Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

646 results about "Mechanical Treatments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

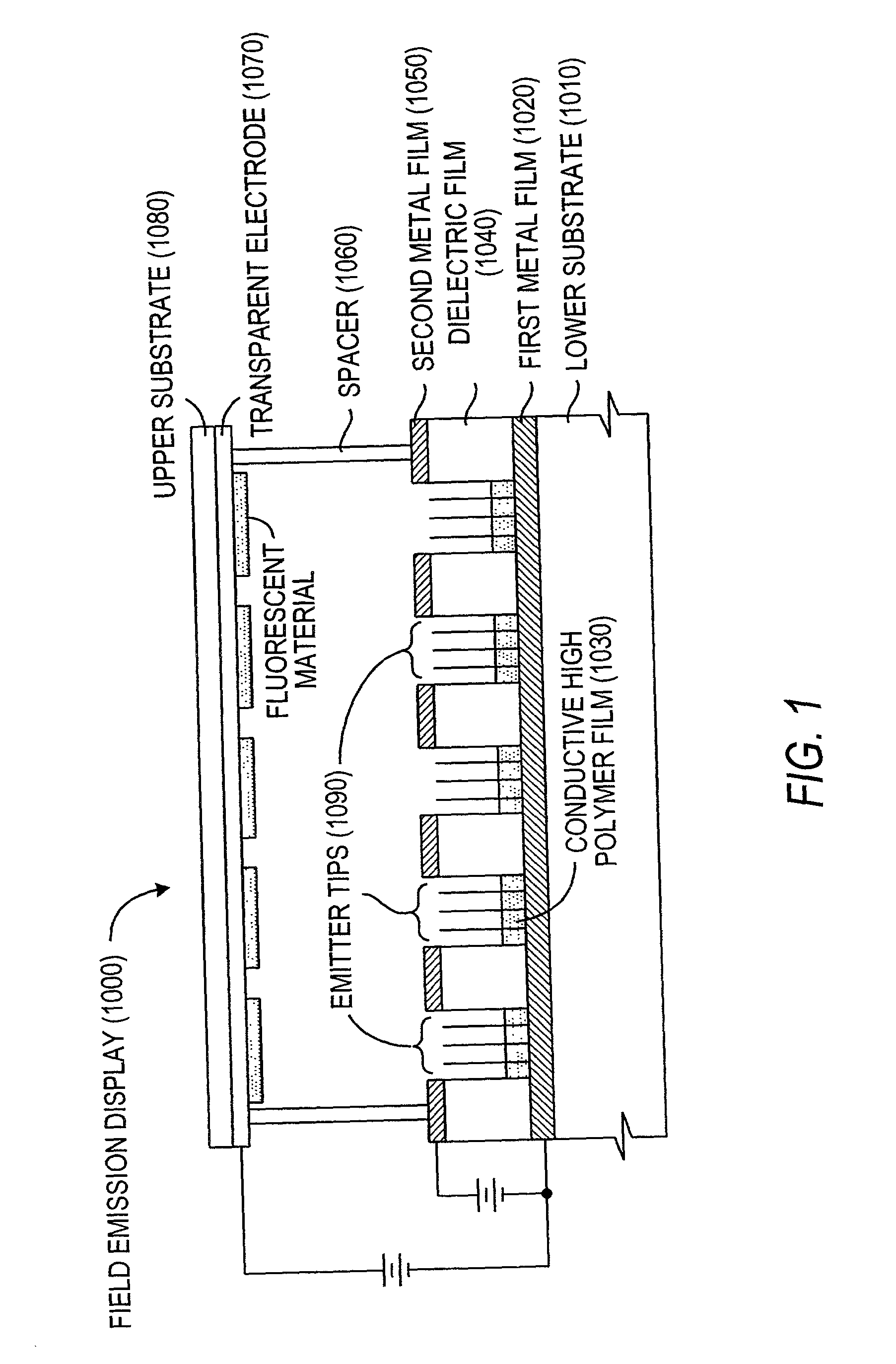

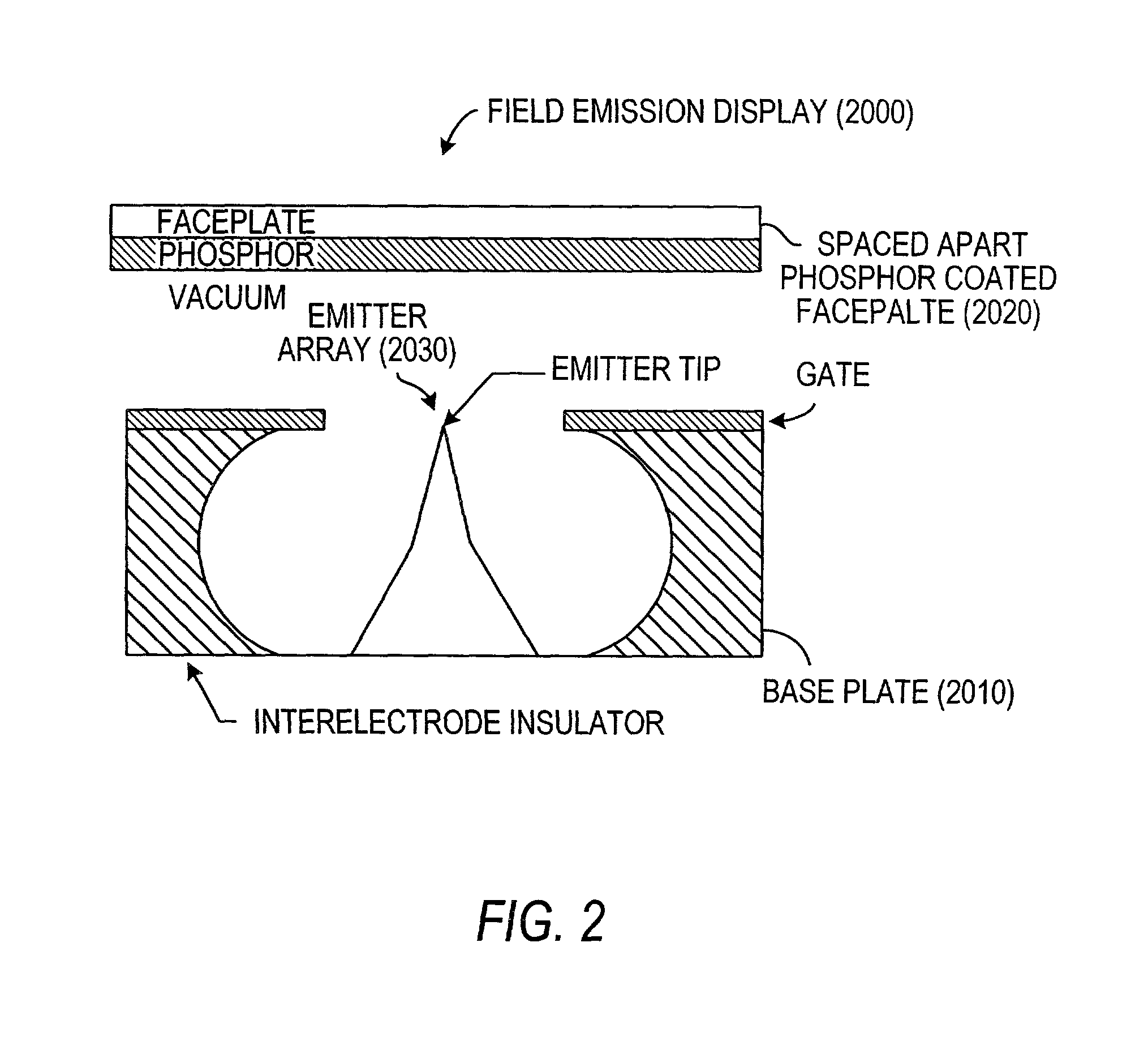

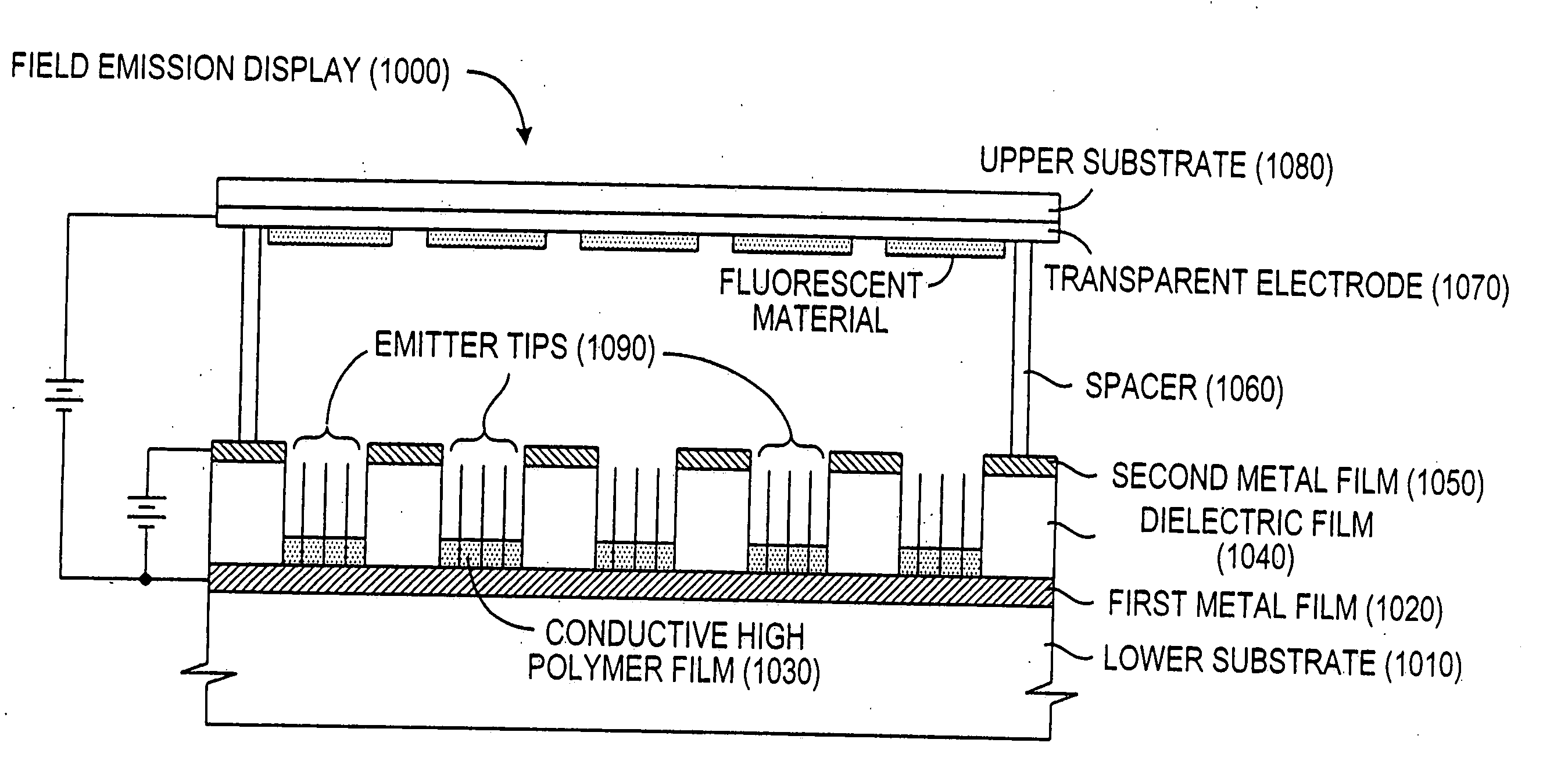

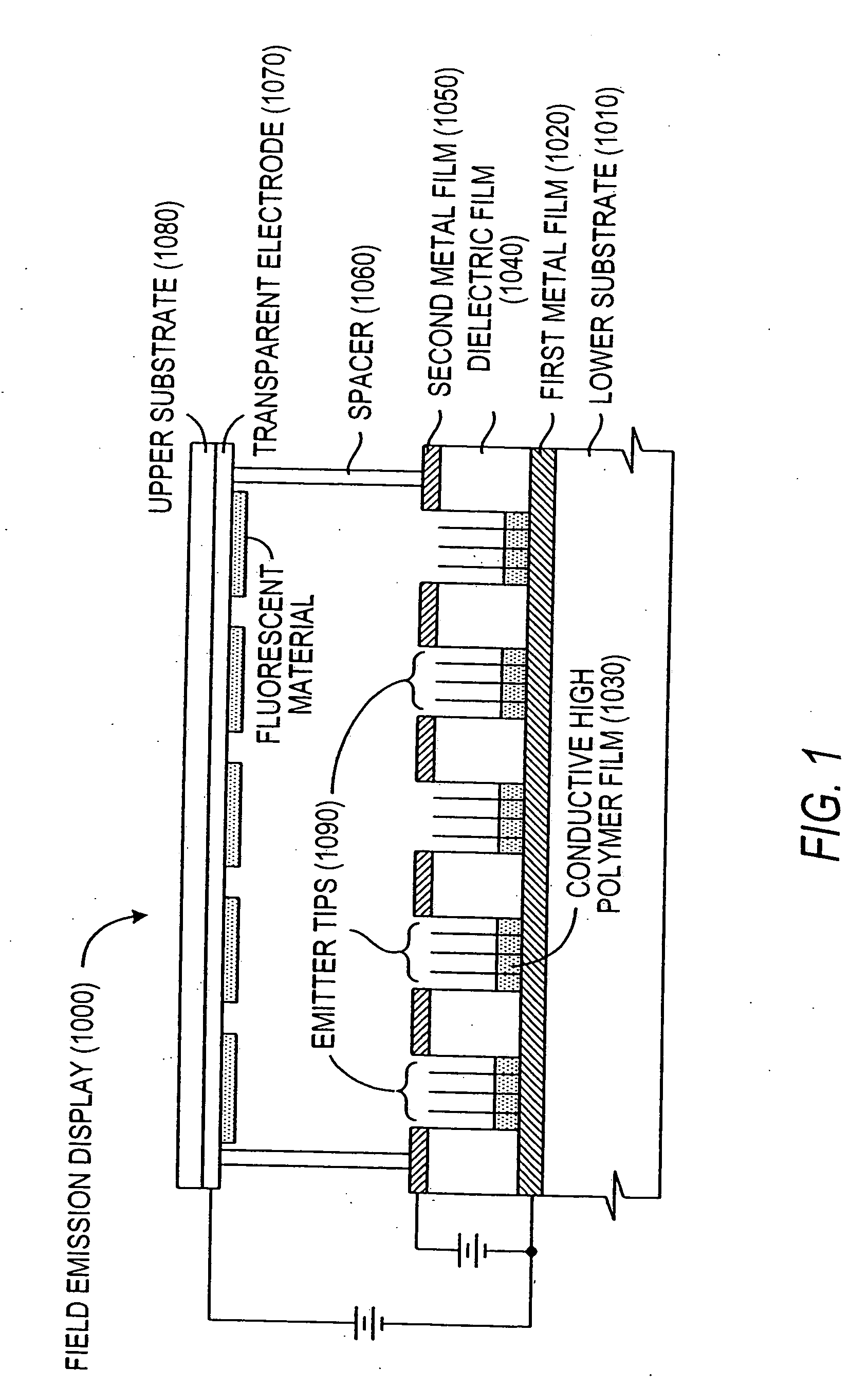

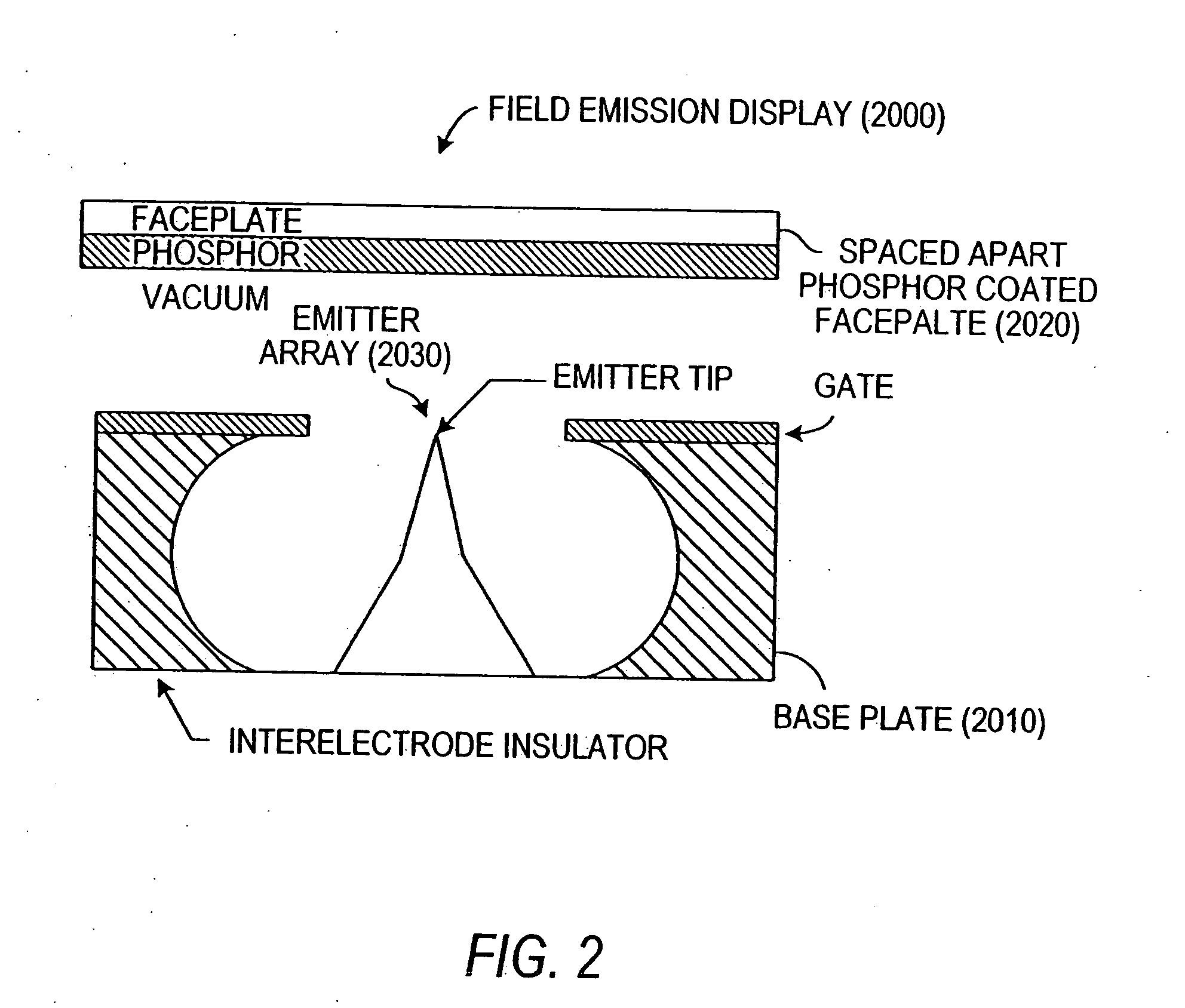

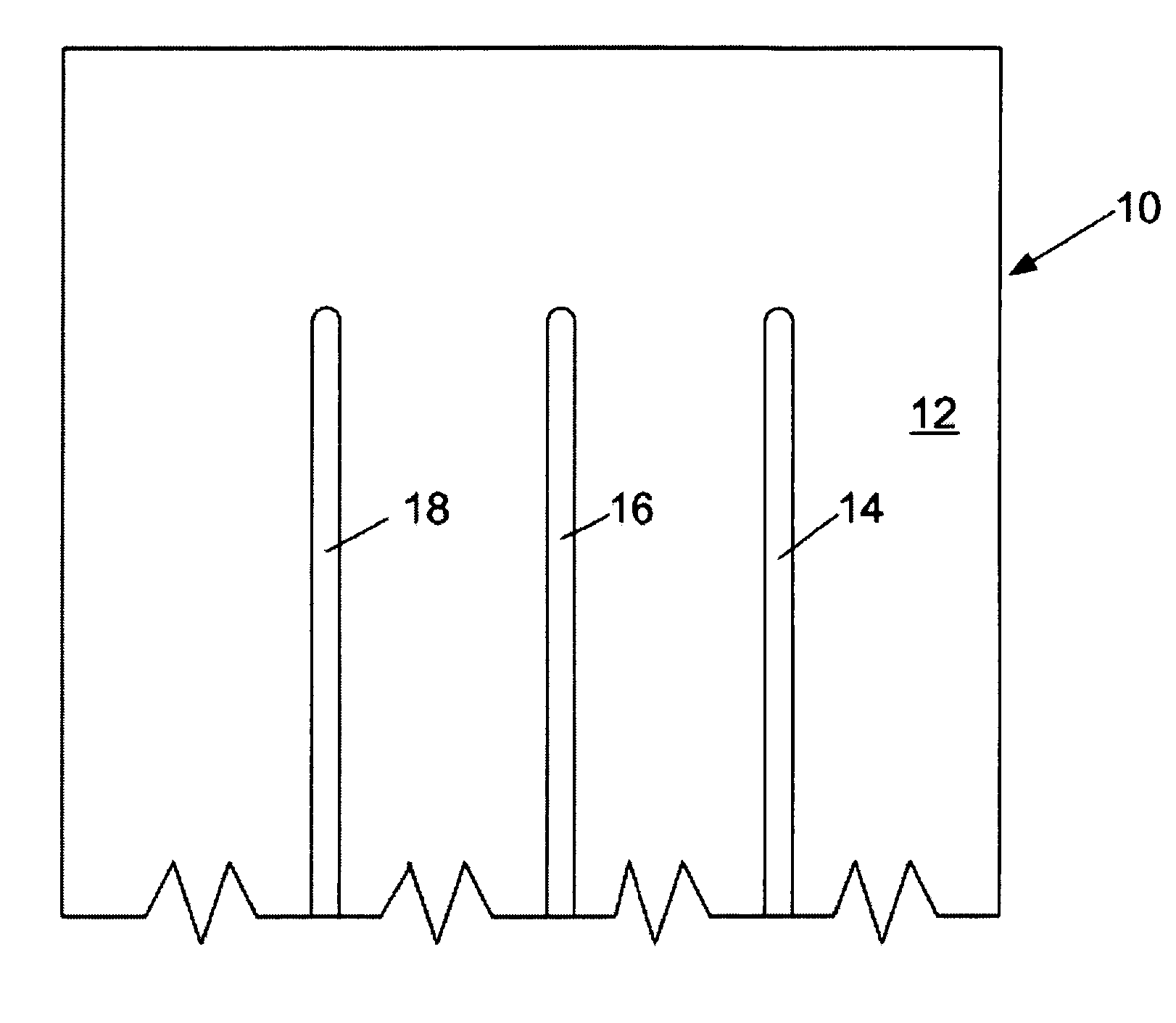

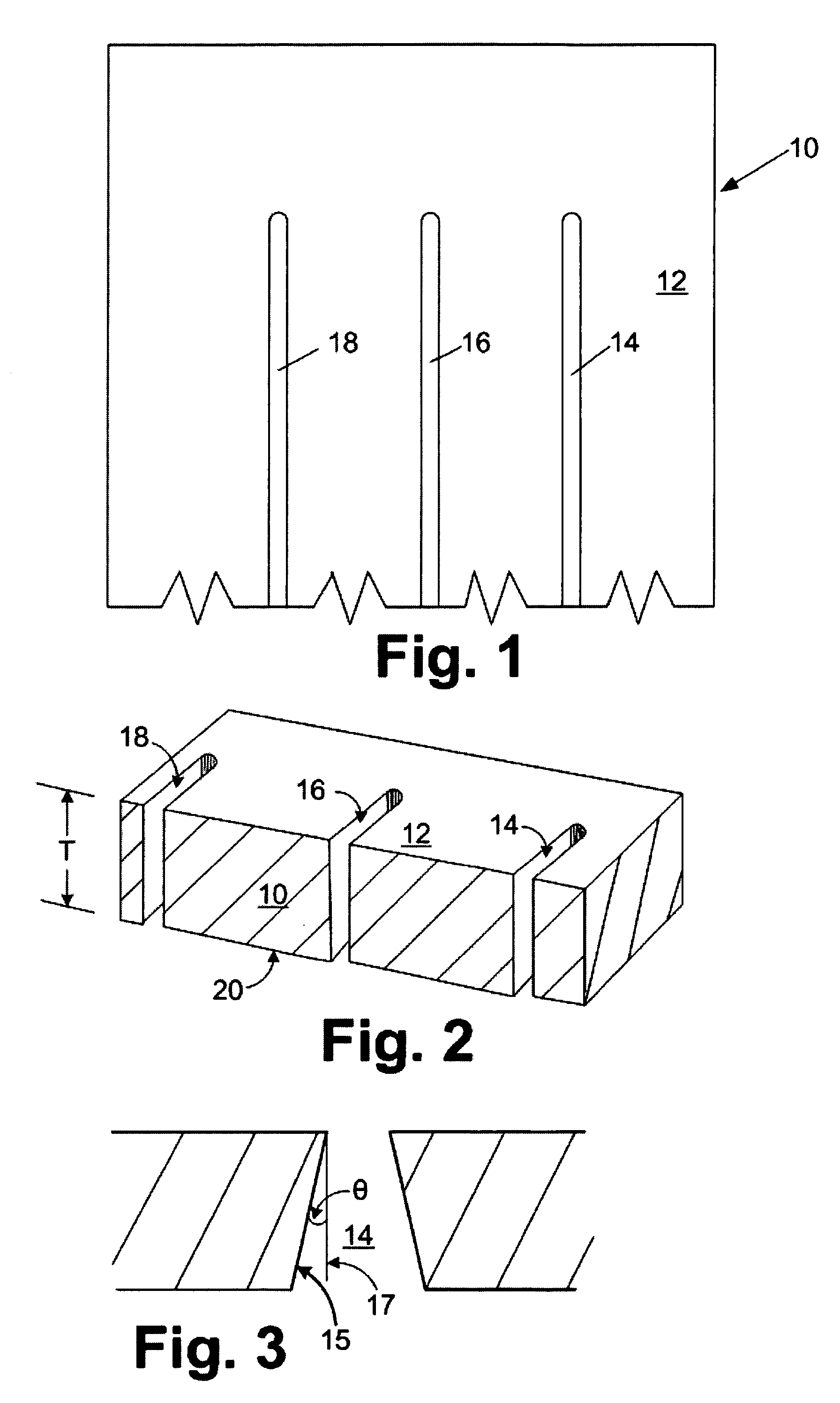

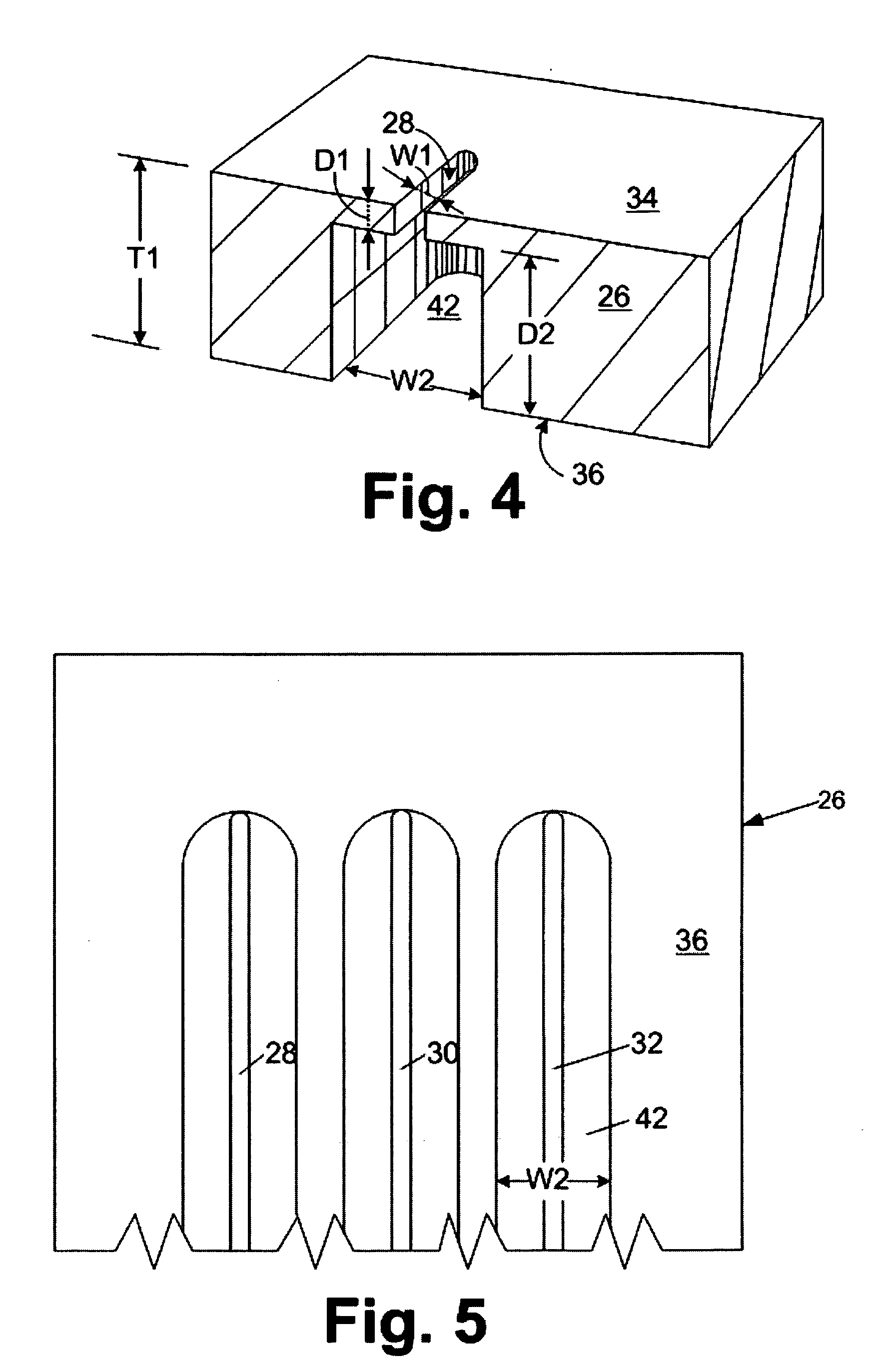

Field emission devices using modified carbon nanotubes

InactiveUS20030090190A1Accelerate emissionsReduce voltageNanostructure manufactureNanoinformaticsField emission deviceModified carbon

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes nanotubes which have been subjected to energy, plasma, chemical, or mechanical treatment. The present invention also relates to a field emission cathode comprising carbon nanotubes which have been subject to such treatment. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been subject to such treatment is further disclosed.

Owner:HYPERION CATALYSIS INT

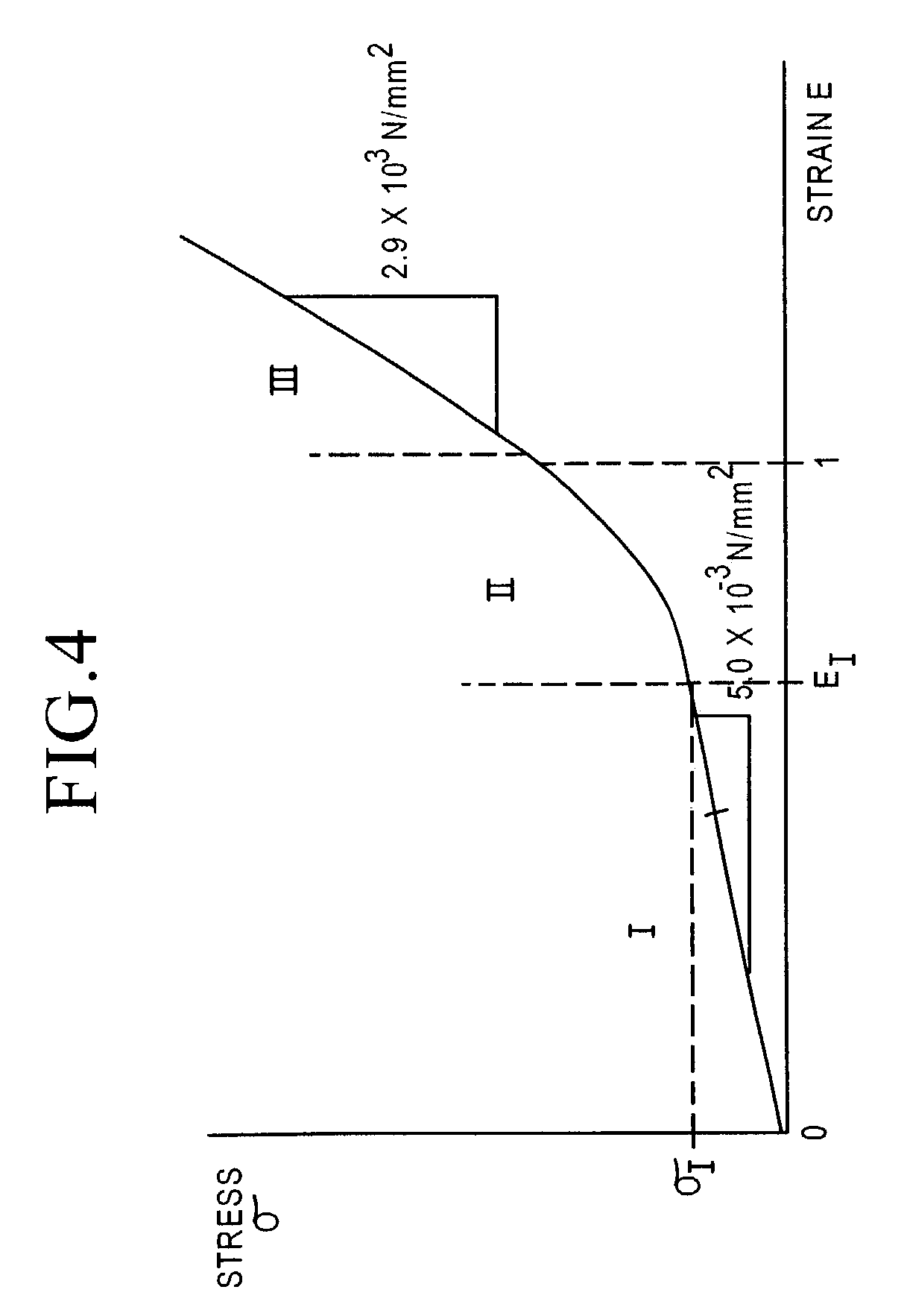

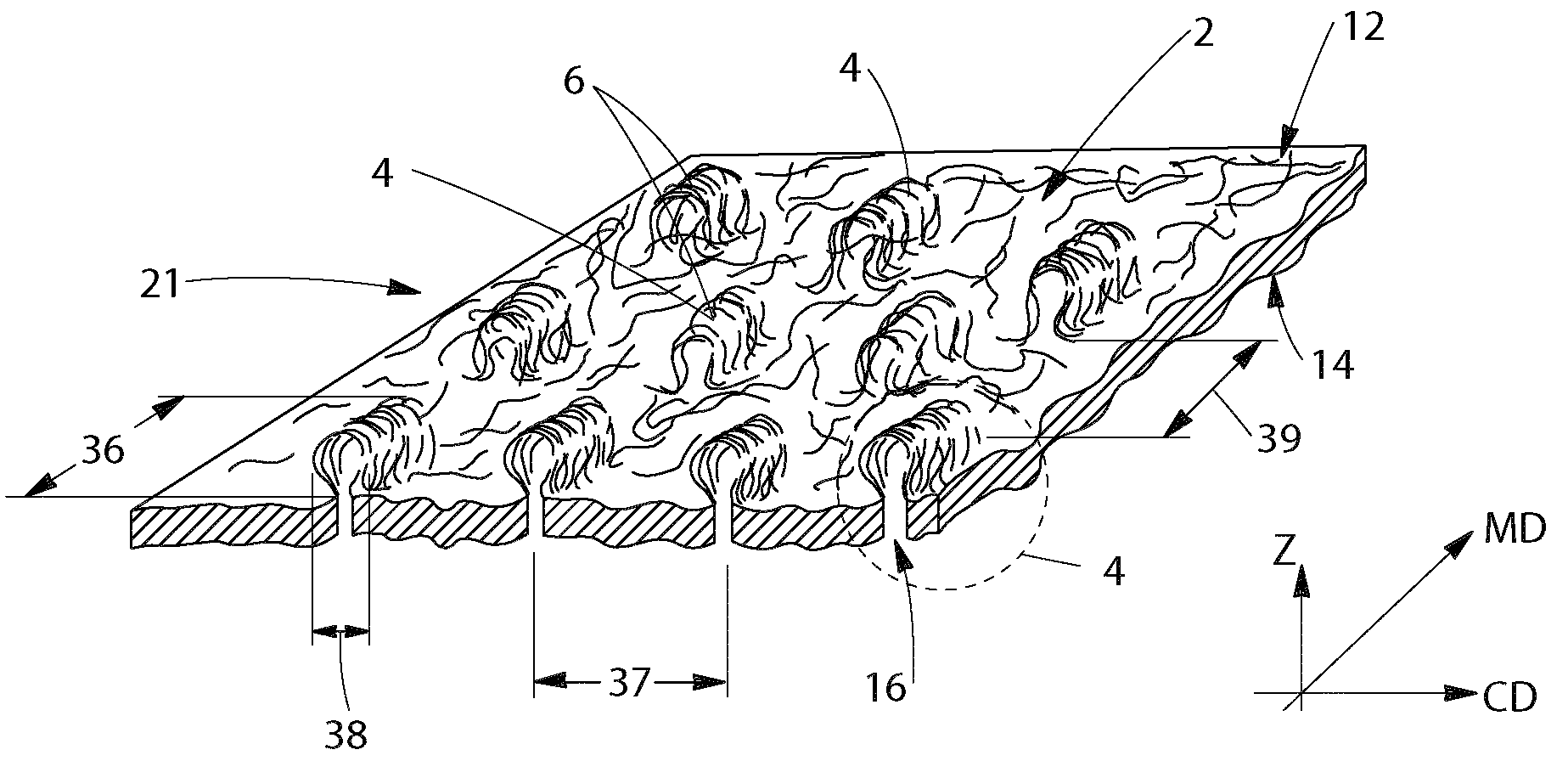

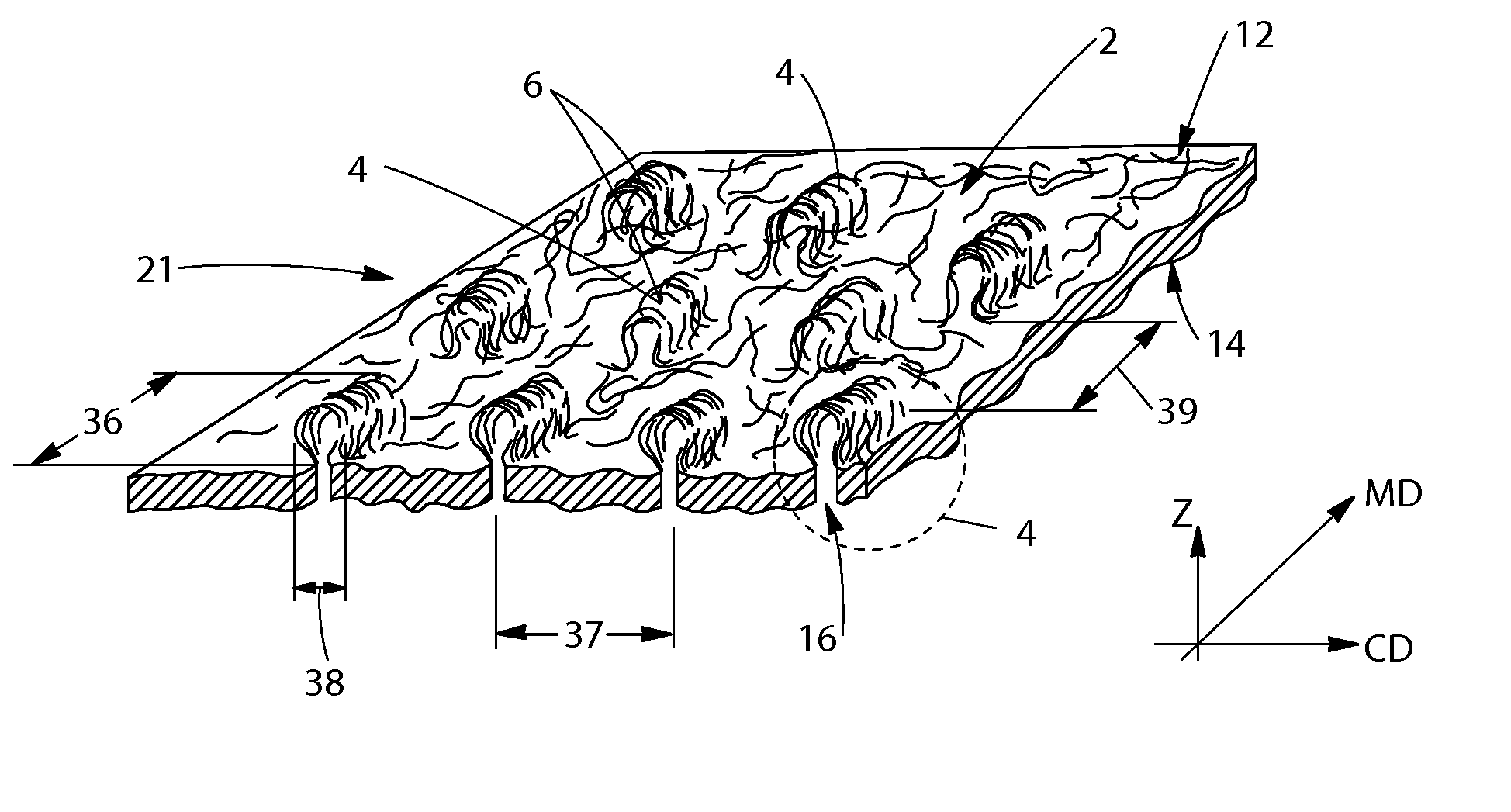

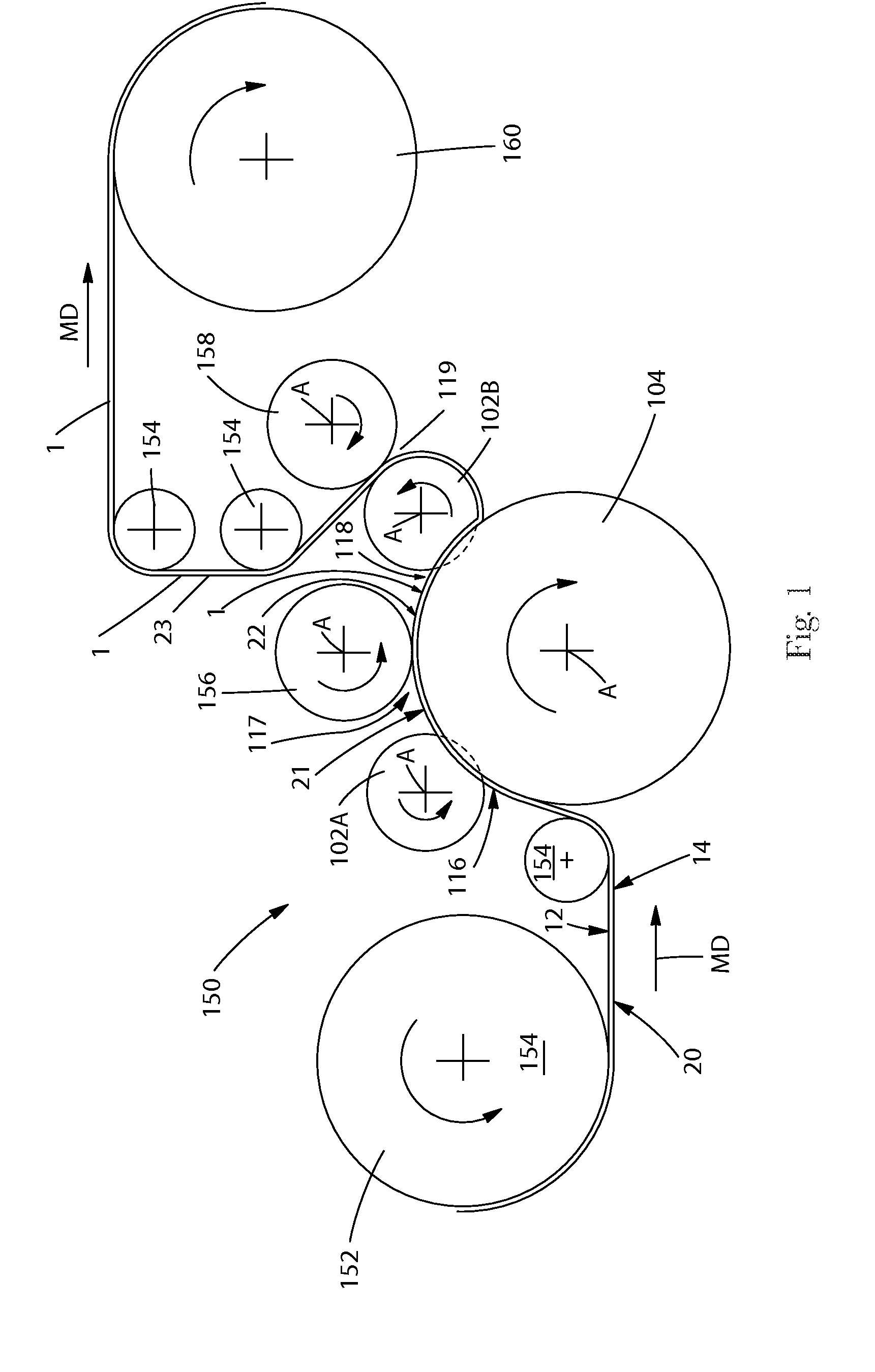

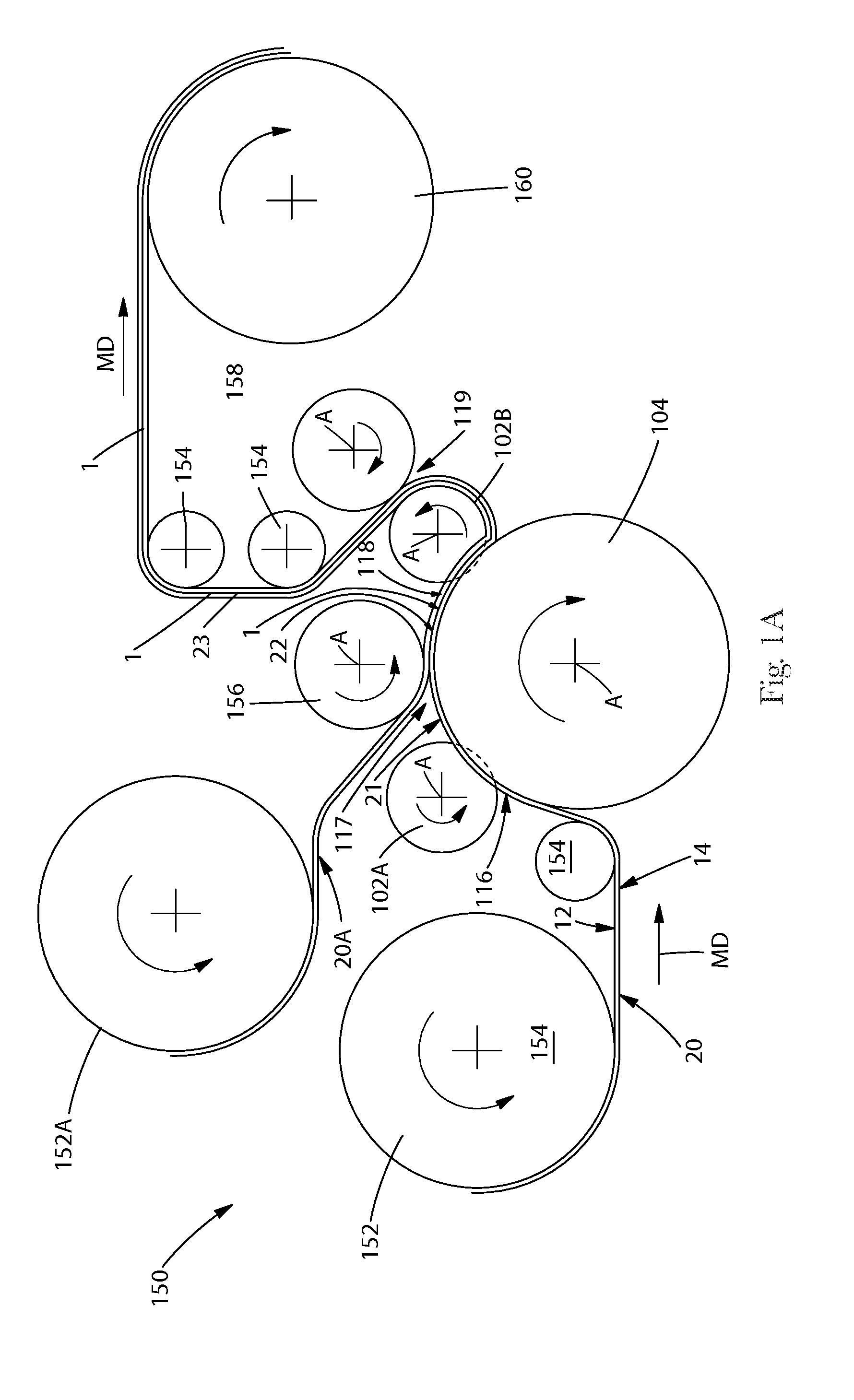

Fluid Permeable Structured Fibrous Web

InactiveUS20100312208A1Increase fiber surface areaImprove abilitiesBaby linensTamponsFiberEngineering

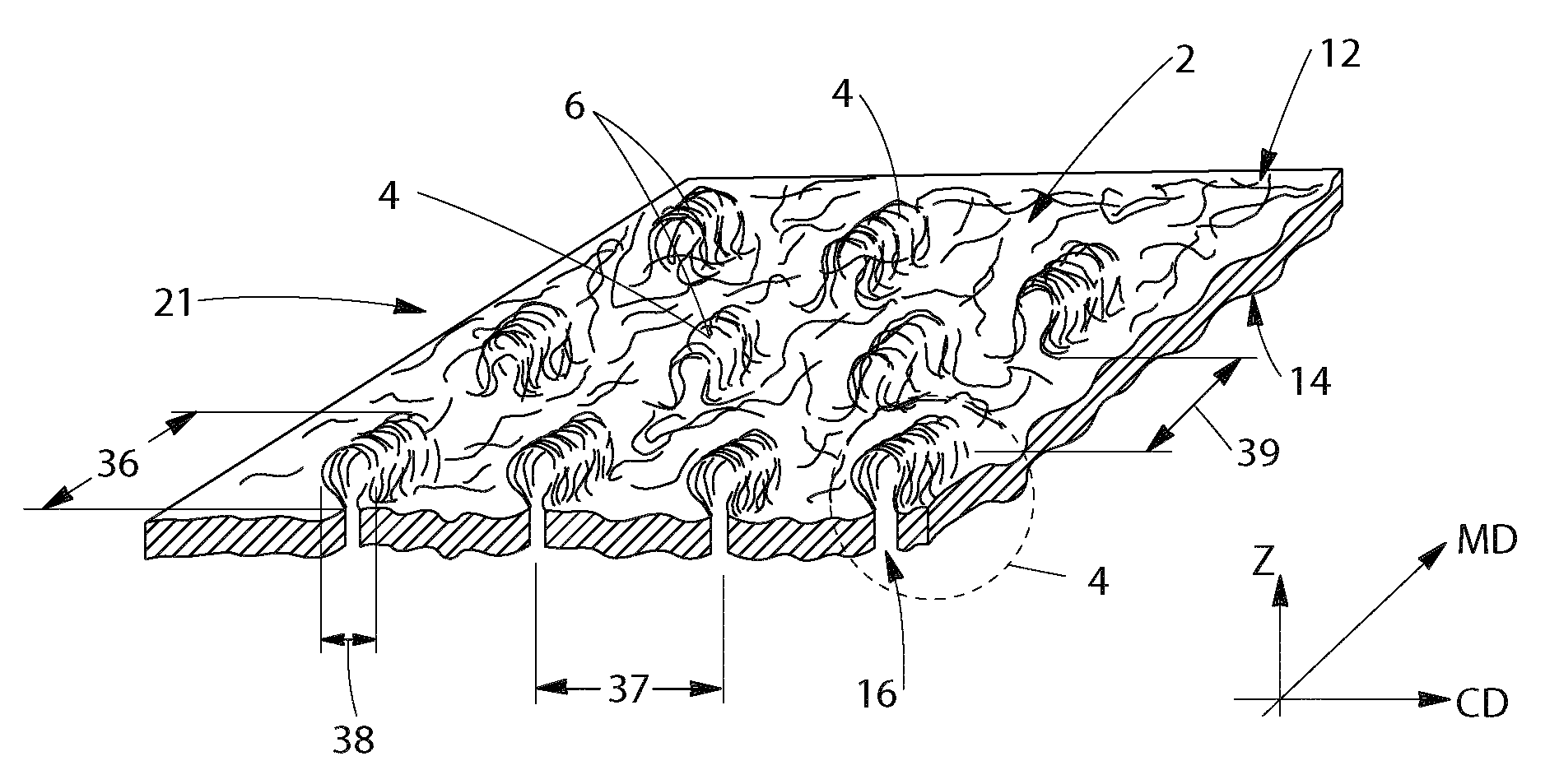

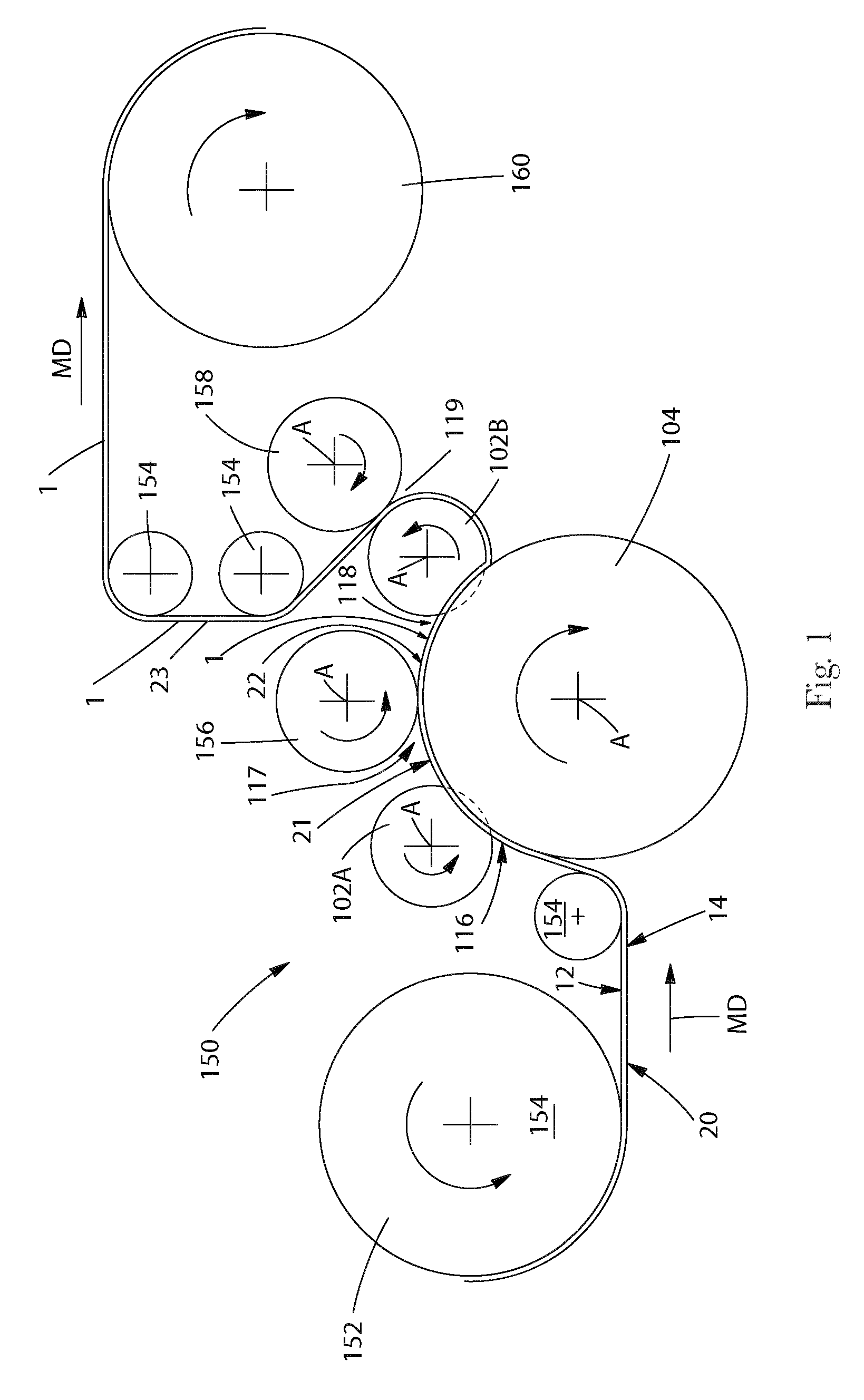

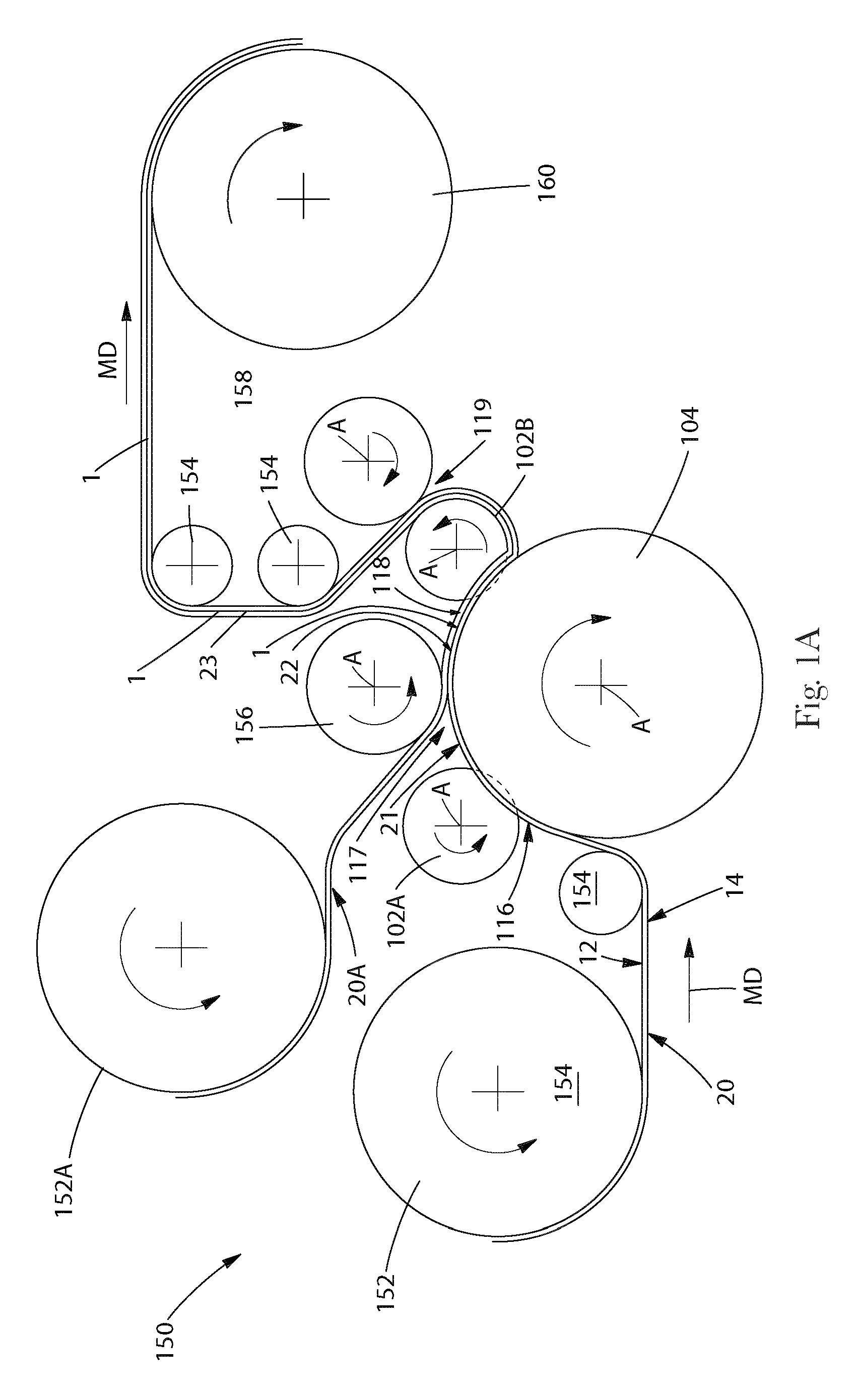

The present disclosure is directed to a disposable absorbent article comprising a fluid permeable structured fibrous web, the fibrous web comprising thermally stable, fibers that are thermally bonded together using heat producing a base substrate that is thermally stable. The base substrate is textured via mechanical treatment producing a structured fibrous web having an aged caliper of less than 1.5 mm, a vertical wicking height of at least 5 mm, a permeability of at least 10,000 cm2 / (Pa·s) and a specific volume of at least 5 cm3 / g. The structured fibrous web provides optimal fluid wicking and the fluid acquisition capabilities and is directed toward fluid management applications.

Owner:THE PROCTER & GAMBLE COMPANY

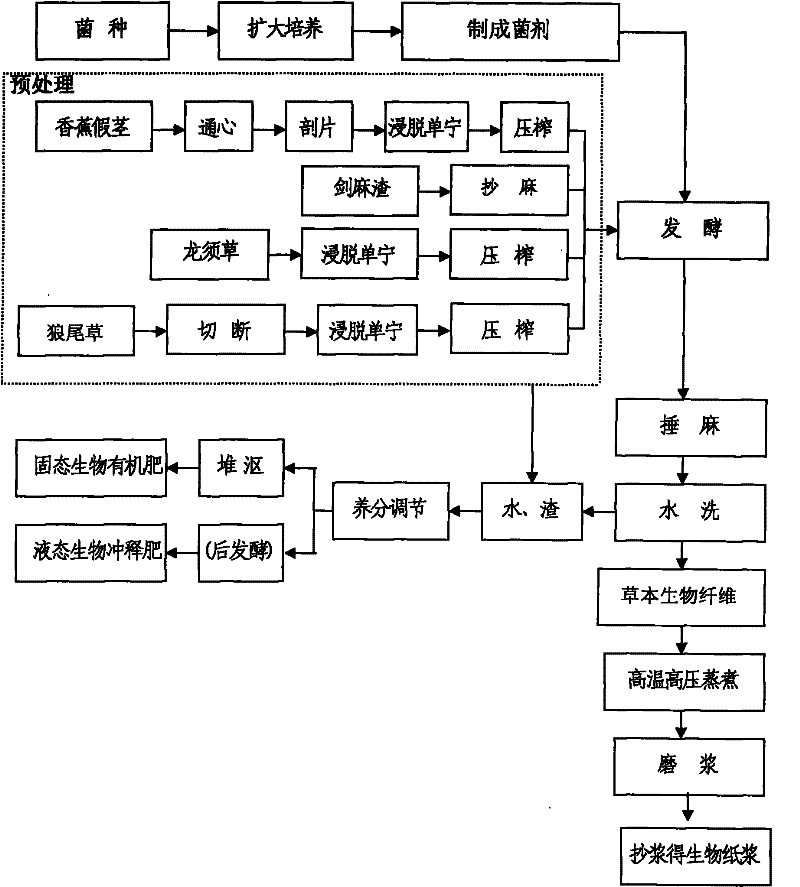

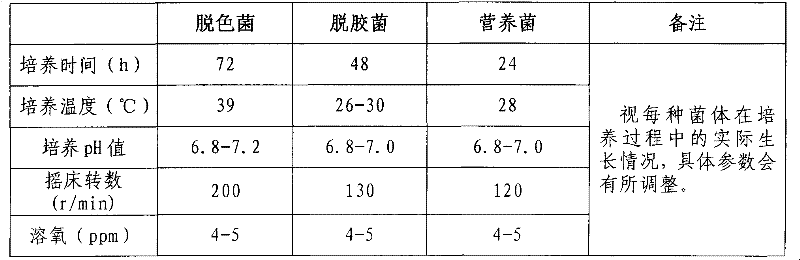

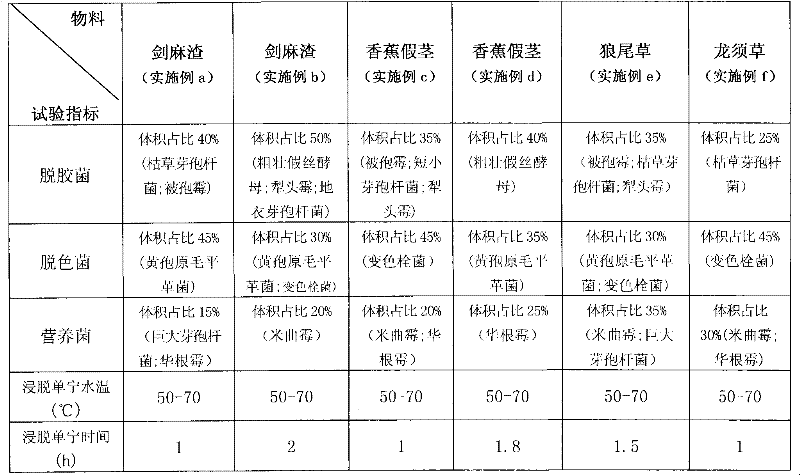

Method for preparing herbal biological fiber and biological paper pulp

InactiveCN102174399AOvercome color differenceOvercome resilienceFungiBio-organic fraction processingFiberWastewater

The invention discloses a method for preparing a herbal biological fiber and biological paper pulp, and the used microbial composite agent and a preparation method thereof. The biological fiber is prepared through pretreatment of a herbal raw material, biological degumming fermentation, and subsequent mechanical treatment of a fermentation product. The composite agent comprises degumming bacteria, nutrition bacteria and decolorizing bacteria, and various strains are synergistic without antagonistic reaction. In the method for preparing the biological fiber and the biological paper pulp, a chemical additive is not needed at all, but the high-cellulose and hemicellulose biological fiber and the biological paper pulp can be industrially produced; decolorization is complete, and the produced biological fiber and biological paper pulp have white color; a bleaching process is avoided, so investment in decolorizing production equipment is saved, and fiber extracting and pulping investment cost can be effectively reduced; in addition, waste gas and waste water are not generated in the fiber extracting and pulping process, inorganic pollutants are not generated, waste water and waste residues produced in each process step can be produced and converted into a biological fertilizer, and water is recycled.

Owner:GUANGXI SAIER PAPER IND

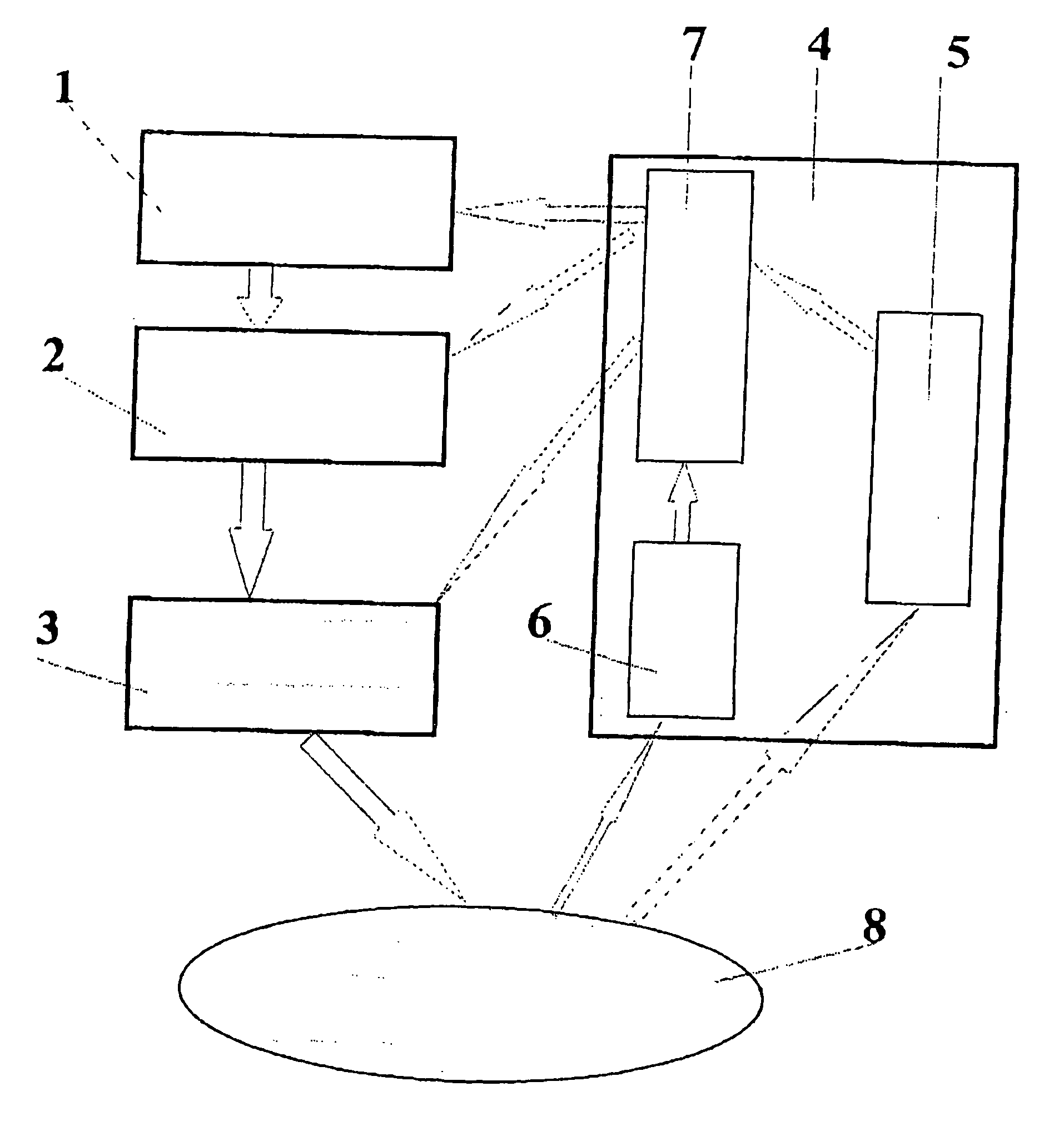

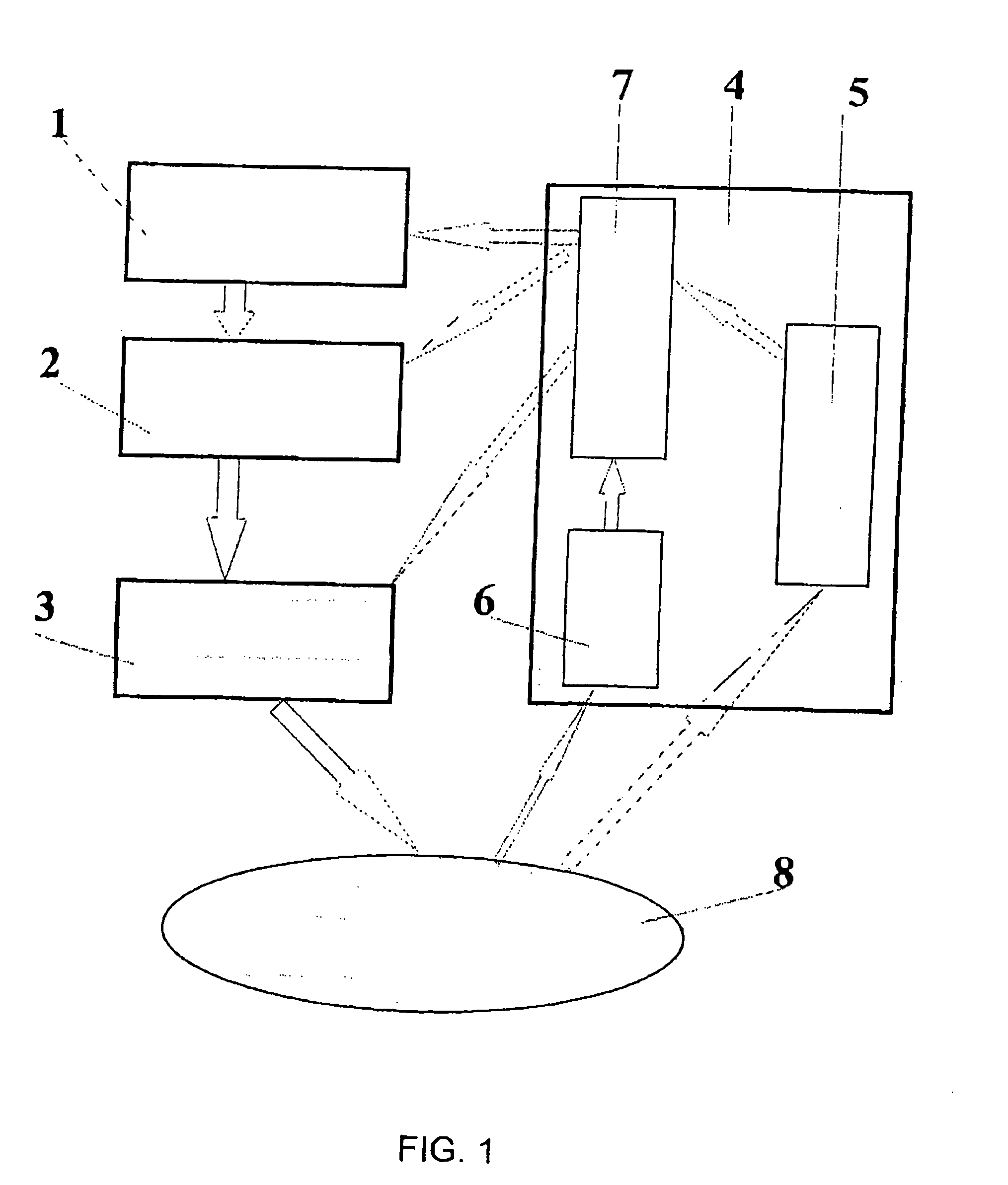

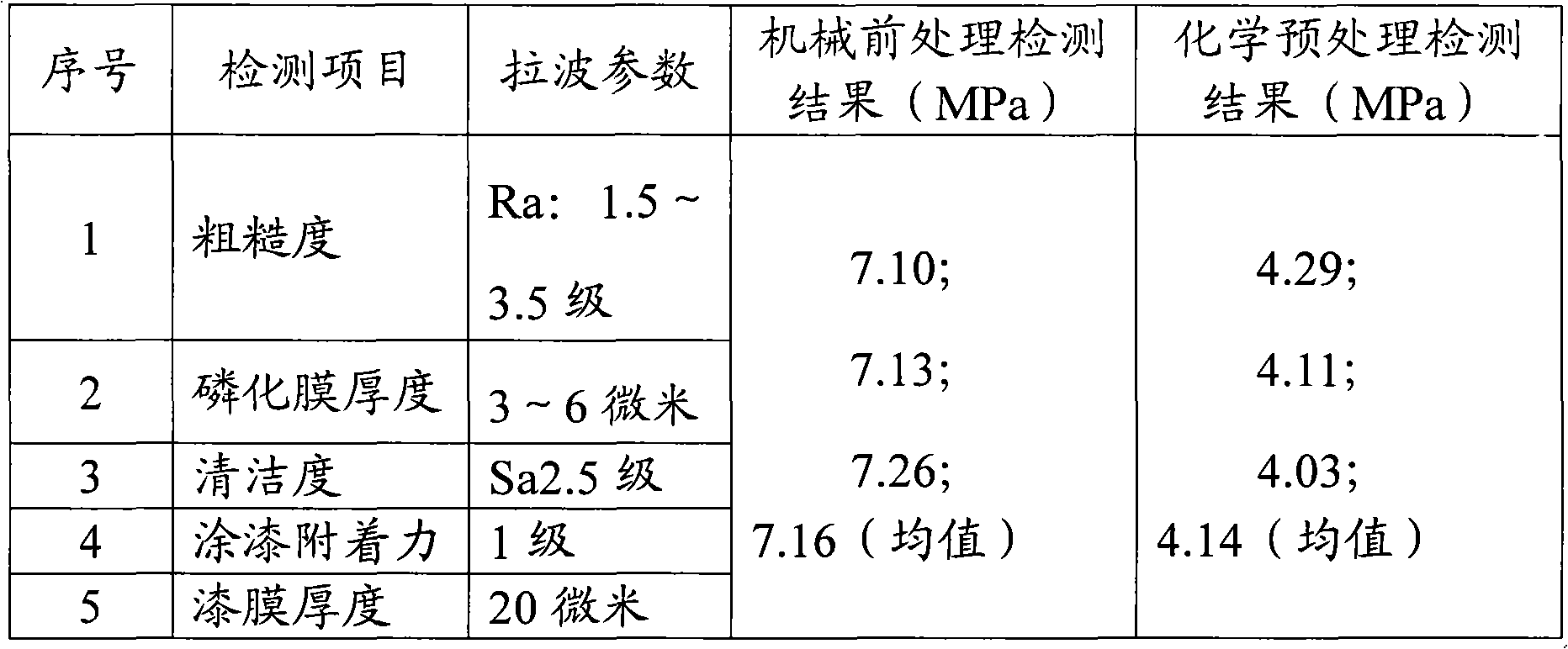

Method and apparatus for opto-thermo-mechanical treatment of biological tissue

InactiveUS20050119643A1Increase and decrease abilityEfficiency of influenceElectrotherapyControlling energy of instrumentOptical radiationControl signal

The invention relates to a method and apparatus for opto-thermo-mechanical treatment of biological tissue. A biological tissue area 8 is irradiated with a radiation in the optical wavelength range with predetermined parameters, the radiation being modulated and spatially formed under a predetermined law; the irradiation is accompanied by simultaneous thermal and mechanical treatment of the area 8; concurrently with the irradiation of the biological tissue area, spatial distribution of physico-chemical and geometrical characteristics is measured both in the zone of direct optical treatment and in close vicinity, using a control diagnostic system 4; a data processing unit 7 coordinates parameters of optical radiation spatial formation and modulation with each other and with the biological tissue characteristics and provides a control signal to an optical radiation power and time modulation control unit 2 and a device 3 for delivering optical radiation and forming spatial distribution of optical radiation power on the surface and in the bulk of the biological tissue 8. Optical radiation parameters are adjusted responsive to control signals of the control-diagnostic system 4 during irradiation as a function of continuously changing characteristics of spatial distribution of physico-chemical and geometrical characteristics both in and beyond the directly treated biological tissue area.

Owner:ARCUO MEDICAL

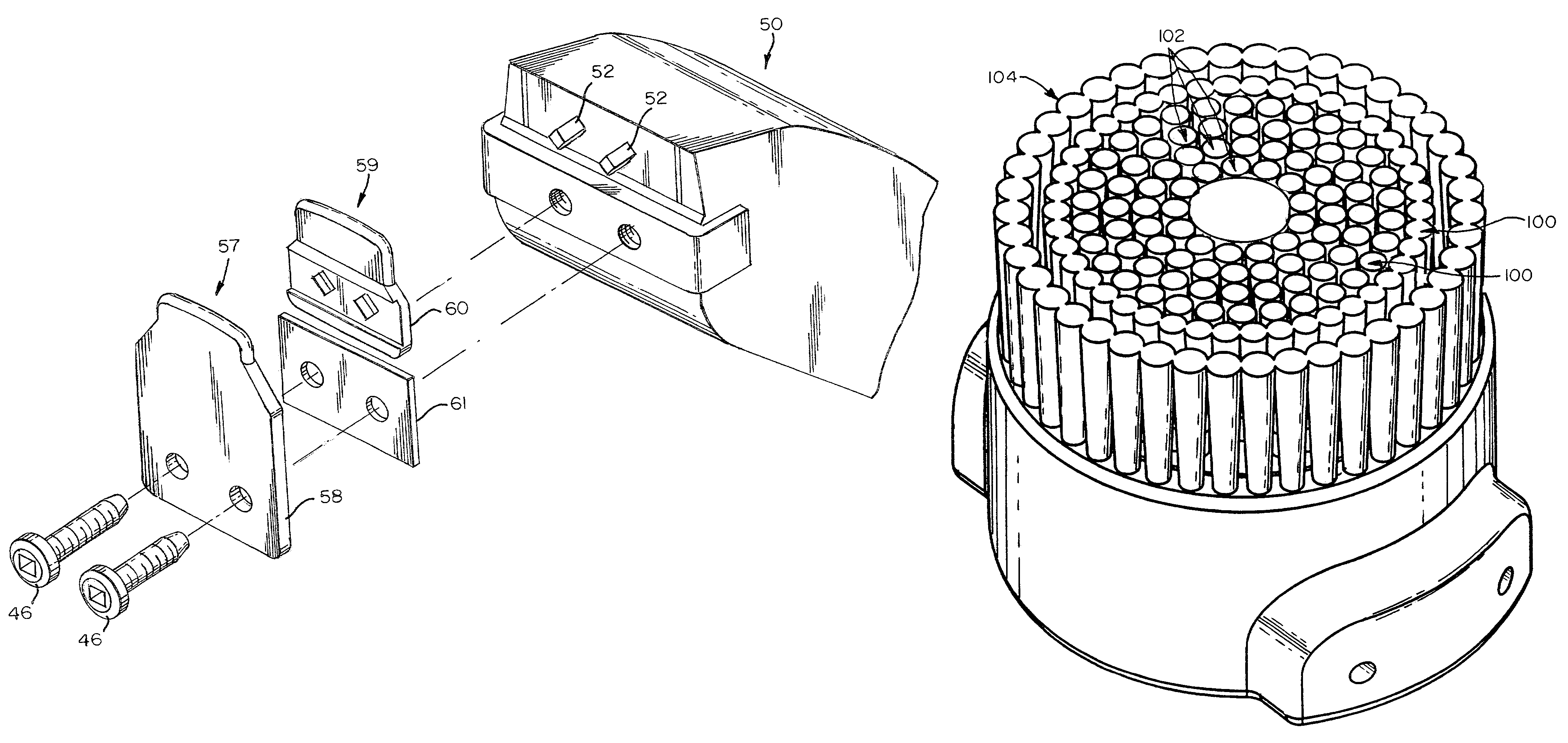

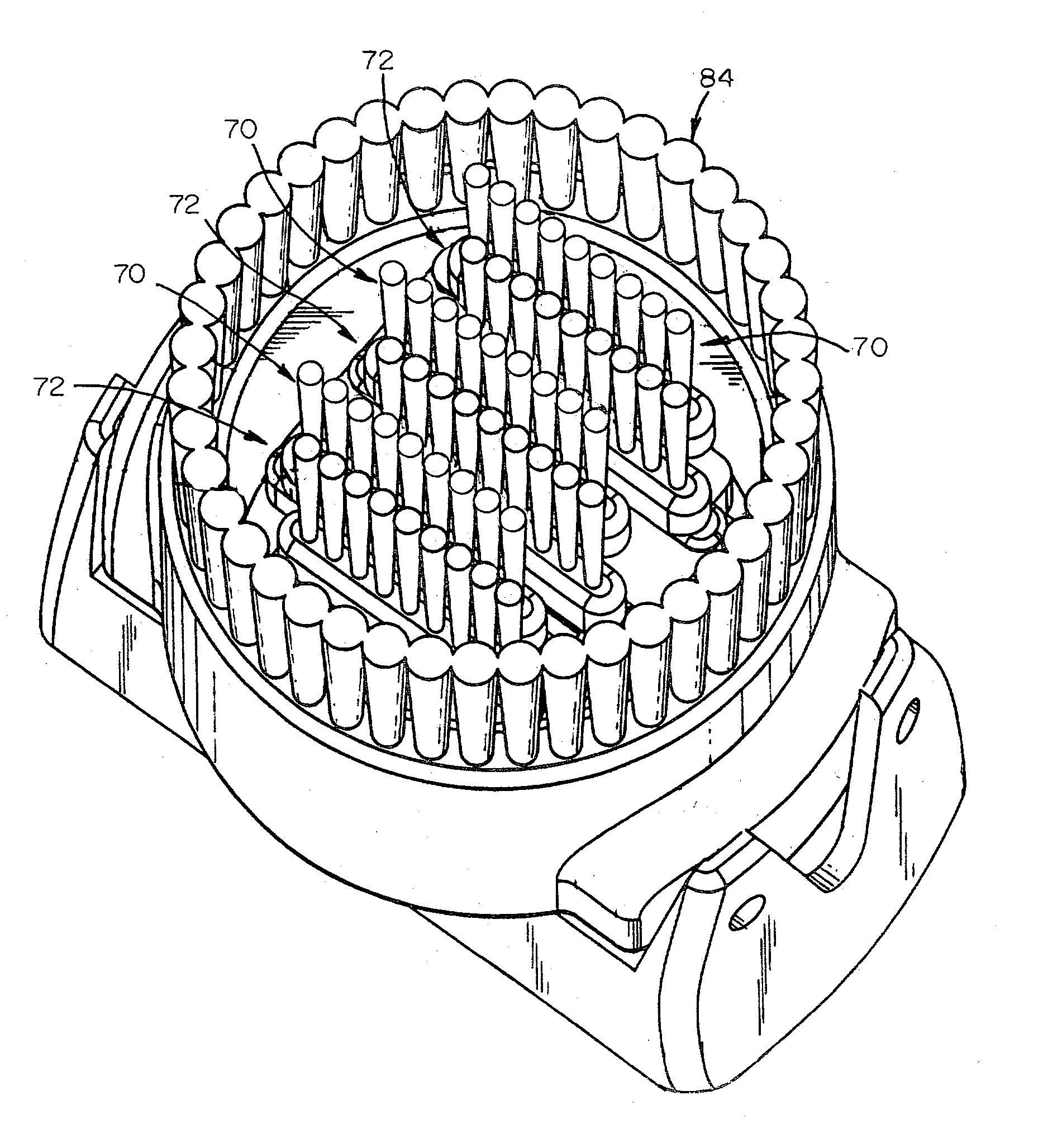

Apparatus and method for acoustic/mechanical treatment of early stage acne

ActiveUS20050277950A1Easy to disassembleMedical applicatorsAbrasive surgical cuttersSkin contactMechanical engineering

The apparatus includes at least two skin-contacting elements, the elements having narrow end faces and a mounting assembly for holding the elements closely adjacent to each other. A driving assembly reciprocally moves one element relative to the adjacent element(s) at a frequency that produces an action on the pores of the skin to loosen sebaceous plugs present in the pores, by permitting their ready removal from the skin.

Owner:LOREAL SA

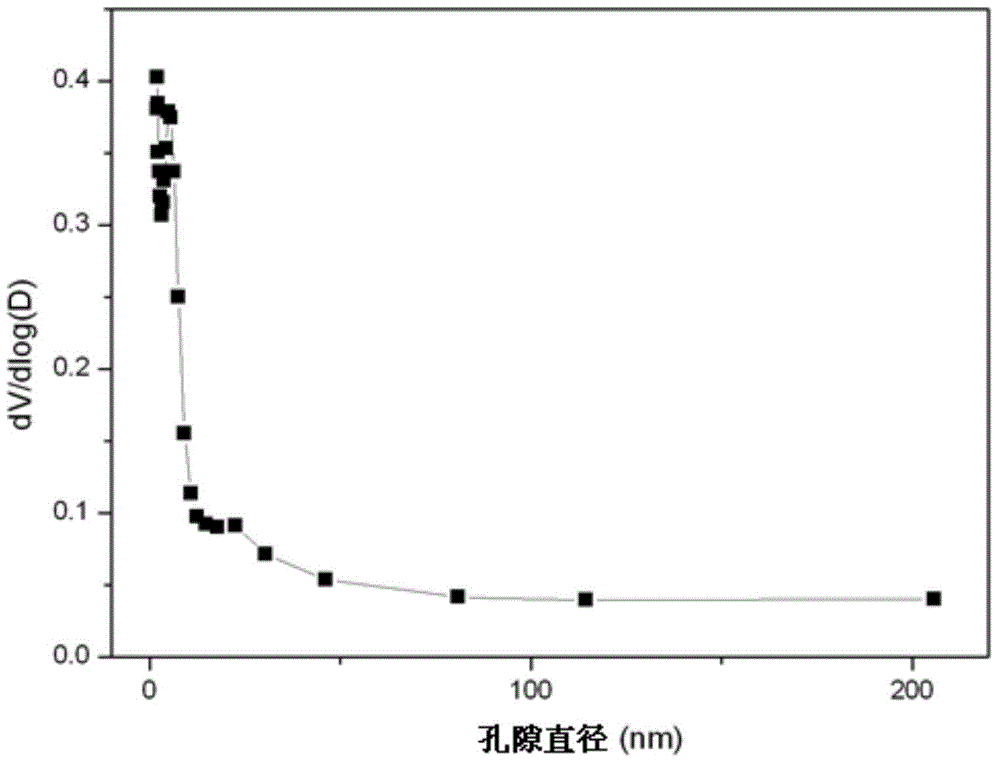

Nanometer cellulose/polyvinyl alcohol gel composite material

ActiveCN102786642ALarge specific surface areaHigh porosityChemical industryChemical industryPolyvinyl alcohol

The invention relates to a nanometer cellulose / polyvinyl alcohol gel composite material, which is characterized by comprising hydrogel and aerogel. A preparation method of the nanometer cellulose / polyvinyl alcohol gel composite material comprises the following process steps of 1, nanometer cellulose preparation by a chemical combination mechanical treatment method; 2, composite hydrogel preparation; and 3, composite aerogel preparation. The nanometer cellulose / polyvinyl alcohol gel composite material has the advantages that the composite aerogel belongs to a porous amorphous solid material consisting of nanometer level colloid particles or high-polymer molecules, and a unique open nanometer level porous structure and a continuous three-dimensional reticular structure are adopted, so the density is extremely low, the specific surface area is high, and the porosity is high, wherein the solid phase of the aerogel accounts for 0.2 percent to 20 percent of the total volume percentage, the characteristics of high adsorption catalytic capability, low thermal conductivity, low sound resistance, low refractive index and the like are shown, and wide application prospects are realized in the fields of aviation, spaceflight, chemical industry, metallurgy, energy-saving building and the like.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

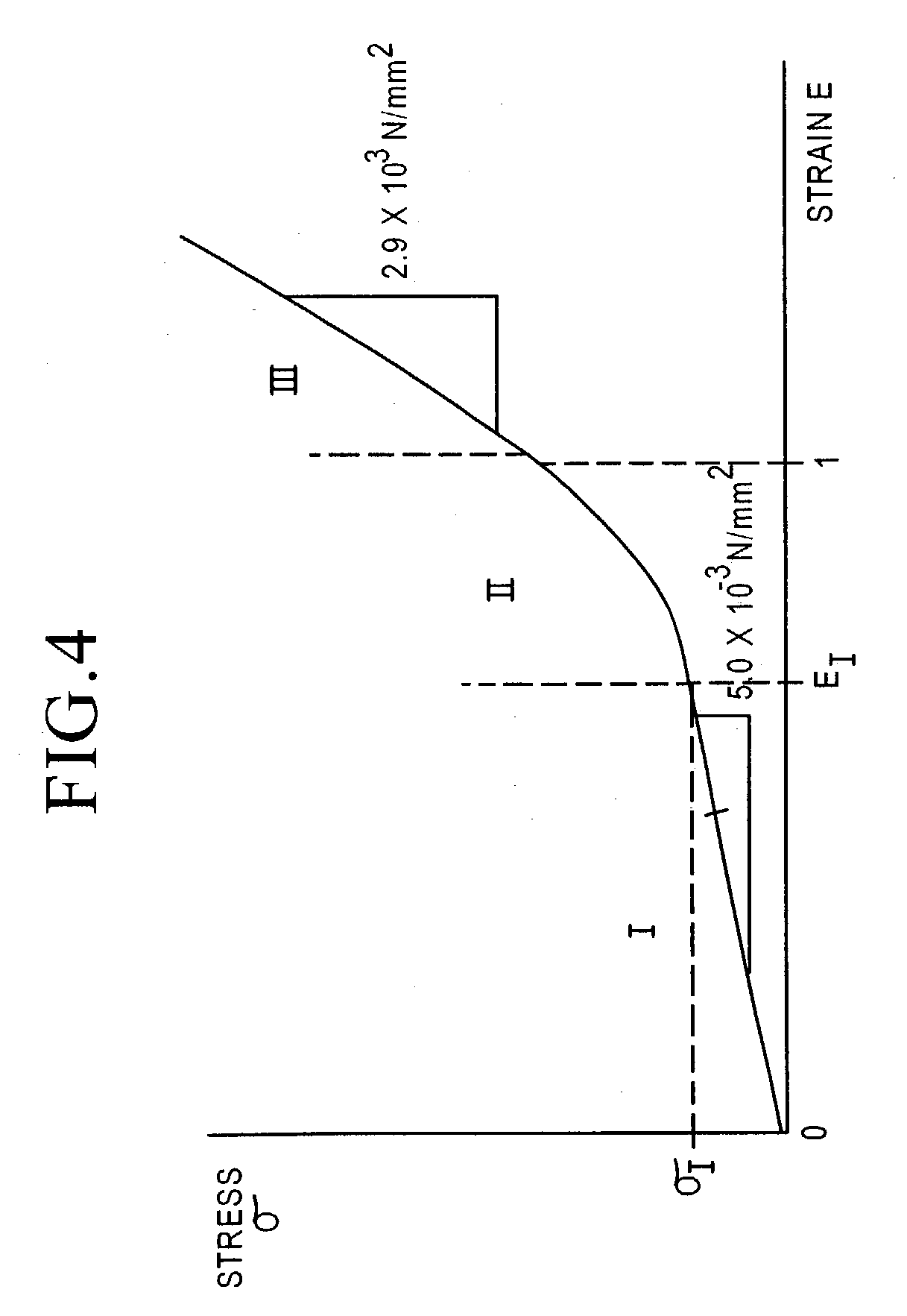

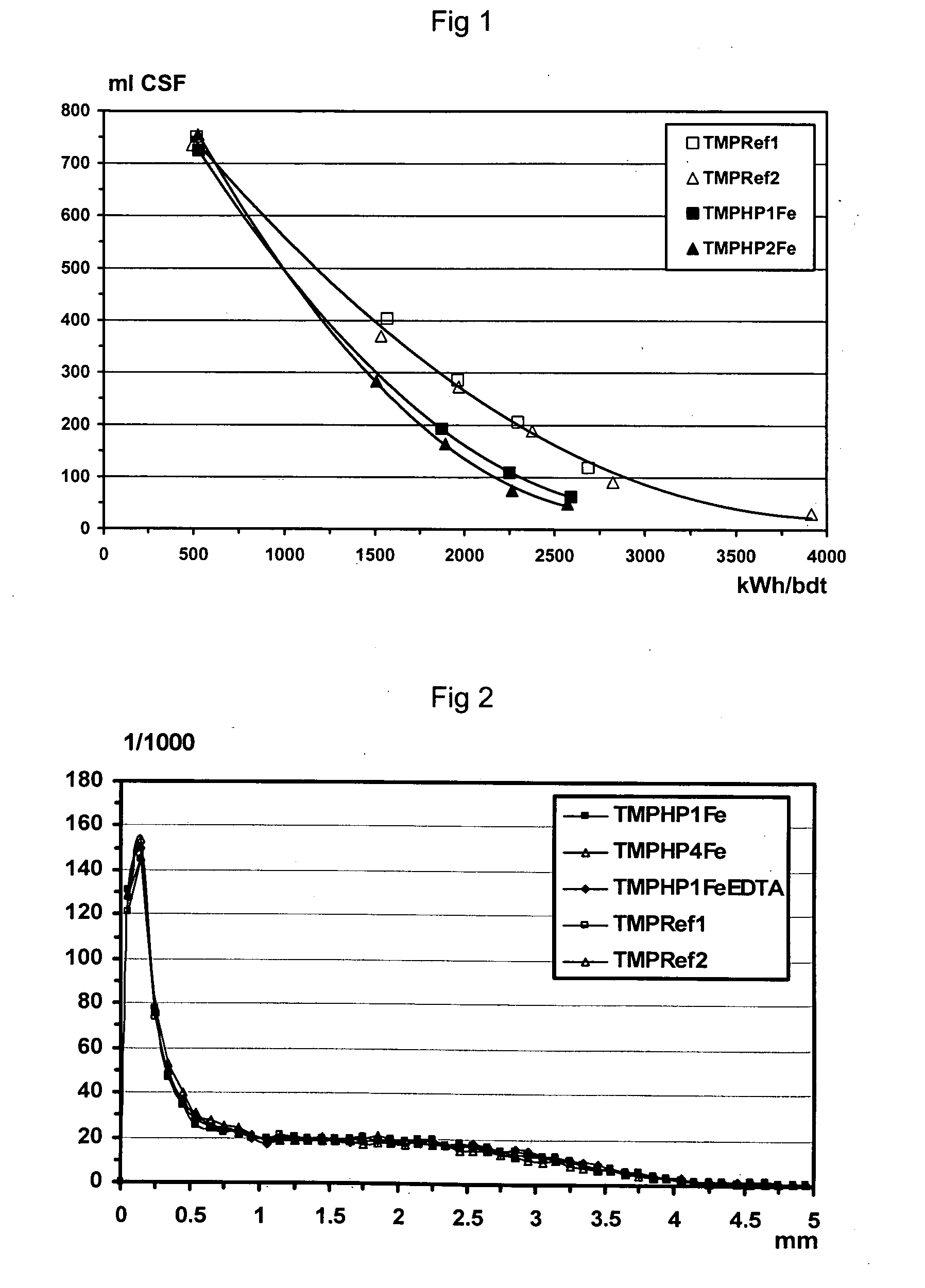

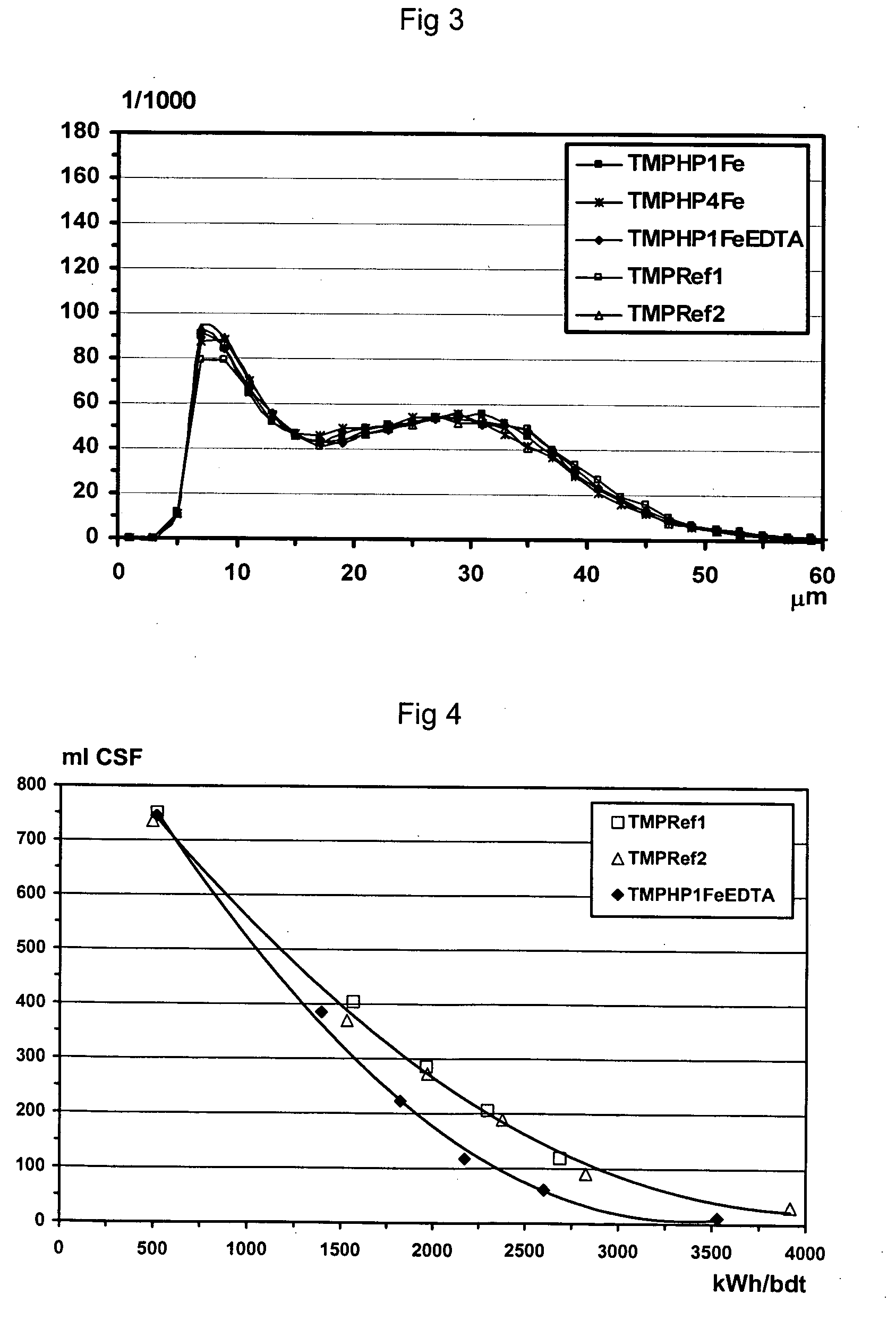

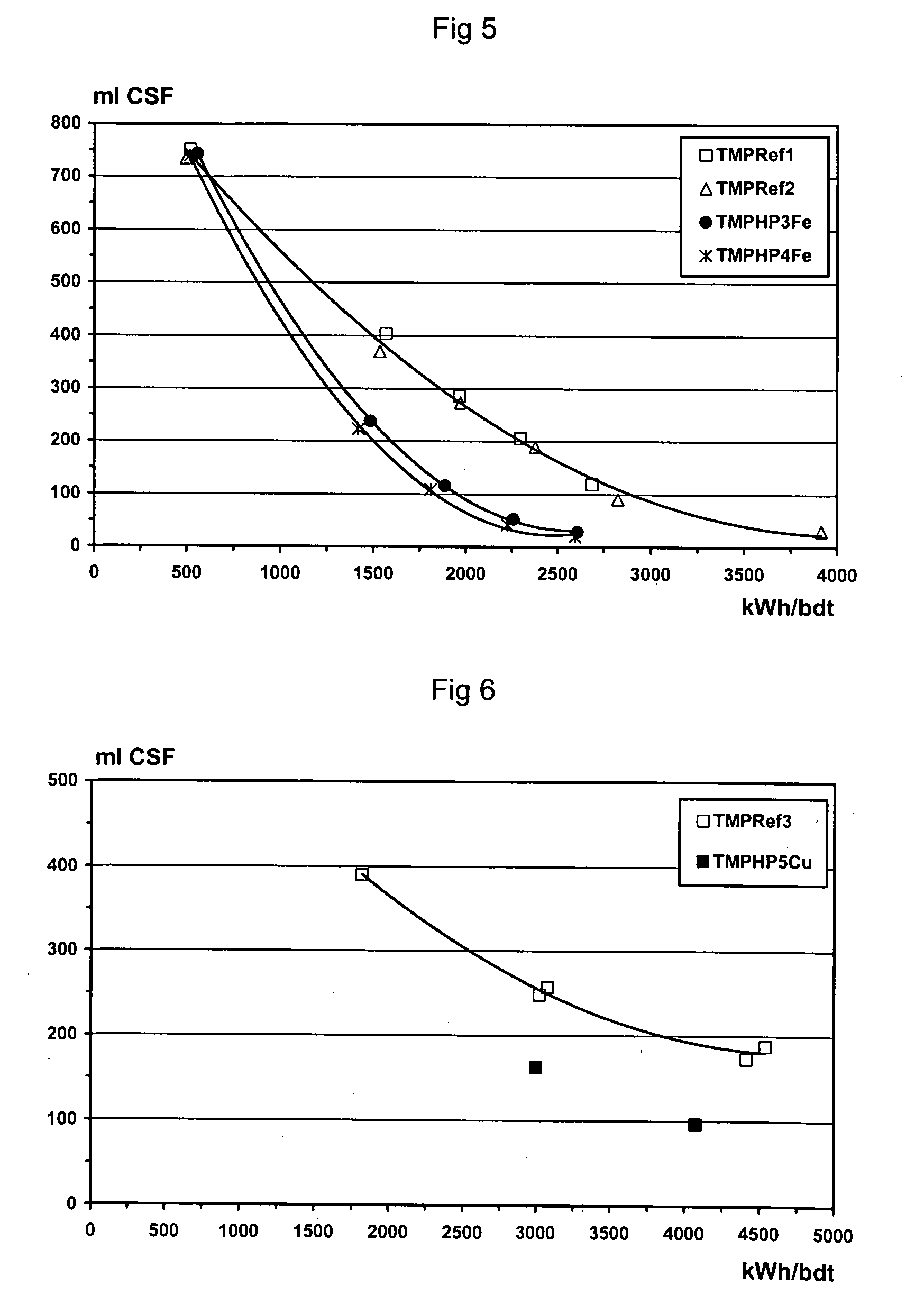

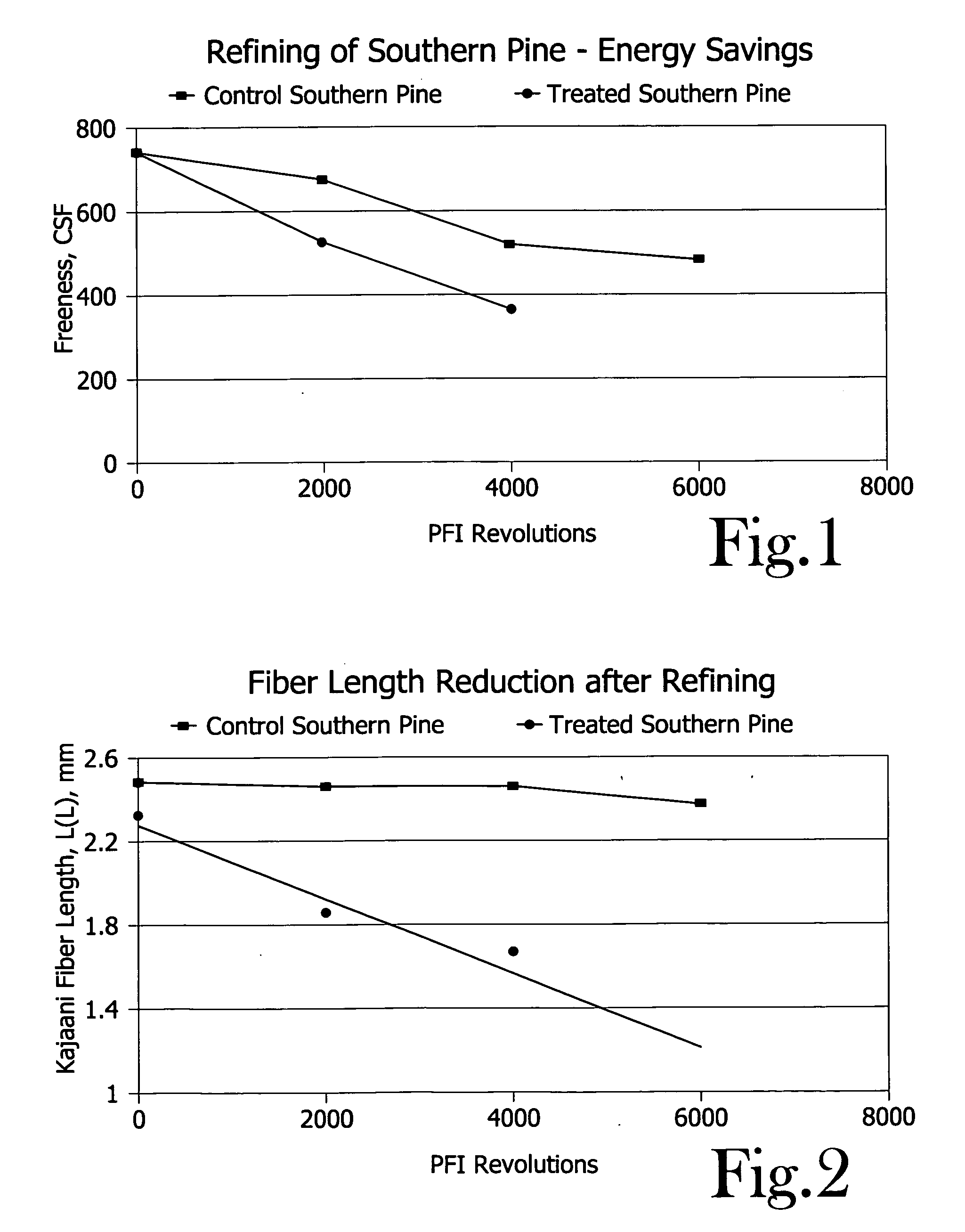

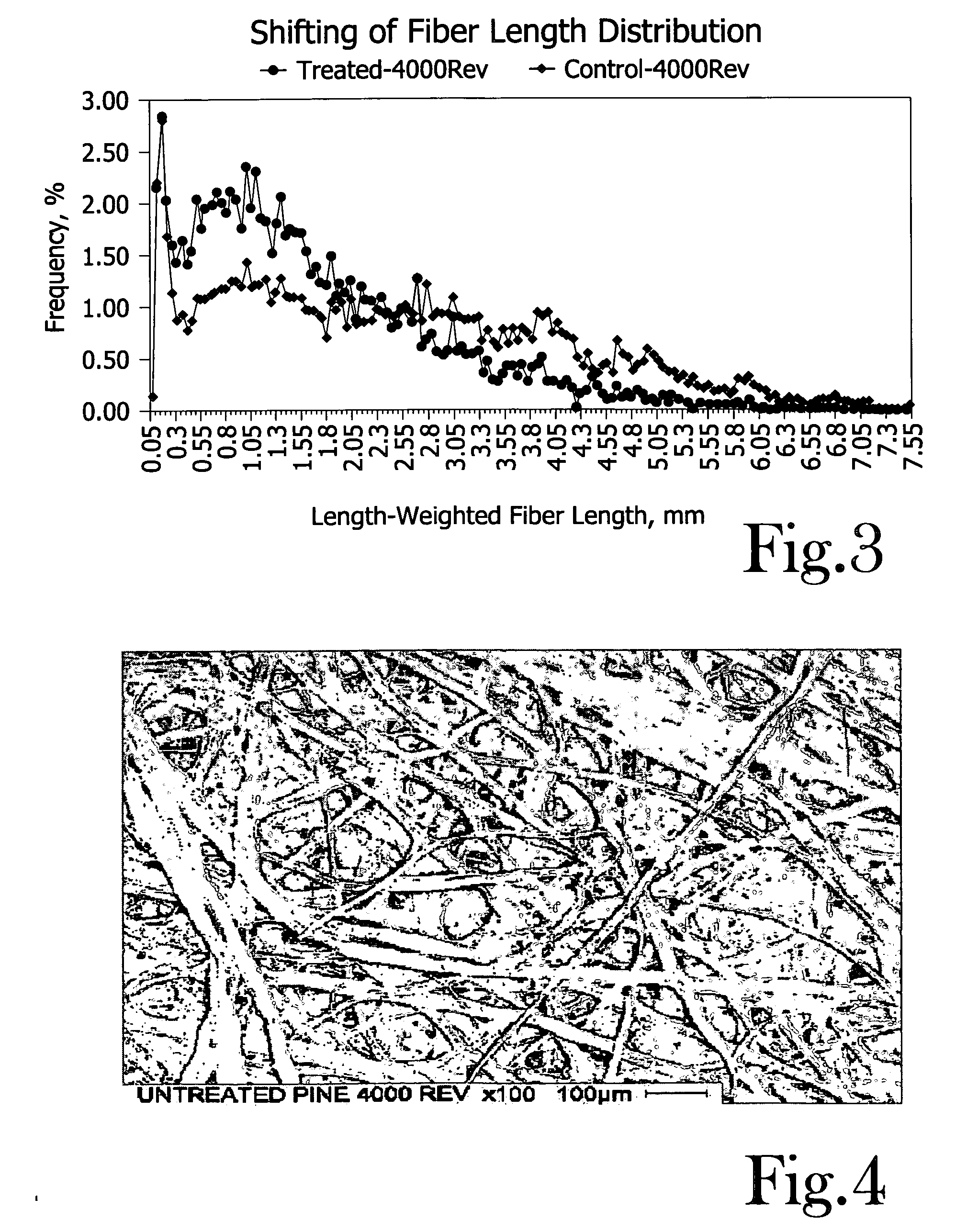

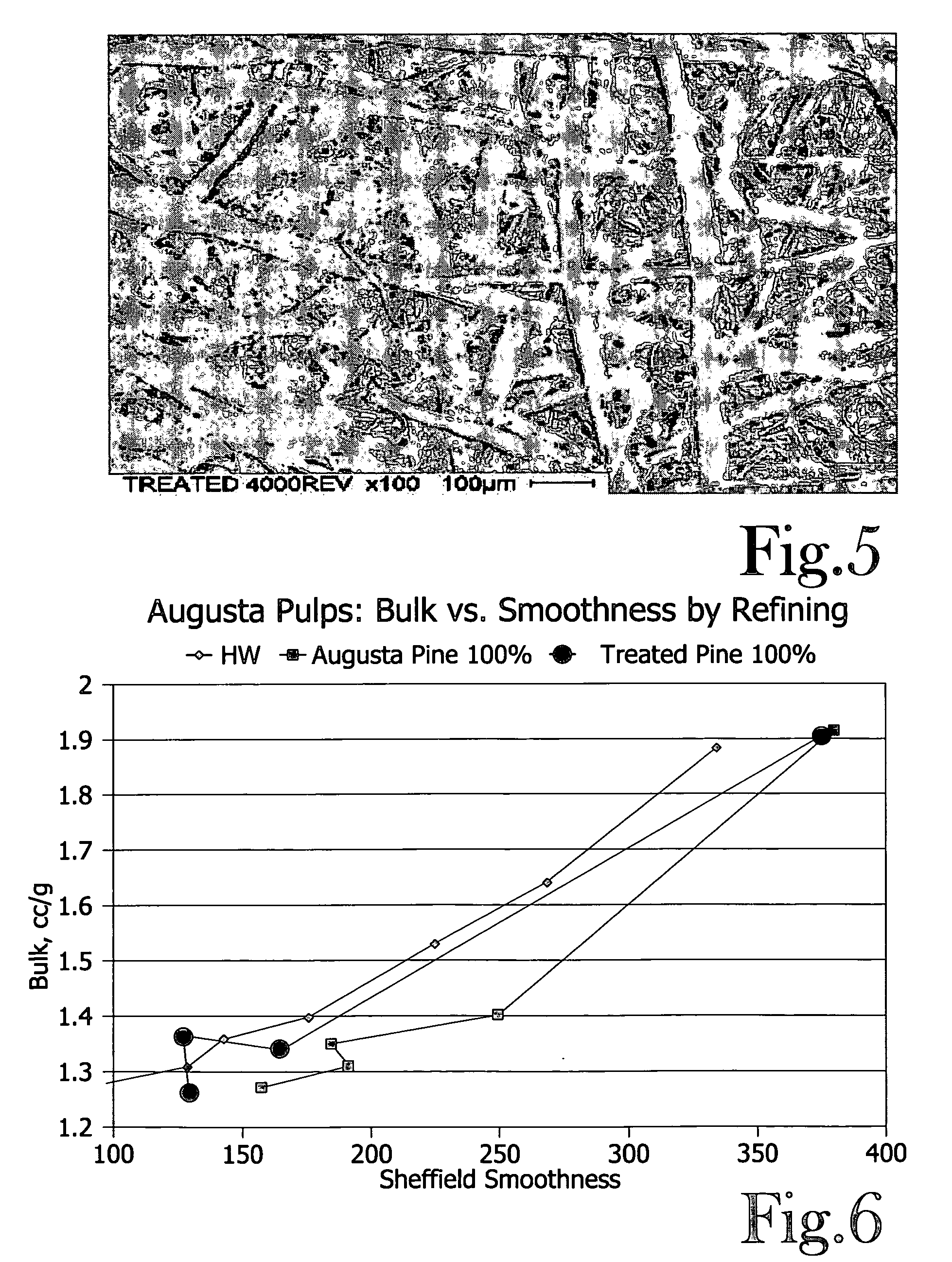

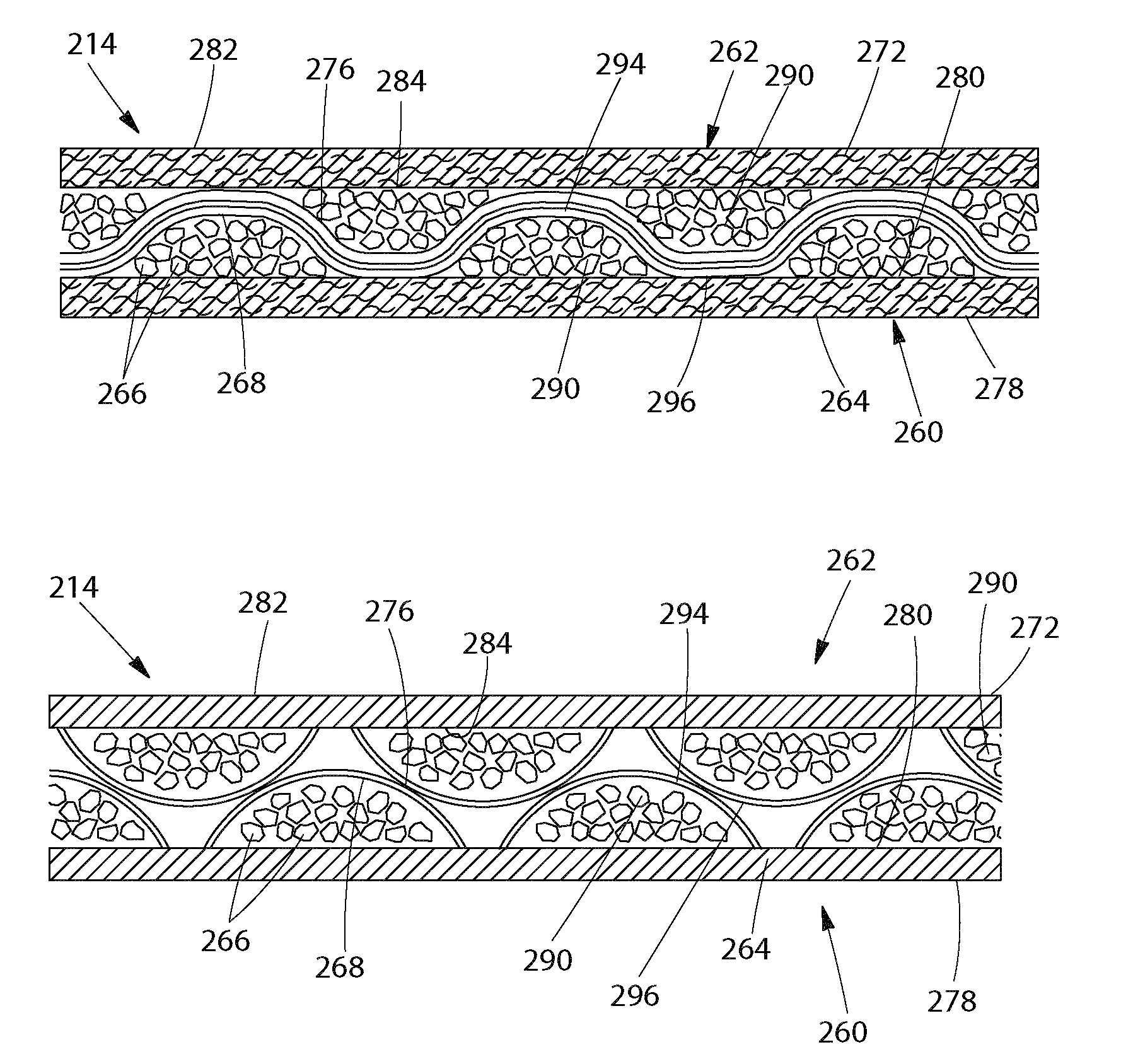

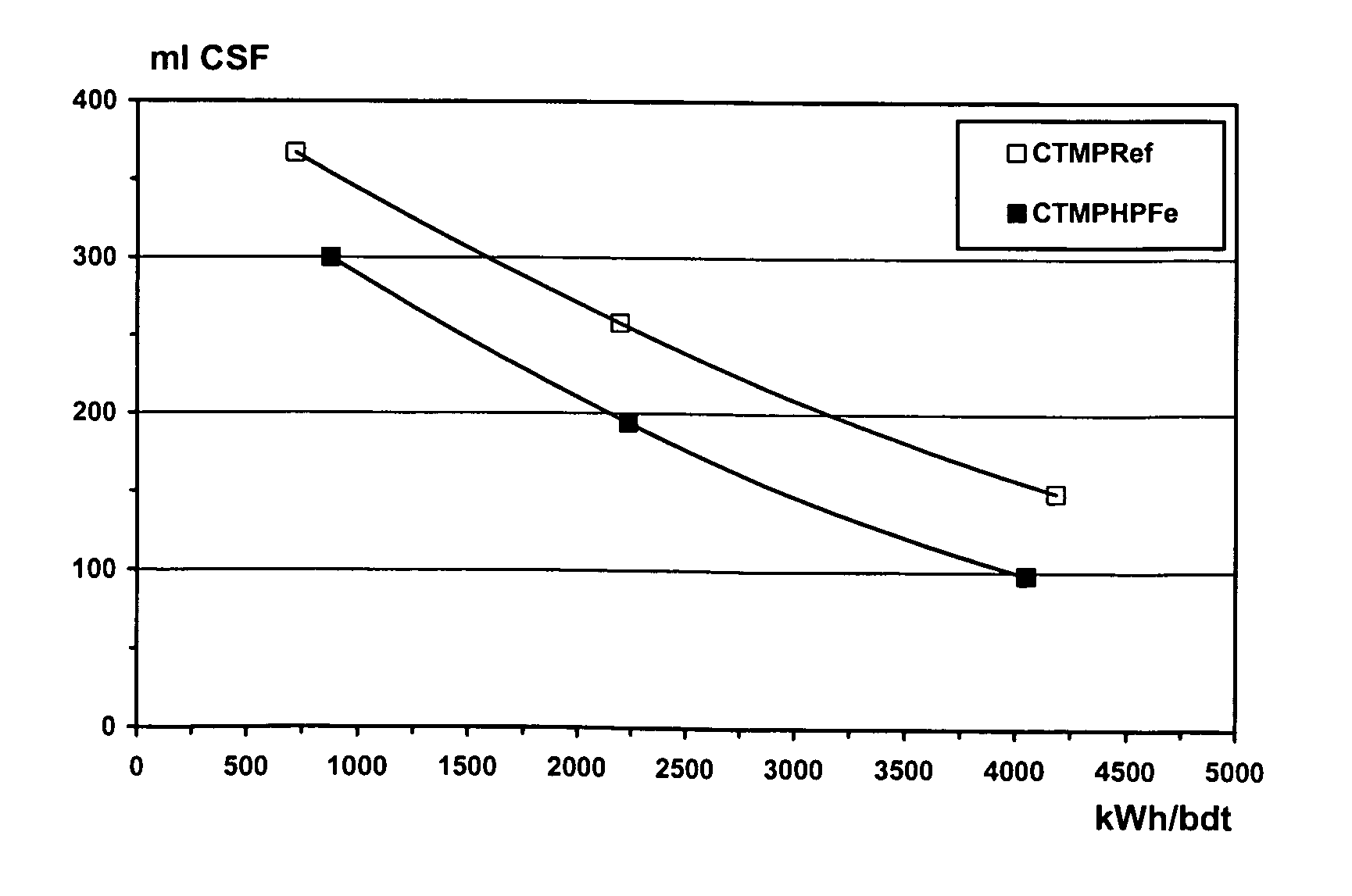

Chemical activation and refining of southern pine kraft fibers

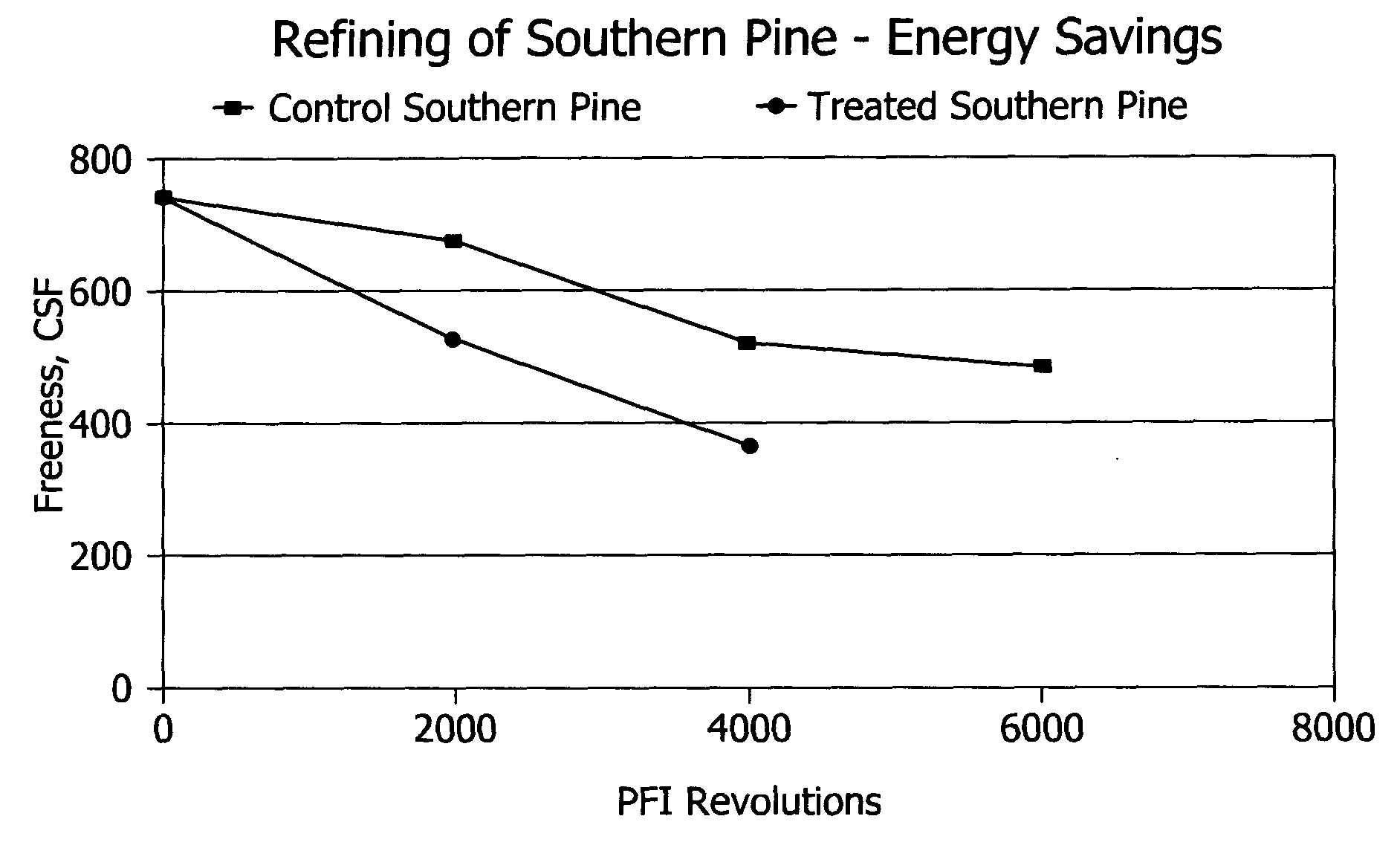

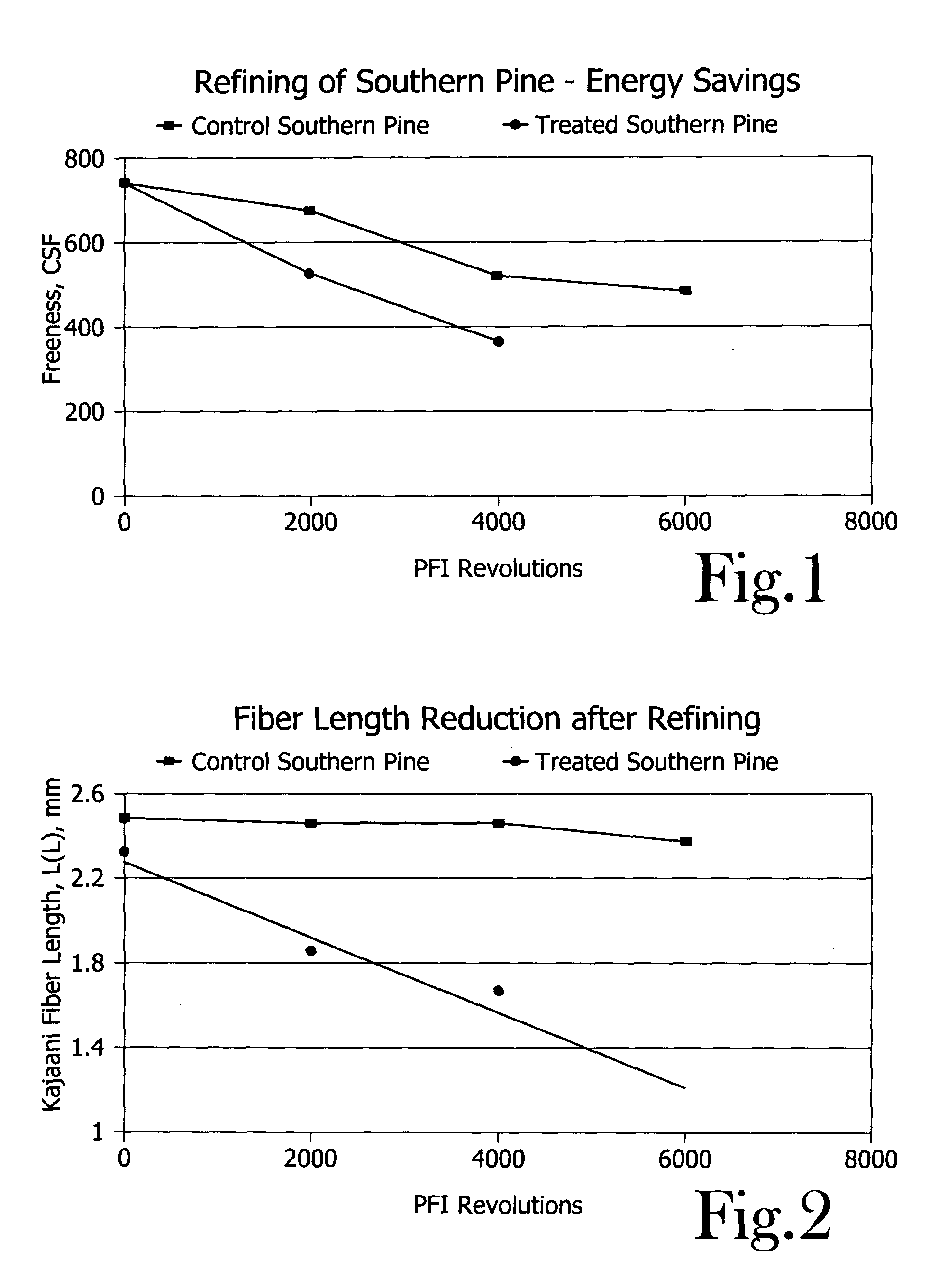

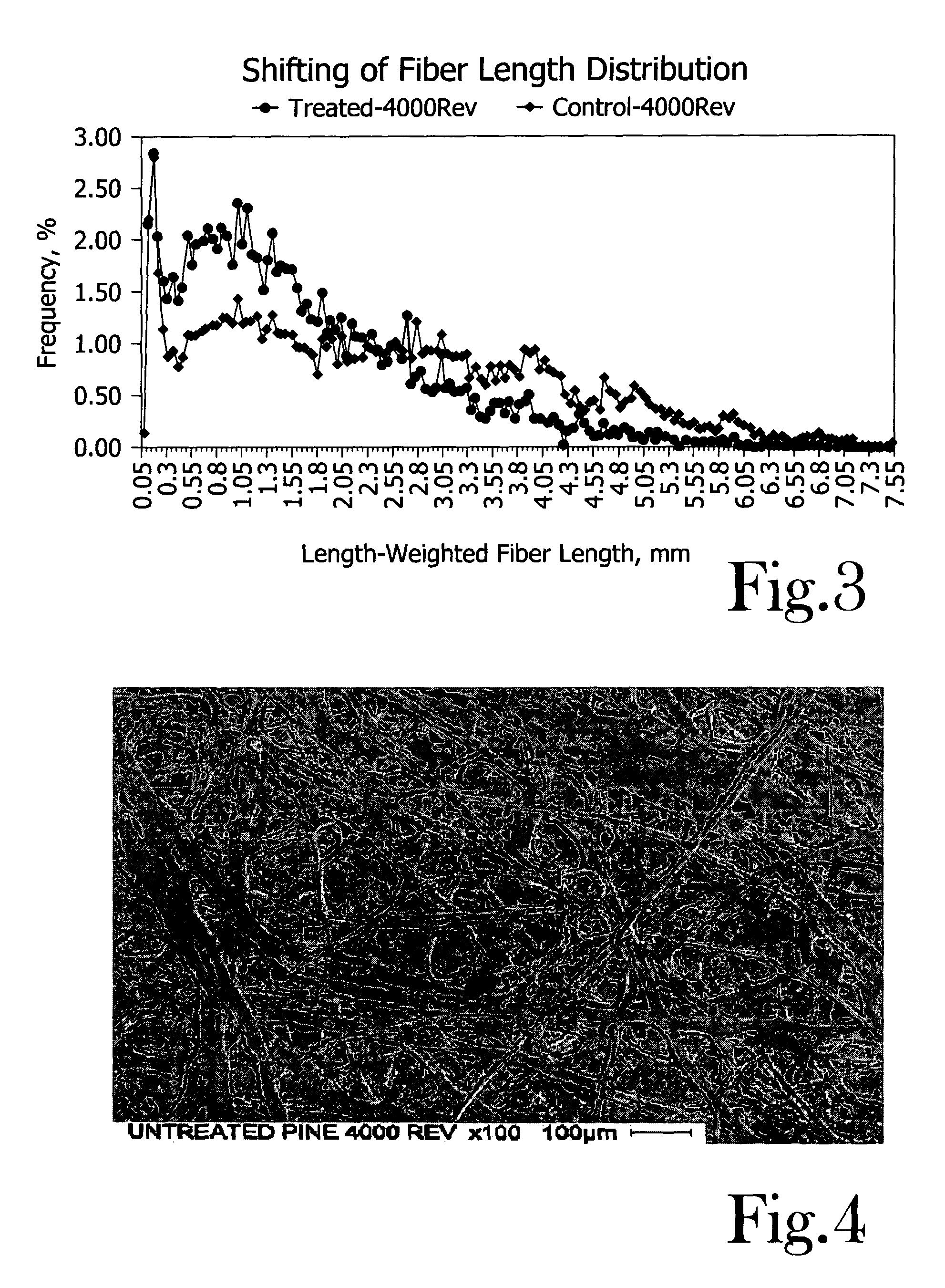

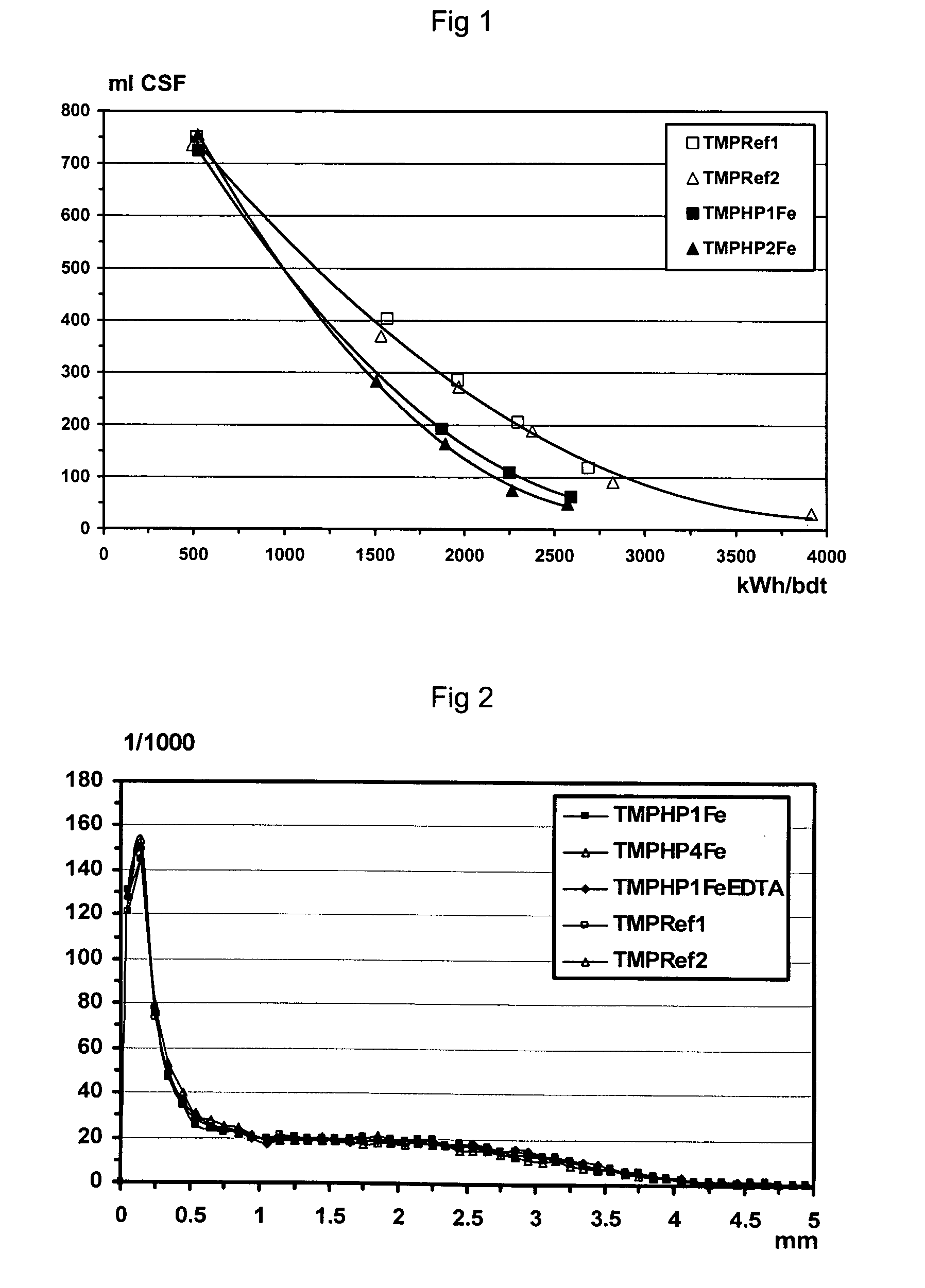

InactiveUS20050061455A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

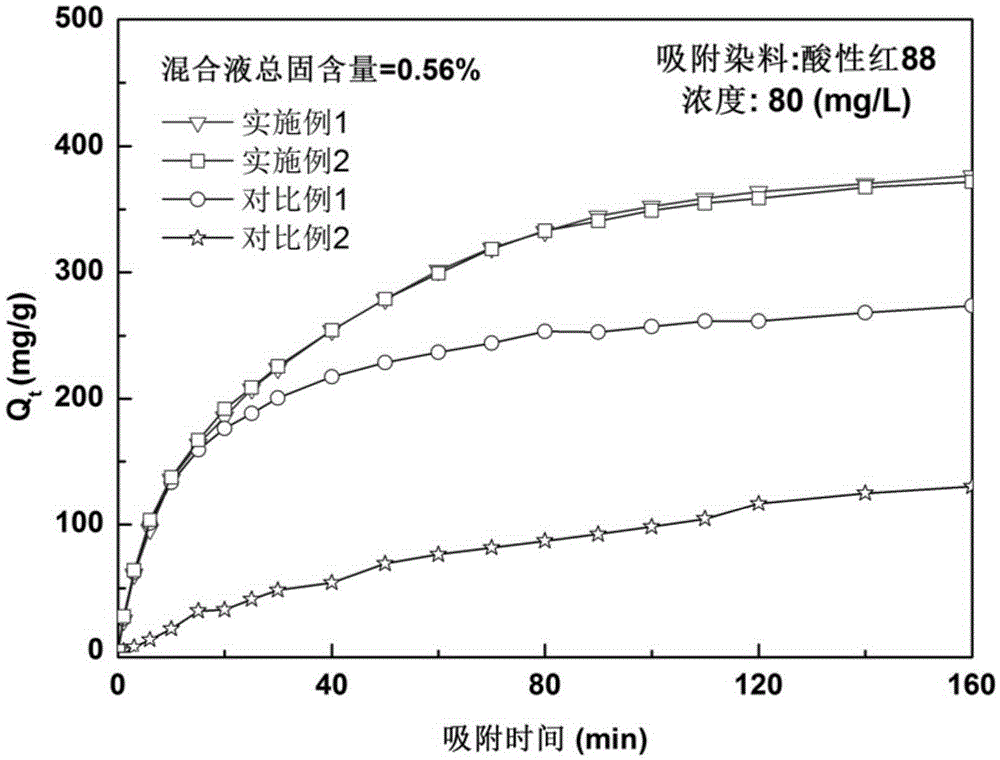

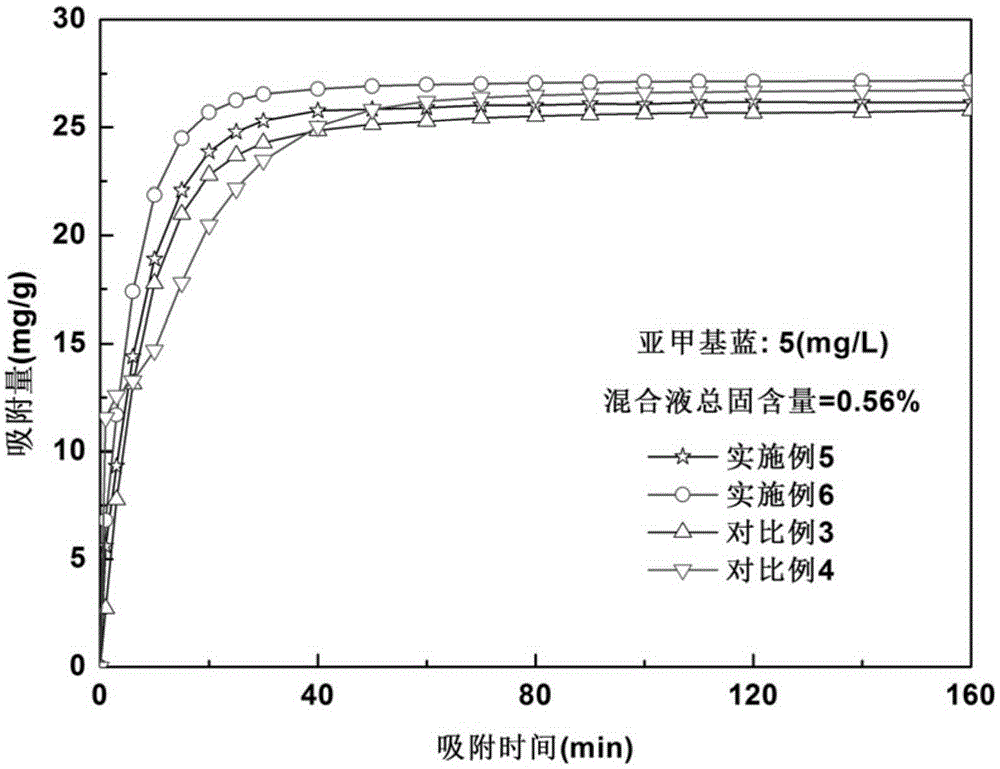

Preparation method of nano-crystalline cellulose-based composite aerogel type organic dye absorption material

ActiveCN105148868AAdsorption is widely applicableOther chemical processesColloidal chemistry detailsPorosityPretreatment method

The invention discloses a preparation method of a nano-crystalline cellulose-based composite aerogel type organic dye absorption material. The method comprises the following steps: preparing nanofibers having functional surfaces by combining a chemical pretreatment method and a mechanical treatment method; and mixing the nanofibers and a natural absorption material to prepare composite aerogel which is used as the organic dye absorption material, wherein the porosity of the prepared composite aerogel is up to 99% or more, the decolourization ratio of the prepared material on organic dyes can exceed 90%, and the prepared material can be widely applied to absorbing the various water-soluble organic dyes.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Process of producing high-yield pulp

The present invention relates to a process for preparing a high-yield pulp comprising a) treating a lignocellulose containing material chemically by means of an oxidising system comprising at least one non-enzymatic oxidant substantially free from ozone and chlorine dioxide and an activator at a pH from about 2 to about 6.5; and b) treating the lignocellulose containing material mechanically for a time sufficient to produce a high-yield pulp, wherein the lignocellulose containing material is chemically treated prior to and / or during any mechanical treatment stage, and wherein the lignocellulose containing material is not chemically treated at a pH from about 11.5 to about 14 between stages a) and b).

Owner:AKZO NOBEL CHEM INT BV

Preparation method of cellulose nano-fiber/polylactic acid composite membrane

InactiveCN103387688AUniform diameter distributionReduce hydrogen bondingPaper material treatmentFiberChemical treatment

The invention provides a preparation method of a cellulose nano-fiber / polylactic acid composite membrane. The preparation method comprises the following steps of: (1) treating raw materials; (2) performing chemical treatment; (3) performing mechanical treatment; (4) preparing a nano cellulose membrane; (5) preparing a nano cellulose / polylactic acid composite membrane material by using a mixing and dissolving method or an immersion method. The preparation method has the advantages that lignin and most of hemicellulose are removed by using a chemical method, and under a water wet swelling condition, water fills the positions in which most of the hemicellulose and the lignin are removed, so that the hydrogen bond acting force among fibrillae is reduced; then lignocellulose nano fibrillae with uniform morphological sizes and mesh gangles are prepared by adopting mechanical treatment. The nano celluloses prepared by grinding for 30 minutes and homogenizing are small in diameter size and are uniformly distributed, the diameters of the nano fibrillae is 15-50nm, and the length-diameter ratio is high and reaches 1200. The cellulose nano-fiber / polylactic acid composite membrane can be used as a substitute and the like for a flexible display, electronic paper, a solar battery, a flexible circuit and a glass substrate.

Owner:NANJING FORESTRY UNIV

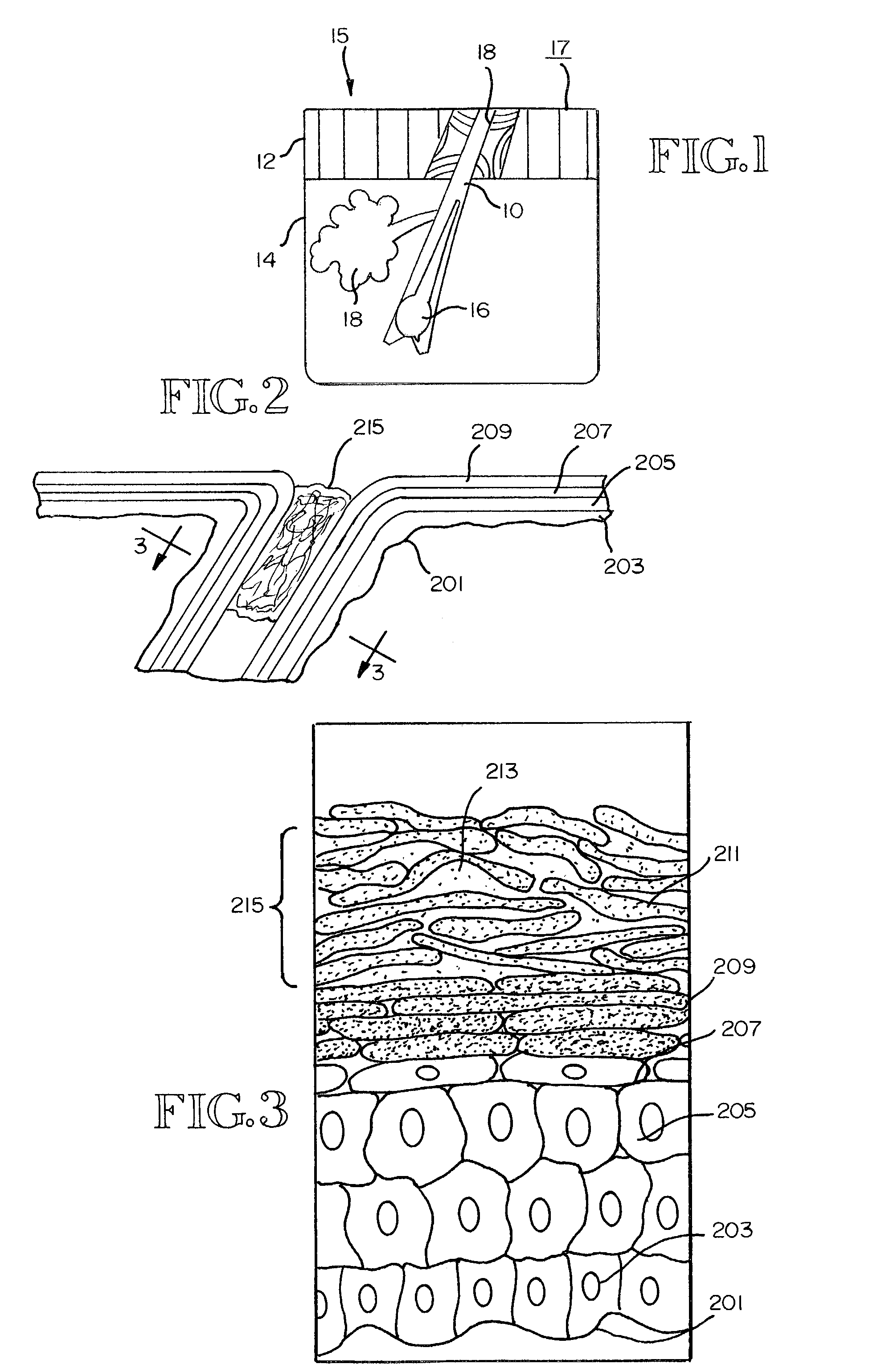

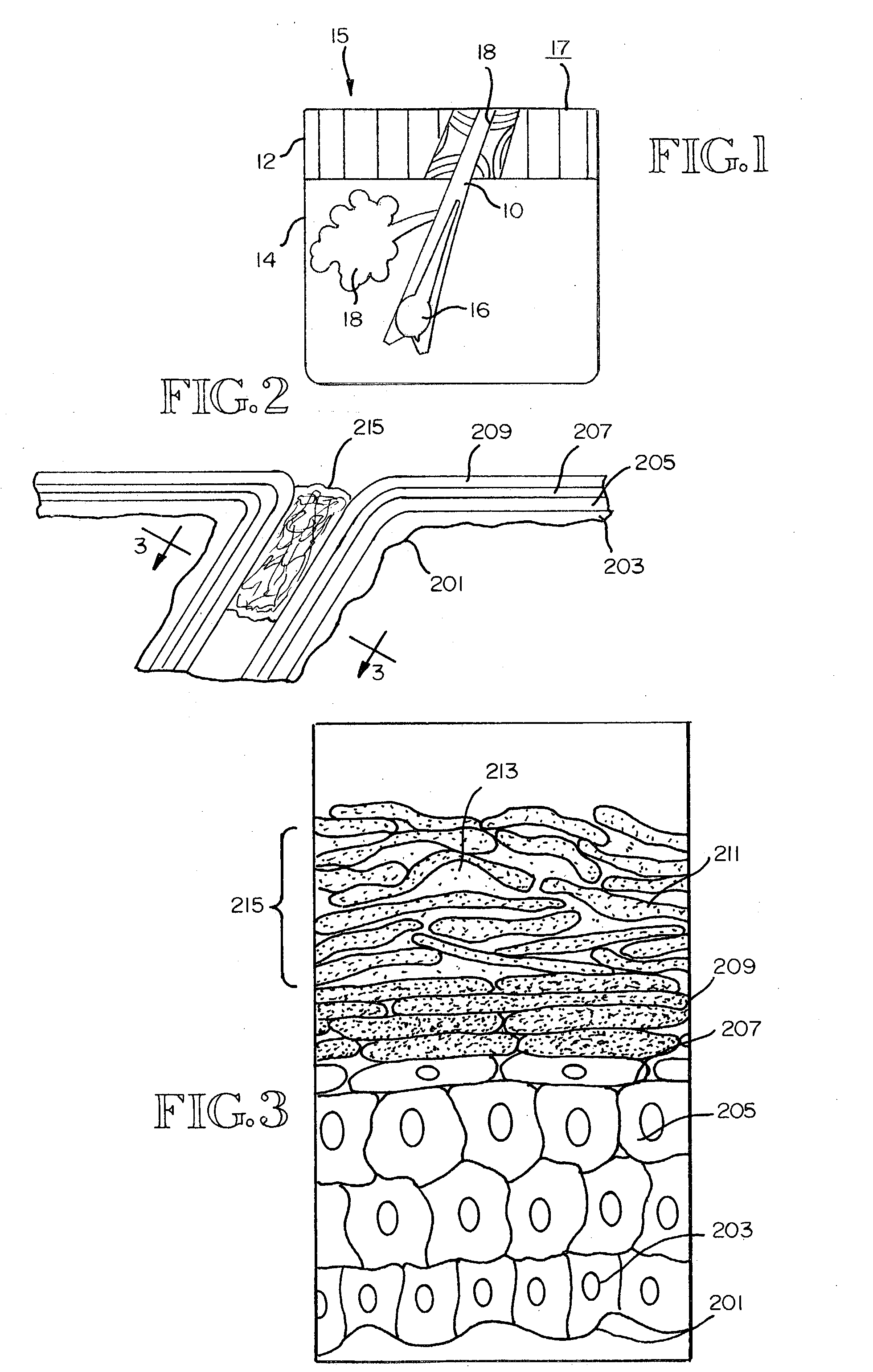

EB Matrix Production from Fetal Tissues and its Use for Tissue Repair

InactiveUS20020146393A1Reducing biological propertyPreserve strengthBiocideHepatocytesCross-linkTissue repair

<heading lvl="0">Abstract of Disclosure< / heading> A method of forming and preserving a bioremodelable, biopolymer scaffold material by subjecting animal tissue, particularly fetal or neo-natal tissue, to chemical and mechanical processing. The process includes, but is not limited t, harvesting the tissue, optionally extracting growth and differentiation factors from the tissue, inactivating infective agents of the tissue, mechanically expressig undesirable components frm the tissue, delipidizing the tissue, washing the tissue, optionally drying the tissue, and optionally cross-linking the tissue not necessarily in the order described. The resulting product, EBM, is characterized by its microbial, fungal, viral and prion inactivated state. EBM is storng, bioremodelable, drapable and does not undergo calicification. EBM supplants previous inventions because of its unique method of preparation and broad applicability in tissue reengineering

Owner:TEI BIOSCI

Chemical activation and refining of southern pine kraft fibers

InactiveUS20070119556A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

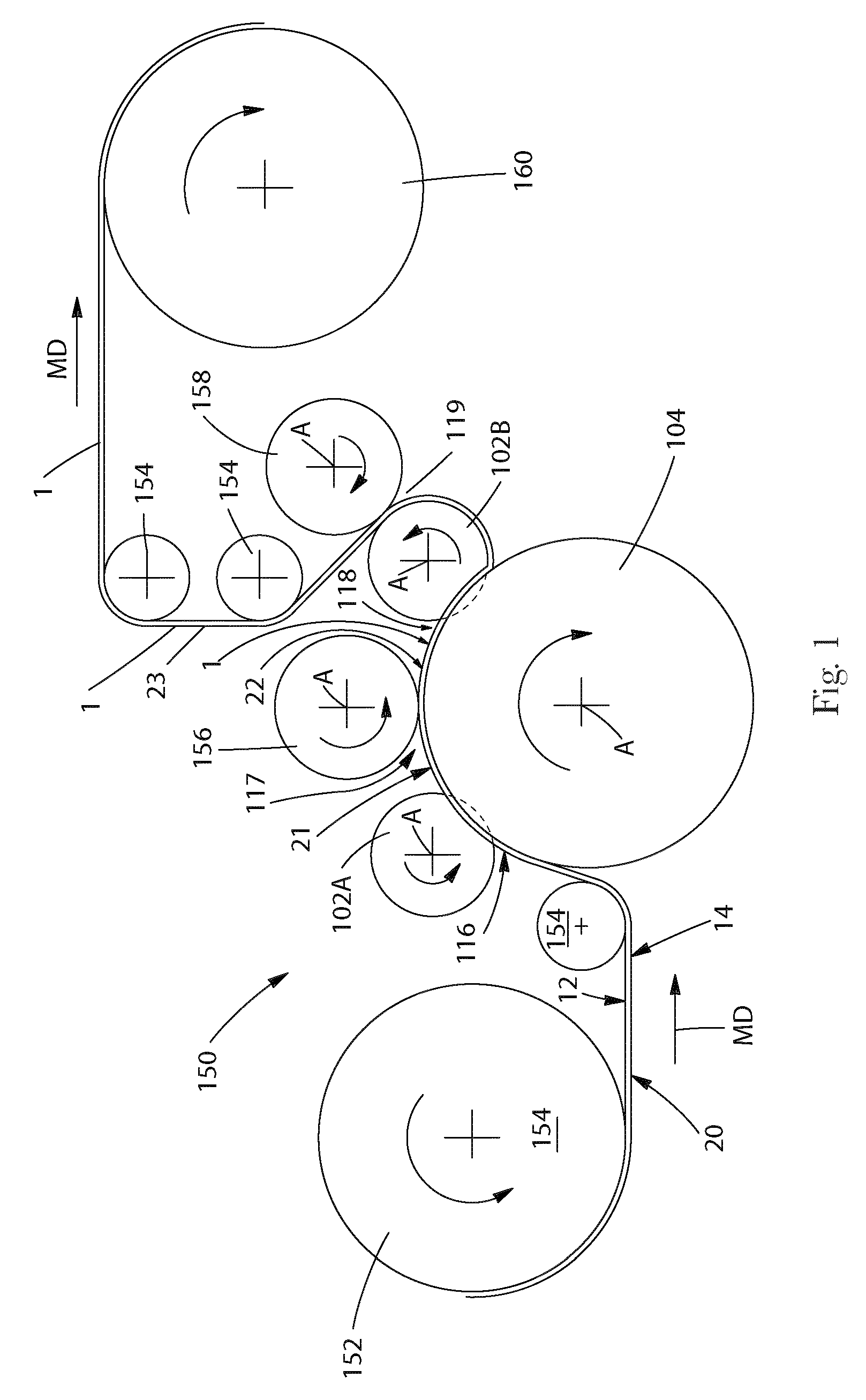

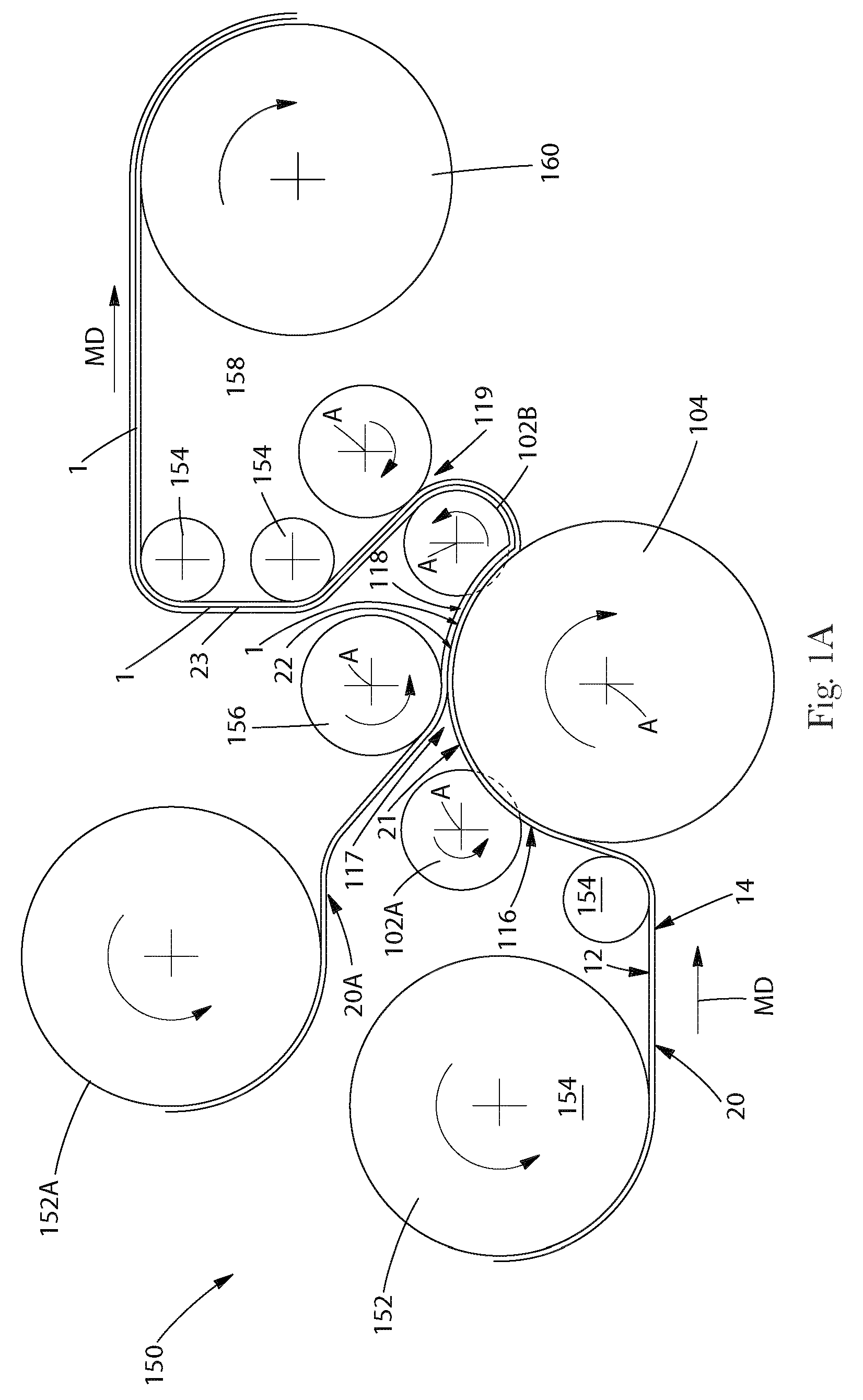

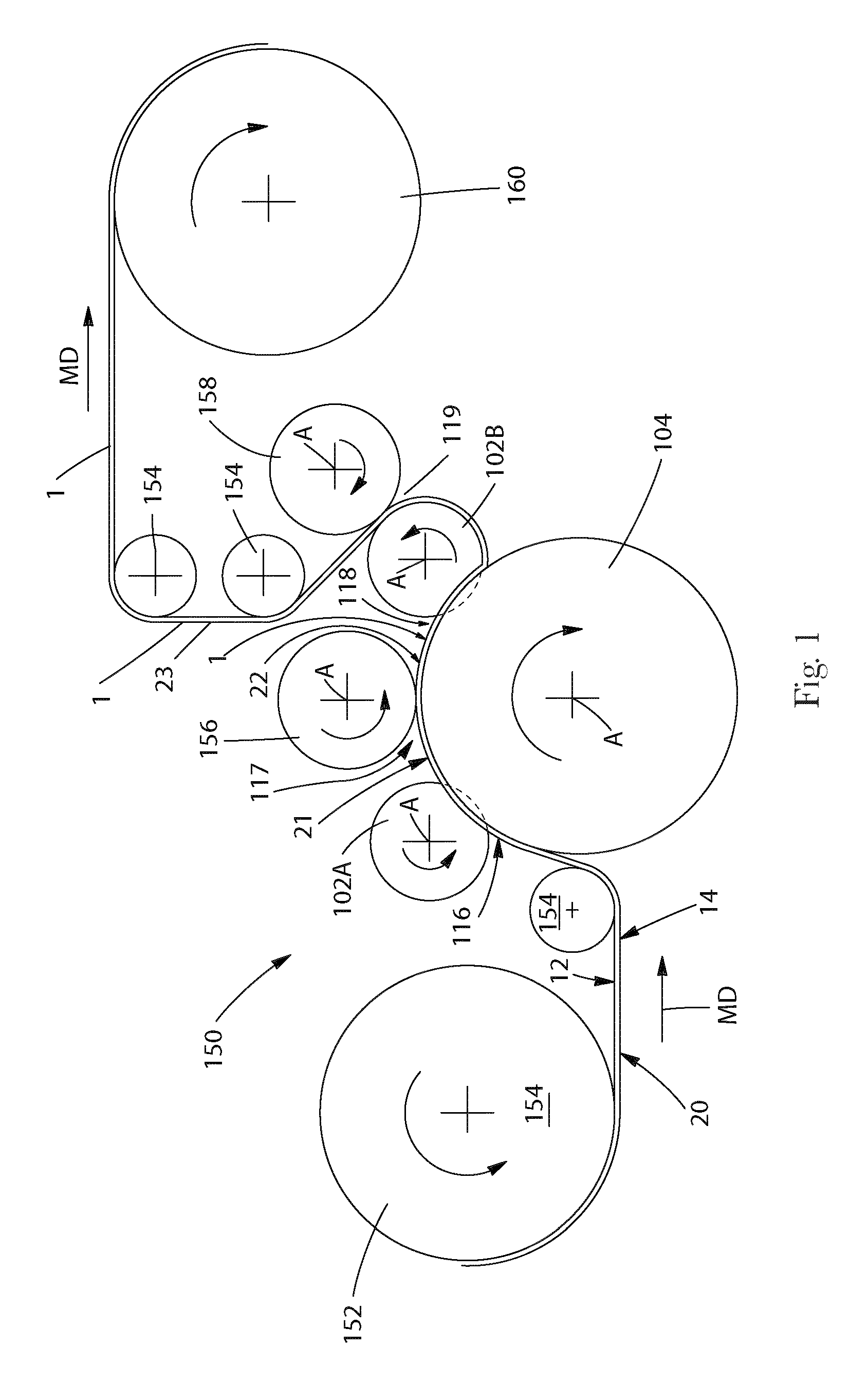

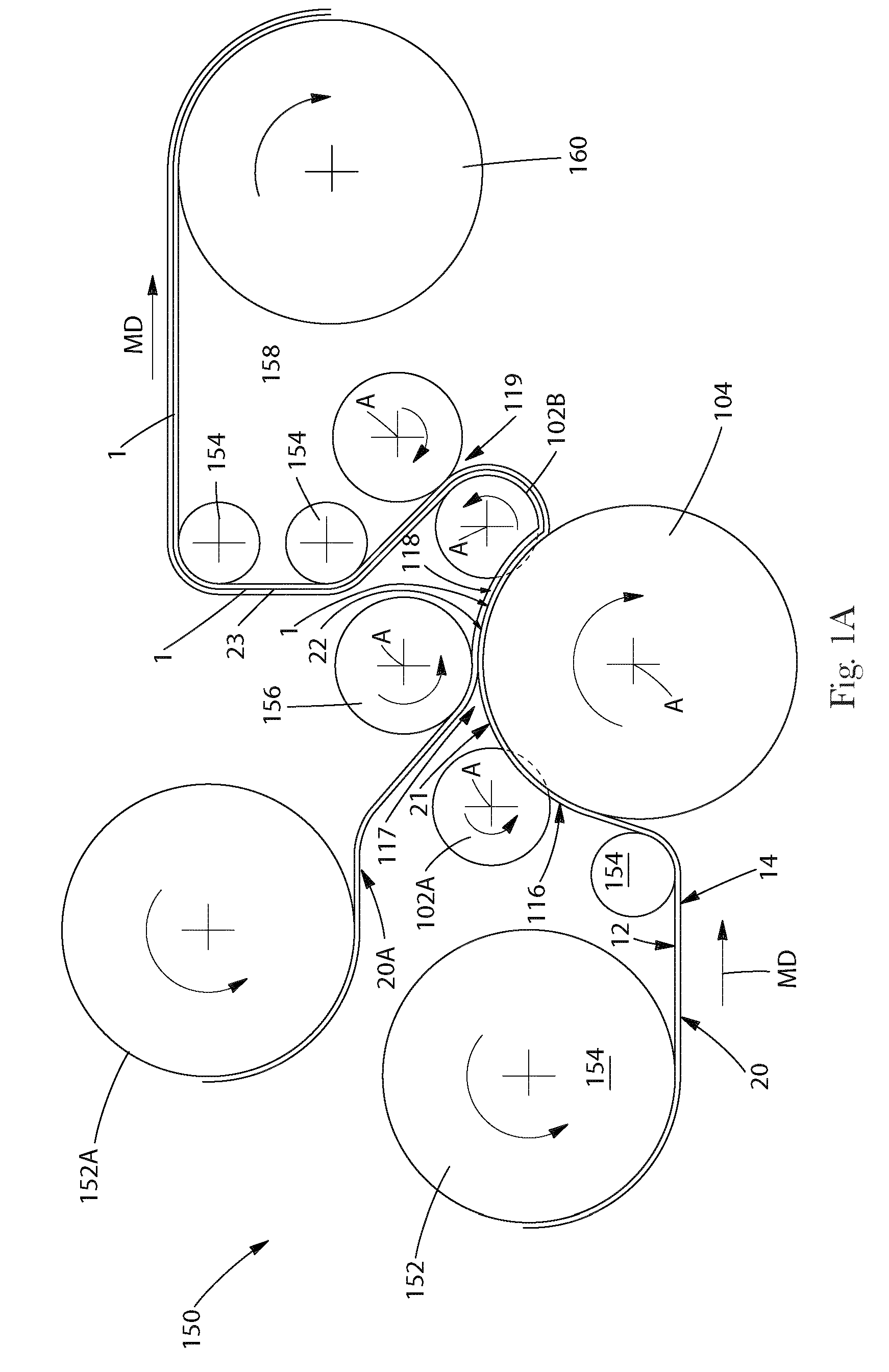

Structured Fibrous Web

InactiveUS20100310810A1Thermally stablePersonal careSynthetic resin layered productsFiberPolymer science

The present disclosure is directed to disposable absorbent articles comprising a structured fibrous web, the structured fibrous web comprising thermally stable, hydrophilic fibers that are thermally bonded together using heat producing a base substrate that is thermally stable. The base substrate is textured via mechanical treatment to increase its thickness and optionally modified via over bonding to improve its mechanical and fluid handling properties. The structured fibrous web provides optimal fluid wicking and fluid acquisition capabilities and is directed toward fluid management applications.

Owner:THE PROCTER & GAMBLE COMPANY

Method for comprehensively treating municipal solid waste

The invention relates to a method for comprehensively treating municipal solid waste. The method comprises mechanical treatment steps of manual sorting, bag breaking, magnetic separation, screening with a roller, winnowing and pulpifying and biological treatment steps of anaerobic digestion and aerobic composting. By combining all the steps for use, different components in the municipal solid waste are classified according to physicochemical properties of the components and then are treated; magnetic metal, plastic paper and the like which are obtained through sorting are recycled; organic waste obtained through sorting is crushed and pulpified and then is subjected to anaerobic digestion so as to produce methane; sludge is subjected to aerobic composting so as to produce organic fertilizer; the residual inorganic substances which cannot be treated or recycled can be subjected to sanitary landfill; and odor which is produced in the waste treatment process is treated in a centralized way, and then is discharged after reaching the standard. The method has great significance for treating the increasing municipal solid waste.

Owner:北京昊业怡生科技有限公司

High speed processing method for realizing superfine crystal grain structure on metallic material surface

The invention relates to a method for processing the high-speed deformation on the surface of metallic material with nano structure, and particularly provides a method for realizing high-speed processing of the organization structure of ultra-fine grains. On the condition of room temperature or low temperature, by adopting a mechanical treatment method with high-speed plastic deformation, the nanoscale bulky crystalline grain structure on the surface layer of the metallic material is refined as equiaxial submicron crystalline grain or nano crystalline grain to form an ultra-fine organization structure of the crystalline grain on the surface layer of the metallic material. With the increase of the depth to the processing surface, the size of microstructure has the change of gradient, increasing from nanoscale and submicron size to micron size. Compared with the existing processing method for forming a surface ultra-fine crystalline grain structure, the high-speed processing method of the invention greatly reduces the roughness of the surface of the processed metallic material and increases the thickness of a deformation layer, and has simple processing method and high working efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of biomass nano cellulose carbon aerogel

The invention relates to a preparation method of a carbon aerogel, particularly a preparation method of a biomass nano cellulose carbon aerogel, and aims to solve the problems of complex preparation process and lack of raw materials in the traditional carbon aerogel. The method comprises the following steps: 1. treatment of biomass material: treating the biomass material with acidified sodium chlorite, and treating with a 1-10 wt% potassium hydroxide solution to obtain purified cellulose; 2. preparing purified cellulose water solutions with different concentrations; 3. mechanical treatment: carrying out ultrasonic treatment on the purified cellulose water solution, carrying out high-pressure homogenization treatment to obtain a nano cellulose water suspension, and standing the nano cellulose water suspension to obtain the nano cellulose aquagel by self-assembly; 4. drying the nano cellulose aquagel to prepare the nano cellulose aerogel; and 5. carrying out carbonizing treatment on the nano cellulose aerogel in a pipe furnace in an inert gas protective atmosphere to prepare the nano cellulose carbon aerogel. The method is applicable to the field of aerogel materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

Field emission devices using modified carbon nanotubes

InactiveUS20050275331A1Reduce voltageAccelerate emissionsNanostructure manufactureNanoinformaticsField emission deviceModified carbon

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes nanotubes which have been subjected to energy, plasma, chemical, or mechanical treatment. The present invention also relates to a field emission cathode comprising carbon nanotubes which have been subject to such treatment. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been subject to such treatment is further disclosed.

Owner:HYPERION CATALYSIS INT

Structured fibrous web

The present invention is directed to a structured fibrous web comprising thermally stable, hydrophilic fibers that are thermally bonded together using heat producing a base substrate that is thermally stable. The base substrate is textured via mechanical treatment to increase its thickness and optionally modified via over bonding to improve its mechanical and fluid handling properties. The structured fibrous web provides optimal fluid wicking and fluid acquisition capabilities and is directed toward fluid management applications.

Owner:THE PROCTER & GAMBLE COMPANY

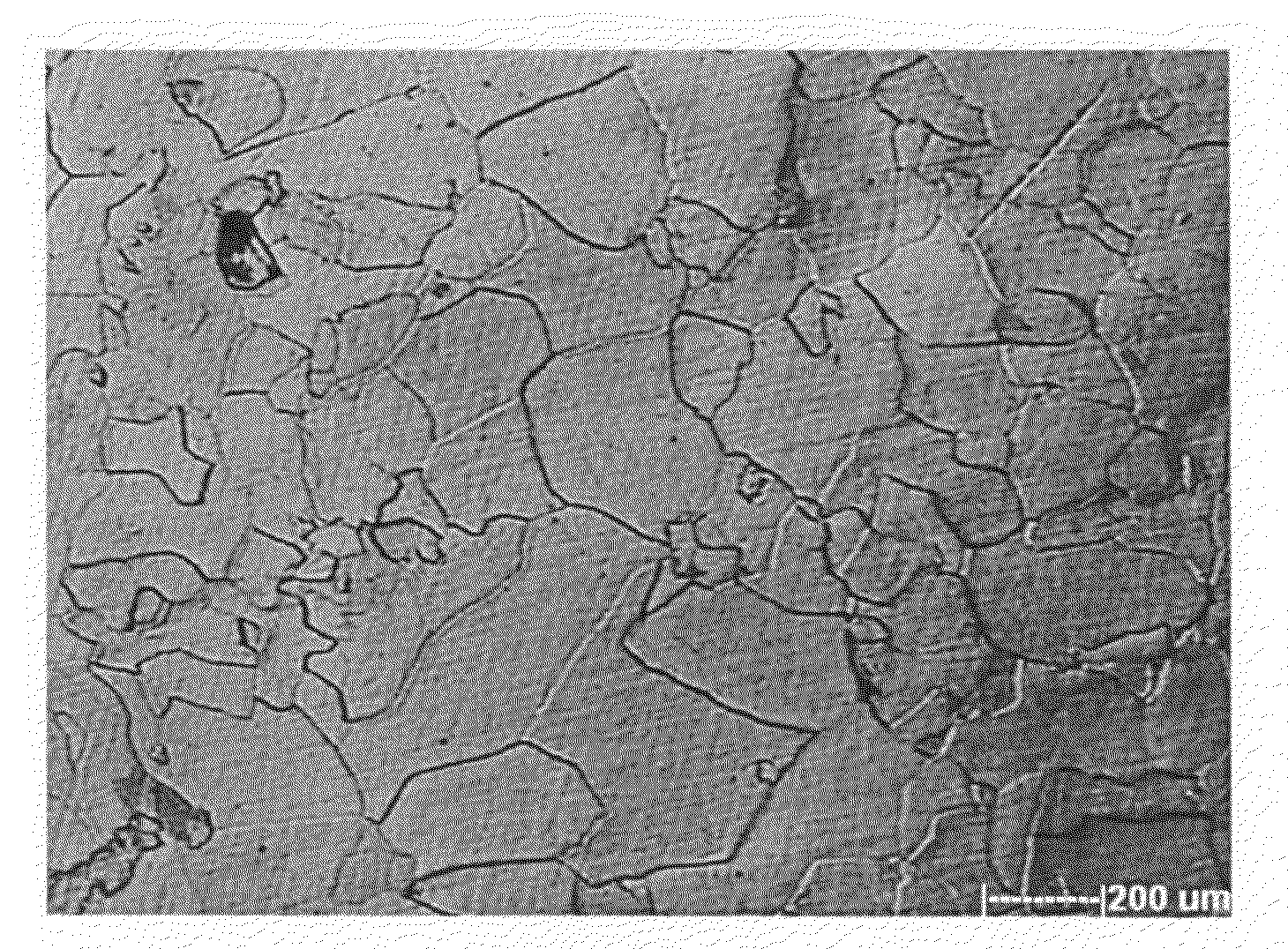

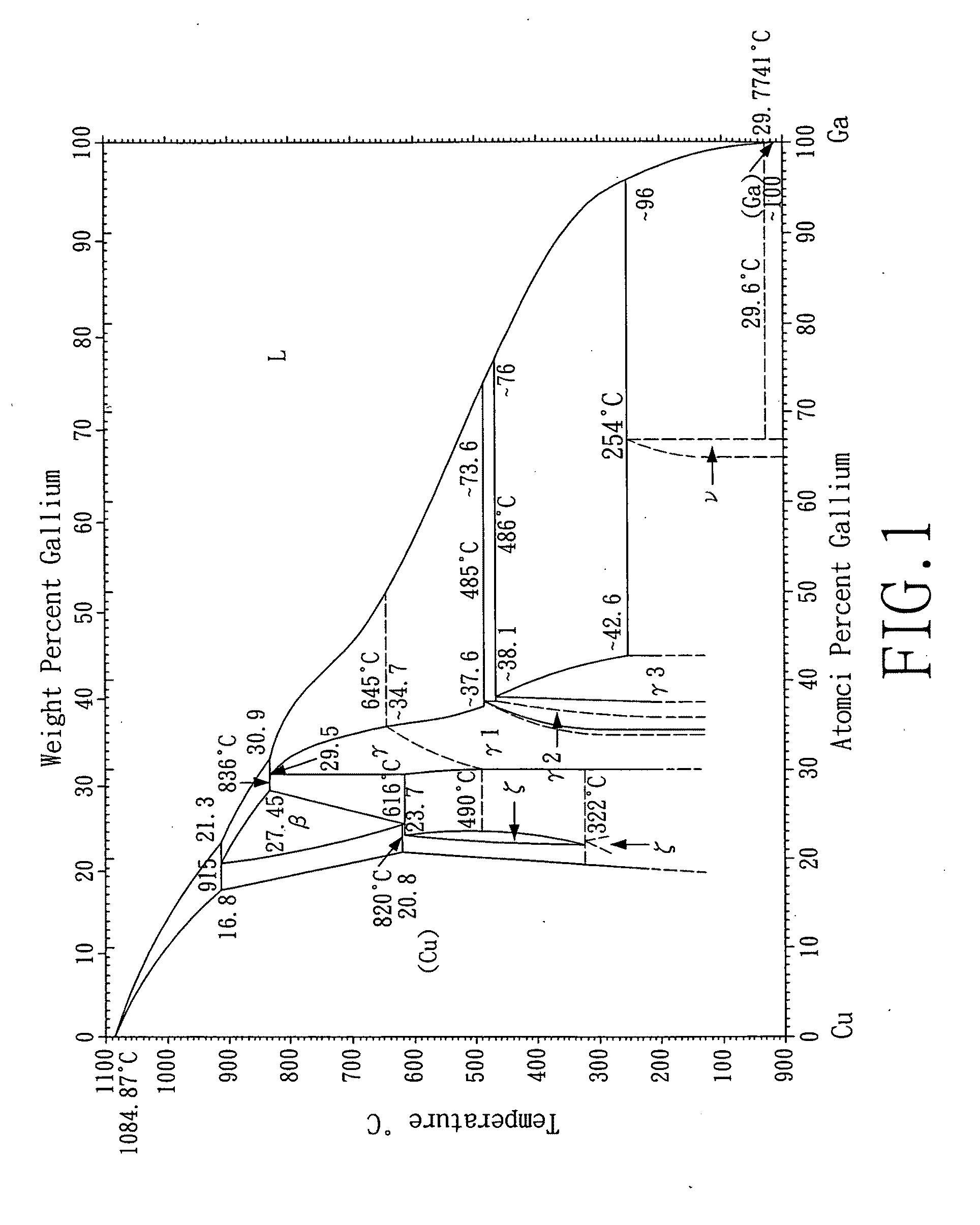

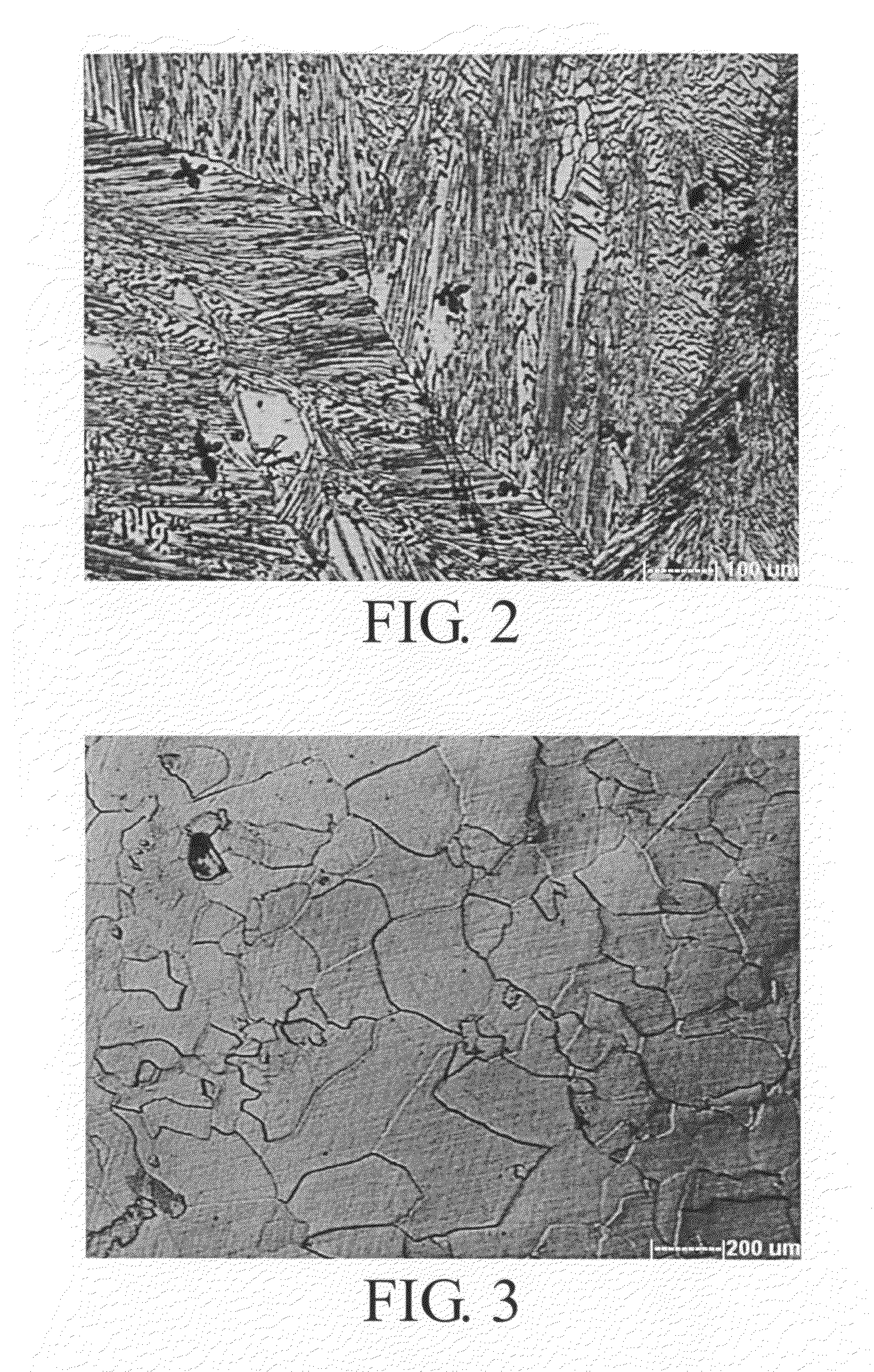

Copper-gallium allay sputtering target, method for fabricating the same and related applications

InactiveUS20100116341A1Improved quality and propertyCellsVacuum evaporation coatingSputteringRoom temperature

A method for fabricating a copper-gallium alloy sputtering target comprises forming a raw target; treating the raw target with at least one thermal treatment between 500° C.˜850° C. being mechanical treatment, thermal annealing treatment for 0.5˜5 hours or a combination thereof to form a treated target; and cooling the treated target to a room temperature to obtain the copper-gallium alloy sputtering target that has 71 atomic % to 78 atomic % of Cu and 22 atomic % to 29 atomic % of Ga and having a compound phase not more than 25% on its metallographic microstructure. Therefore, the copper-gallium alloy sputtering target does not induce micro arcing during sputtering so a sputtering rate is consistent and forms a uniform copper-gallium thin film. Accordingly, the copper-gallium thin film possesses improved quality and properties.

Owner:SOLAR APPLIED MATERIALS TECHNOLOGY CORPORATION

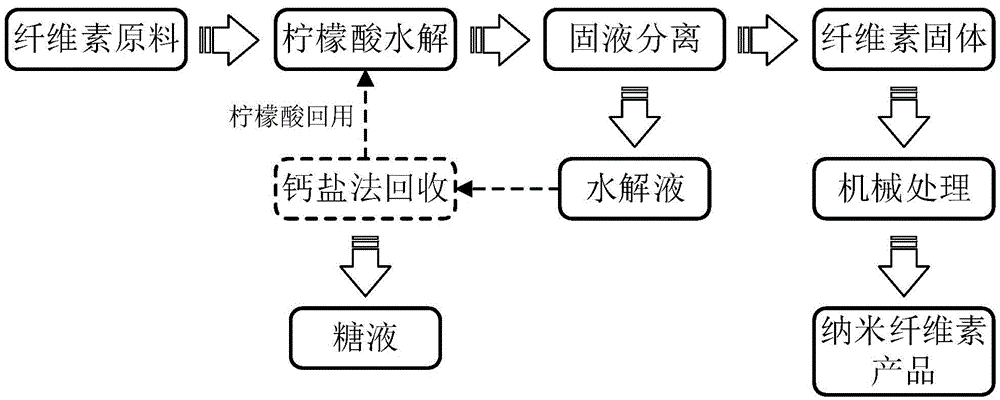

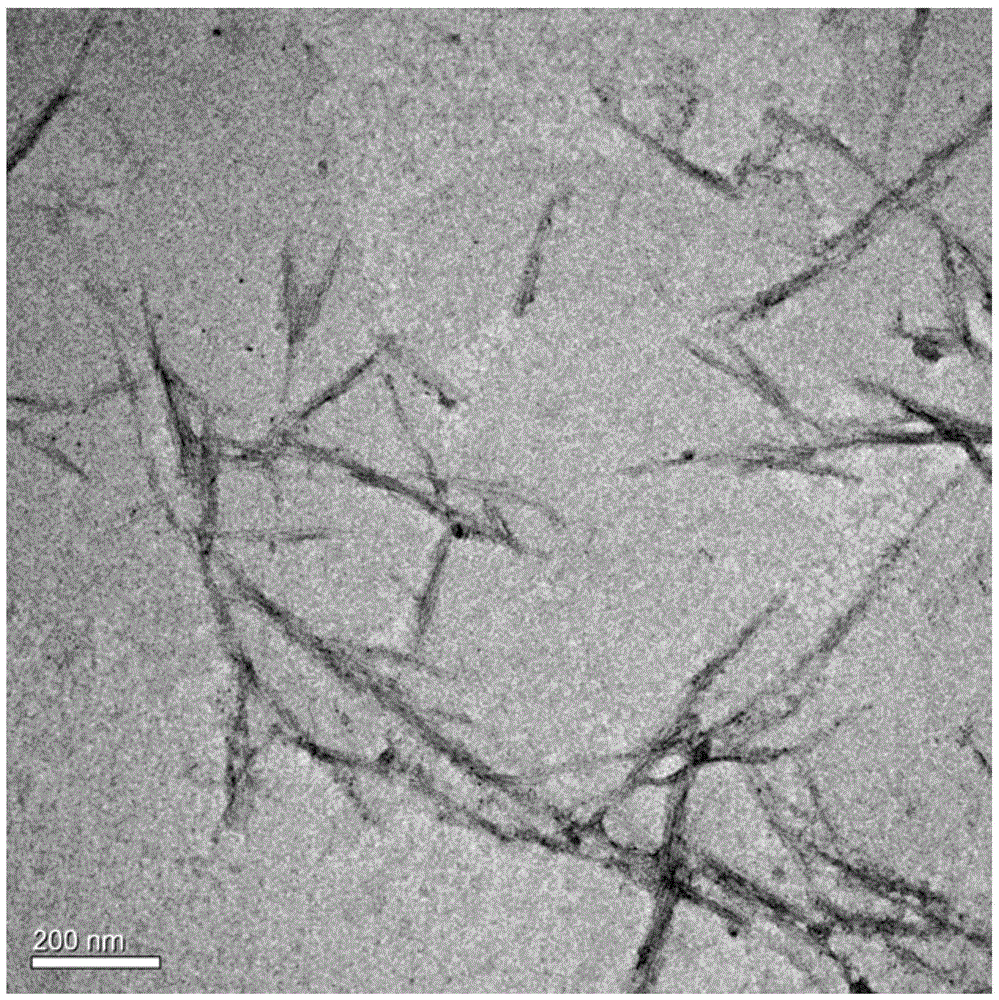

Preparation method of nanocellulose fibrils

The invention relates to a green, economical and sustainable method for preparing nanocellulose fibrils. The preparation method comprises the following steps that 1, a cellulose raw material is added to a citric acid solution to be heated, stirred and hydrolyzed; 2, treated cellulose and hydrolysate are separated through methods of centrifugal sedimentation and the like, and precipitated cellulose is centrifugally washed with water multiple times and diluted into a cellulose suspension; 3, the separated hydrolysate can be directly recycled at least once, citric acid is recovered from the recycled hydrolysate, and the citric acid obtained through recovery can be recycled continuously; 4, the natural structure of the cellulose suspension obtained in the second step is further destroyed through a high pressure homogenizer or ultrasonication or physical mechanical treatment of a disc mill, and the colloidal nanocellulose fibrils are obtained. According to the method for preparing the nanocellulose fibrils, a catalyst is not adopted, the reaction condition is relatively mild, the reaction is easy to control, operation is easy, and the method is friendly to environment.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Preparation method for composite material of cellulose nanofiber and reinforced polyurethane

InactiveCN103436002AHigh strengthReduce forcePaper recyclingWaste paper working-upCelluloseChemical treatment

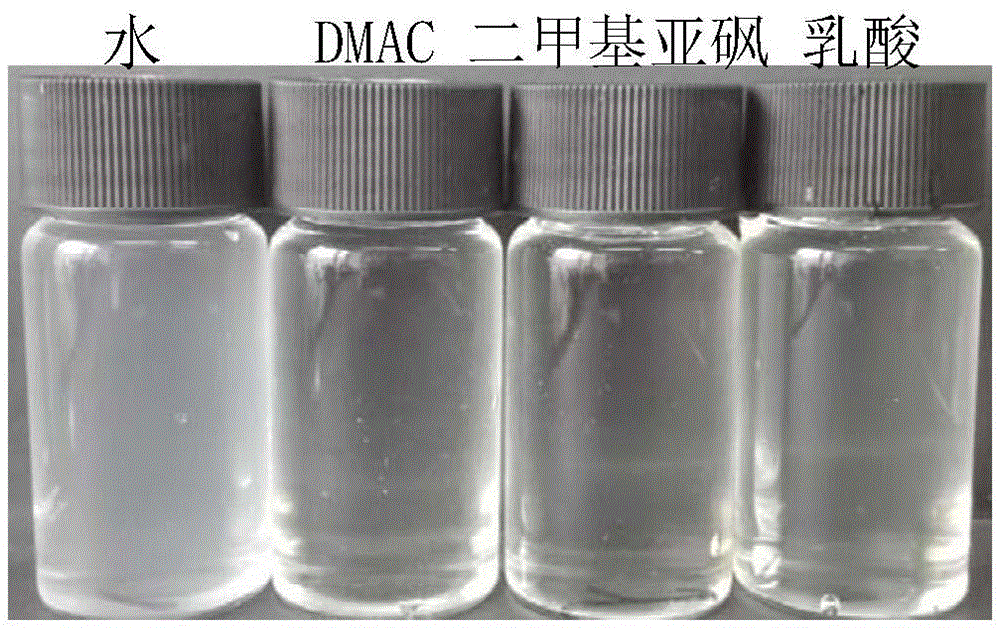

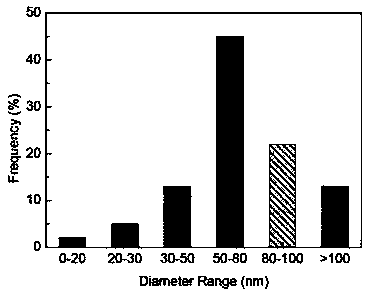

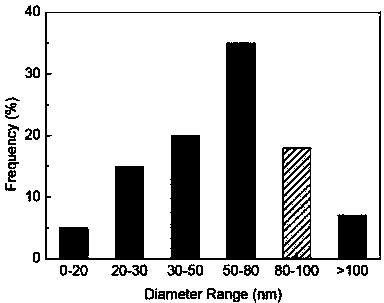

The invention discloses a preparation method for a composite material of cellulose nanofiber and reinforced polyurethane. The method comprises the following steps: 1) pretreating in a chemical method; 2) unfastening fibers in a mechanical method. According to the invention, chemical treatment and mechanical treatment are adopted to separate the cellulose nanofiber, which has a high length diameter ratio and is used for reinforced polyurethane, from newspaper; the transparent nano composite material with high-intensity is prepared; wood meal and newspaper are adopted as raw materials to prepare cellulose nanofiber through the chemical treatment combined with the mechanical treatment; the diameter range of the cellulose nanofiber is 30-100 nm, and the length diameter ratio is higher than 1000.

Owner:NANJING FORESTRY UNIV

Structured Fibrous Web

The present disclosure is directed to disposable absorbent articles comprising a structured fibrous web, the structured fibrous web comprising thermally stable, hydrophilic fibers that are thermally bonded together using heat producing a base substrate that is thermally stable. The base substrate is textured via mechanical treatment to increase its thickness and optionally modified via over bonding to improve its mechanical and fluid handling properties. The structured fibrous web provides optimal fluid wicking and fluid acquisition capabilities and is directed toward fluid management applications.

Owner:THE PROCTER & GAMBLE COMPANY

Process of producing high-yield pulp

InactiveUS8268122B2Pulp bleachingPretreatment with oxygen-generating compoundsCelluloseChemical treatment

The present invention relates to a process for preparing a high-yield pulp comprisinga) treating a lignocellulose containing material chemically by means of an oxidizing system comprising at least one non-enzymatic oxidant substantially free from ozone and chlorine dioxide and an activator at a pH from about 2 to about 6.5; andb) treating the lignocellulose containing material mechanically for a time sufficient to produce a high-yield pulp, wherein the lignocellulose containing material is chemically treated prior to and / or during any mechanical treatment stage, and wherein the lignocellulose containing material is not chemically treated at a pH from about 11.5 to about 14 between stages a) and b).

Owner:NOURYON CHEM INT BV

Method for providing a nanocellulose involving modifying cellulose fibers

ActiveUS20110036522A1Increases anionic charge densityReduce energy consumptionNanostructure manufacturePulp properties modificationAqueous electrolyteCellulose fiber

A method for the manufacturing of nanocellulose. The method includes a first modification of the cellulose material, where the cellulose fibres are treated with an aqueous electrolyte-containing solution of an amphoteric cellulose derivative. The modification is followed by a mechanical treatment. By using this method for manufacturing nanocellulose, clogging of the mechanical apparatus is avoided. Also the nanocellulose is manufactured in accordance with the method and uses of the cellulose.

Owner:INNVENTIA

Microfluidic substrates having improved fluidic channels

ActiveUS20060077221A1Lower surface energyLow wettabilitySemiconductor/solid-state device manufacturingPrintingChemical treatmentEngineering

A method for improving fluidic flow for a microfluidic device having a through hole or slot therein. The method includes the steps of forming one or more openings through at least part of a thickness of a substrate from a first surface to an opposite second surface using a reactive ion etching process whereby an etch stop layer is applied to side wall surfaces in the one or more openings during alternating etching and passivating steps as the openings are etched through at least a portion of the substrate. Substantially all of the etch stop layer coating is removed from the side wall surfaces by treating the side wall surfaces using a method selected from chemical treatment and mechanical treatment, whereby a surface energy of the treated side wall surfaces is increased relative to a surface energy of the side wall surfaces containing the etch stop layer coating.

Owner:FUNAI ELECTRIC CO LTD

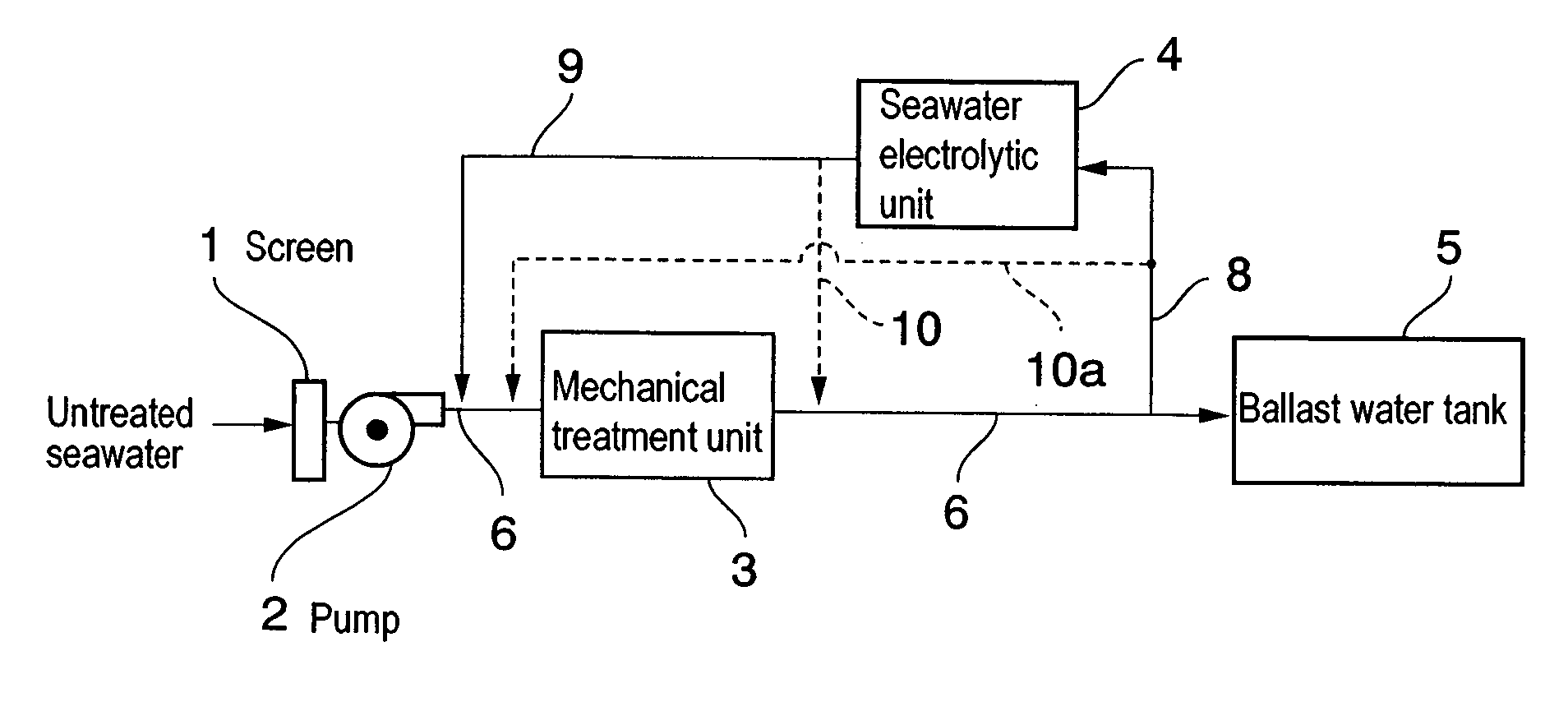

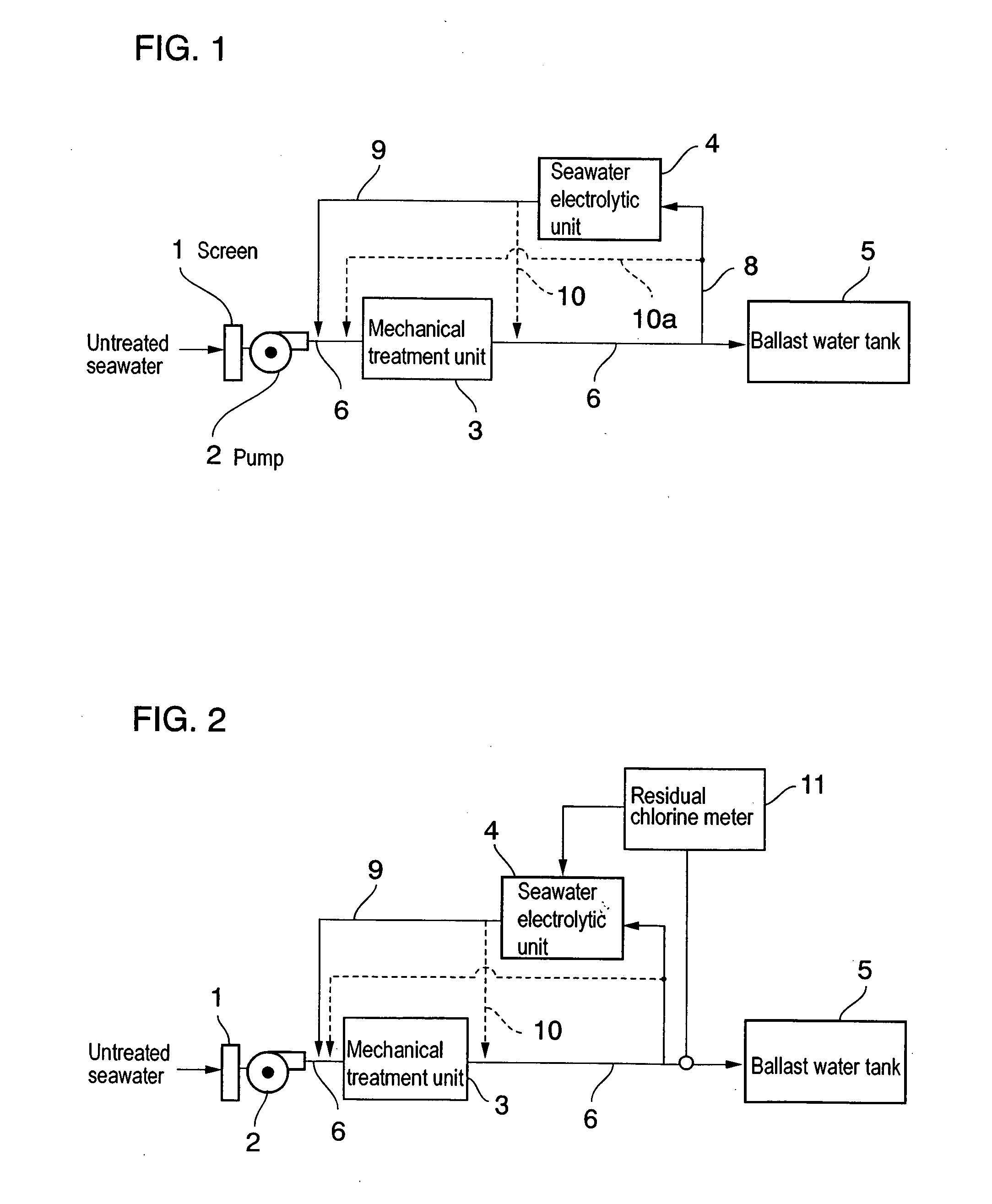

Method of Liquid Detoxification and Apparatus Therefor

InactiveUS20080164217A1Low power operationLength minimizationAuxillariesEnergy based wastewater treatmentOperational costsExtinction

Conversion of an untreated liquid to a clean harmless treated liquid through microbe removal, characterized in that a mechanical treatment for damaging microbes present in a liquid to thereby effect extinction thereof and sterilization, combined with a chlorination in which a chlorine-containing substance is formed from a liquid and injected into a liquid to thereby effect microbe extinction and sterilization, is applied to a liquid. There is further provided an electrolytic circulation system comprising applying a detoxification treatment for extinction of microbes in seawater and sterilization by means of detoxification facilities on land or on the sea to seawater introduced through a seawater introduction channel and accommodating the seawater having been thus treated in a ballast water tank. As a result, facility and operating costs can be reduced. Extinction of microbes of unlimited size and sterilization can be securely achieved without any strength drop on the side of treated liquid accommodation body. Further, the space for installation of detoxification apparatus for ballast water in ships can be reduced to thereby enable increasing of loading space for cargo, etc. Still further, on existing ships, the hull rework cost for installation of detoxification apparatus can be minimized.

Owner:MITSUBISHI HEAVY IND LTD

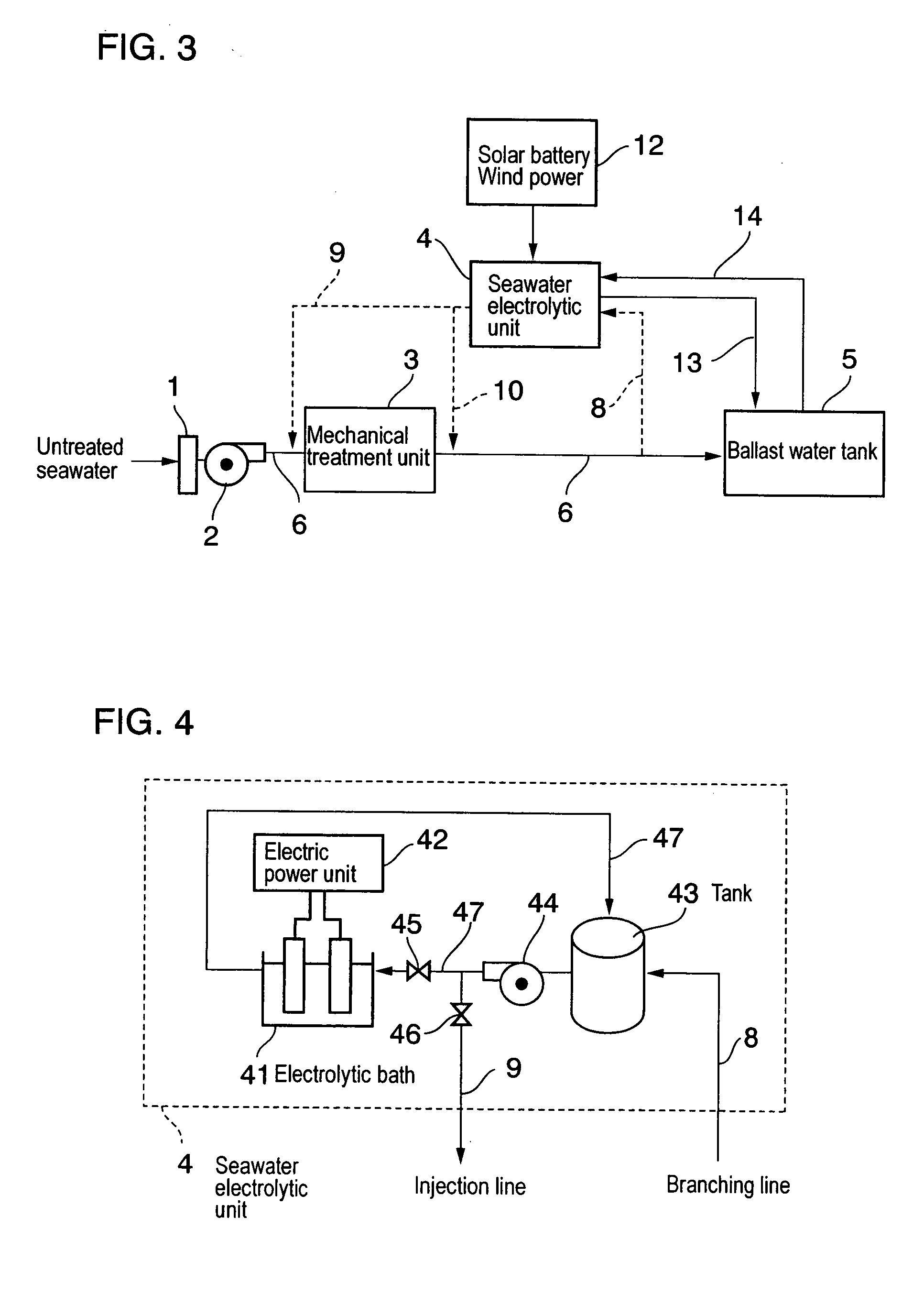

Car body adaptable to high-temperature and high-humidity areas and coating method thereof

The invention provides a car body adaptable to high-temperature and high-humidity areas and a coating method thereof. The car body comprises an end side wall, a car roof, a chassis and a bogie. The car body coating method comprises the following steps of: carrying out mechanical treatment, wall primer coating, puttying, wall anti-corrosion paint spraying, wall floating coat spraying, wall finish spraying and wall varnish spraying on the substrate of the end side wall; carrying out mechanical treatment, top primer coating, top floating coat spraying, top finish spraying and top varnish spraying on the substrate of the car roof; and carrying out mechanical treatment, chassis / bogie primer coating, chassis / bogie floating coat spraying and chassis / bogie finish spraying on the substrates of the chassis and the bogie. In the invention, mechanical pretreatment is used for replacing chemical pretreatment, which increases the adhesive force of coatings, and the problem that paint of various parts of the car body falls off from bottom layers is thoroughly solved; and the coating scheme of the car roof can solve the problem of car roof bleeding brought by strong ultraviolet irradiation, and the coating scheme of the end side wall improves the weather resistance of the whole coatings, thus the whole car body can meet the service requirements on high temperature and high humidity environment.

Owner:CRRC TANGSHAN CO LTD

Method of removing the fibrous shells from cereal grains

InactiveUS6368649B1Risk minimizationNeed for relatively lowGrain huskingGrain polishingFiberPre treatment

The invention relates to a method of removing the fibrous shells from cereal grains. This method according to the invention comprises a pretreatment step, wherein the moisture content of the cereal grains is increased, e.g. in the case of corn grains from 16 to more than 20% by weight, followed by the step of exposure of the pretreated grains to a thermal shock by means of a cryogenic medium and thereafter mechanical treatment step thereof.

Owner:CARGILL AMSTERDAM

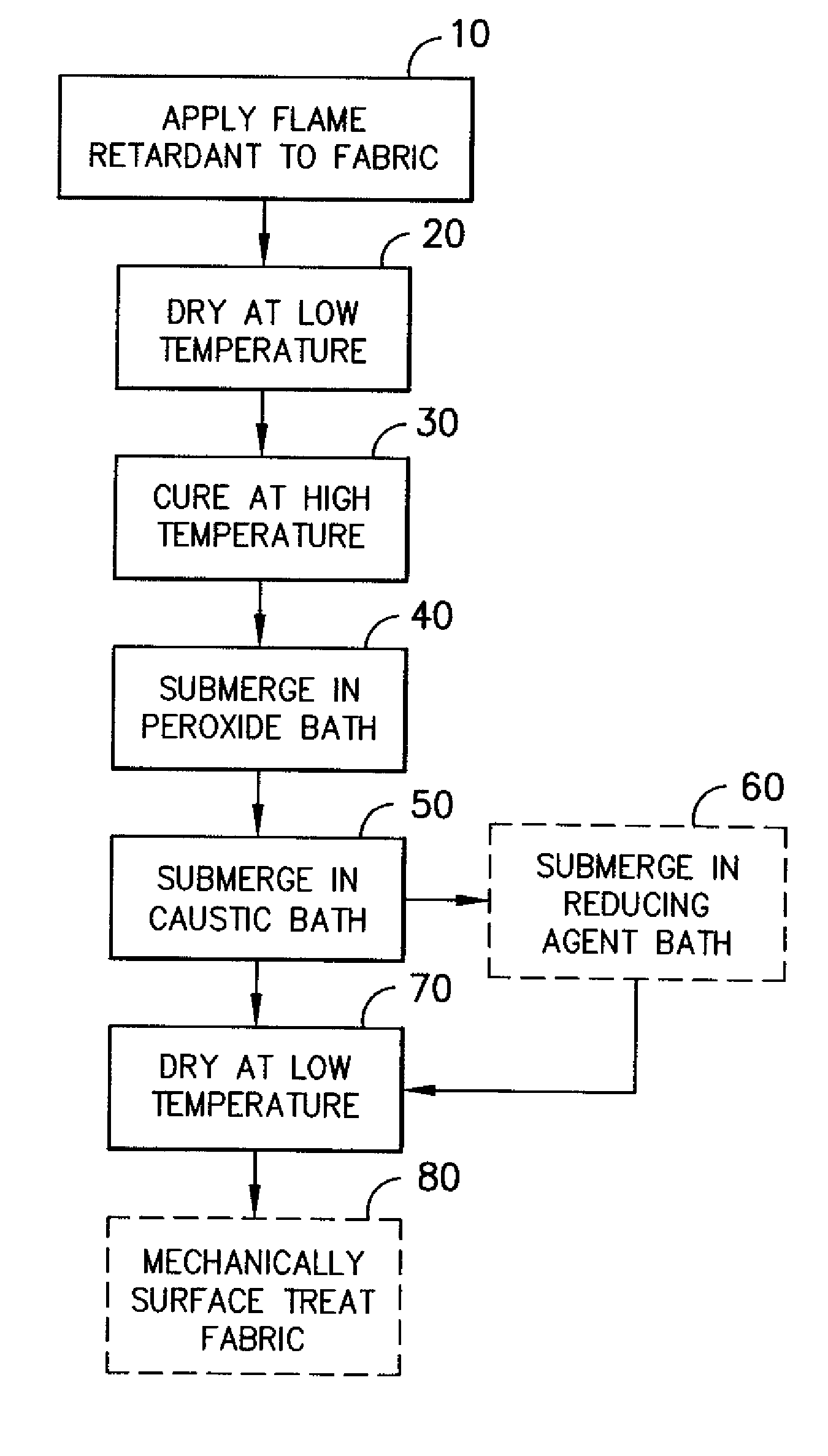

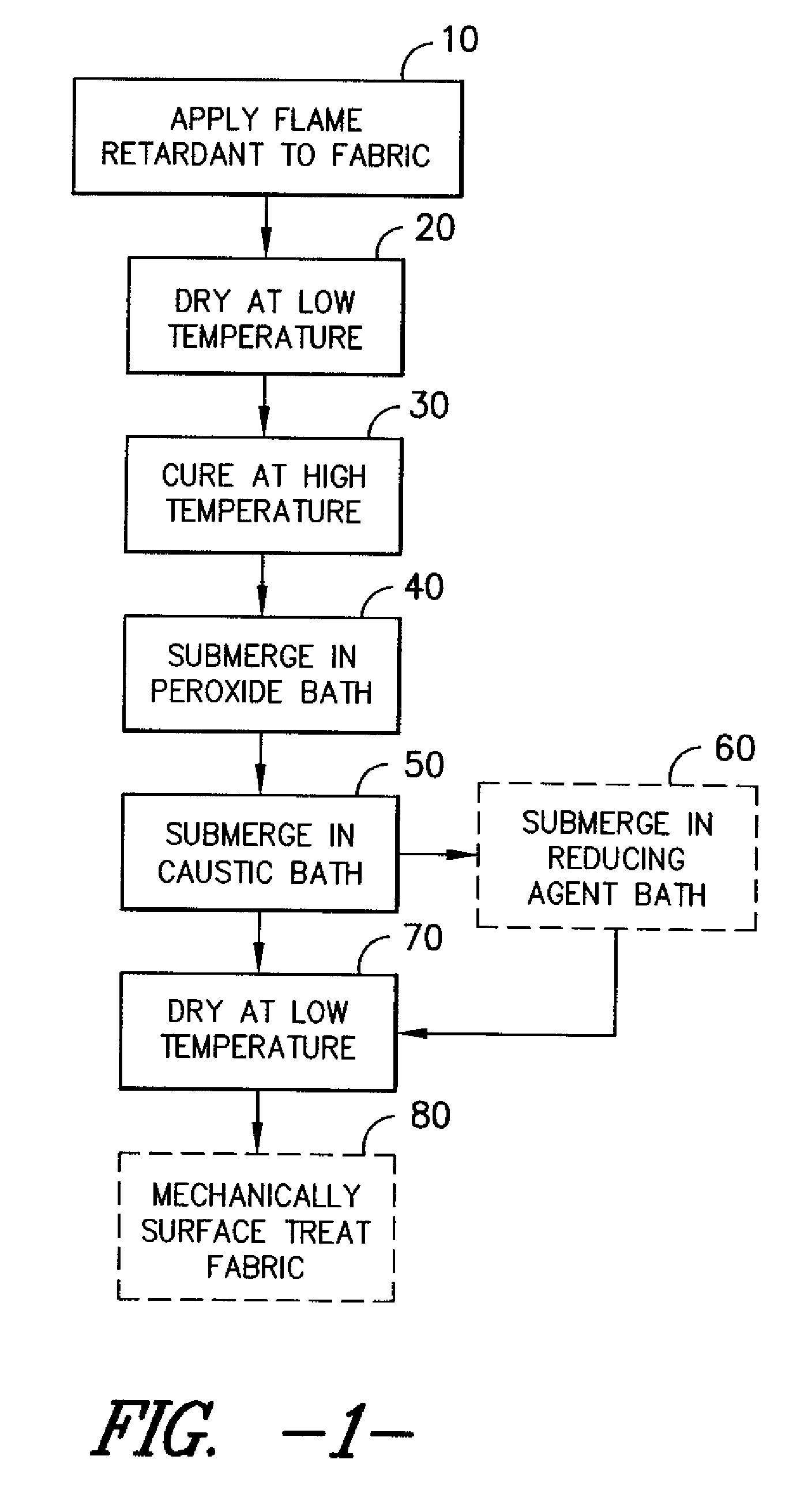

Flame resistant fabrics having a high synthetic content and process for making

ActiveUS8012890B1Good flexibilityImprove performanceSynthetic resin layered productsClothingsPolymer scienceFire-retardant fabric

Provided herein are flame resistant fabrics having a thermoplastic fiber content of as much as 65% (where no more than 5% of the fibers are non-thermoplastic synthetic fibers). The flame resistant properties are imparted by treating the fabric with one or more flame retardant chemicals and then by curing the treated fabric at high temperatures. Optionally, softeners, stain release agents, soil repellent agents, permanent press resins, and the like may be added to the bath of flame retardant chemicals. Alternately, the treated fabric may be subjected to mechanical treatment to increase softness. The fabrics produced by the present process exhibit improved performance and tear strength, as compared to conventionally treated fabrics.

Owner:MILLIKEN & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com