Preparation method of cardanol-based high temperature-resistant epoxy resin curing agent

A technology of epoxy resin curing and cardanol, which is applied in the chemical field, can solve the problems of poor toughness, high curing conditions, and high toxicity, and achieve the effects of good high temperature resistance, wide curing temperature range, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add bisphenol A (1mol), cardanol (300g, 1mol) and paraformaldehyde (30g, 1mol) into a four-necked flask with a heating mantle, and add 3g of zinc acetate as a catalyst, and heat at 100°C for 2 hours to obtain an intermediate Body SM. Cool SM down to 65°C, add diethylenetriamine (1mol), add paraformaldehyde (30g, 1mol) in batches under stirring at this temperature, then raise the temperature to 80°C and react for 5 hours. The water discharge generated in the reaction is removed to obtain the curing agent (S1). Viscosity 30000mPa.S, amine value 290mgKOH / g, solid content 95%, surface hardness > 2H, Shore hardness > 95 degrees

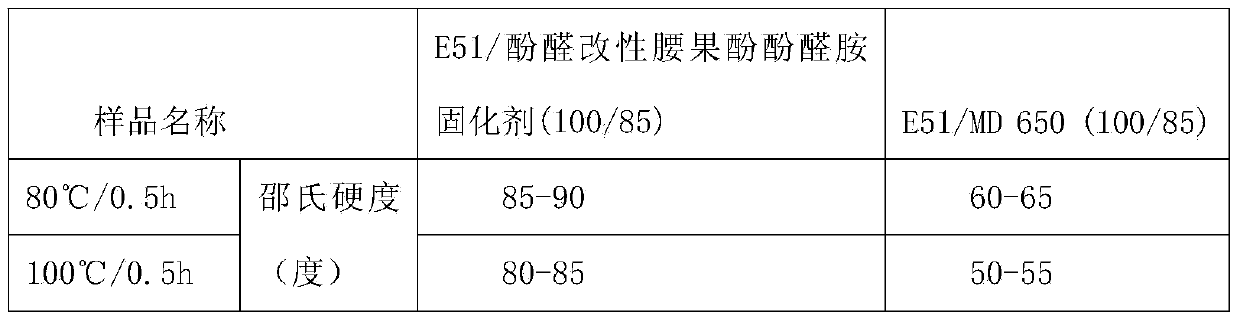

[0016] Comparison of Heat Resistance

[0017]

[0018] Among them, MD650 is a cardanol phenalkamine curing agent produced by Shanghai Meidong Biomaterials Co., Ltd., which has been commercialized. It is a mid-to-high-end product with excellent performance and is the mainstream product of cardanol curing agent. It can be seen from the compariso...

Embodiment 2

[0020] Add cardanol (600g, 2mol) and paraformaldehyde (30g, 1mol) into a four-neck flask with a heating jacket, and add 3g of zinc acetate as a catalyst, and heat at 100°C for 2 hours to obtain intermediate SM. Cool the SM to 65°C, add tetraethylenepentamine (1mol), add paraformaldehyde (1mol) in batches under stirring at this temperature, then raise the temperature to 80°C and react for 5 hours, and remove the reaction under vacuum after the reaction The water produced in is discharged to obtain the curing agent (S2). Viscosity 100Pa.S, amine value 285mgKOH / g, solid content 98%, surface hardness > 2H, Shore hardness 90-95 degrees

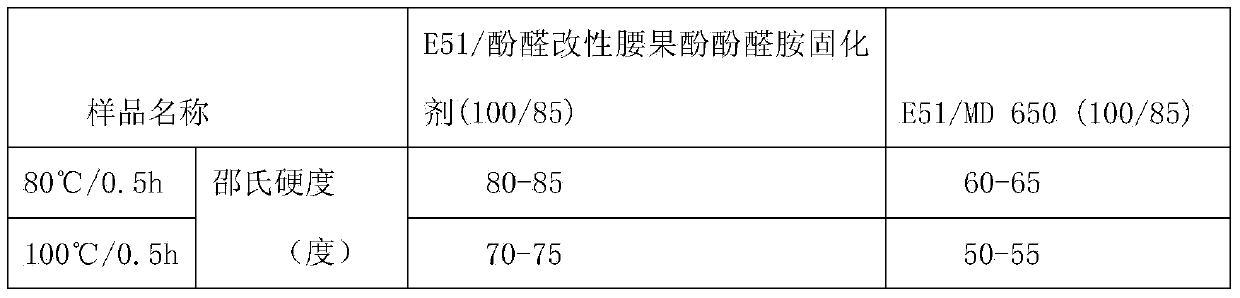

[0021] Comparison of Heat Resistance

[0022]

[0023] Among them, MD650 is a cardanol phenalkamine curing agent produced by Shanghai Meidong Biomaterials Co., Ltd., which has been commercialized. It is a mid-to-high-end product with excellent performance and is the mainstream product of cardanol curing agent. It can be seen from the compariso...

Embodiment 3

[0025] Add phenol A (1mol), cardanol (300g, 1mol) and paraformaldehyde (30g, 1mol) into a four-necked flask with a heating mantle, and add 5g of zinc acetate as a catalyst, and heat at 100°C for 2 hours to obtain an intermediate SM. Cool the SM to 65°C, add tetraethylenepentamine (189g, 1mol), add paraformaldehyde (30g, 1mol) in batches under stirring at this temperature, then raise the temperature to 80°C and react for 5 hours, and vacuum state after the reaction The water discharge generated in the reaction is removed to obtain the curing agent (S1). Viscosity 30000mPa.S, amine value 290mgKOH / g, solid content 95%, surface hardness > 2H, Shore hardness > 95 degrees

[0026] Comparison of Heat Resistance

[0027]

[0028] Among them, MD650 is a cardanol phenalkamine curing agent produced by Shanghai Meidong Biomaterials Co., Ltd., which has been commercialized and has excellent performance. It is a mid-to-high-end product and is the mainstream product of cardanol curing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com