Transparent low-temperature-resistant scuffing-resistant polycarbonate composite material

A technology of polycarbonate and composite materials, which is applied in the field of transparent low-temperature-resistant and scratch-resistant polycarbonate composite materials and its preparation, to achieve good mechanical properties, increase surface tension, and good impact performance at room temperature and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

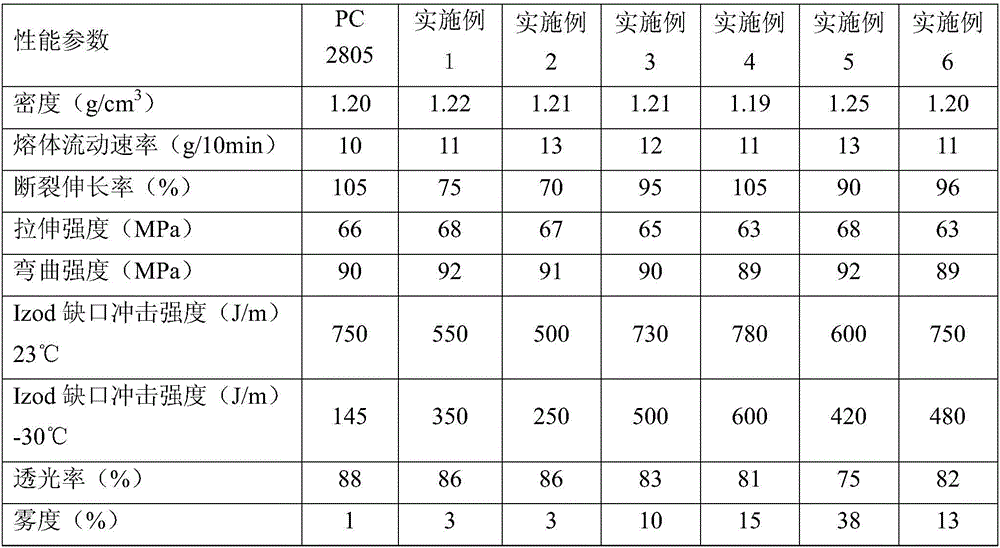

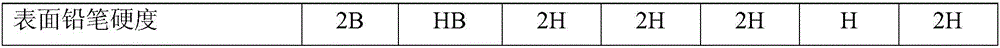

Examples

Embodiment 1

[0033] With the following components in parts by weight (1 part=100g): 637 parts of models are 2805 PC, 300 parts of siloxane copolymerized PC, 50 parts of nano anti-scratch masterbatches, 2 parts of antioxidant 168, 1 part Antioxidant 1076, 5 parts of pentaerythritol stearate, 2 parts of light stabilizer 770, 2 parts of ultraviolet absorber UV-234 and 1 part of toner are mixed in a high-mixer for 2 to 3 minutes, and then mixed at 260 to 280 ° C Twin-screw extrusion granulation, the obtained pellets are dried at 120°C for 4 hours and then injection molded into standard strips at 260-280°C.

Embodiment 2

[0035] The following components in parts by weight (1 part=100g): 537 parts of models are 2805 PC, 300 parts of siloxane copolymerized PC, 100 parts of surface hardness improving agent H881, 50 parts of nano anti-scratch masterbatch, 2 Mix 1 part of antioxidant 168, 1 part of antioxidant 1076, 5 parts of pentaerythritol stearate, 2 parts of light stabilizer 770, 2 parts of ultraviolet absorber UV-234 and 1 part of toner in a high mixer for 2 to 3 minutes , and then twin-screw extrusion granulation at 260-280°C, the resulting pellets were dried at 120°C for 4 hours and then injection-molded into standard strips at 260-280°C.

Embodiment 3

[0037] The following components in parts by weight (1 part=100g): 507 parts of PC model 2805, 300 parts of siloxane copolymerized PC, 100 parts of surface hardness improving agent H881, 30 parts of silicone toughening agent S2030, 50 parts of nano anti-scratch masterbatch, 2 parts of antioxidant 168, 1 part of antioxidant 1076, 5 parts of pentaerythritol stearate, 2 parts of light stabilized 770, 2 parts of ultraviolet absorber UV-234 and 1 part of toner Mix in a high mixer for 2-3 minutes, then twin-screw extrusion pelletization at 260-280°C, dry the obtained pellets at 120°C for 4 hours, and then inject them into standard strips at 260-280°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com