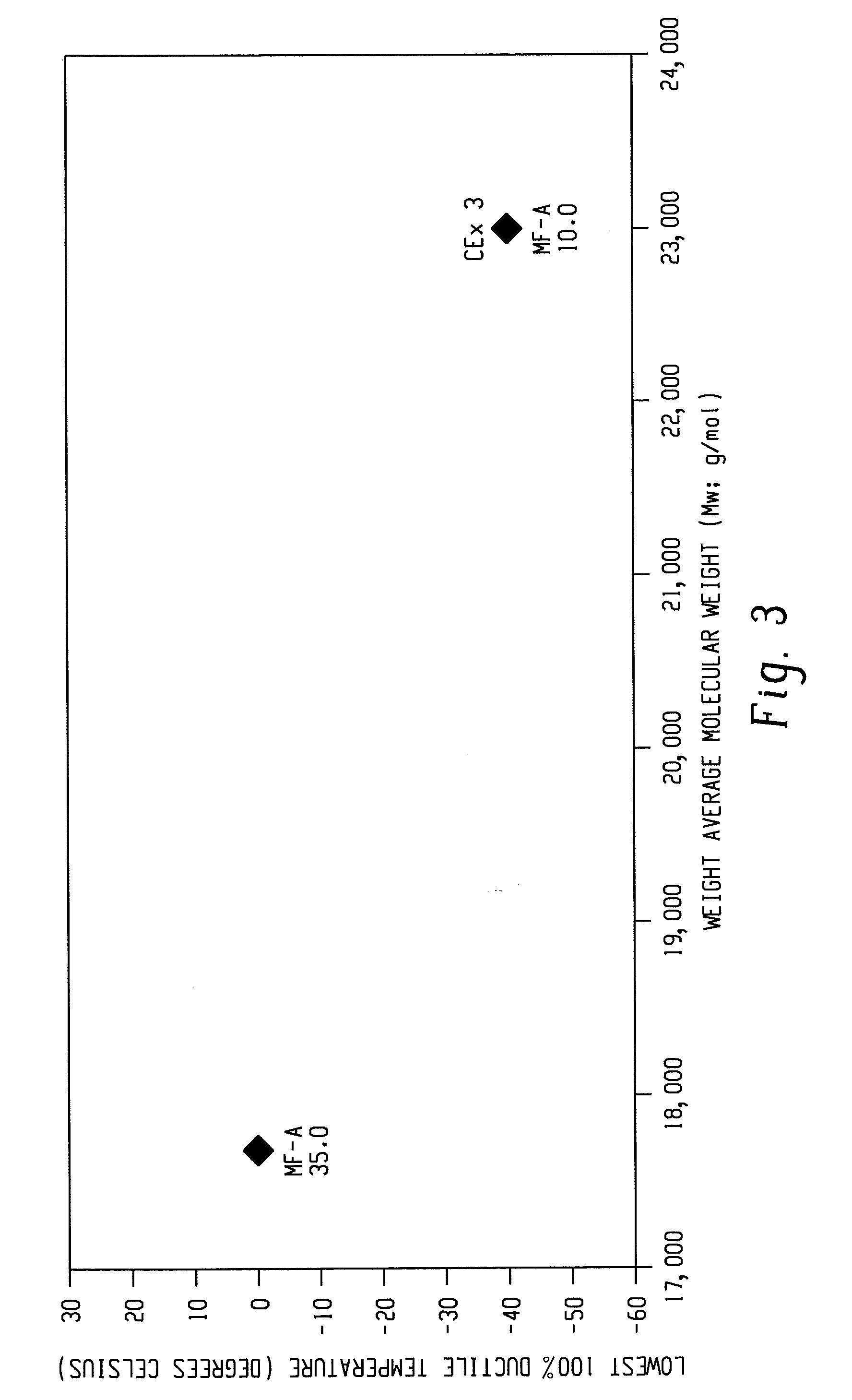

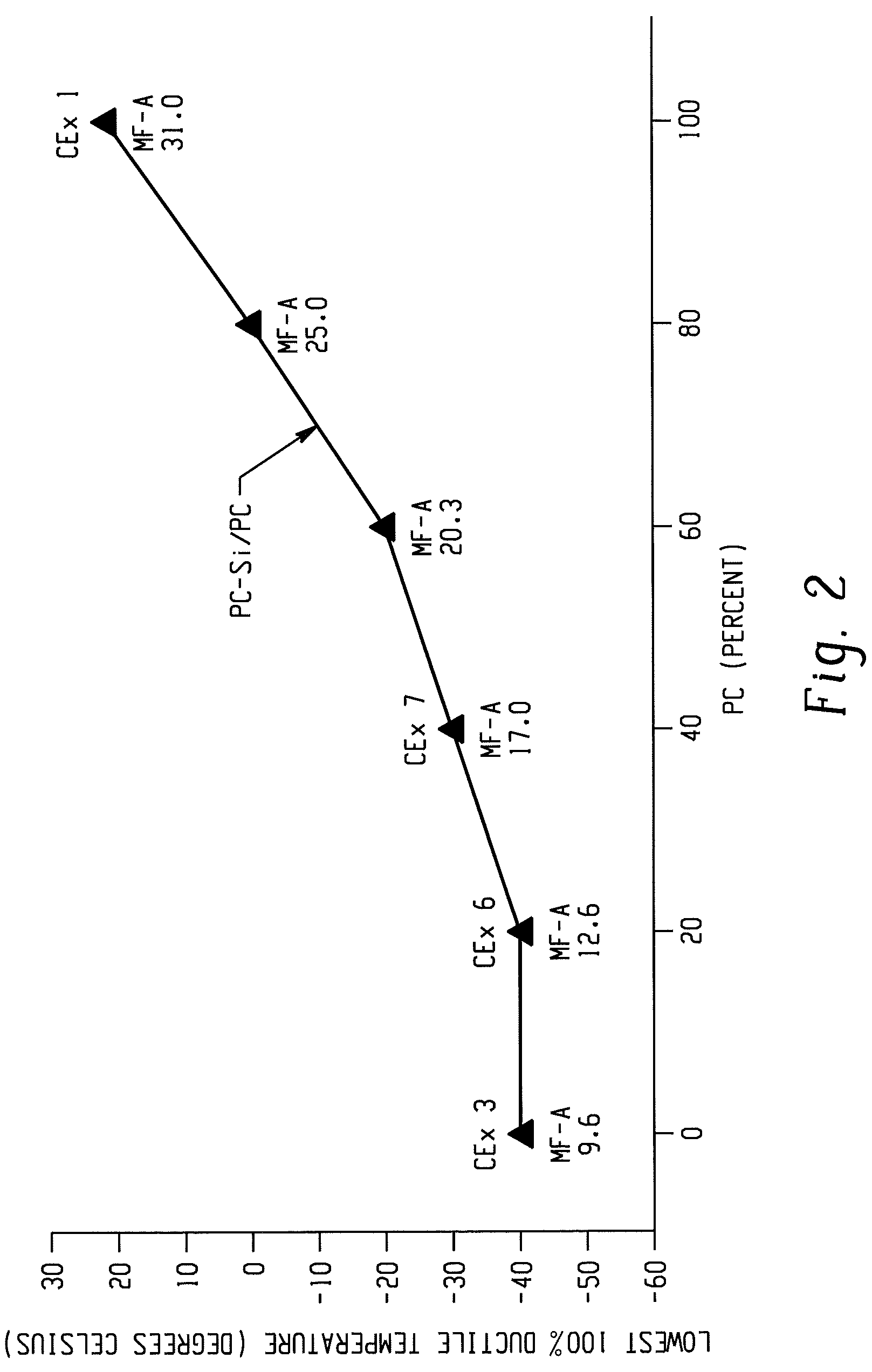

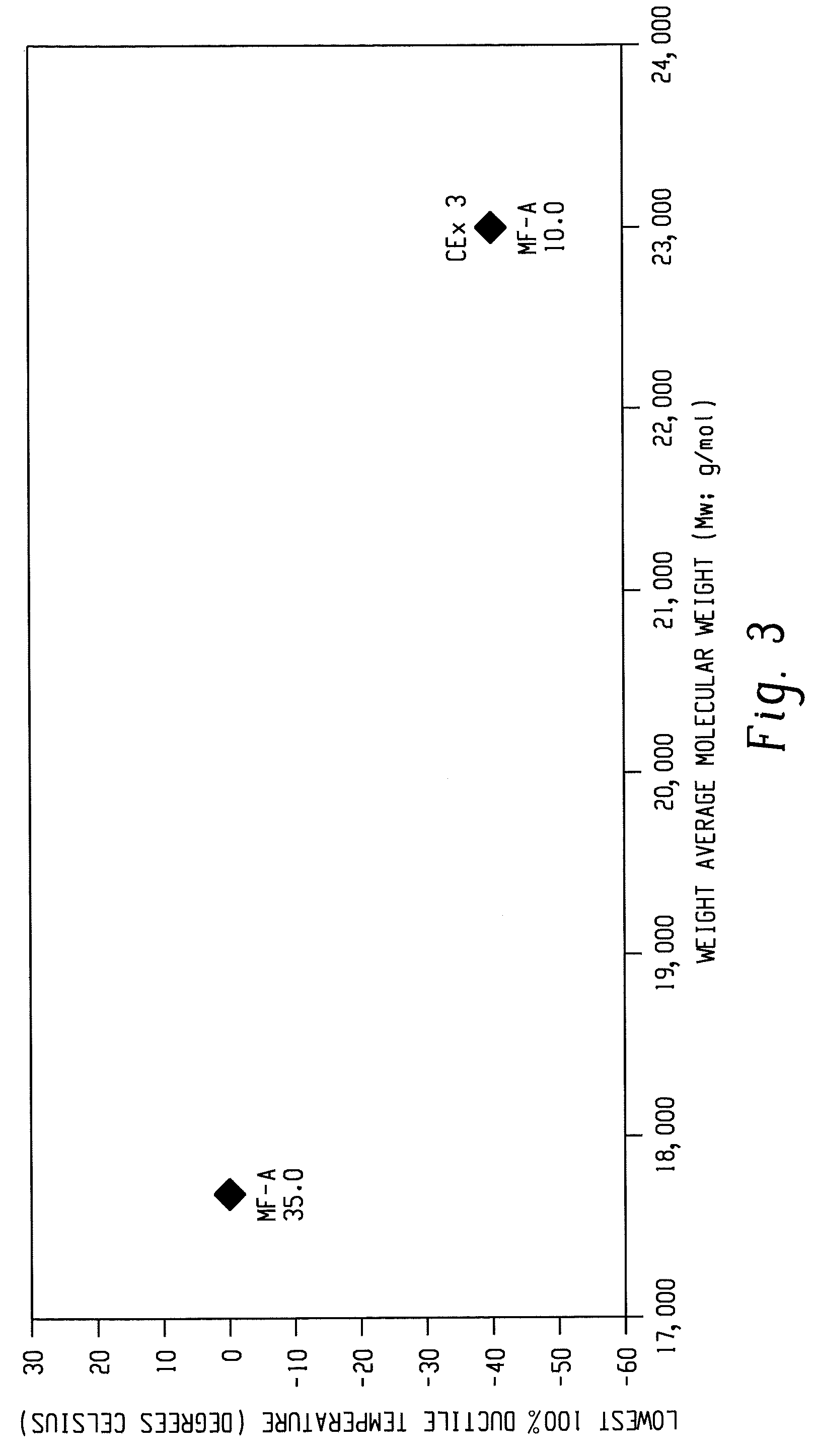

Transparent thermoplastic compositions having high flow and ductiliy, and articles prepared therefrom

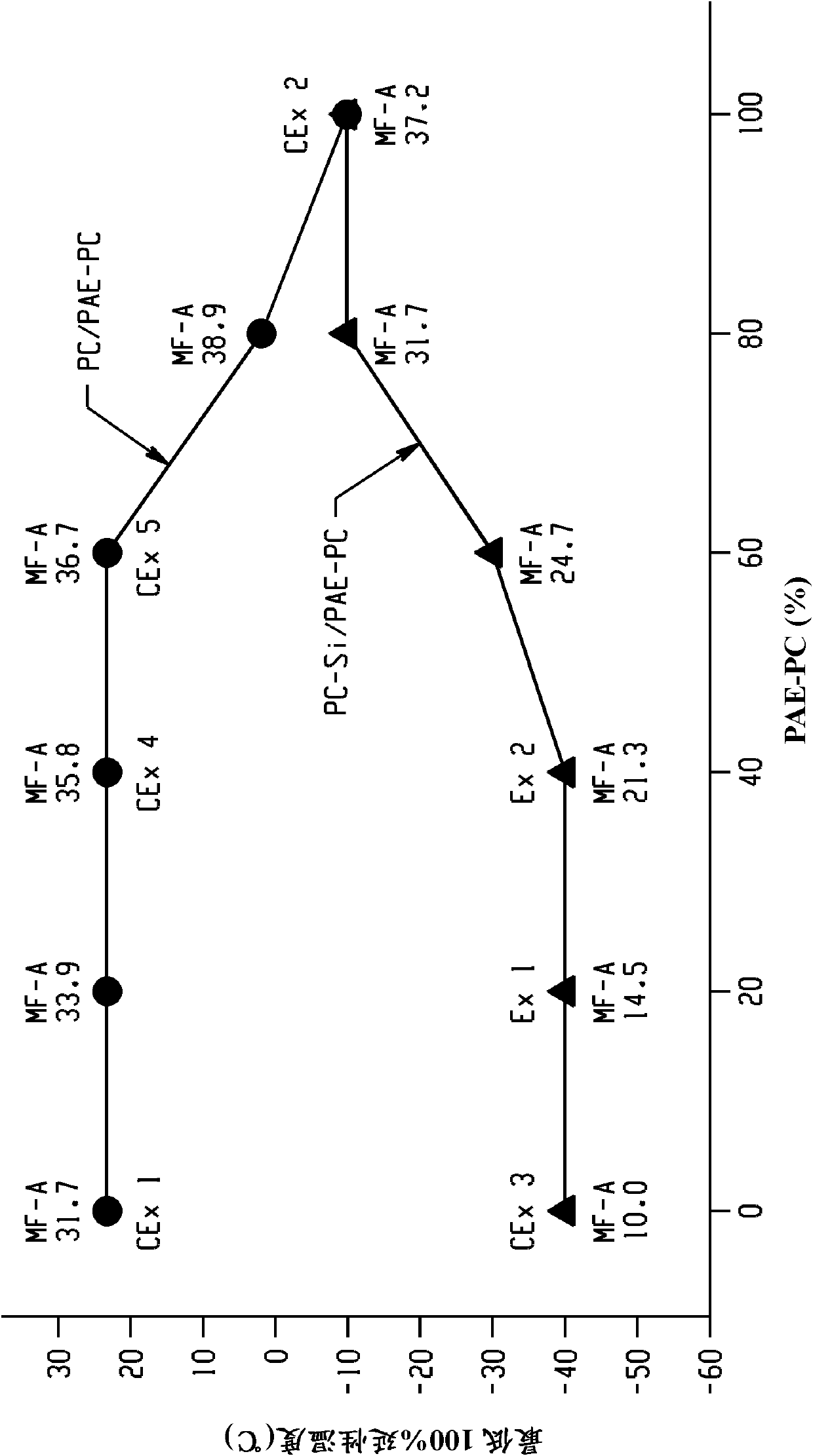

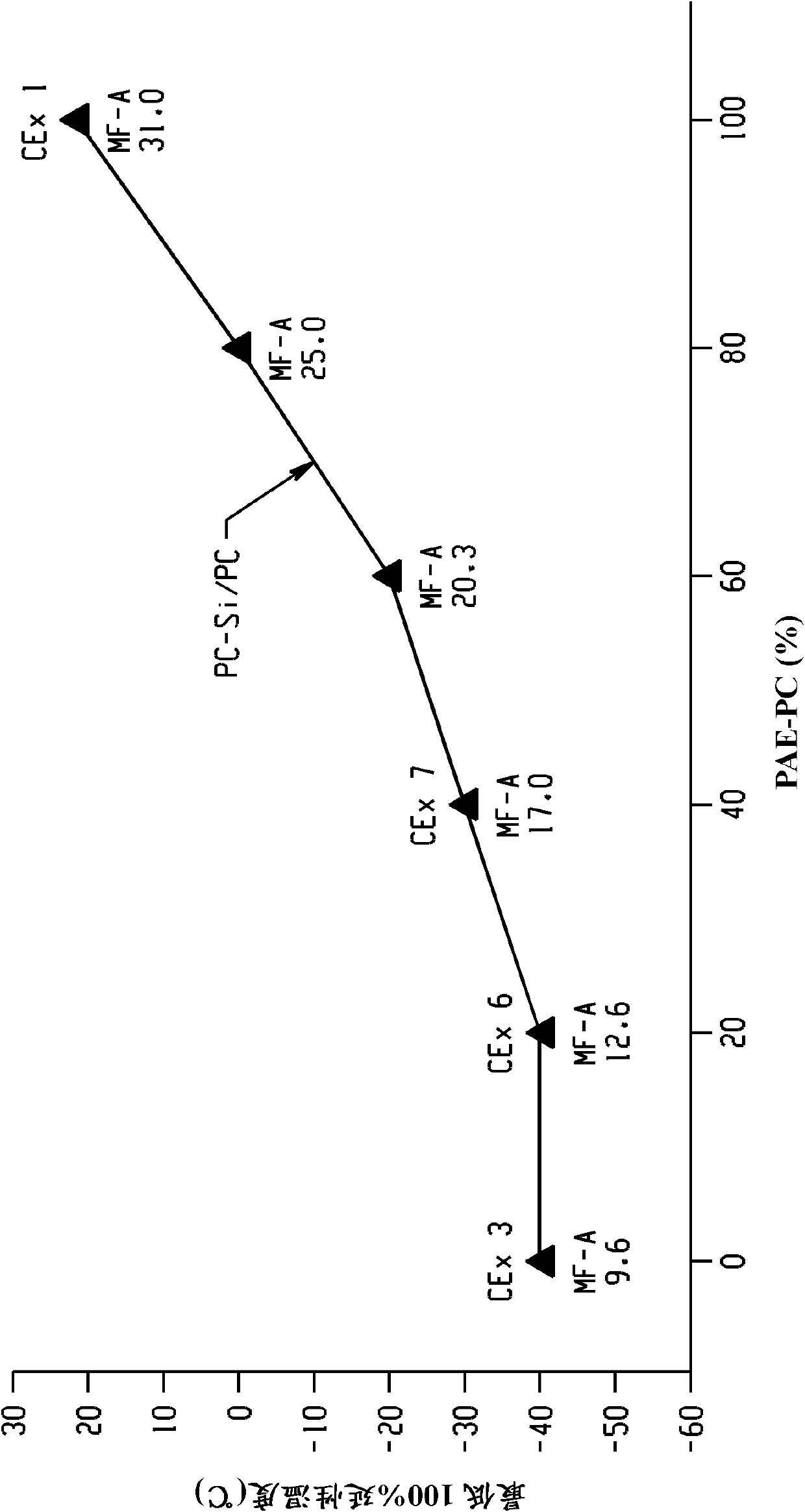

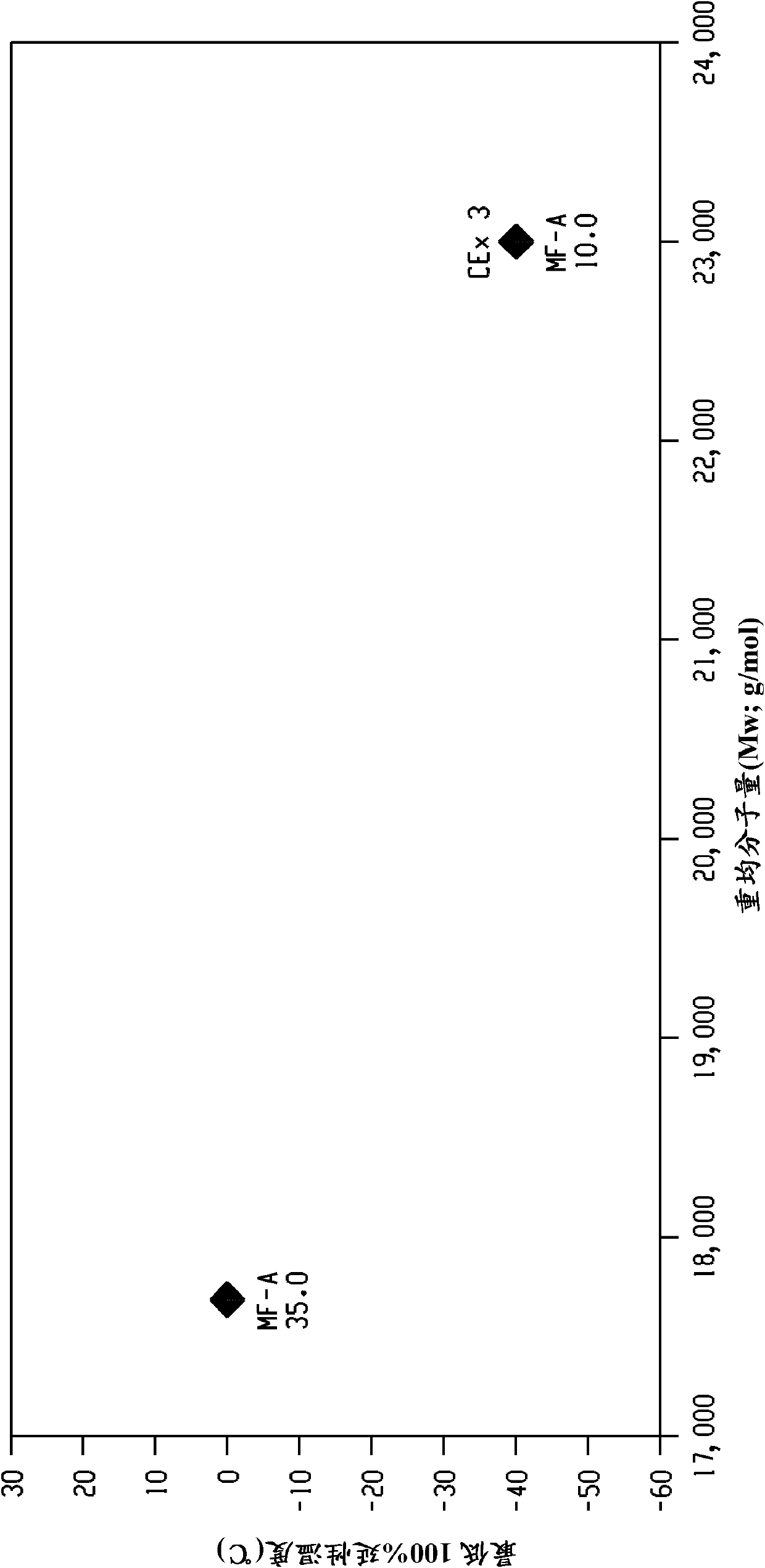

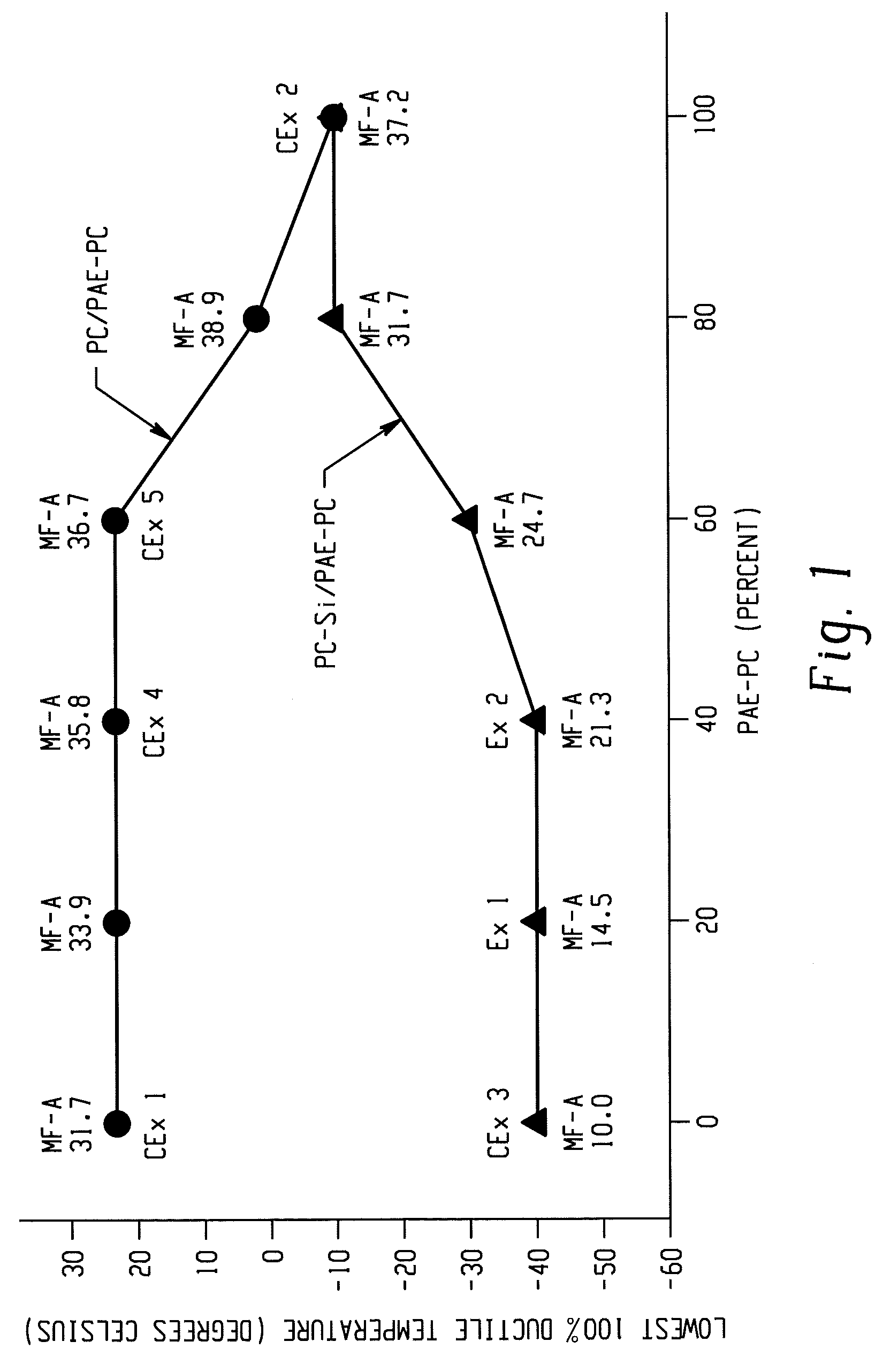

Disclosed herein is a thermoplastic composition comprising a combination of: a polysiloxane-polycarbonate copolymer and a poly(aliphatic ester)-polycarbonate copolymer comprising soft block ester units of the formula (8a):wherein m is 4 to 18, wherein the thermoplastic composition has a melt volume rate of 14 cc / 10 min to 22 cc / 10 min at 300° C. and under a load of 1.2 Kg and a dwell time of 6 minutes, according to ASTM D1238-04, wherein an article molded from the thermoplastic composition and having a thickness of 3.2 mm has a percent transmittance of greater than 85% according to ASTM D1003-00, and wherein 100% of a set of five test articles each having a thickness of 3.2 mm and molded from the thermoplastic composition exhibit ductile fracture at −40° C. when measured for notched Izod Impact according to ASTM D256-04. An article comprising the thermoplastic composition is also disclosed.

Owner:SHPP GLOBAL TECH BV

Polycarbonate composition and articles formed therefrom

ActiveUS20130309474A1Speed up the flowImprove aestheticsSynthetic resin layered productsConductive materialPolysiloxane polycarbonate copolymerCarbon fibers

A composition includes at least one poly(aliphatic ester)-polycarbonate copolymer, a polysiloxane-polycarbonate copolymer, and an electromagnetic shielding agent (such as metal fibers). The composition exhibits excellent impact properties and electromagnetic shielding properties when formed into an article. Another composition includes at least one poly(aliphatic ester)-polycarbonate copolymer, a polysiloxane-polycarbonate copolymer, and carbon fibers. This composition has excellent impact properties when formed into an article.

Owner:SHPP GLOBAL TECH BV

Polycarbonate-polysiloxane copolymer compositions and articles formed therefrom

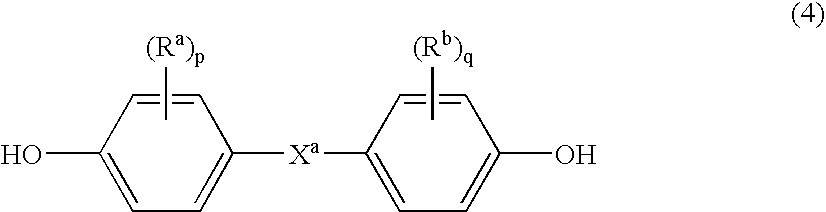

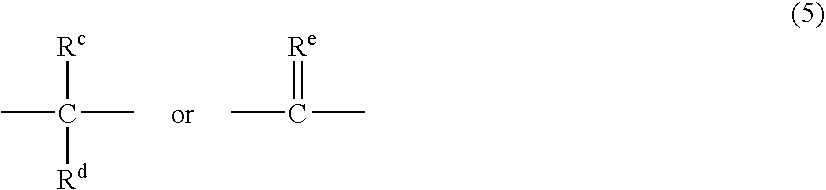

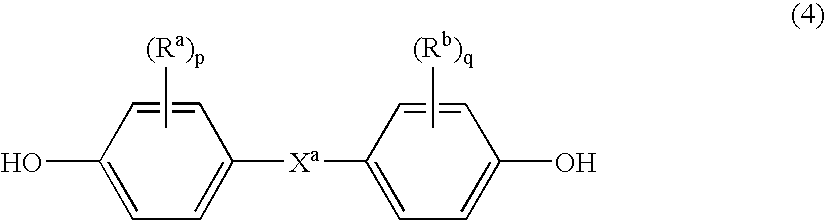

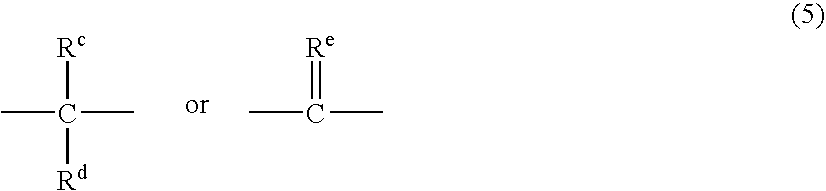

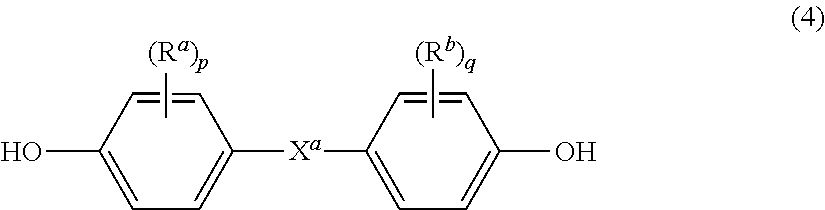

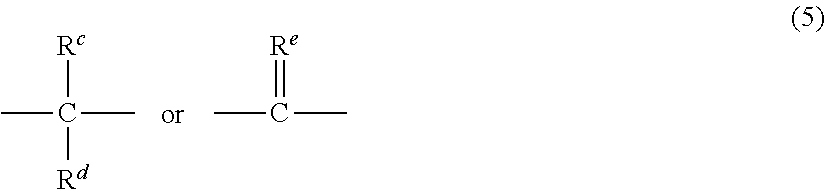

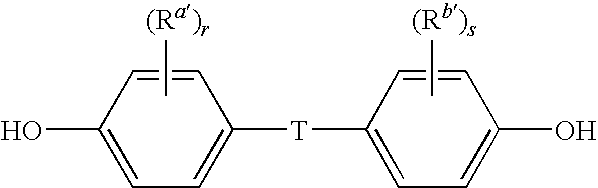

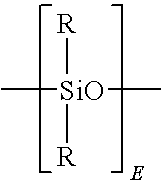

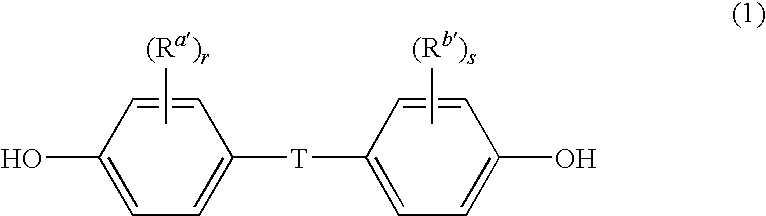

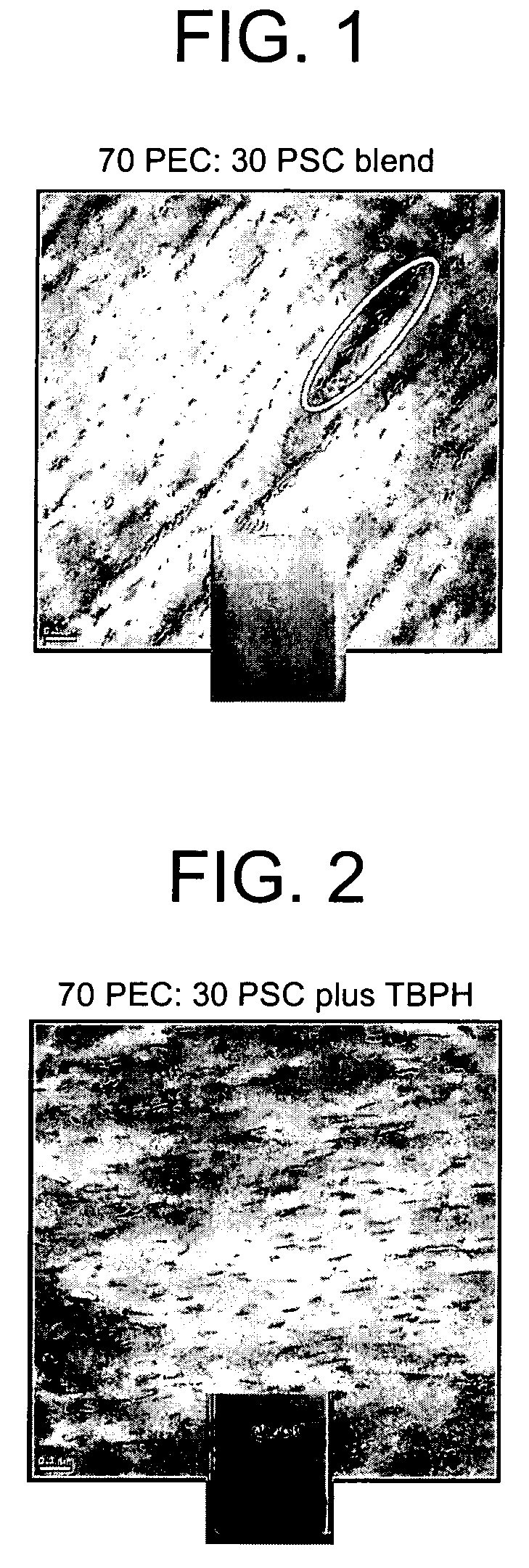

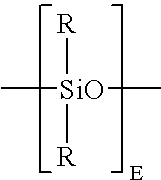

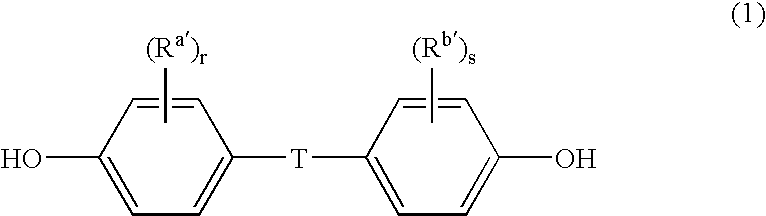

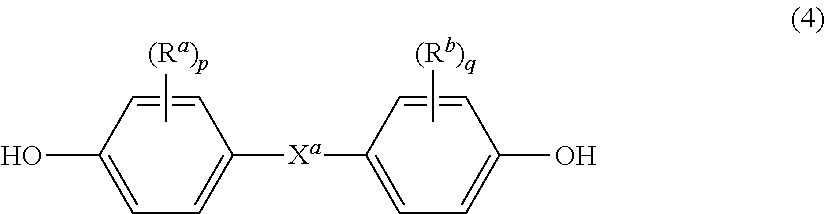

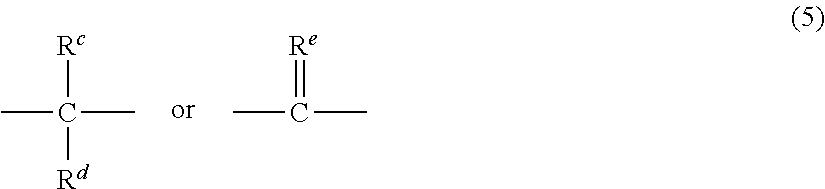

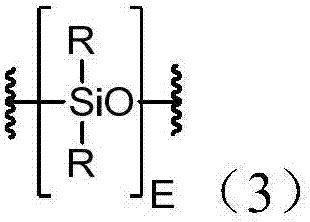

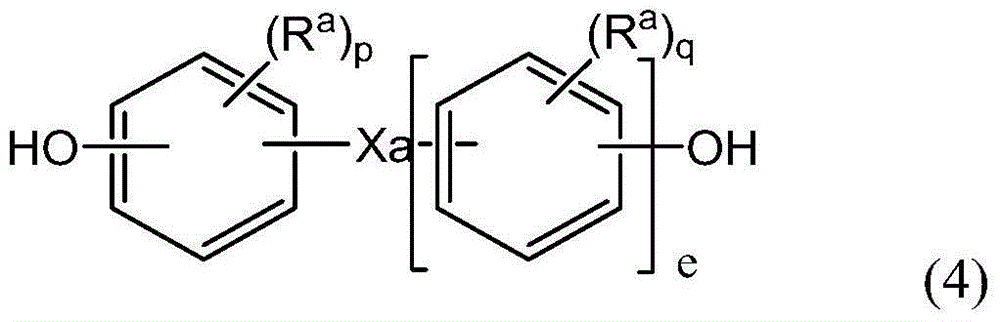

A thermoplastic composition comprises a copolycarbonate comprising 25 to 100 mole percent of a first carbonate unit derived from a dihydroxy aromatic compound having the formulawherein Ra′ and Rb′ are C1-12 alkyl, T is a C5-16 cycloalkylene, a C5-16 cylcloalkylidene, a C1-5 alkylene, a C1-5 alkylidene, a C6-13 arylene, a C7-12 arylalkylene, C7-12 arylalkylidene, a C7-12 alkylarylene, or a C7-12 arylenealkyl, and r and s are each independently 1 to 4, and r and s are 1 to 4; and 0 to 75 mole percent of a second carbonate unit, wherein the first carbonate unit and second carbonate unit are not identical; a polysiloxane-polycarbonate copolymer comprising 0.15 to 30 weight percent of a polysiloxane block comprising siloxane units of the formulawherein E is on average of 4 to 60 units, and 70 to 99.85 weight percent of a third carbonate unit, wherein an article having a thickness of 3.2 mm and molded from the thermoplastic composition has a Dynatup total energy of greater than 50 Joules, as measured at a constant speed of 3.3 to 3.6 m / sec at 23° C. according to ASTM D3763-02. A method of making and articles prepared therefrom are also disclosed.

Owner:SHPP GLOBAL TECH BV

Transparent compositions, methods for the preparation thereof, and articles derived therefrom

A thermoplastic composition is disclosed, comprising the reaction product of: a polyester polycarbonate comprising a polyester unit and a polycarbonate unit; a polysiloxane polycarbonate copolymer having a haze of 30% or less, comprising a polycarbonate unit and a polysiloxane unit; and a transesterification catalyst. The resulting thermoplastic composition has a haze of 30% or less as measured according to ASTM D1003-00 at a thickness of 3.2 millimeters. A method of forming the composition and articles formed from the composition are also disclosed.

Owner:SHPP GLOBAL TECH BV

Methods of sterilizing polycarbonate articles and methods of manufacture

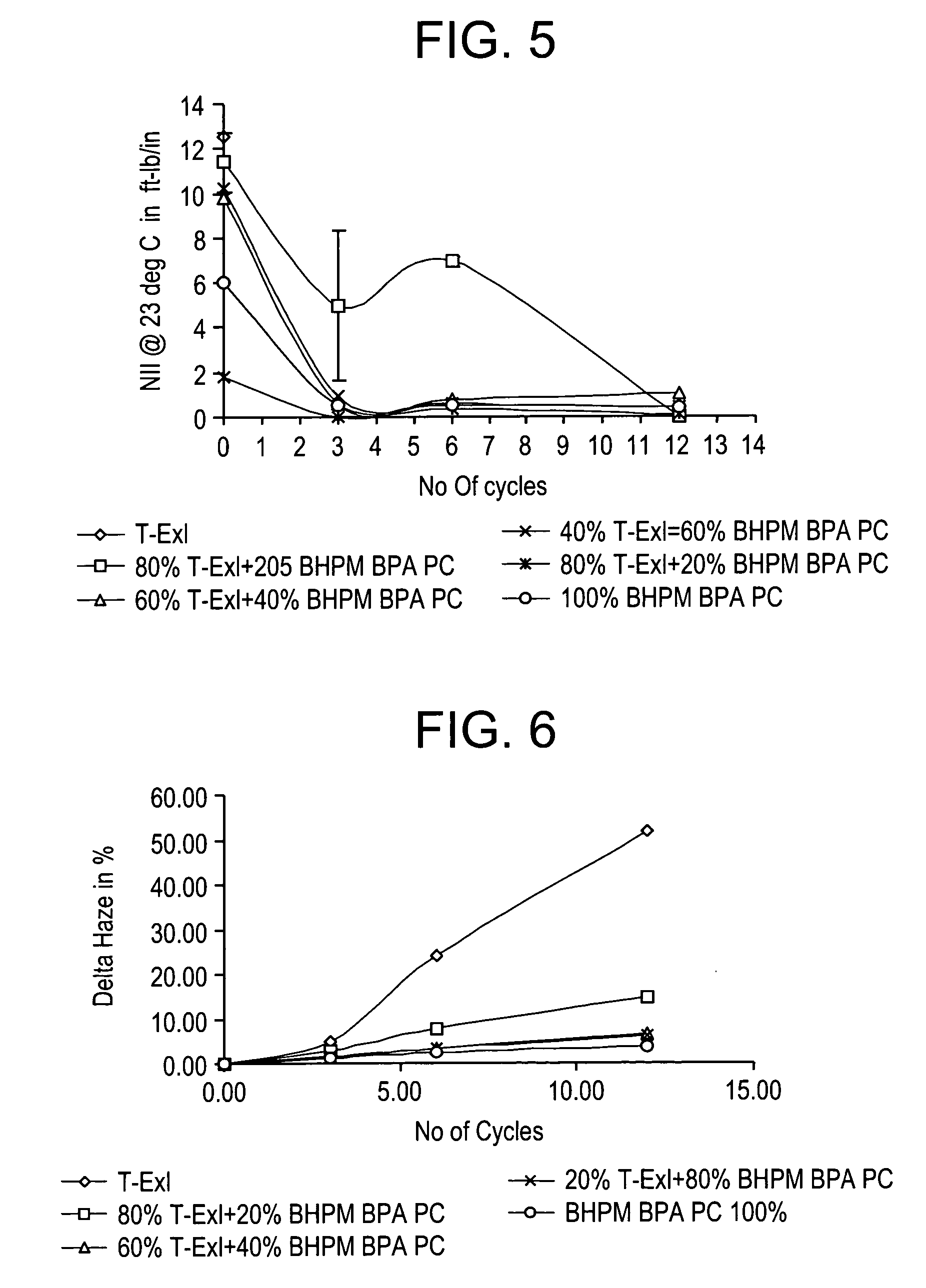

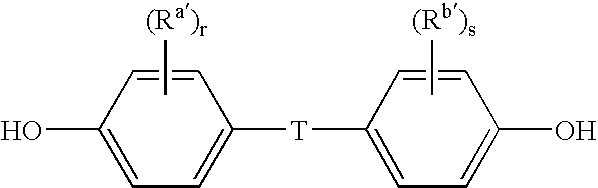

A method comprising treating an article with steam, wherein the article comprises a composition comprising an amount of a polysiloxane-polycarbonate copolymer effective to provide thermal and hydrolytic stability to the article for at least 15 cycles, wherein each cycle comprises 20 minutes of contact with steam at 100° C., at atmospheric pressure. The articles are of utility in a wide variety of applications such as food service and medical applications.

Owner:SHPP GLOBAL TECH BV

Polycarbonate-polysiloxane copolymer compositions and articles formed therefrom

A thermoplastic composition comprises a copolycarbonate comprising 25 to 100 mole percent of a first carbonate unit derived from a dihydroxy aromatic compound having the formulawherein Ra′ and Rb′ are C1-12 alkyl, T is a C5-16 cycloalkylene, a C5-16 cylcloalkylidene, a C1-5 alkylene, a C1-5 alkylidene, a C6-13 arylene, a C7-12 arylalkylene, C7-12 arylalkylidene, a C7-12 alkylarylene, or a C7-12 arylenealkyl, and r and s are each independently 1 to 4, and r and s are 1 to 4; and 0 to 75 mole percent of a second carbonate unit, wherein the first carbonate unit and second carbonate unit are not identical; a polysiloxane-polycarbonate copolymer comprising 0.15 to 30 weight percent of a polysiloxane block comprising siloxane units of the formulawherein E is on average of 4 to 60 units, and 70 to 99.85 weight percent of a third carbonate unit, wherein an article having a thickness of 3.2 mm and molded from the thermoplastic composition has a Dynatup total energy of greater than 50 Joules, as measured at a constant speed of 3.3 to 3.6 m / sec at 23° C. according to ASTM D3763-02. A method of making and articles prepared therefrom are also disclosed.

Owner:SHPP GLOBAL TECH BV

Transparent thermoplastic compositions having high flow and ductiliy, and articles prepared therefrom

Disclosed herein is a thermoplastic composition comprising a combination of: a polysiloxane-polycarbonate copolymer and a poly(aliphatic ester)-polycarbonate copolymer comprising soft block ester units of the formula (8a); wherein m is 4 to 18, wherein the thermoplastic composition has a melt volume rate of 14 cc / 10 min to 22 cc / 10 min at 300 DEG C and under a load of 1.2 Kg and a dwell time of 6 minutes, according to ASTM D1238-04, wherein an article molded from the thermoplastic composition and having a thickness of 3.2 mm has a percent transmittance of greater than 85% according to ASTM D1003-00, and wherein 100% of a set of five test articles each having a thickness of 3.2 mm and molded from the thermoplastic composition exhibit ductile fracture at -40 DEG C when measured for notched Izod Impact according to ASTM D256-04. An article comprising the thermoplastic composition is also disclosed.

Owner:SHPP GLOBAL TECH BV

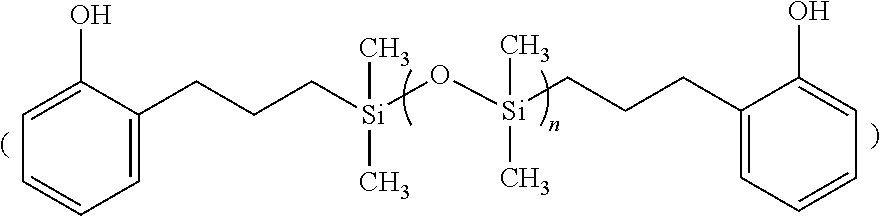

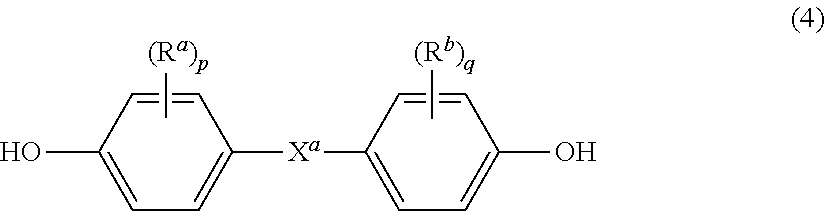

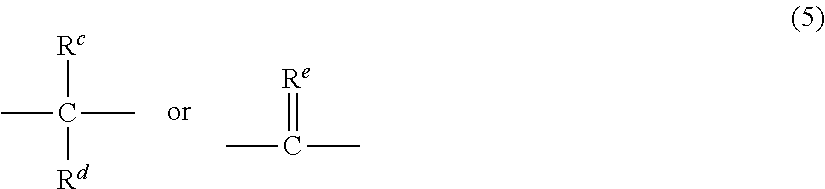

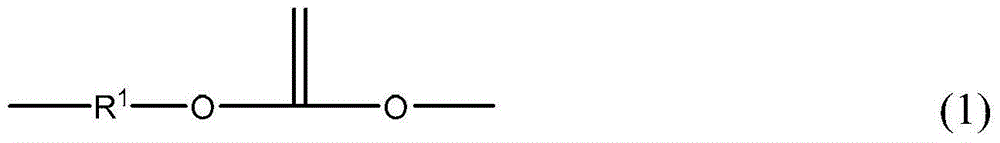

Polysiloxane-polycarbonate copolymer article

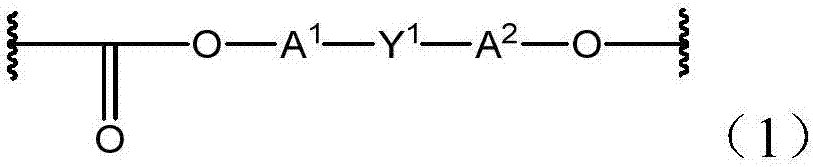

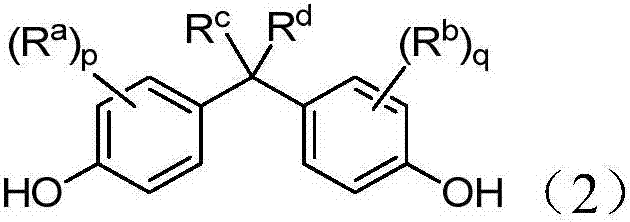

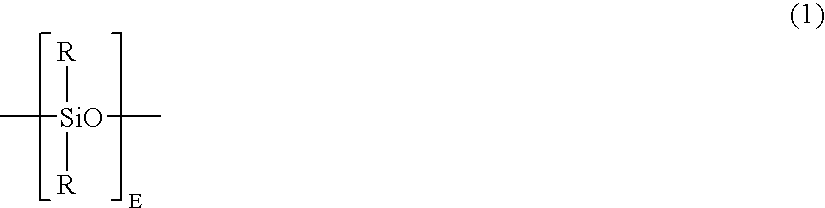

Disclosed herein are polysiloxane-polycarbonate copolymer articles. In one embodiment, a ⅛th inch thick bar formed from the thermoplastic composition has a B-Y ratio of less than or equal to about 1.75. This article, which has a dimension that is greater than or equal to 1.5 cm, comprises the thermoplastic composition which comprises a polysiloxane-polycarbonate copolymer, wherein the copolymer comprises repeating diorganosiloxane units of formula (1): wherein each R is, independently, a C1-13 monovalent organic group; and E has an average value of 20 to 35.

Owner:SHPP GLOBAL TECH BV

Transparent thermoplastic compositions having high flow and ductiliy, and articles prepared therefrom

Owner:SHPP GLOBAL TECH BV

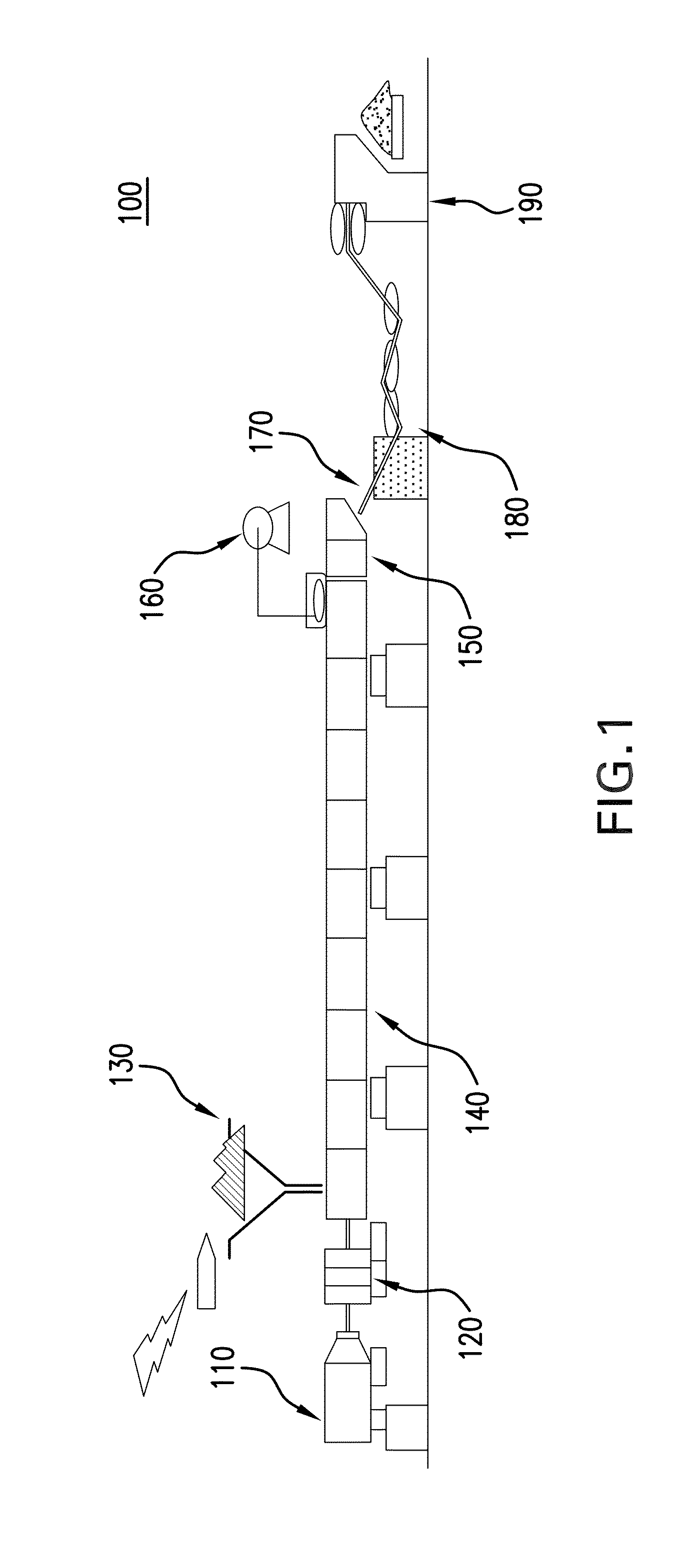

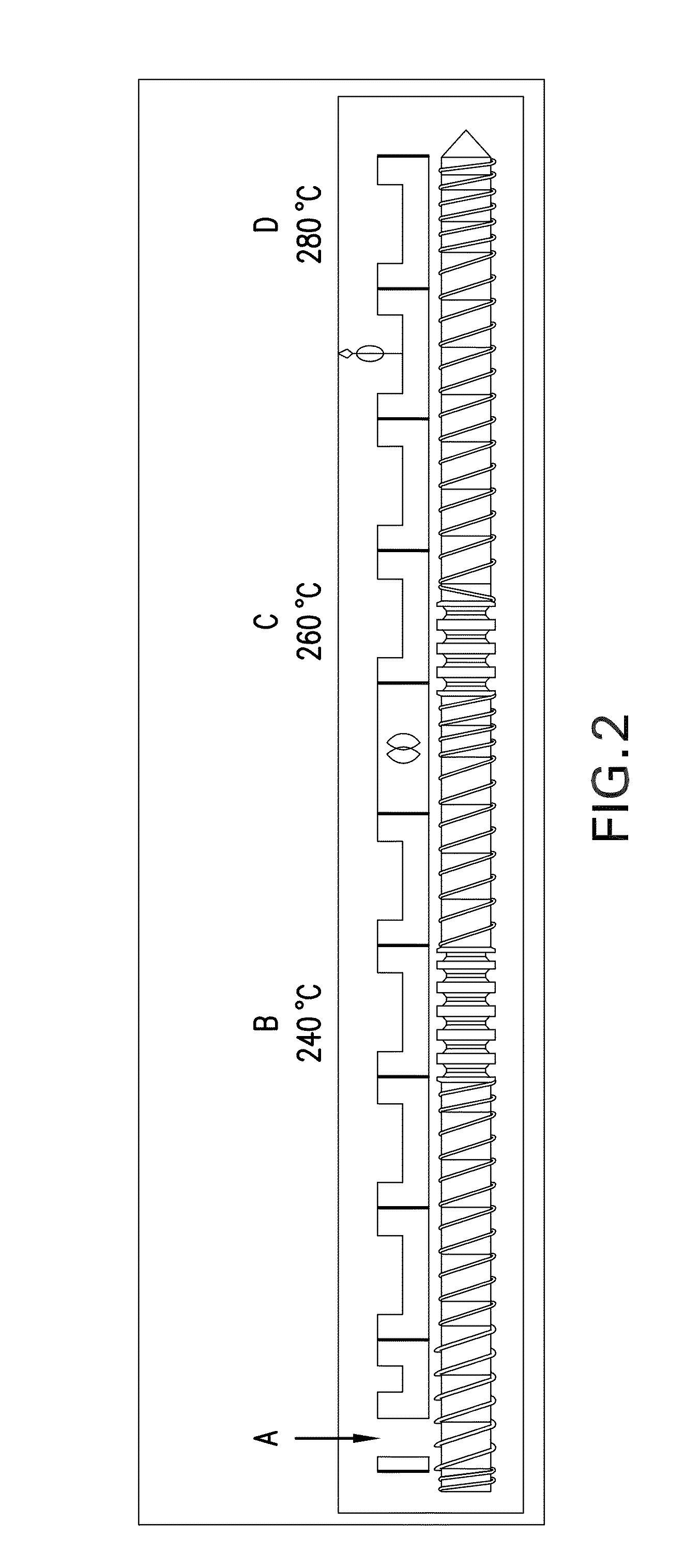

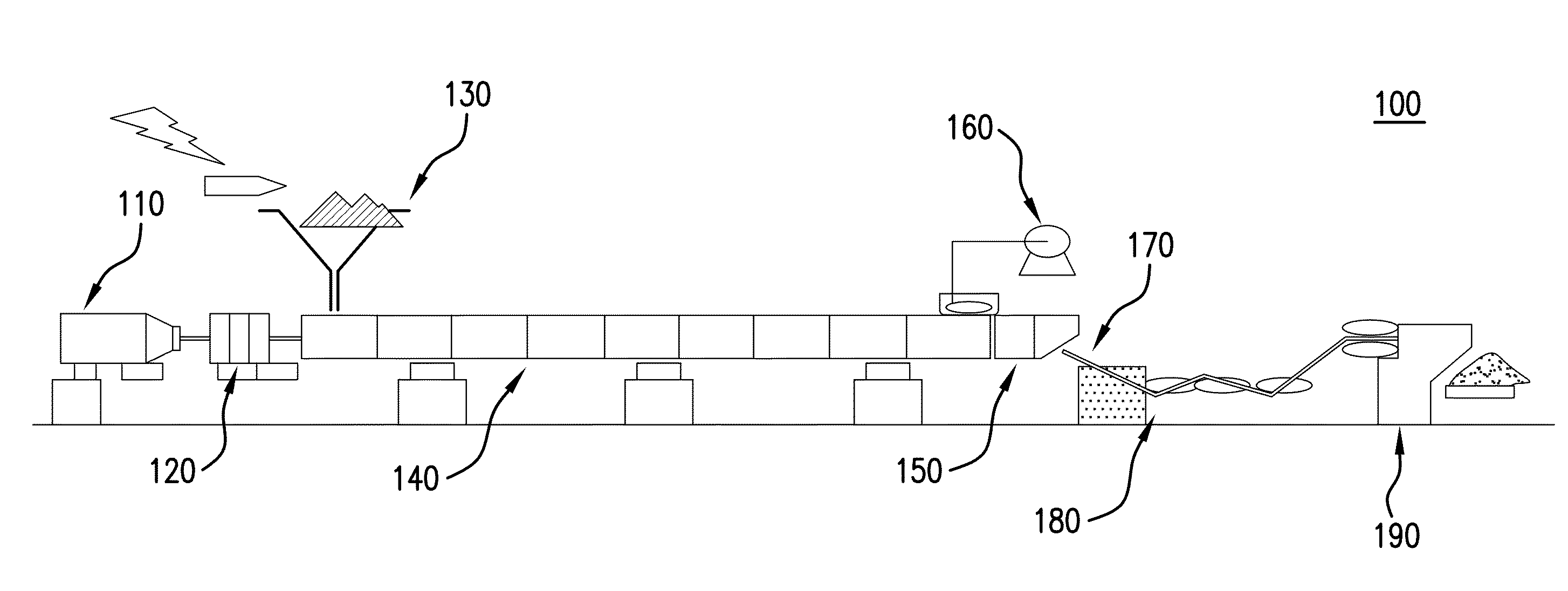

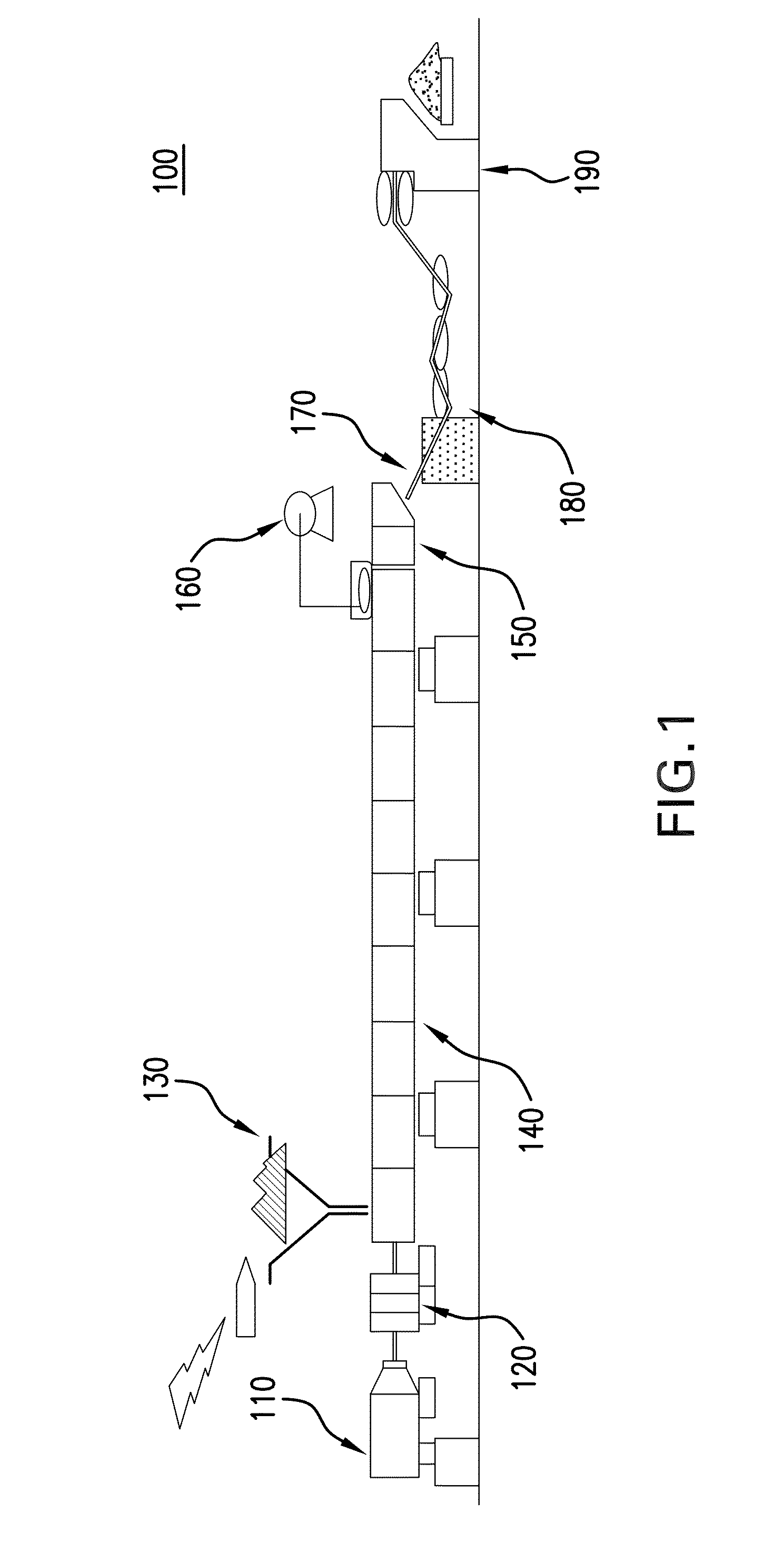

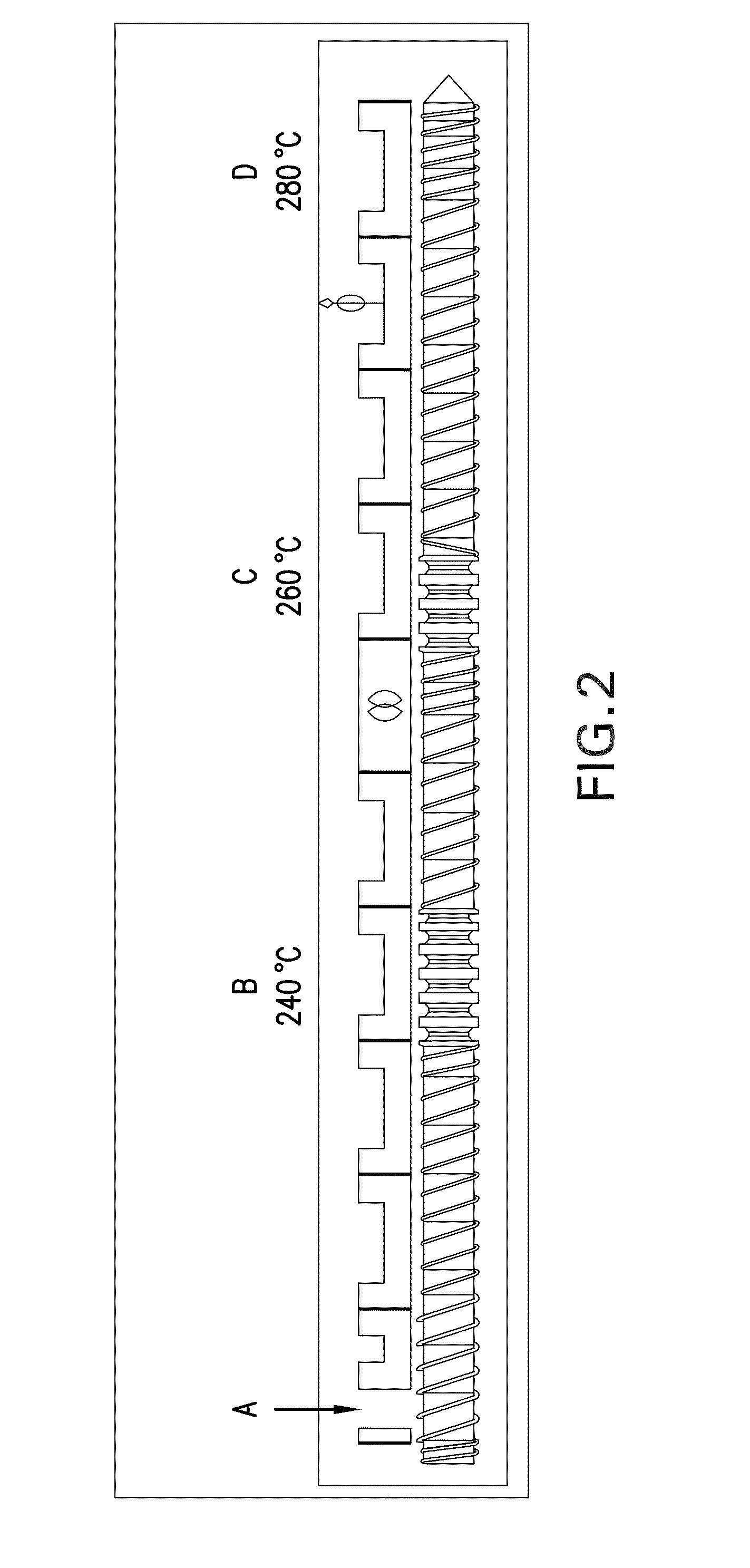

Thermoplastic compositions for laser direct structuring and methods for the manufacture and use thereof

The present disclosure relates to thermoplastic compositions. The disclosed compositions comprise a polycarbonate polymer, a polysiloxane-polycarbonate copolymer, a laser direct structuring additive, and a siloxane additive. Also disclosed are methods for making the disclosed thermoplastic compositions and articles of manufacture comprising the disclosed thermoplastic compositions.

Owner:SHPP GLOBAL TECH BV

Transparent compositions, methods for the preparation thereof, and articles derived therefrom

A thermoplastic composition is disclosed, comprising the reaction product of: a polyester polycarbonate comprising a polyester unit and a polycarbonate unit; a polysiloxane polycarbonate copolymer having a haze of 30% or less, comprising a polycarbonate unit and a polysiloxane unit; and a transesterification catalyst. The resulting thermoplastic composition has a haze of 30% or less as measured according to ASTM D1003-00 at a thickness of 3.2 millimeters. A method of forming the composition and articles formed from the composition are also disclosed.

Owner:SHPP GLOBAL TECH BV

Flame retardant thermoplastic polycarbonate compositions, use and method thereof

InactiveUS20080227896A9Plastic/resin/waxes insulatorsDyeing processThermoplasticPolysiloxane polycarbonate copolymer

A thermoplastic composition contains about 20 to about 90 wt. % of a polycarbonate resin; up to about 35 wt. % of an impact modifier; about 0.5 to about 30 wt. % of a polysiloxane-polycarbonate copolymer; and about 0.5 to about 20 wt. % of a phosphorus-containing flame retardant, each based on the total combined weight of the thermoplastic composition, exclusive of any filler. An article of manufacture having a wall having a thickness of 3 mm or less may be made using the composition, e.g., by molding, extruding, or shaping the above-described composition into an article. Alternatively, an article may be made by ultrasonically welding a first part comprising the foregoing composition a second part.

Owner:SHPP GLOBAL TECH BV

Flame retardant thermoplastic compositions having EMI shielding

ActiveUS8399546B2Good physical propertiesConductive materialNon-conductive material with dispersed conductive materialPolysiloxane polycarbonate copolymerMetal fibers

Owner:SHPP GLOBAL TECH BV

Thermoplastic composition, method of making, and articles formed therefrom

A thermoplastic composition is disclosed, comprising a polymer component comprising a polysiloxane-polycarbonate copolymer comprising siloxane units of the formulawherein each occurrence of R is the same or different and is independently a C1-13 monovalent organic group; the average value of E is 4 to 60; and carbonate units of the formulawherein at least about 60 percent of the total number of R1 groups are a divalent C6-36 aromatic organic group, and the balance thereof are C1-36 aliphatic, C5-36 alicyclic, or C6-36 aromatic organic groups; and 0.03 to 5 weight percent, based on the total weight of the polymer component, of a polymeric compound comprising at least two epoxy groups, wherein the polymeric compound has a weight average molecular weight of 1,500 to 18,000 Daltons.

Owner:SABIC INNOVATIVE PLASTICS IP BV

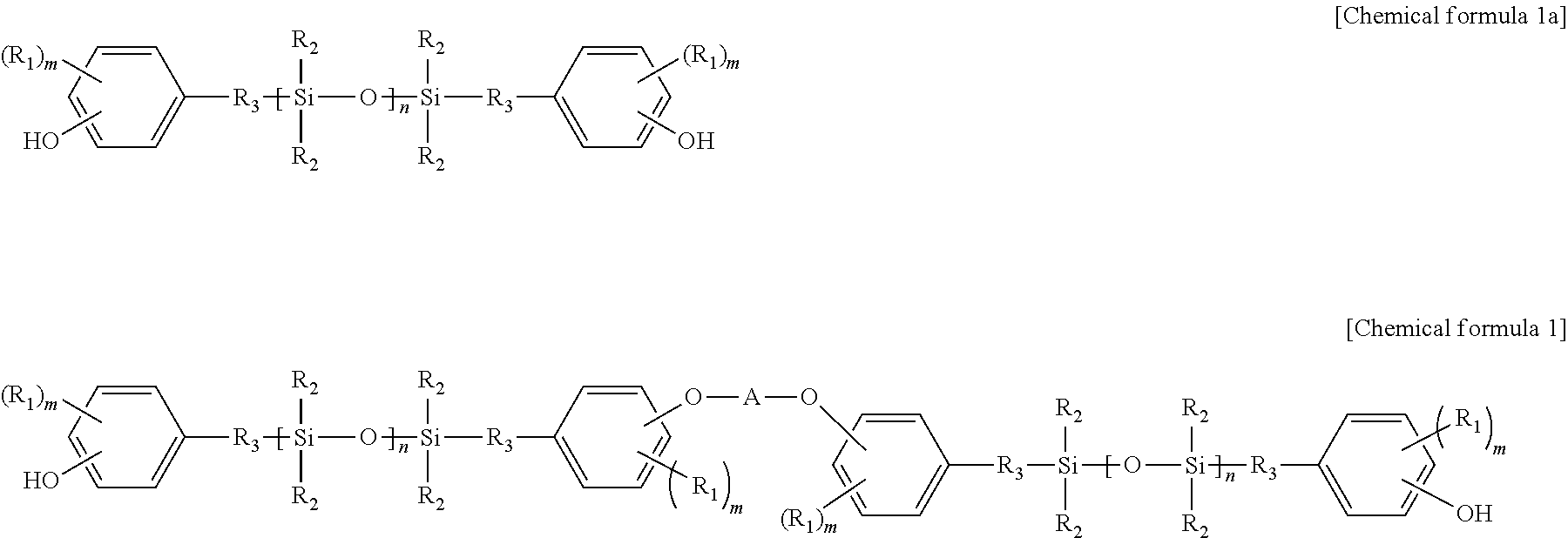

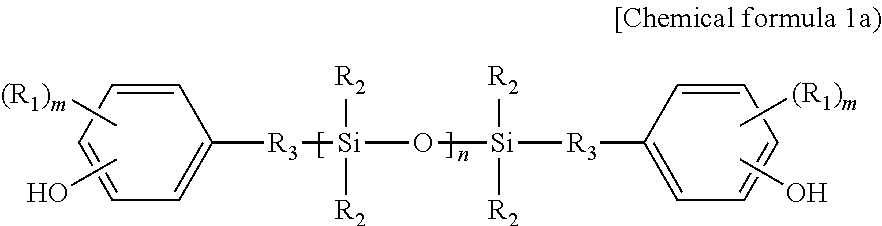

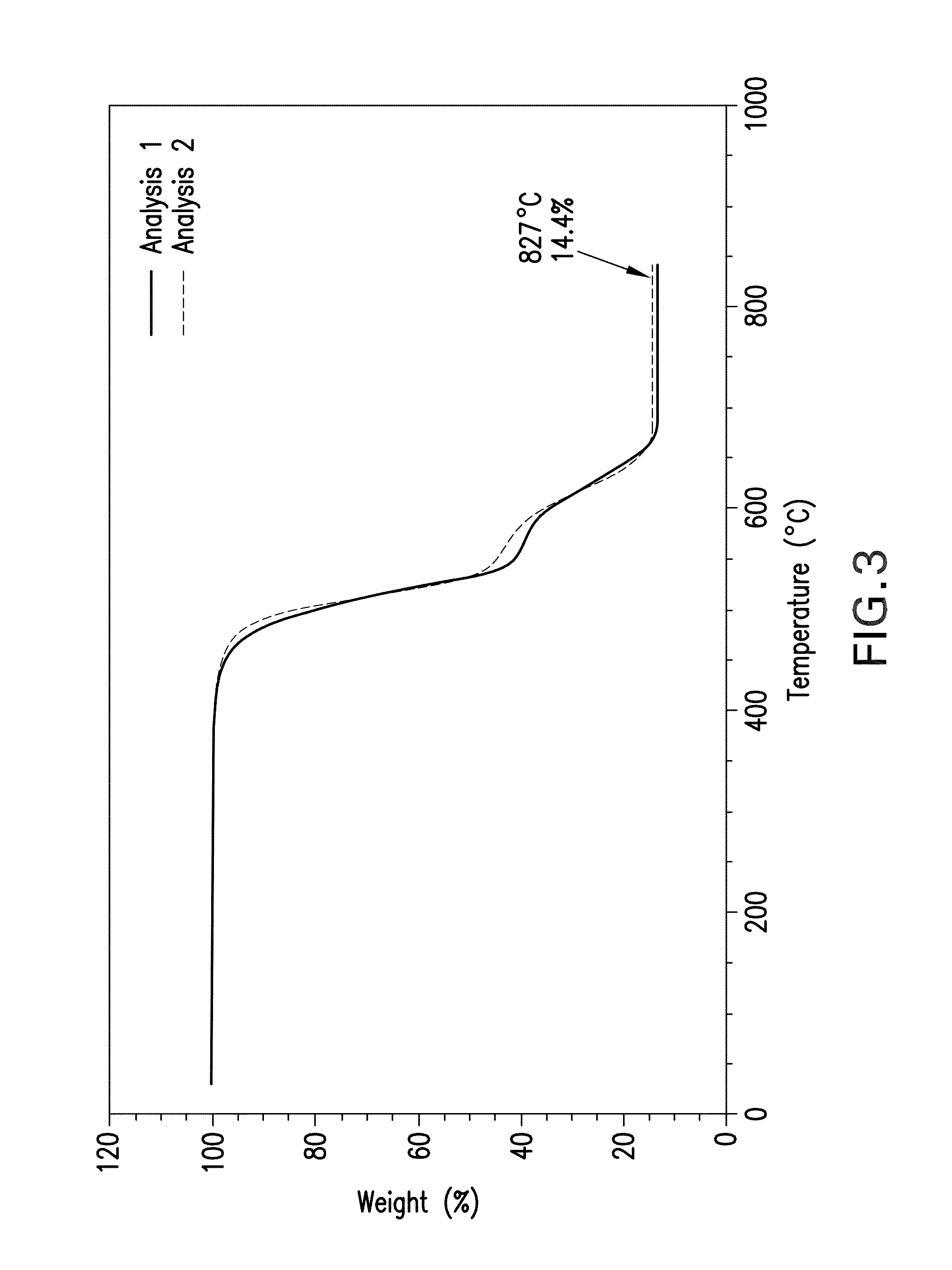

Hydroxy-terminated siloxane, polysiloxane-polycarbonate copolymer, and preparation method thereof

ActiveUS20120309922A1Improve heat resistanceImprove impact resistanceSilicon organic compoundsPolysiloxane polycarbonate copolymerPolycarbonate

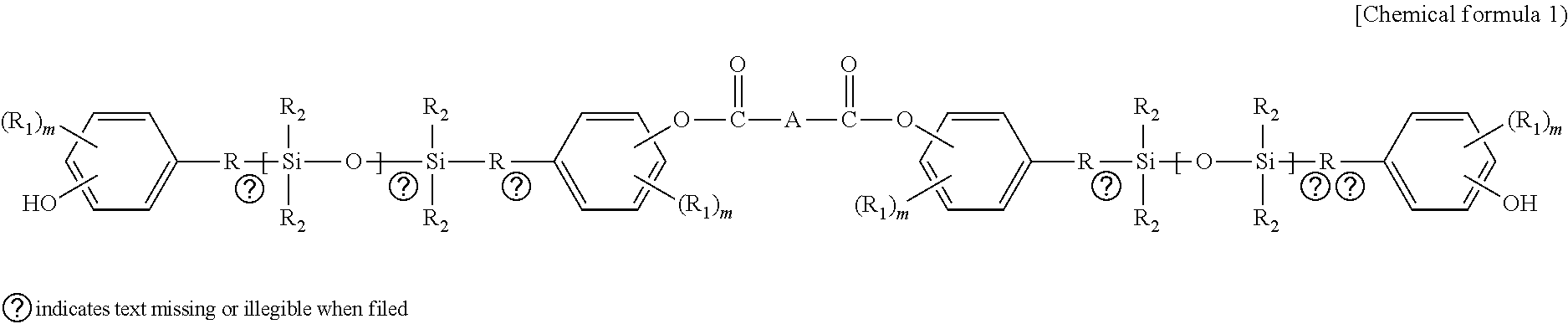

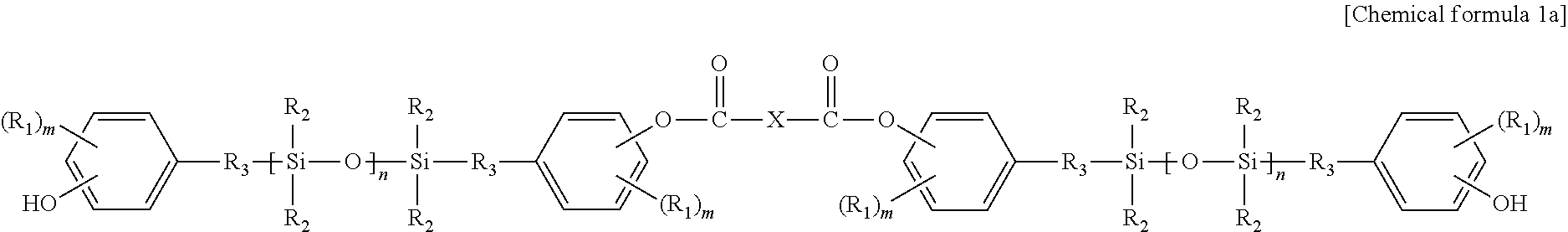

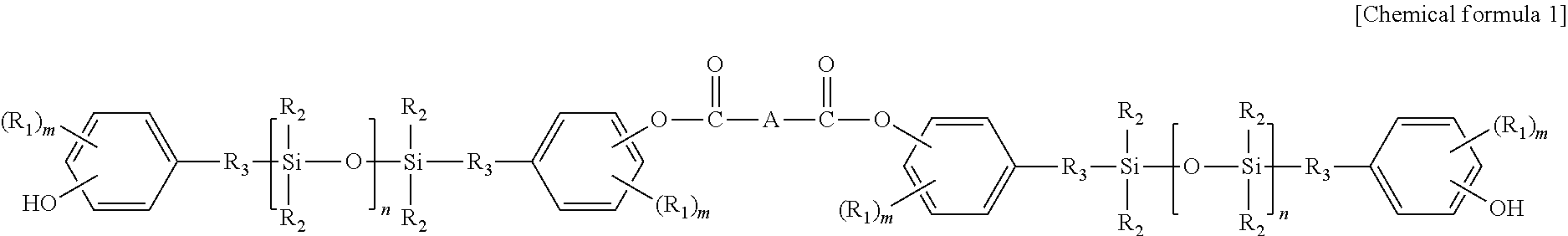

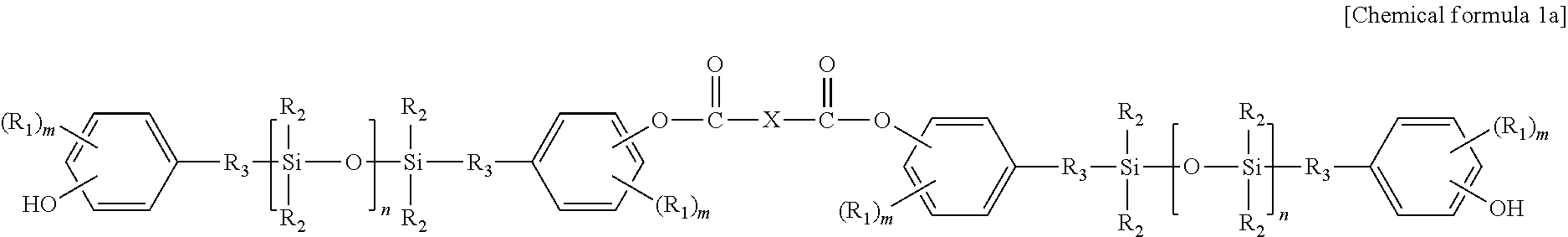

Provided are a hydroxy-terminated siloxane, a polysiloxane-polycarbonate copolymer including same as a repeating unit, and a preparation method thereof. The hydroxyl-terminated siloxane has the structure of chemical formula 1.

Owner:SAMSANG CORP

Hydroxy-terminated siloxane, polysiloxane-polycarbonate copolymer, and preparation method thereof

ActiveUS8802804B2Avoid serious impactIncrease resistanceSilicon organic compoundsPolysiloxane polycarbonate copolymerPolycarbonate

Owner:SAMSANG CORP

Thermoplastic compositions for laser direct structuring and methods for the manufacture and use thereof

ActiveUS8816019B2Special tyresAnti-corrosive paintsPolysiloxane polycarbonate copolymerPolycarbonate

The present disclosure relates to thermoplastic compositions. The disclosed compositions comprise a polycarbonate polymer, a polysiloxane-polycarbonate copolymer, a laser direct structuring additive, and a siloxane additive. Also disclosed are methods for making the disclosed thermoplastic compositions and articles of manufacture comprising the disclosed thermoplastic compositions.

Owner:SHPP GLOBAL TECH BV

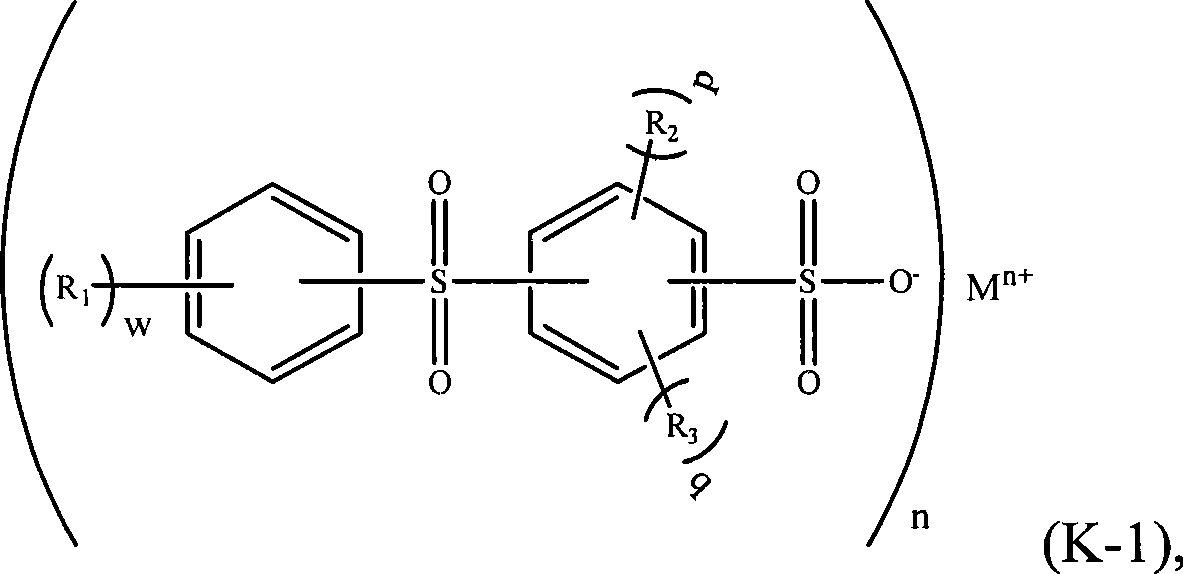

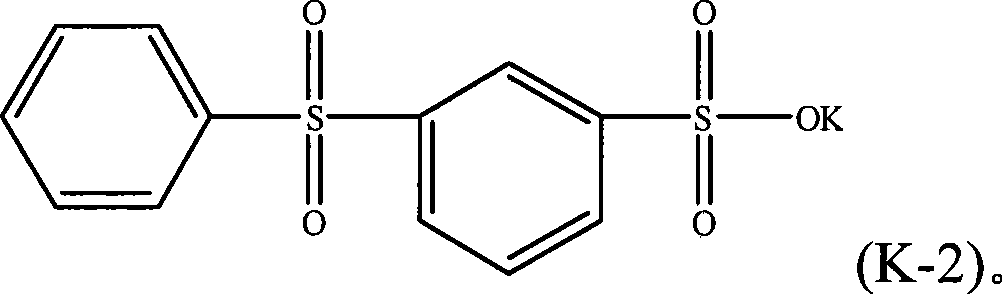

Polycarbonate compositions and articles formed therefrom

A polycarbonate composition is disclosed having zero or minimum halogen content, while also exhibiting improved fire-retardance and / or drip-resistant characteristics. The composition comprises an effective amount of a polycarbonate, an anti-dripping agent, an aromatic sulfone sulfonate, an aromatic sulfonate, a synergistic combination of an elastomer-modified graft copolymer and a polysiloxane-polycarbonate copolymer, and an optional siloxane oligomer. The polycarbonate composition is useful for manufacture of electronic and mechanical articles, among others.

Owner:SHPP GLOBAL TECH BV

Polycarbonate composition

ActiveUS20150079375A1Good aesthetic propertyGood flow propertySynthetic resin layered productsPolysiloxane polycarbonate copolymerGlass fiber

A composition includes at least one poly(aliphatic ester)-polycarbonate copolymer, a polysiloxane-polycarbonate copolymer, and glass fibers. The composition exhibits good flow, aesthetic, and impact properties.

Owner:SHPP GLOBAL TECH BV

Polycarbonate composition

ActiveUS20150344687A1Easy to moveSynthetic resin layered productsGlass fiberPolysiloxane polycarbonate copolymer

A composition includes at least one poly(aliphatic ester)-polycarbonate copolymer, a polysiloxane-polycarbonate copolymer, non-bonding glass fibers, and titanium dioxide. The composition exhibits excellent impact properties and an ultra-white color.

Owner:SHPP GLOBAL TECH BV

Polysiloxane-polycarbonate copolymer compositions

InactiveCN107466309ACasings/cabinets/drawers detailsPolysiloxane polycarbonate copolymerFire retardant

Electronics housings that include a thermoplastic composition are provided. The thermoplastic compositions include at least one polycarbonate, at least two polysiloxane- polycarbonate copolymers, and a flame retardant. The thermoplastic compositions can include an additional polycarbonate, an impact modifier, one or more additives, or any combination of these components. Methods used to prepare the thermoplastic compositions and electronics housings are also provided.

Owner:SHPP GLOBAL TECH BV

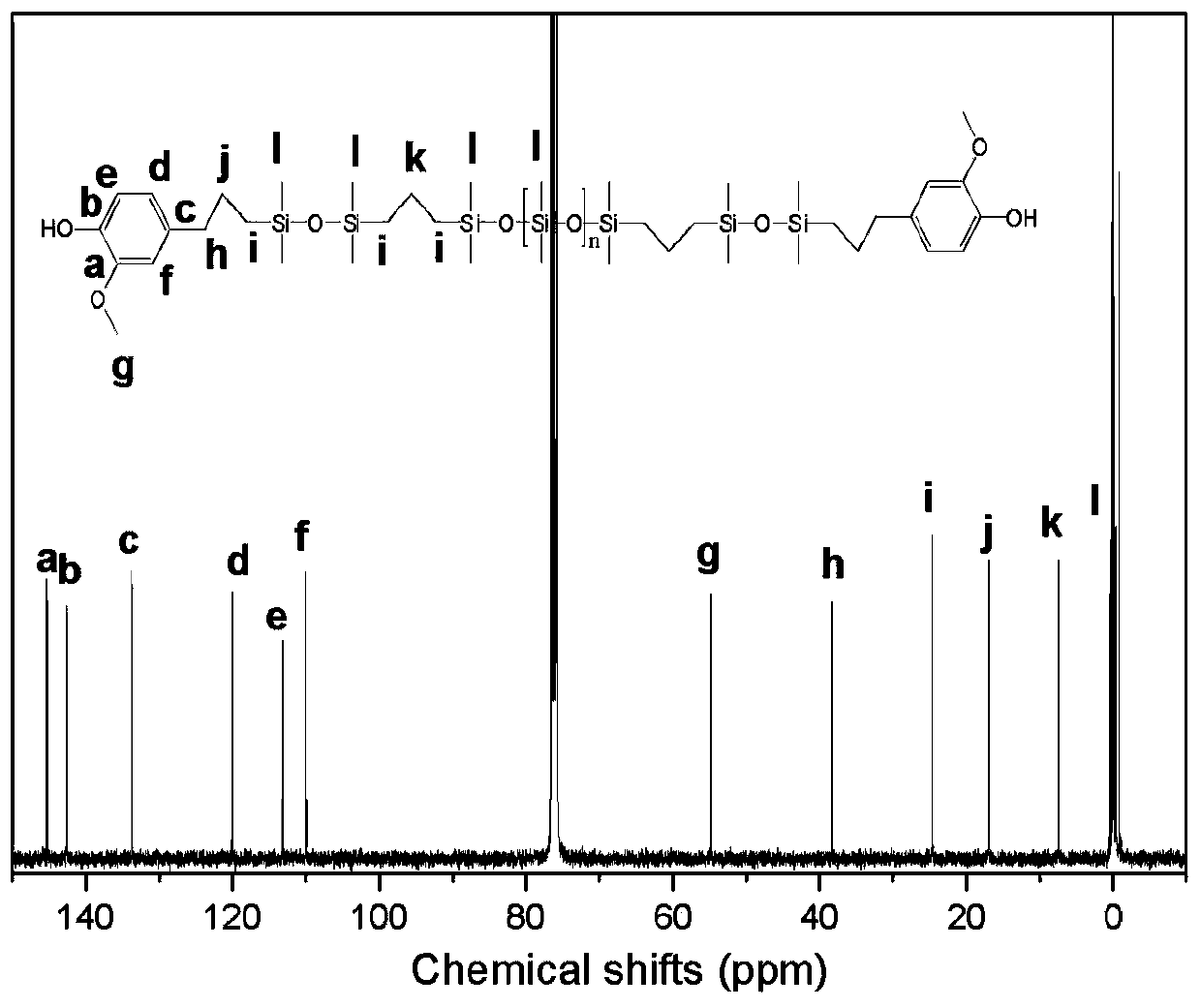

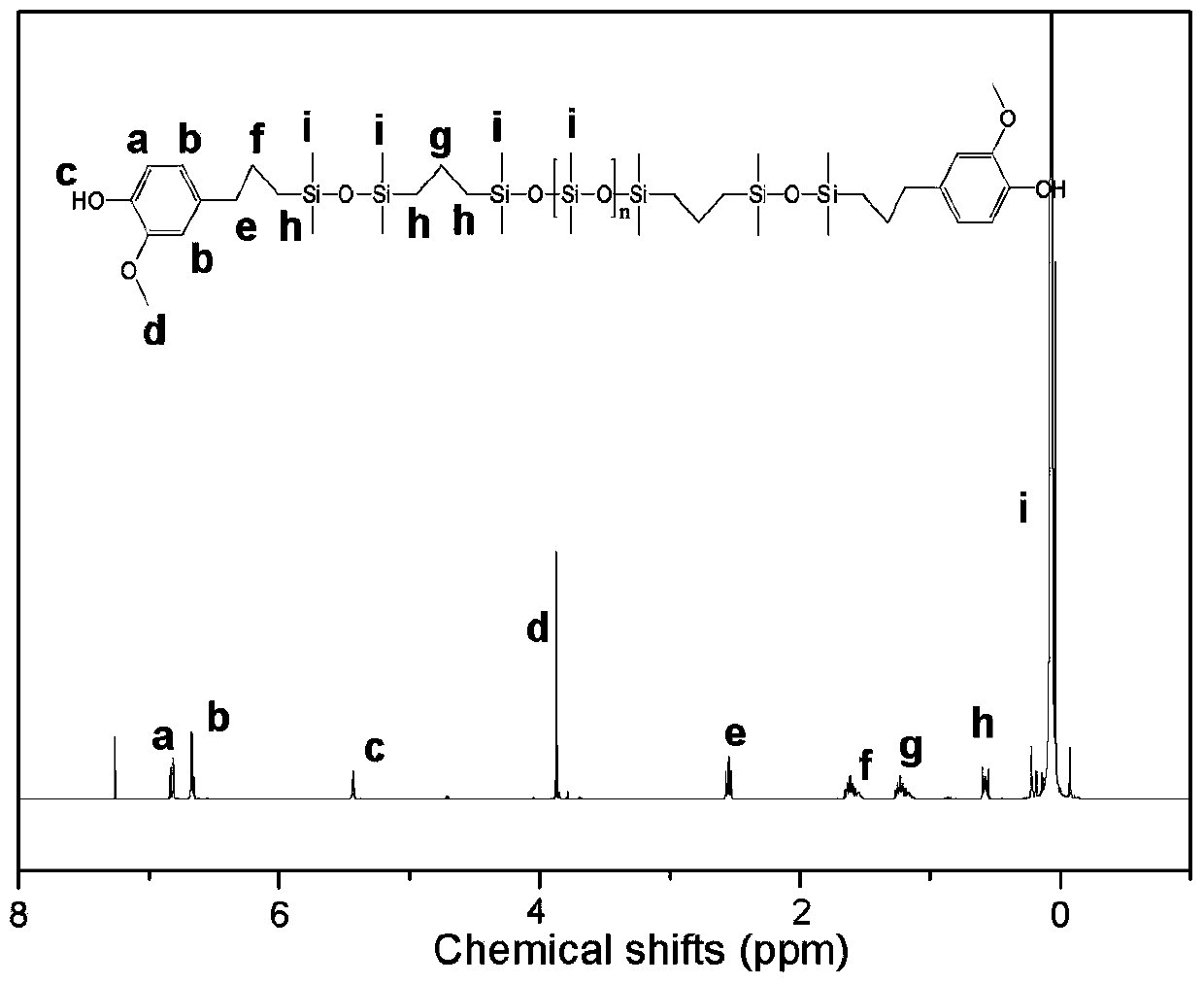

Phenol-terminated polysiloxane, preparation method thereof, and polysiloxane-polycarbonate copolymer

The invention discloses phenol-terminated polysiloxane, a preparation method thereof, and a polysiloxane-polycarbonate copolymer. The method includes the following steps: a) catalyzing a reaction of tetramethyldisiloxane and an allyl-containing phenolic compound by using a transition metal catalyst A to prepare phenol-modified hydrogen-containing silane having a phenol group at one end and a silicon-hydrogen bond at one end; b) performing separation by using reduced-pressure rectification to obtain phenol-modified hydrogen-containing silane with purity of >=99%; and c) catalyzing B by using atransition metal catalyst, performing a hydrosilylation reaction on the pure phenol-modified hydrogen-containing silane and polysiloxane with a vinyl end group to obtain the polysiloxane containing aphenol group at the end group. The content of the free allyl-containing phenol compound in the phenol-terminated polysiloxane is 100 ppm or less, the phenol group capping rate is 98% or more, and theresidual metal platinum content is <= 5 ppm. The phenol-terminated polysiloxane is used for preparing the modified polycarbonate, and the obtained polysiloxane-polycarbonate copolymer has a high polysiloxane content, and excellent heat resistance and yellowing resistance.

Owner:WANHUA CHEM GRP CO LTD +1

Polysiloxane-polycarbonate copolymer article

Owner:SHPP GLOBAL TECH BV

Flame retardant polycarbonate compositions, methods of manufacture thereof and articles comprising the same

Owner:SHPP GLOBAL TECH BV

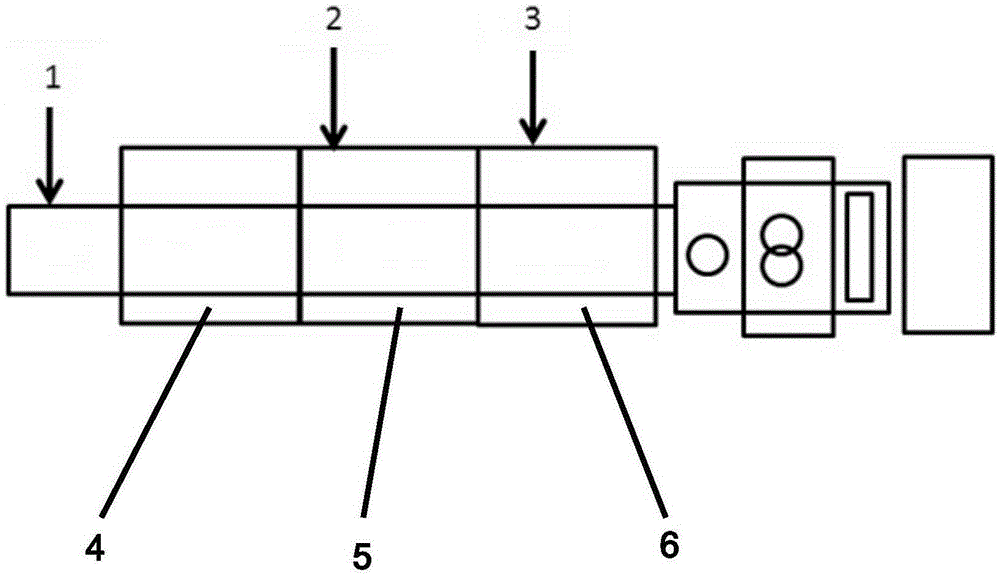

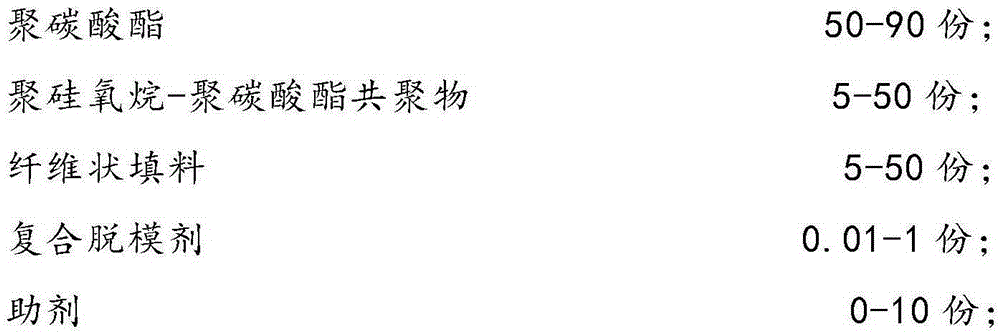

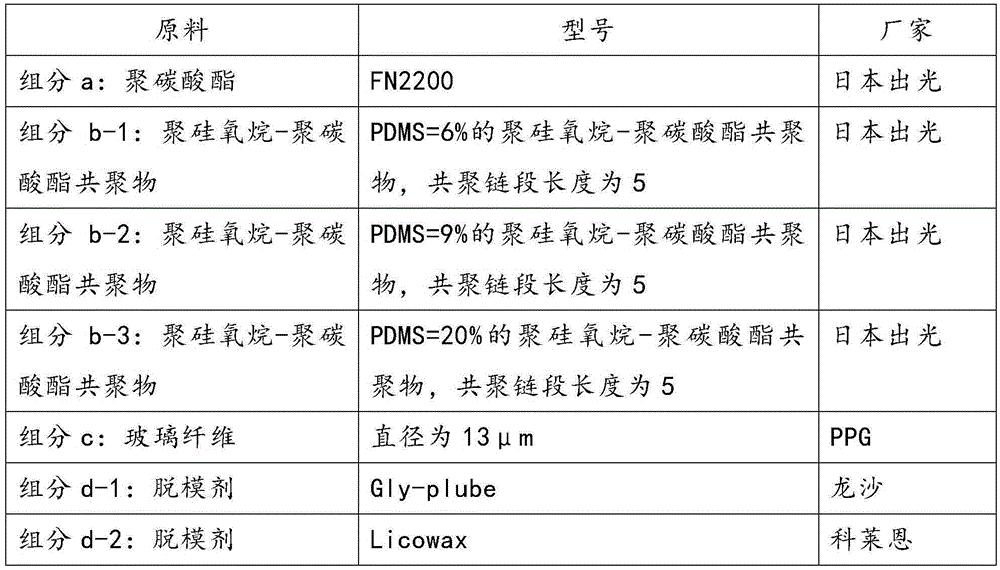

Fiber-reinforced polycarbonate composition and preparation method thereof

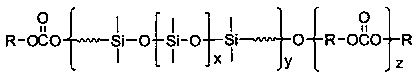

InactiveCN105419289AImprove rigidityImprove low temperature toughnessPolysiloxane polycarbonate copolymerFilling materials

The invention discloses a fiber-reinforced polycarbonate composition which includes the following components, by weight: 50-90 parts of polycarbonate, 5-50 parts of a polysiloxane-polycarbonate copolymer, 5-50 parts of a fiber-like filling material, 0.01-1 part of a composite demoulding agent and 0-10 parts of an additive. The polysiloxane-polycarbonate copolymer is prepared by polymerizing polydimethylsiloxane and polycarbonate. The polydimethylsiloxane accounts for 0.05-30% by weight of the polycarbonate composition. The invention also provides a preparation method of the fiber-reinforced polycarbonate composition. In the invention, by means of regulation of distributions of length and content of the fiber-like filling material in the polycarbonate composition, double-peak distribution of the fiber-like filling material in the polycarbonate composition is achieved. With combination of the composite demoulding agent, the polycarbonate composition is improved in rigidity and also has flame-retarding property and excellent toughness. Meanwhile, the polycarbonate composition is reduced in demoulding force and damage on a mould, and is improved in applicability and practicability.

Owner:SHANGHAI KINGFA SCI & TECH

Polycarbonate composition and application of polysiloxane-polycarbonate copolymer in improving toughness and liquidity of mineral-filled polycarbonate

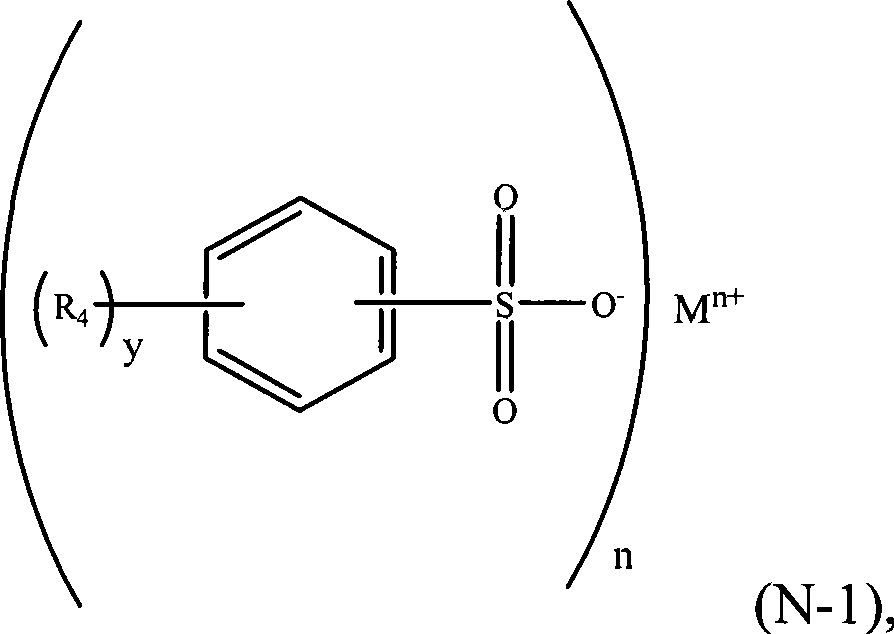

InactiveCN109777074ALow densityReduce heat release rateSulfonatePolysiloxane polycarbonate copolymer

The invention discloses a polycarbonate composition. The polycarbonate composition comprises the following components in parts by weight: 70-100 parts of a polycarbonate resin and polysiloxane-polycarbonate copolymer, 1-35 parts of a mineral filling, 0.1-1.5 parts of sulfonate and 1-12 parts of a phosphorous-containing compound; and according to the weight parts, the ratio of the polycarbonate resin to the polysiloxane-polycarbonate copolymer is (9:1) to (1:9). The polycarbonate composition disclosed by the invention has the advantages of low smoke density, low heat release speed and high toughness and liquidity. The toughness of the polysiloxane-polycarbonate copolymer is slightly lower than that of traditional polycarbonate; however, after mineral-filled polycarbonate is added to the polysiloxane-polycarbonate copolymer, the toughness of the polycarbonate filled with the minerals can be obviously improved; and the liquidity of the composition is also improved.

Owner:KINGFA SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com