Polypropylene-surlyn resin composite material

A sarin resin and composite material technology, applied in the field of polymer materials, can solve environmental protection and other problems, and achieve the effects of improving scratch resistance, outstanding visual effects, and improving surface gloss

Inactive Publication Date: 2019-04-16

严静儿

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a polypropylene-sarrin composite material to solve the environmental protection problems caused by the appearance and spray painting of polypropylene products in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

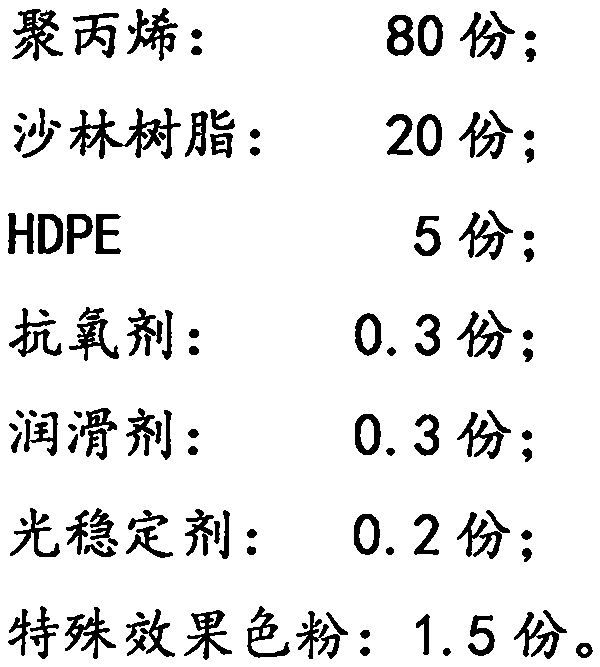

[0028] The polypropylene-sarin composite material in this example is made up of following raw materials by weight:

[0029]

Embodiment 2

[0031] The polypropylene-sarin composite material in this example is made up of following raw materials by weight:

[0032]

Embodiment 3

[0034] The polypropylene-sarin composite material in this example is made up of following raw materials by weight:

[0035]

[0036]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a polypropylene-surlyn resin composite material. The composite material comprises, by weight, 55-85 parts of polypropylene, 5-25 parts of surlyn resin, 3-5 parts of HDPE, 0-10parts of a toughening agent, 0-15 parts of an enhancer, 0.3-0.8 part of an antioxidant, 0.2-1 part of a lubricant, 0.2-0.4 part of a light stabilizer and 1-3 parts of special effect color powder. Thesurlyn resin has excellent low-temperature impacting performance, the low temperature brittleness of a PP material can be significantly improved, the surlyn resin is transparent and has high glossiness, the surface gloss level of the composite material can be significantly improved after the surlyn resin is added, a metal imitation visual effect is more outstanding, the surlyn resin has higher scratching resistance, and therefore the scratching resistance of the material can be significantly improved.

Description

technical field [0001] The invention belongs to the technical field of polymer materials, in particular to a polypropylene-surrin composite material. Background technique [0002] Polypropylene (PP) is a widely used polymer material. It has good molding processability and good heat resistance. It is widely used in the field of home appliances, such as rice cookers and vacuum cleaners. With the improvement of people's living standards, the design and appearance of home appliances are becoming more and more exquisite. For example, some metal appearance requirements are usually solved by spraying paint, which does not meet the general trend of energy conservation and environmental protection. [0003] In response to this situation, the present invention has produced a polypropylene-sarin composite material with a metal-like appearance and a corresponding preparation method, which not only solves the problems of environmental protection and yield caused by spraying paint on poly...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/12C08L23/14C08L23/08C08L23/06C08K13/02C08K3/30C08K3/34

CPCC08L23/12C08K2003/3045C08L23/14C08L2205/035C08L2205/06C08L2207/062C08L23/0876C08L23/06C08K13/02C08K3/30C08K3/34

Inventor 严静儿

Owner 严静儿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com