Transparent thermoplastic compositions having high flow and ductiliy, and articles prepared therefrom

A technology for thermoplastic compositions and products, which is applied in the field of thermoplastic compositions of poly-polycarbonate copolymers, can solve problems such as damage to polycarbonate impact strength mechanical properties (elongation at break, fatigue stress, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

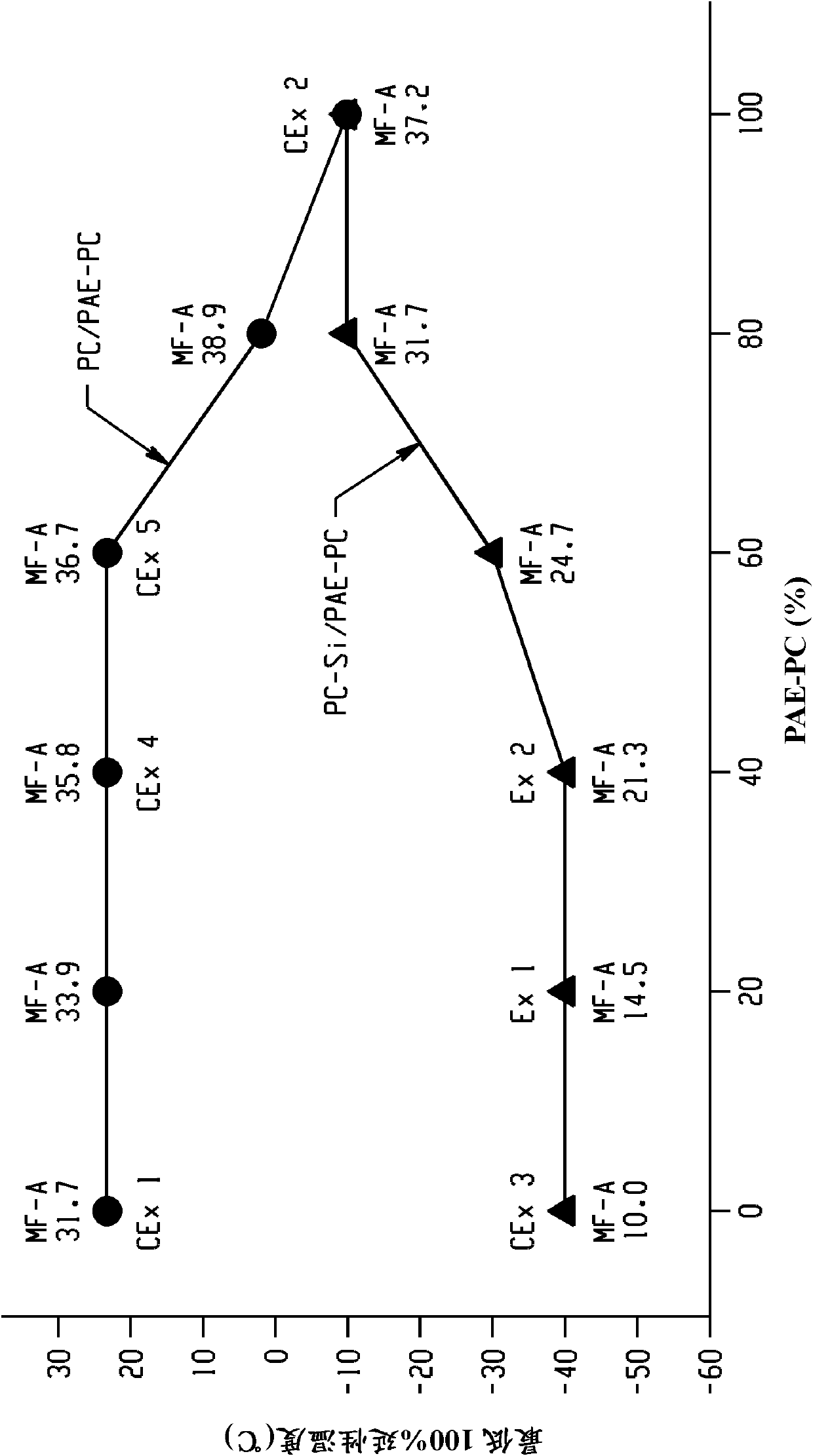

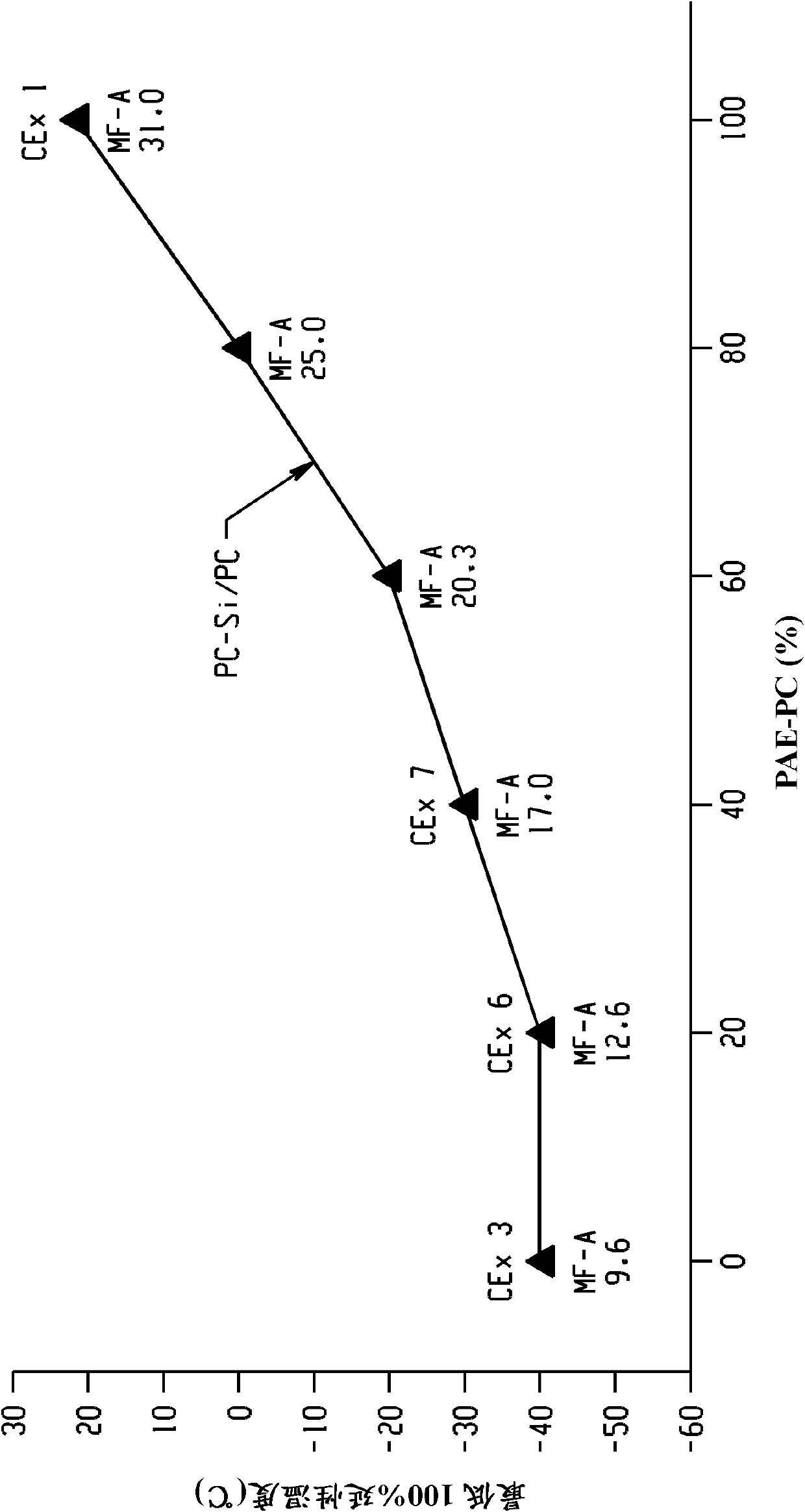

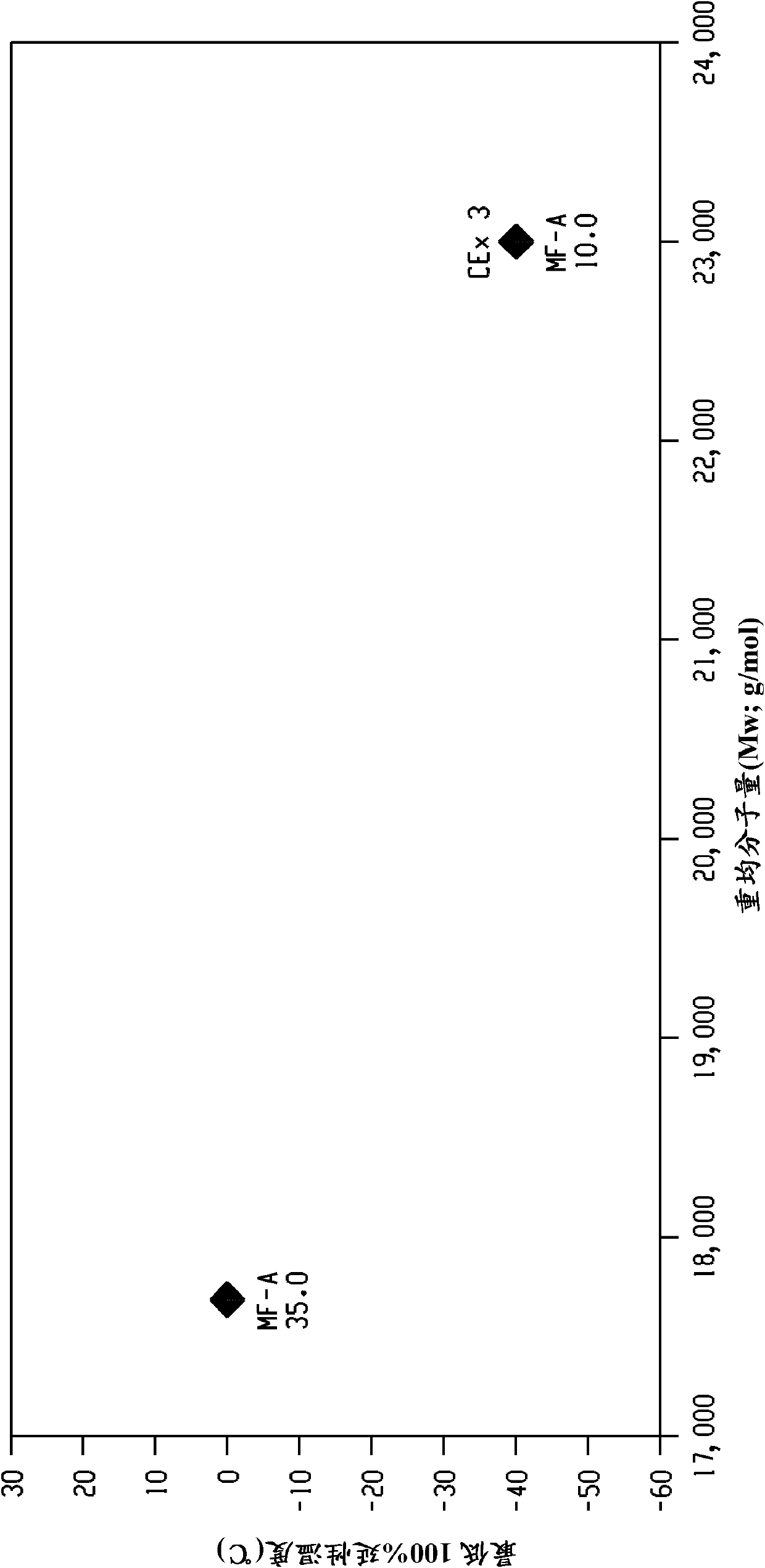

[0155] Examples 1 and 2. Blends of PC-Si and PAE-PC copolymers were prepared as shown in Table 2, and their properties were measured. The PC-Si used had a siloxane content of 6 wt %, a weight average molecular weight of 23,000 g / mol, and an MVR of 10 cc / 10 min. The PAE-PC copolymer also had a similar molecular weight, and had a MVR of 38 cc / 10 min, and a soft block (ie, sebacate unit) content of 6 wt%. It can be seen that as the amount (wt%) of PAE-PC copolymer in the blend increases relative to PC-Si, the melt flow increases linearly from 10cc / 10min to 38cc / 10min, and the blend Keep optically clear.

[0156] Table 2 shows the data for the following examples: Example 1 with a blend ratio of PAE-PC to PC-Si of 20:80 w / w, and a blend ratio of PAE-PC to PC-Si of 40:60 w / w Example 2. Example 1 shows a MVR of 14.5 cc / 10 min and maintains 100% ductility down to -40°C. Example 2 shows a MVR of 21.3 cc / 10 min and also maintains 100% ductility down to -40°C.

[0157] Unexpectedly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com