Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Increase fiber surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

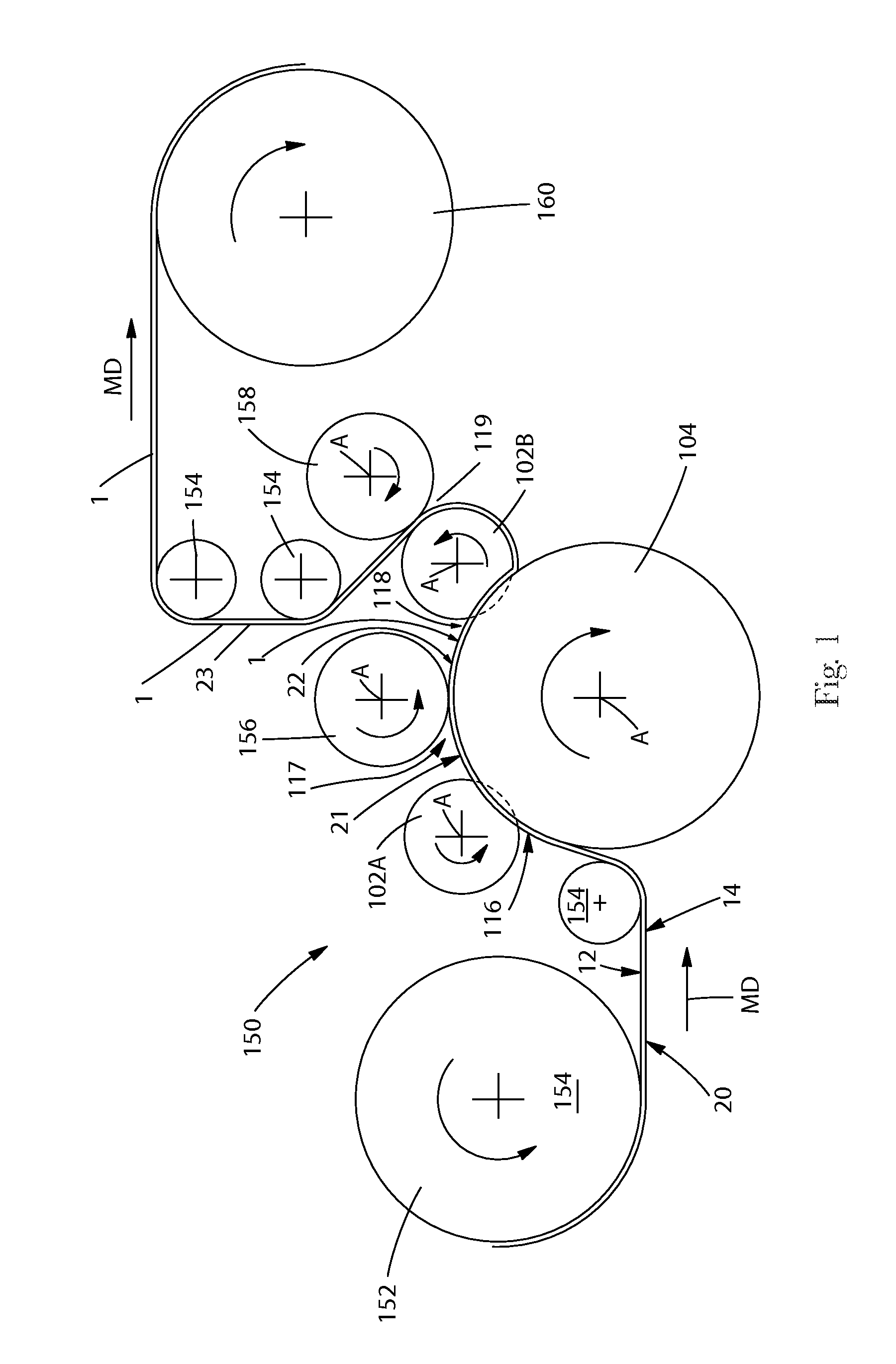

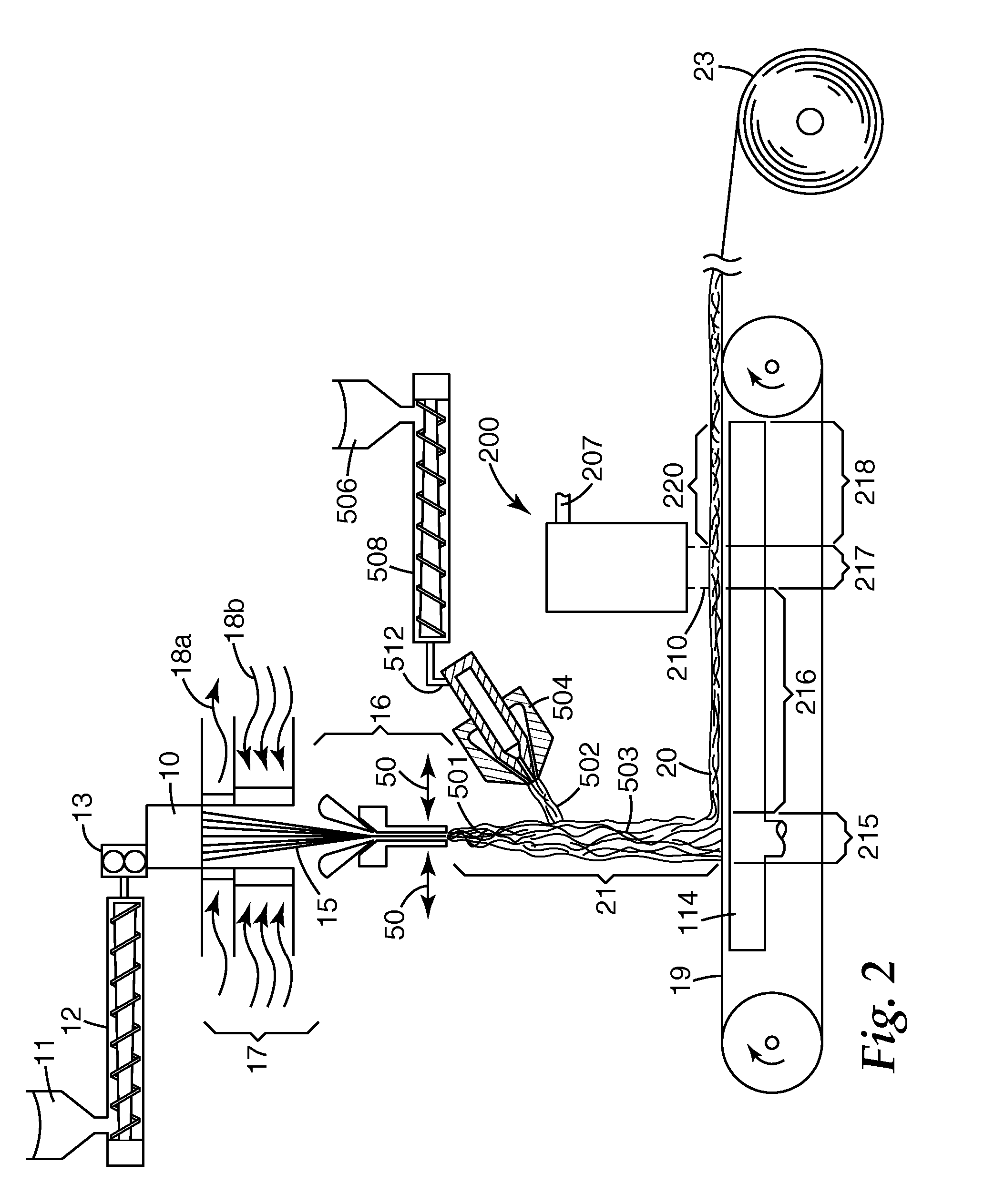

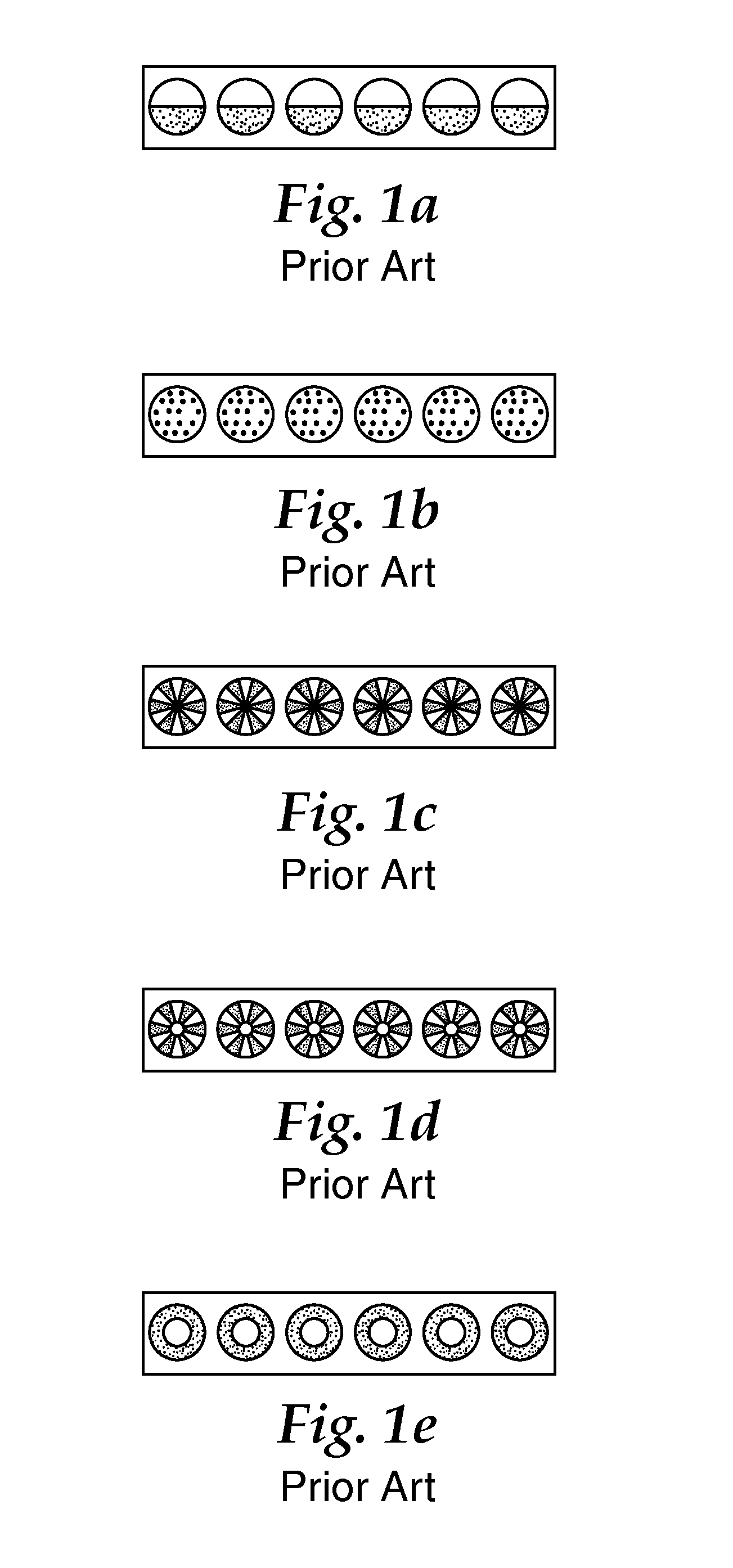

Monocomponent monolayer meltblown web and meltblowing apparatus

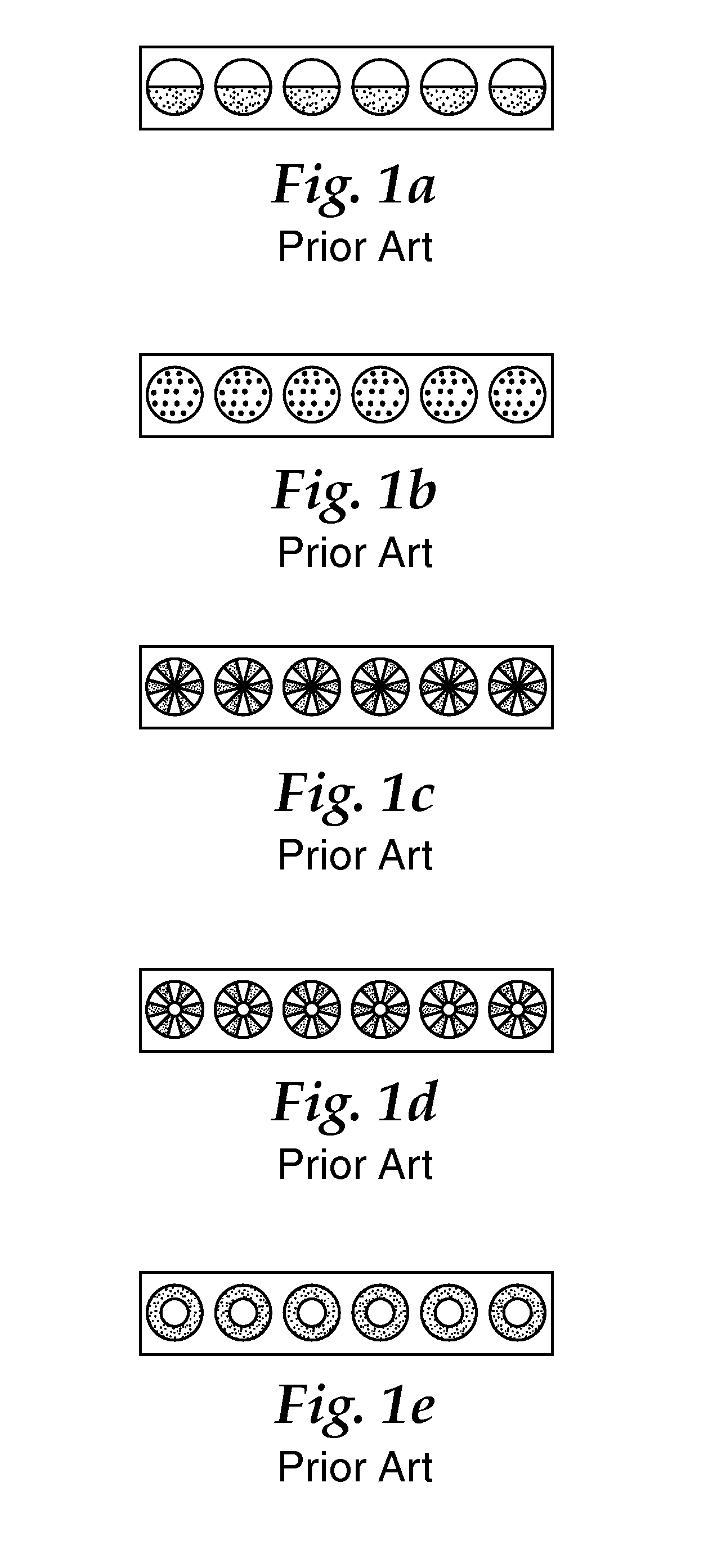

ActiveUS7902096B2Narrow distributionReduced service lifeDispersed particle filtrationFilament/thread formingPolymer scienceAir filter

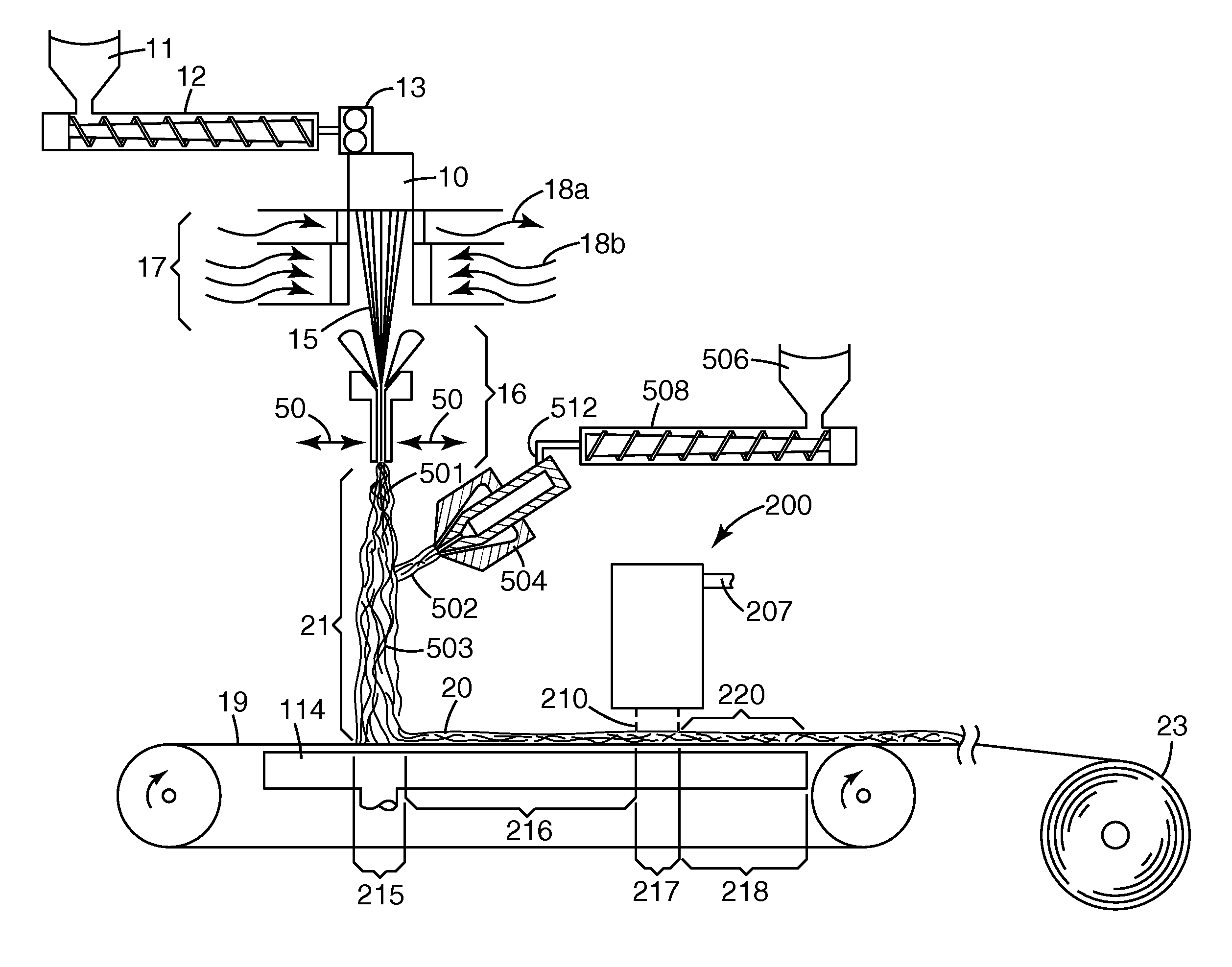

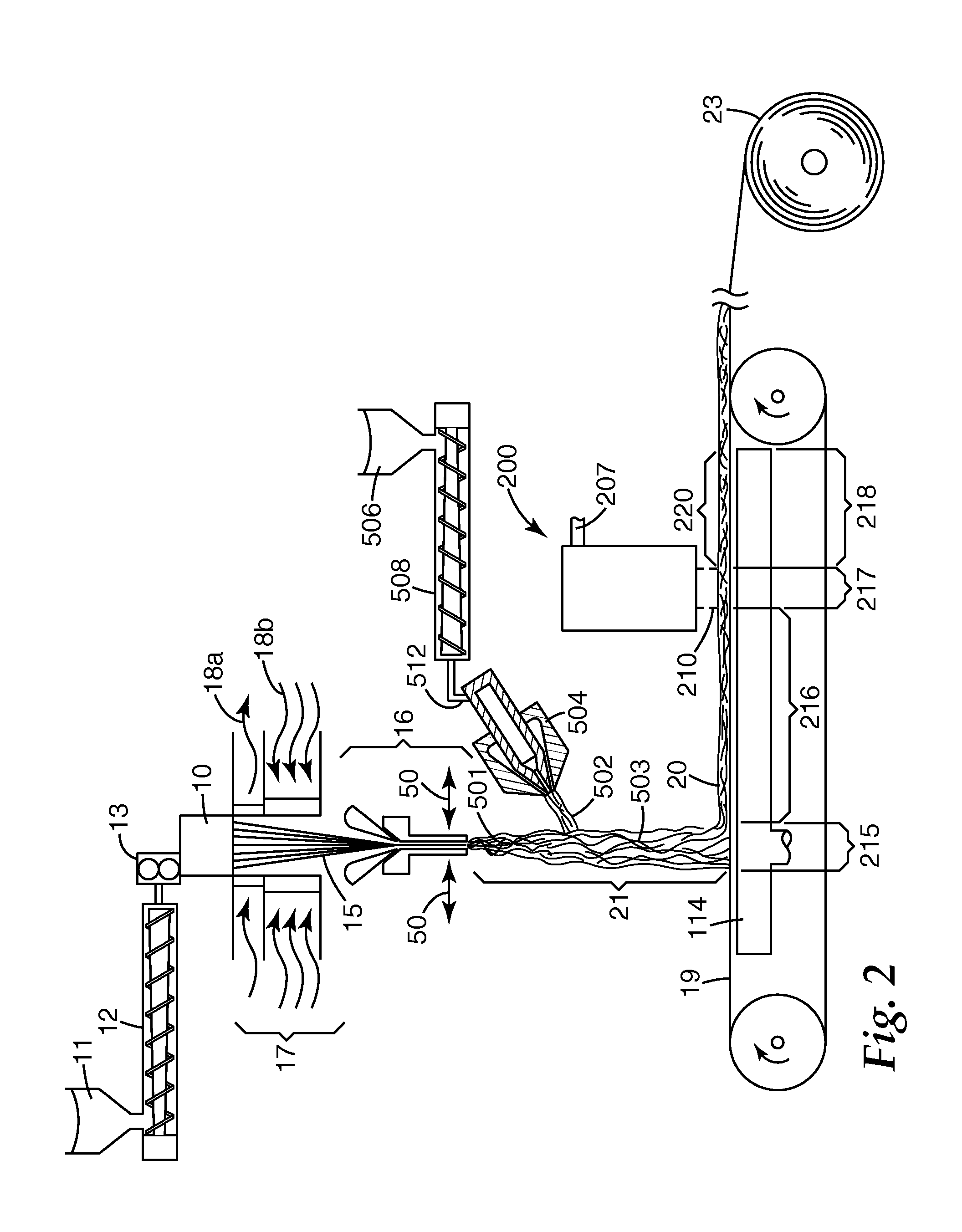

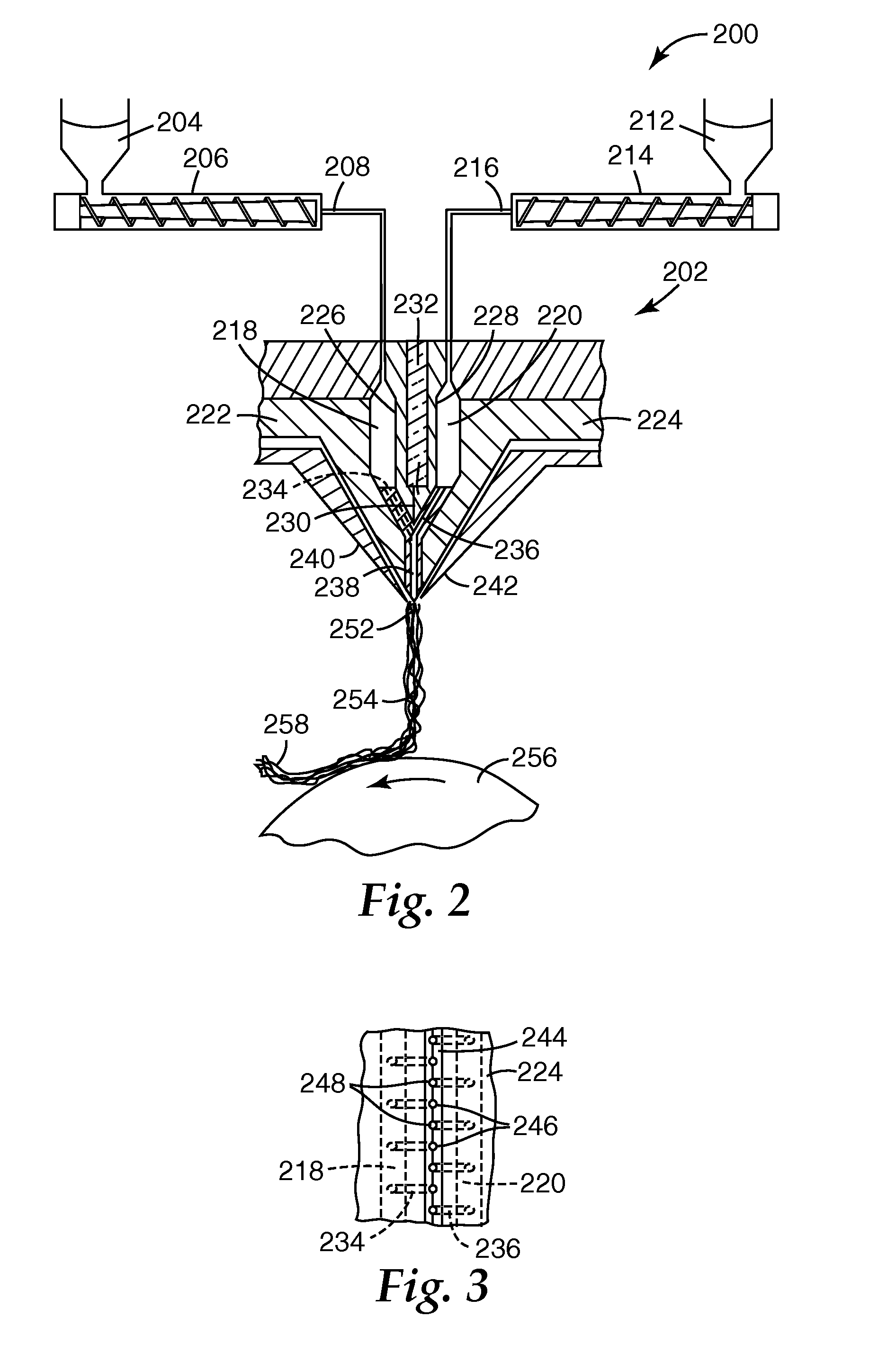

A porous monocomponent nonwoven web contains a bimodal mass fraction / fiber size mixture of intermingled continuous microfibers and larger size fibers of the same polymeric composition. There are at least five times as many microfibers as larger size fibers, and a histogram of the mass fraction of fibers vs. fiber size exhibits a larger size fiber mode greater than 10 μm. The web may be made by flowing fiber-forming material through a die cavity having larger size orifices and at least five times as many smaller size orifices to form filaments, attenuating the filaments into fibers and collecting the attenuated fibers to form the nonwoven web. The web is especially well suited to the manufacture of self-supporting three dimensional articles such as molded cup-shaped respirators and pleated air filters.

Owner:3M INNOVATIVE PROPERTIES CO

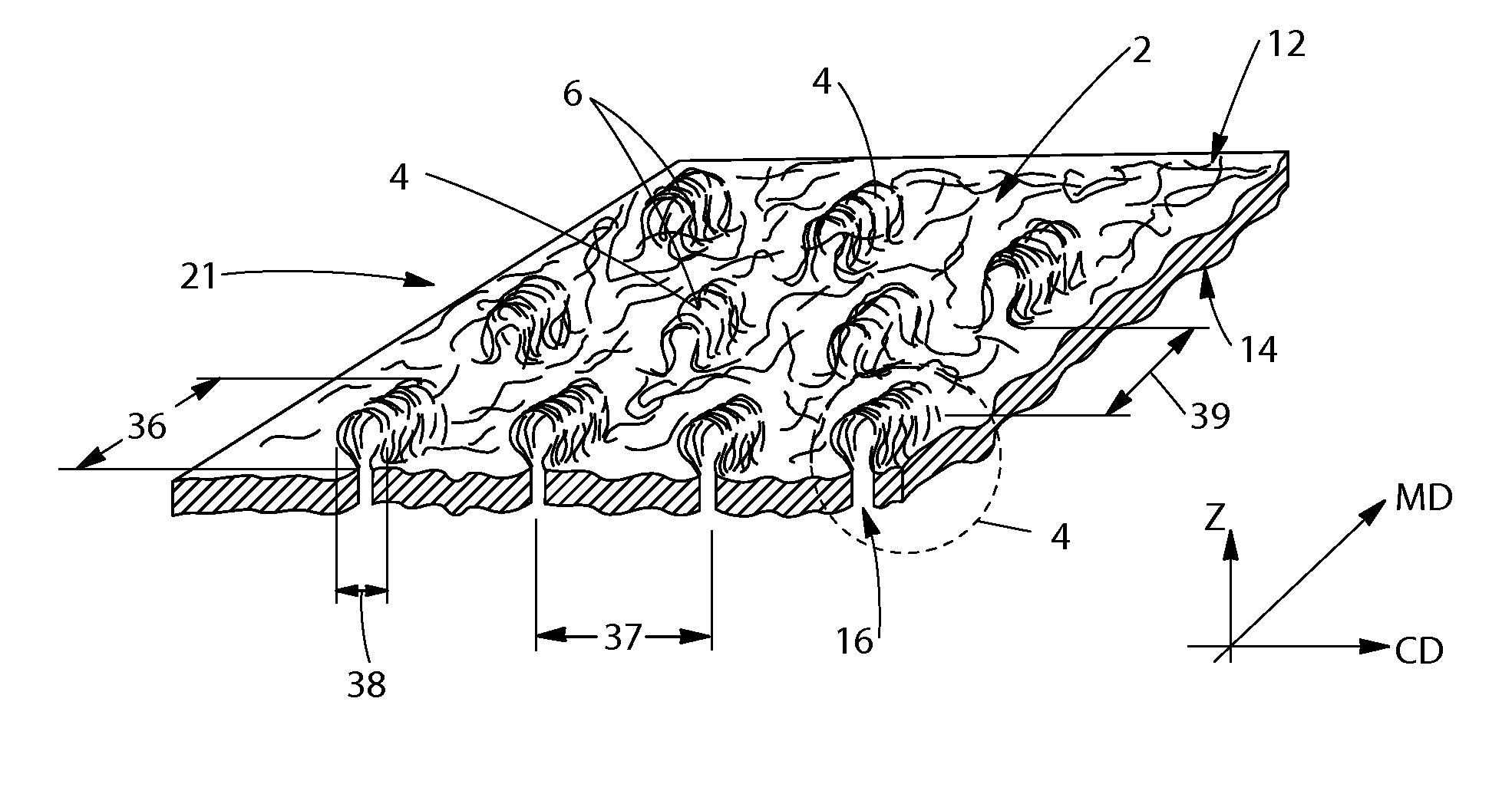

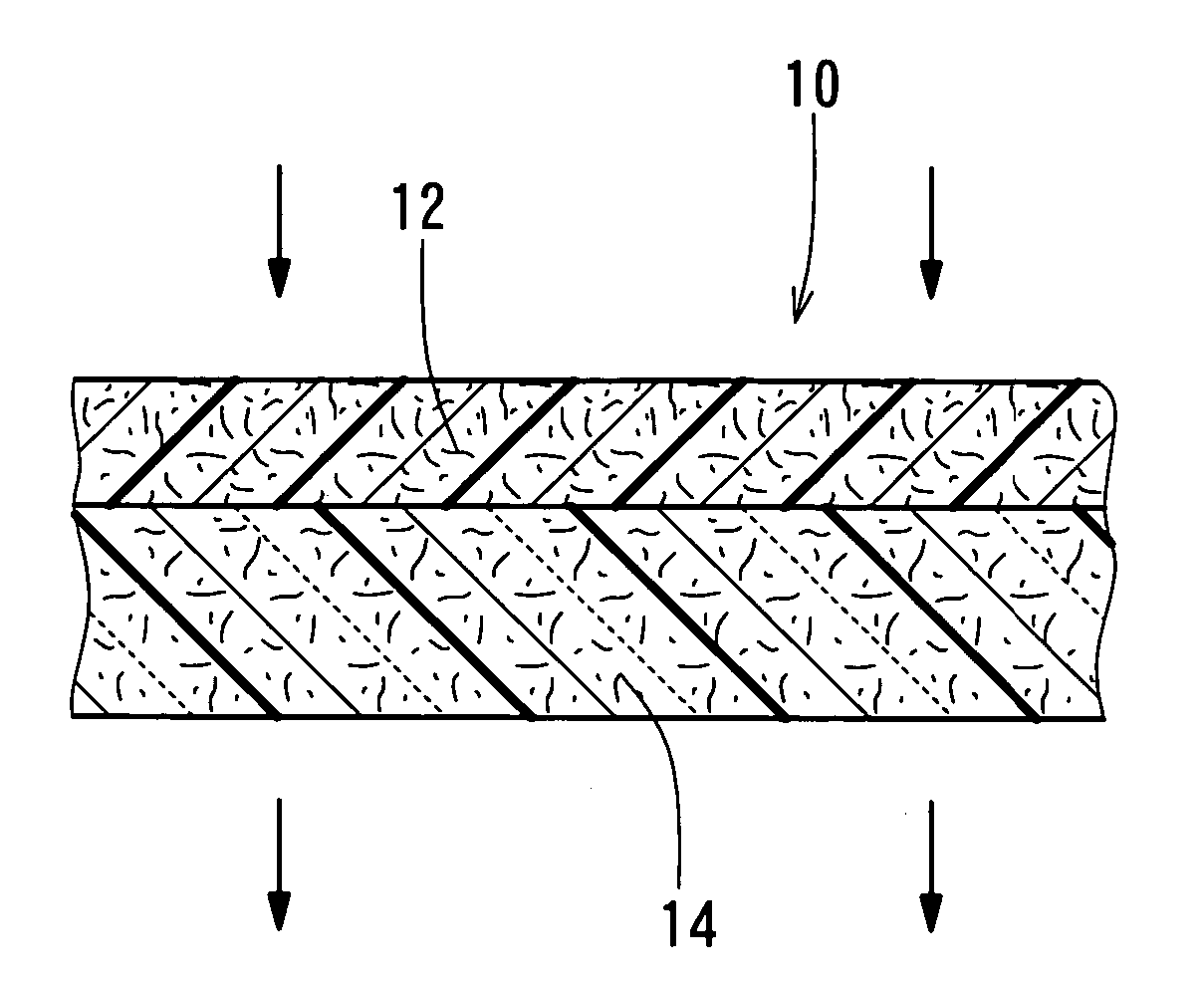

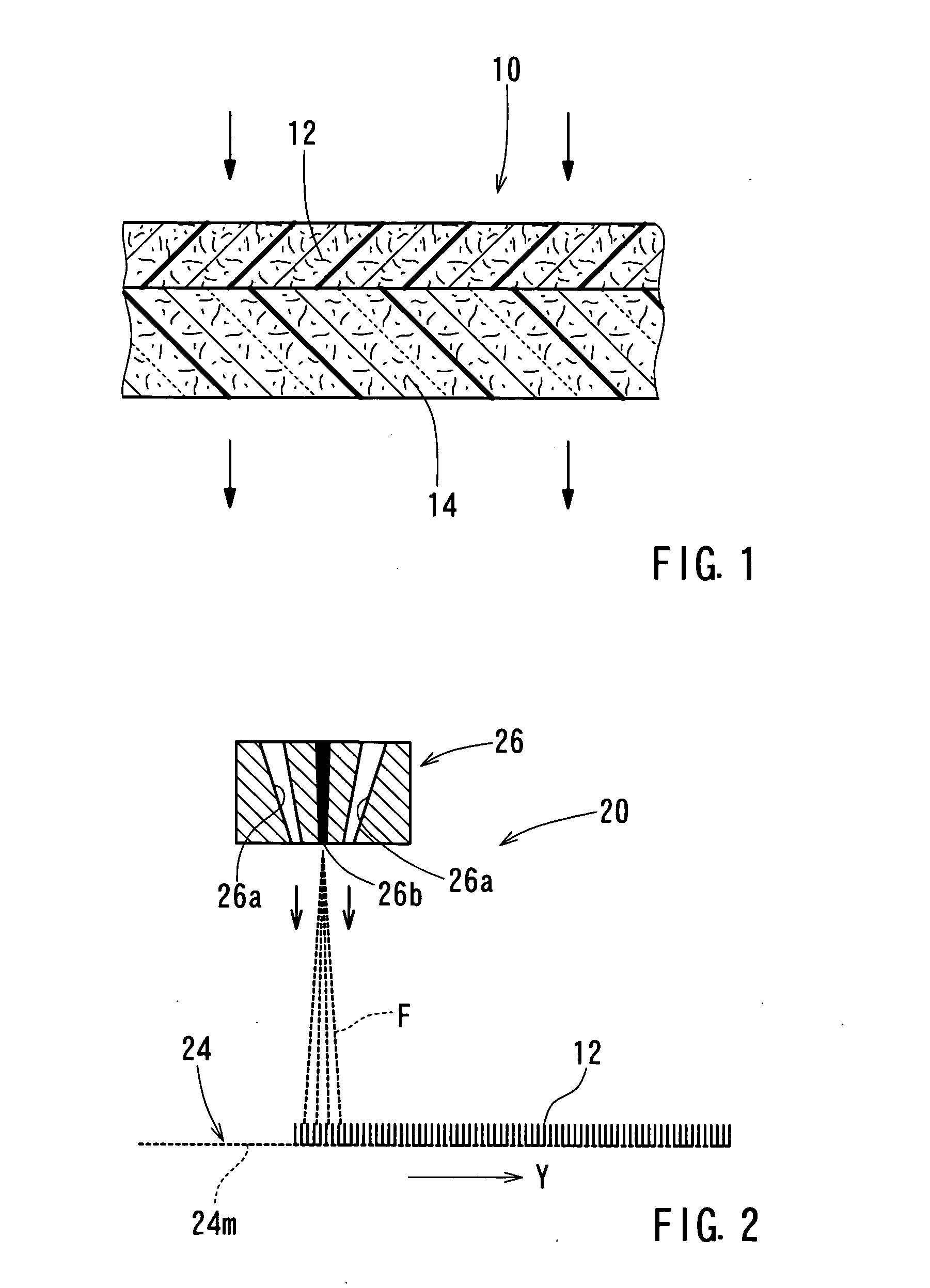

Fluid permeable structured fibrous web

InactiveUS20100310845A1Increase fiber surface areaImprove abilitiesAbsorbent padsBaby linensSpecific volumeFiber

The present invention is directed to a fluid permeable structured fibrous web comprising thermally stable, fibers that are thermally bonded together using heat producing a base substrate that is thermally stable. The base substrate is textured via mechanical treatment producing a structured fibrous web having an aged caliper of less than 1.5 mm, a vertical wicking height of at least 5 mm, a permeability of at least 10,000 cm2 / (Pa·s) and a specific volume of at least 5 cm3 / g. The structured fibrous web provides optimal fluid wicking and the fluid acquisition capabilities and is directed toward fluid management applications.

Owner:THE PROCTER & GAMBLE COMPANY

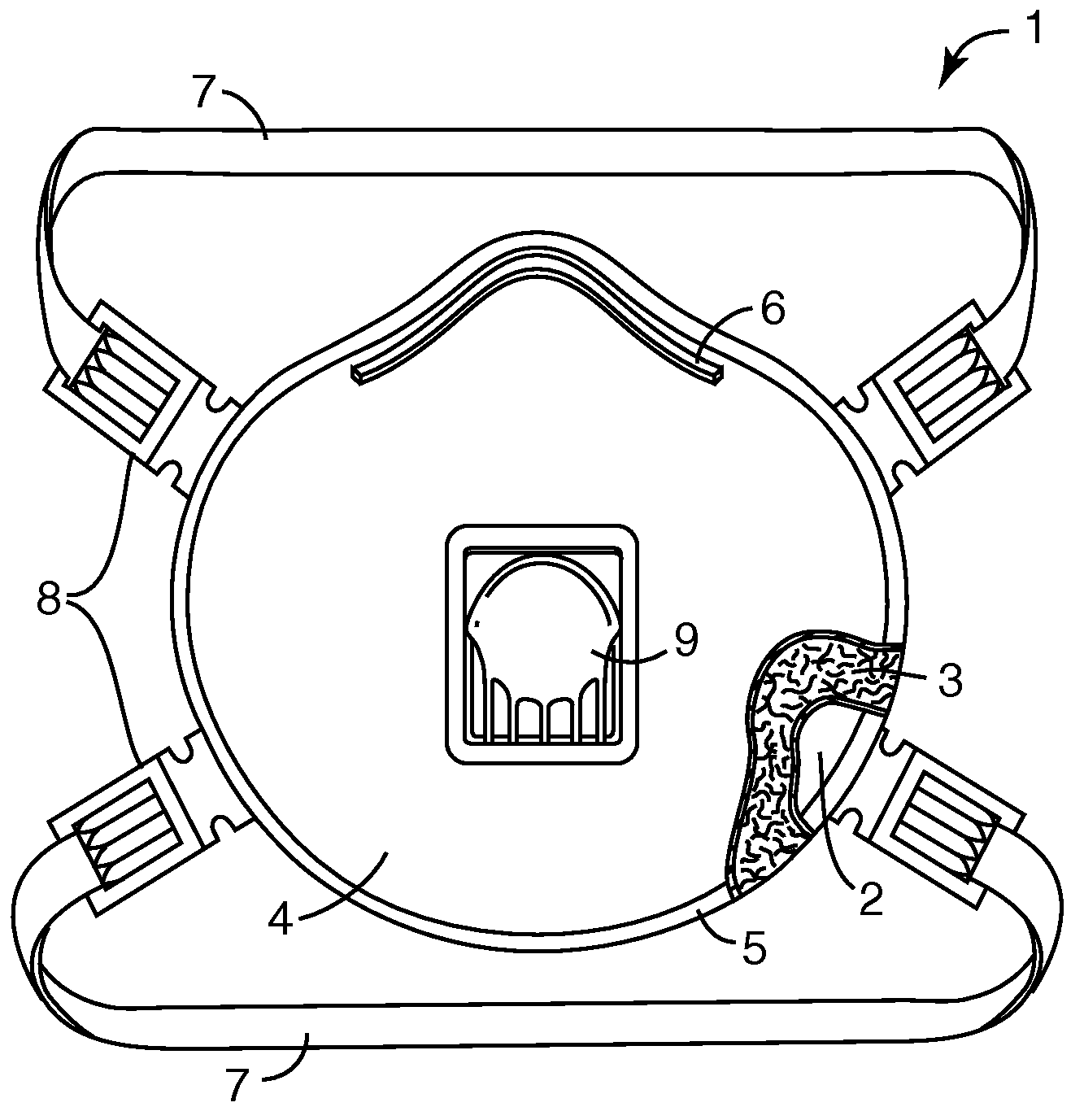

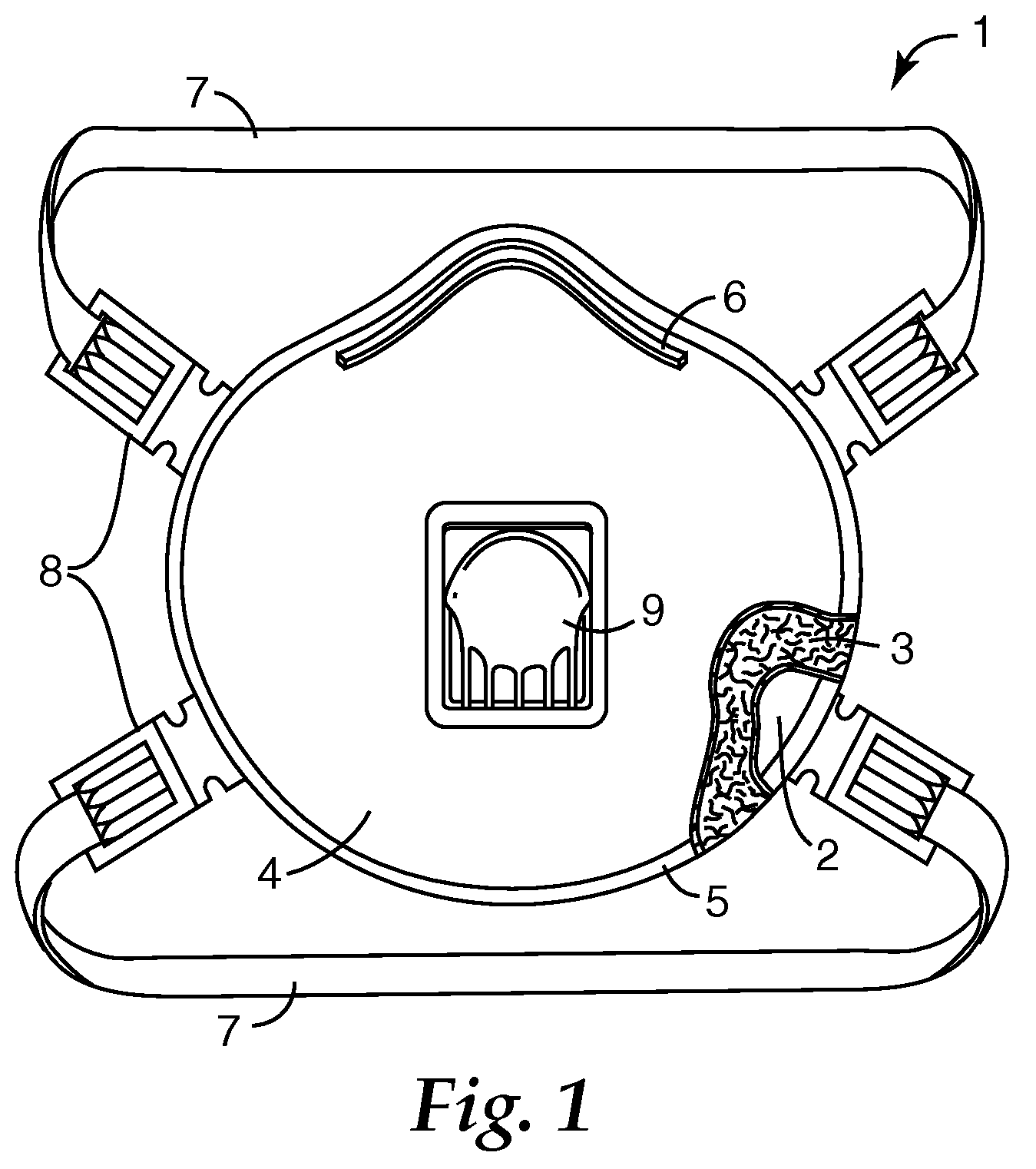

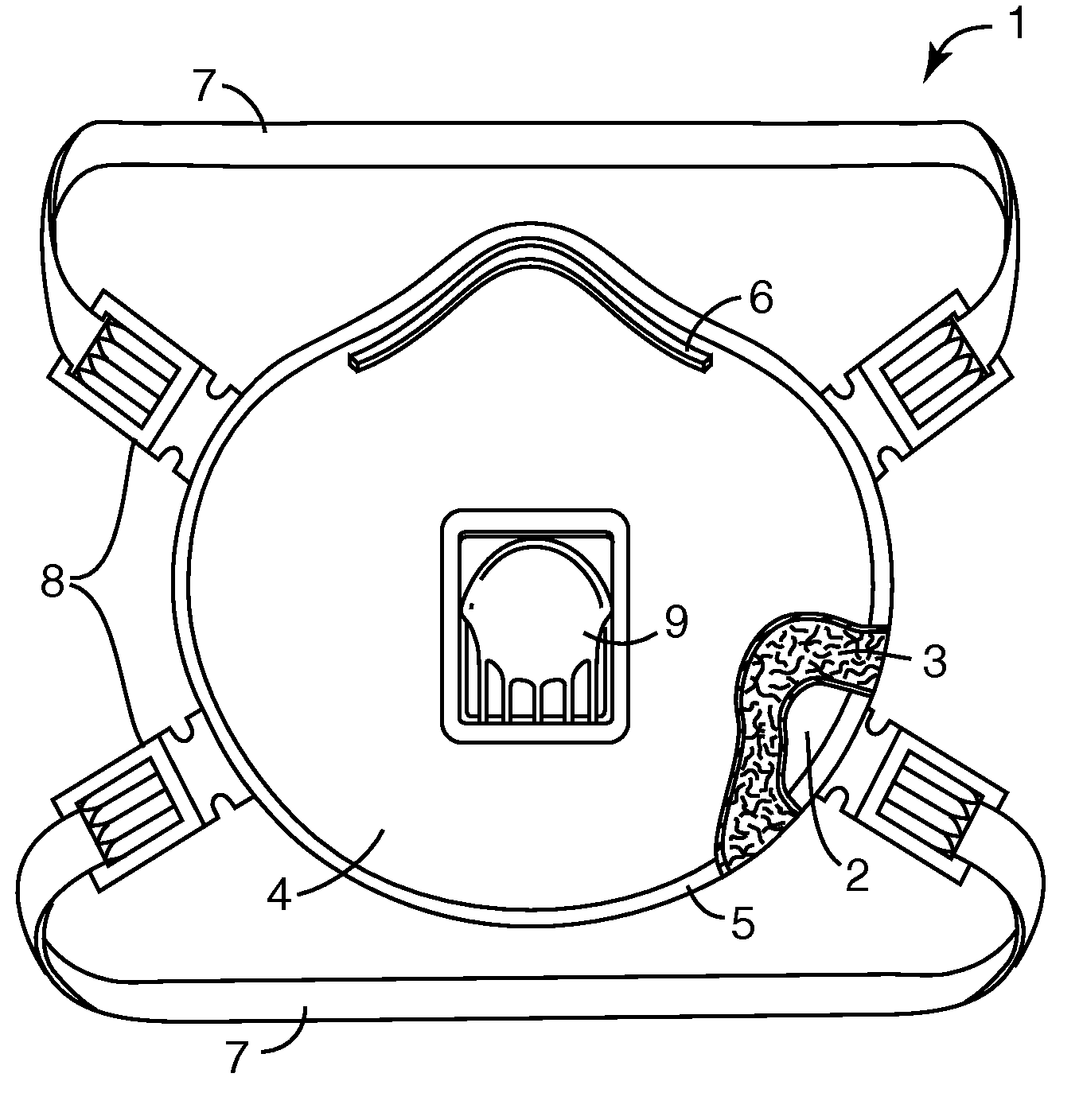

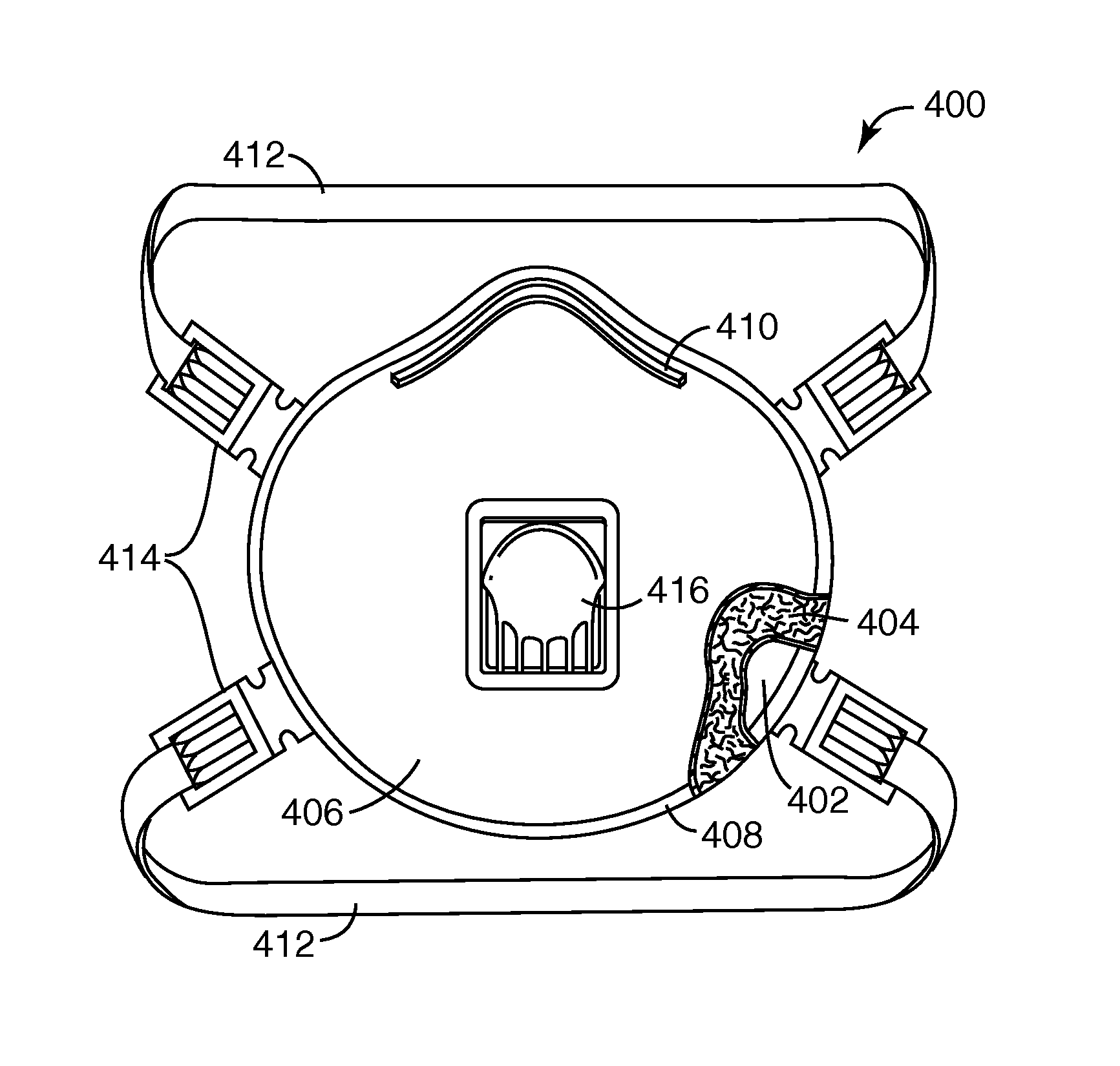

Molded Monocomponent Monolayer Respirator With Bimodal Monolayer Monocomponent Media

InactiveUS20080026173A1Good molding effectIncrease fiber surface areaBreathing filtersLayered productsPolymer scienceRespirator

A molded respirator is made from a monocomponent monolayer nonwoven web containing a bimodal mass fraction / fiber size mixture of intermingled continuous monocomponent polymeric microfibers and larger size fibers of the same polymeric composition. The respirator is a cup-shaped porous monocomponent monolayer matrix whose matrix fibers are bonded to one another at at least some points of fiber intersection. The matrix has a King Stiffness greater than 1 N. The respirator may be formed without requiring stiffening layers, bicomponent fibers, or other reinforcement in the filter media layer.

Owner:3M INNOVATIVE PROPERTIES CO

Fluid Permeable Structured Fibrous Web

InactiveUS20100312212A1Increased fiber surface areaEnhanced capabilityBaby linensTamponsSpecific volumeEngineering

The present disclosure is directed to a disposable absorbent article comprising a fluid permeable structured fibrous web, the fibrous web comprising thermally stable, fibers that are thermally bonded together using heat producing a base substrate that is thermally stable. The base substrate is textured via mechanical treatment producing a structured fibrous web having an aged caliper of less than 1.5 mm, a vertical wicking height of at least 5 mm, a permeability of at least 10,000 cm2 / (Pa·s) and a specific volume of at least 5 cm3 / g. The structured fibrous web provides optimal fluid wicking and the fluid acquisition capabilities and is directed toward fluid management applications.

Owner:THE PROCTER & GAMBNE CO

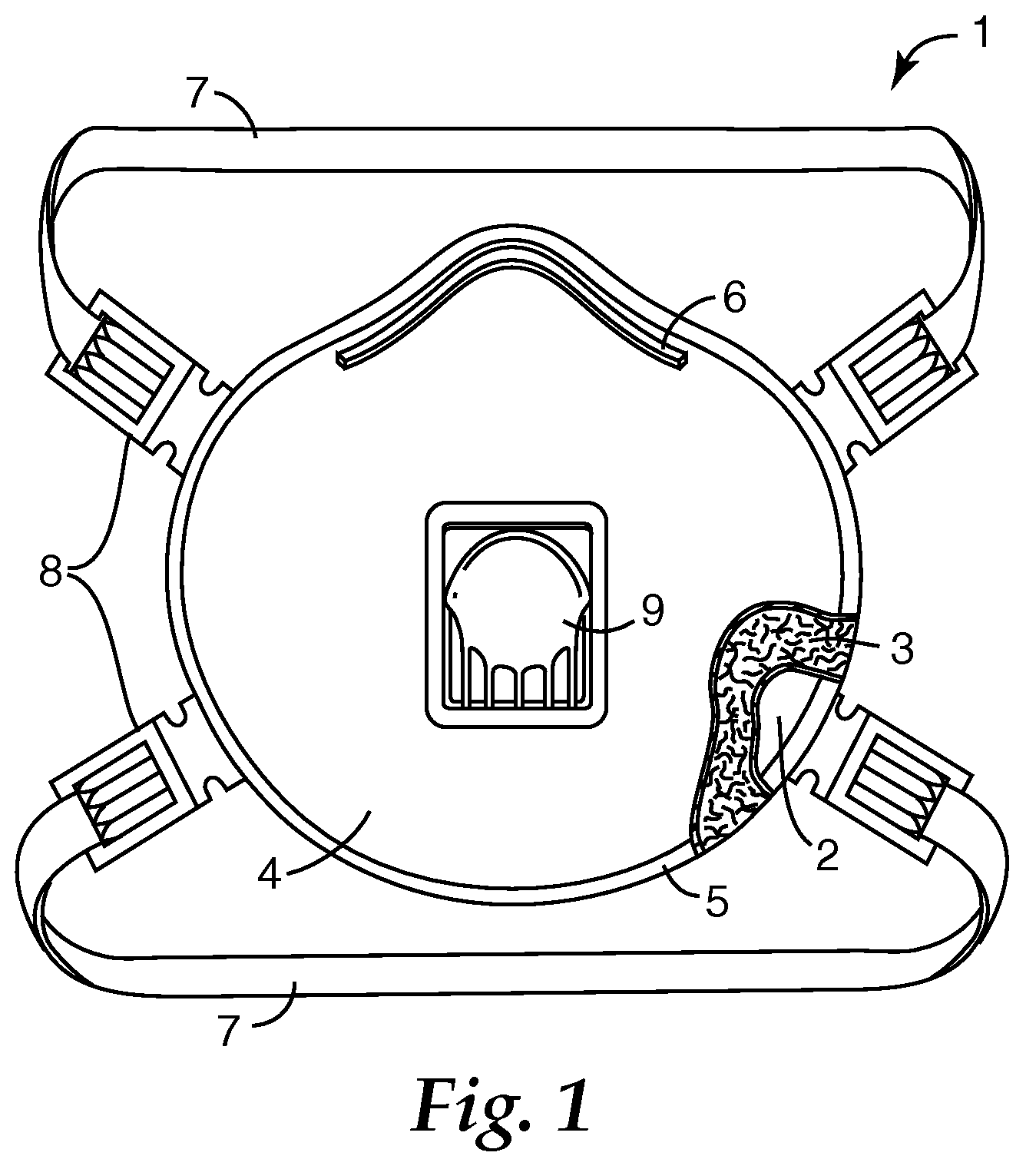

Molded monocomponent monolayer respirator with bimodal monolayer monocomponent media

InactiveUS7858163B2Good molding effectIncrease fiber surface areaBreathing filtersLayered productsPolymer scienceRespirator

Owner:3M INNOVATIVE PROPERTIES CO

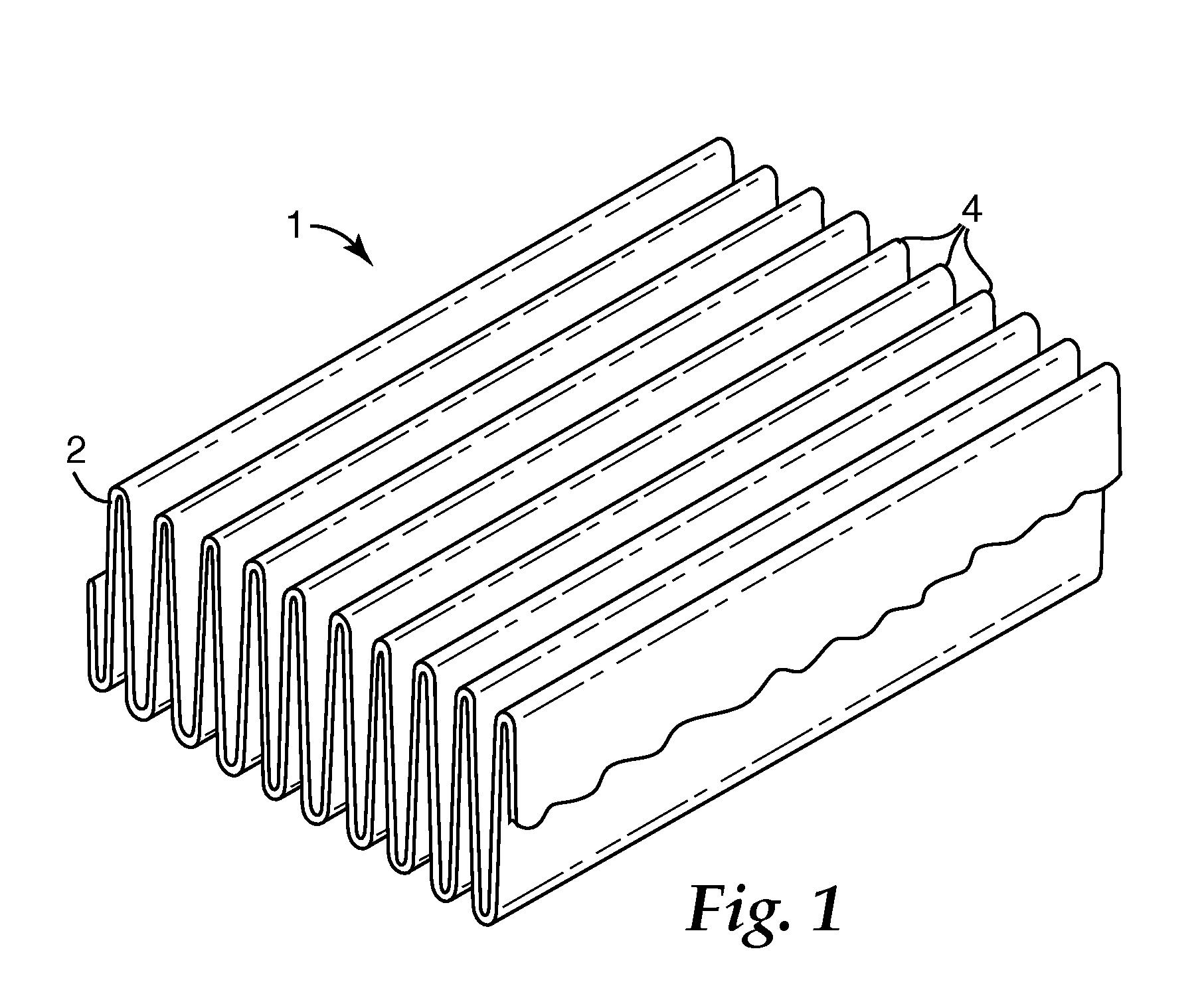

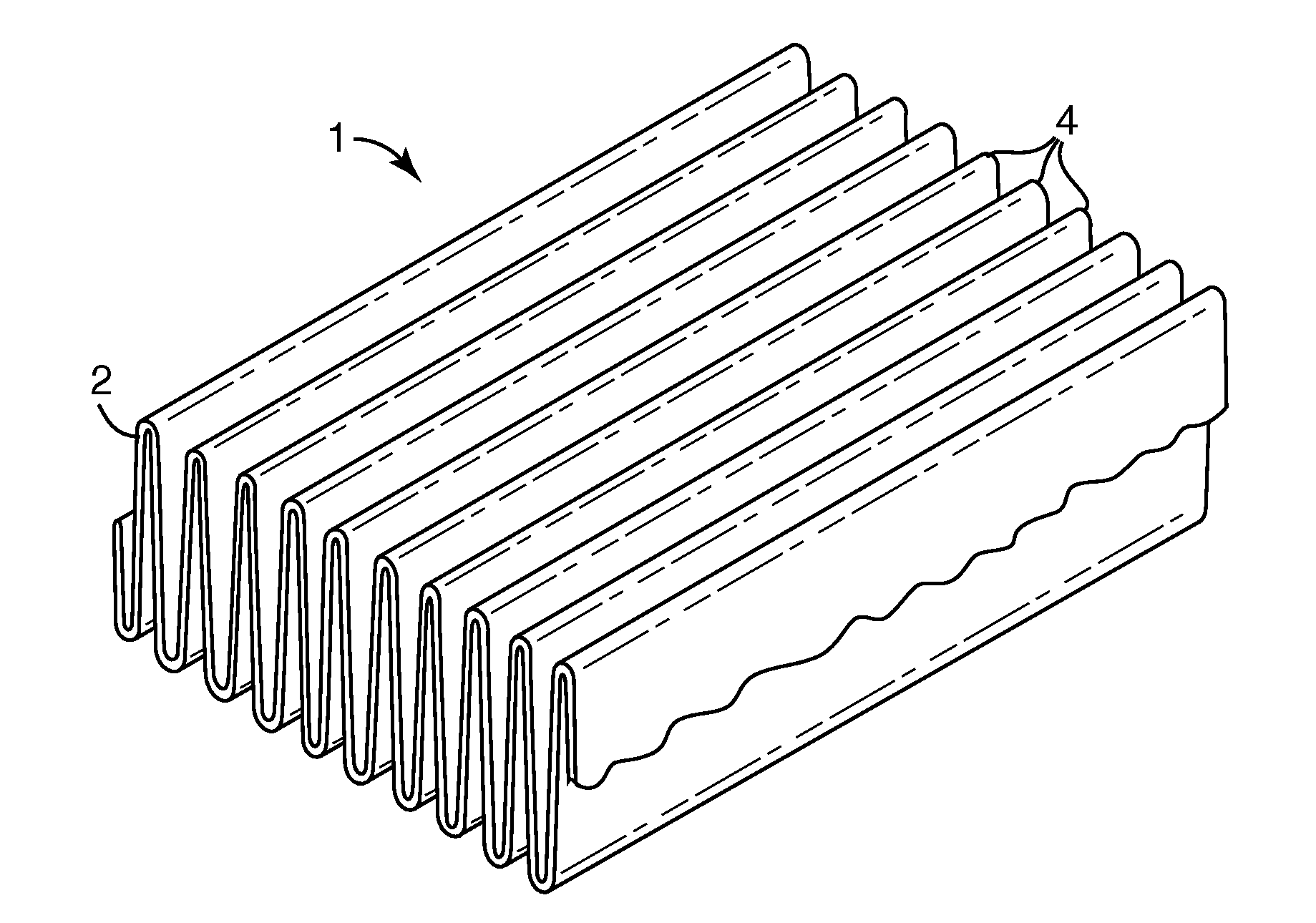

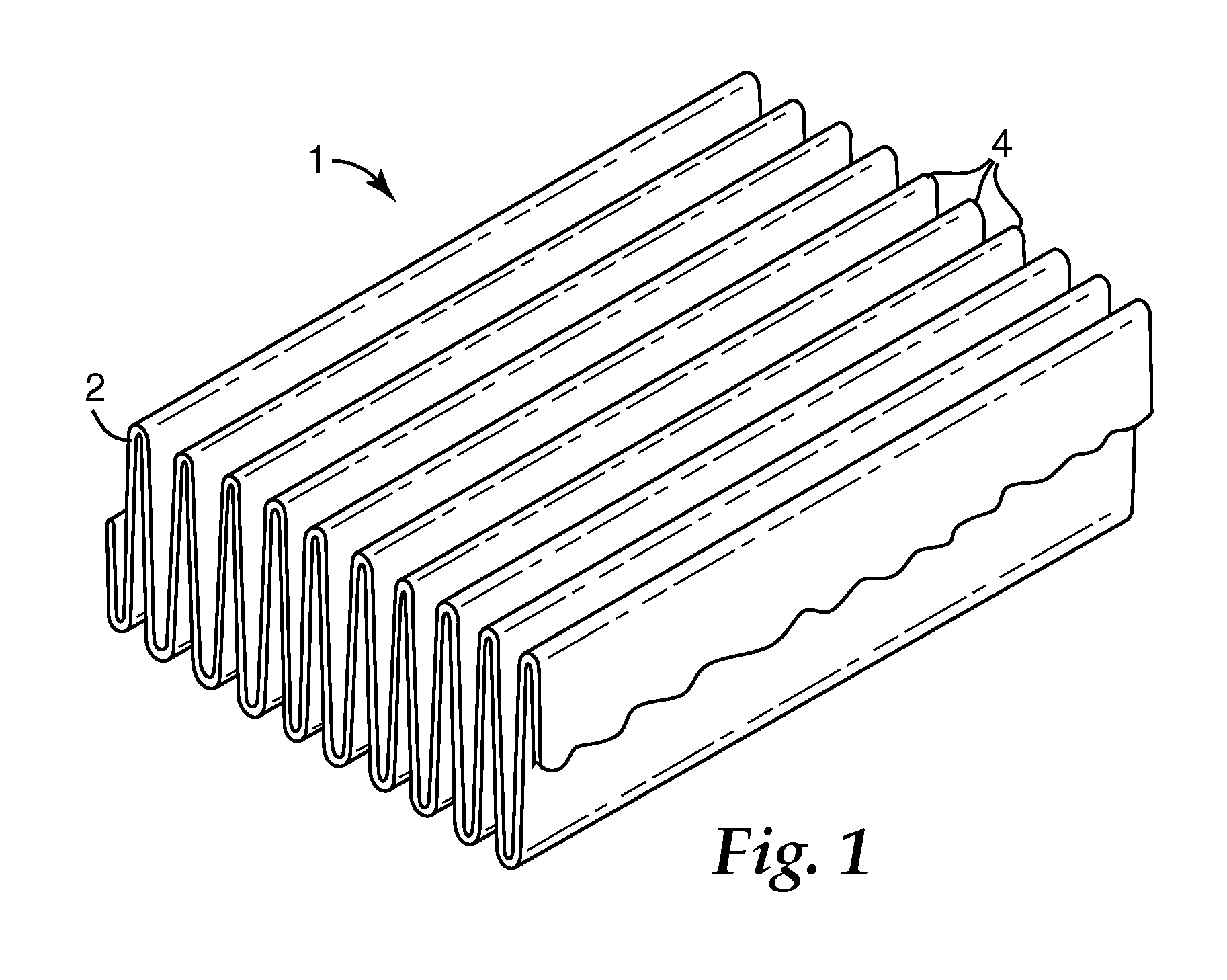

Pleated filter with bimodal monolayer monocomponent media

InactiveUS7754041B2Lower overall pressure dropEfficient captureDispersed particle filtrationLoose filtering material filtersPolymer scienceFilter media

A pleated filter is made from a monocomponent monolayer nonwoven web containing a bimodal mass fraction / fiber size mixture of intermingled larger size and smaller size continuous monocomponent polymeric fibers of the same polymeric composition. Rows of pleats are formed in the nonwoven web, and the pleated web is cut to a desired size and shape to provide a filter element containing a self-supporting porous monocomponent monolayer matrix of fibers bonded to one another at at least some points of fiber intersection and having an average initial submicron efficiency of at least 15% at a 1.52 meters / sec face velocity. The filter element is deformation resistant without requiring stiffening layers, bicomponent fibers or other reinforcing measures in the filter media layer.

Owner:3M INNOVATIVE PROPERTIES CO

Method for processing vegetable fish balls

InactiveCN102160658AIncrease fiber surface areaImprove solubilityFood preparationIsolated Soy ProteinFresh fish

The invention discloses a method for processing vegetable fish balls, which comprises the following steps of: preprocessing fresh fish, mining meat, and rinsing; adding the rinsed fish into a fine filtering machine for fine filtration; preparing refined minced fillet and refined mashed vegetable by using a colloid mill; mixing the refined minced fillet, refined mashed vegetable, starch, isolated soy protein and seasoning auxiliary materials, and performing grinding treatment; and finally, forming, boiling, cooling, quickly freezing and packaging. The method is low in cost, the process is simple, and the method is convenient to use and has higher application and promotion value.

Owner:FUZHOU XUHUANG FOODS

Pleated filter with bimodal monolayer monocomponent media

ActiveUS20100229516A1Lower overall pressure dropEfficient captureDispersed particle filtrationMembrane filtersPolymer scienceFilter media

A pleated filter is made from a monocomponent monolayer nonwoven web containing a bimodal mass fraction / fiber size mixture of intermingled larger size and smaller size continuous monocomponent polymeric fibers of the same polymeric composition. Rows of pleats are formed in the nonwoven web, and the pleated web is cut to a desired size and shape to provide a filter element containing a self-supporting porous monocomponent monolayer matrix of fibers bonded to one another at least some points of fiber intersection and having an average initial submicron efficiency of at least 15% at a 1.52 meters / sec face velocity. The filter element is deformation resistant without requiring stiffening layers, bicomponent fibers or other reinforcing measures in the filter media layer.

Owner:3M INNOVATIVE PROPERTIES CO

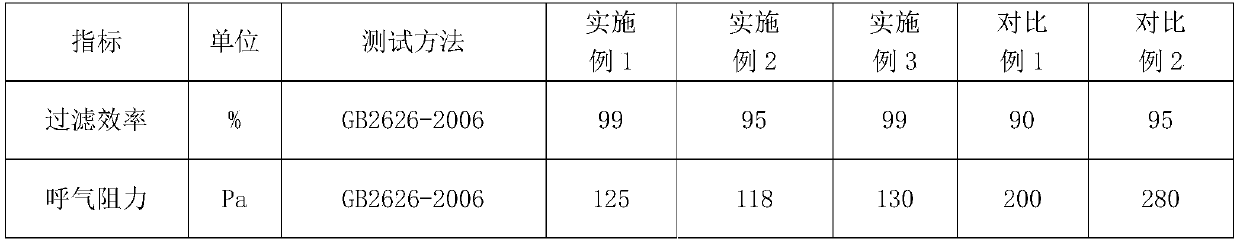

Long-acting electret PP non-woven fabric and preparation method thereof

ActiveCN111321516AReduce surface tensionLow densityUltrasonic/sonic fibre treatmentConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention provides long-acting electret PP non-woven fabric. The long-acting electret PP non-woven fabric is mainly prepared from the following components in parts by weight: 30 to 35 parts of electret master batch, 36 to 44 parts of melt-blown polypropylene, 8 to 17 parts of surface-treated silicon dioxide, 3 to 5 parts of polyvinylidene fluoride, 5 to 7 parts of polytetrafluoroethylene and 3to 5 parts of PFA. According to the long-acting electret PP non-woven fabric and the preparation method thereof provided by the invention, after the non-woven fabric is treated by an electret process, the filtering performance and charge storage performance of fibers are greatly improved, the high temperature resistance and high humidity resistance of the non-woven fabric are effectively improved, meanwhile, the hydrophobic and oleophobic properties of the fibers are also improved, and the service life is prolonged. In addition, the long-acting electret non-woven fabric also has the functionsof antibiosis, disinfection, deodorization and the like.

Owner:青岛科凯达橡塑有限公司 +1

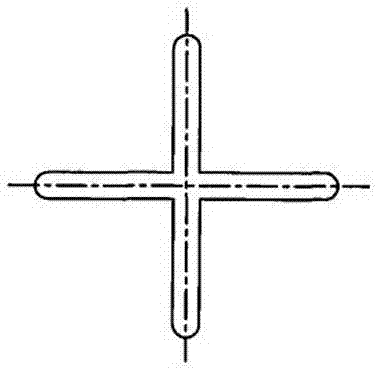

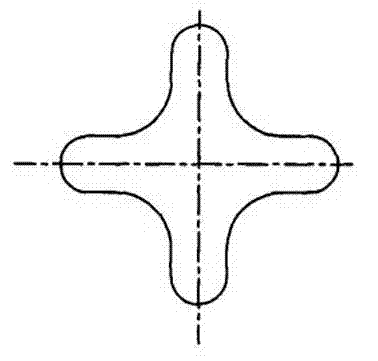

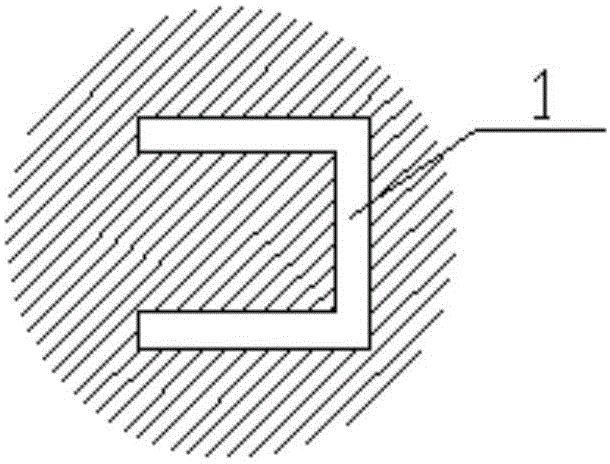

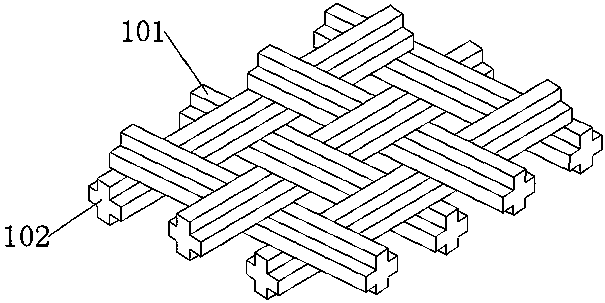

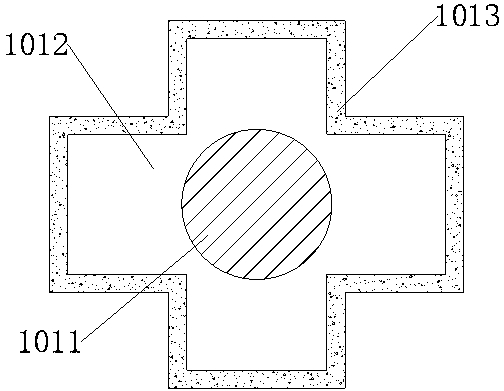

Preparation method of three-component composite fiber with special-shaped cross section

ActiveCN102691119AImprove stabilityStrong moisture wickingNew-spun product collectionStretch-spinning methodsPolyesterFiber

The invention relates to the technical field of fiber preparation. The invention provides a preparation method of a three-component composite fiber with a special-shaped cross section, to solve problems that chemical fiber products have no good moisture conductivity or moisture permeability, and that single-component fibers with special-shaped cross sections are high in modulus, bad in fabric handles, difficult in dyeing, and not good in comprehensive properties. The preparation method comprises the following steps: three types of polyester slices are fused and extruded from a metering pump respectively, entera special-shaped spinneret, and are stretched and wound, thereby obtaining the multi-component composite fiber with the special-shaped cross section. Of the composite fiber prepared in the invention, the caking property between two components is greatly improved to ensure that two components are not separated. The composite fiber is a special, novel, and special-shaped fiber, which is endowed with better stability and maintains excellent functions of ordinary special-shaped fibers such as a moisture absorbable and breathable function.

Owner:浙江双兔新材料有限公司

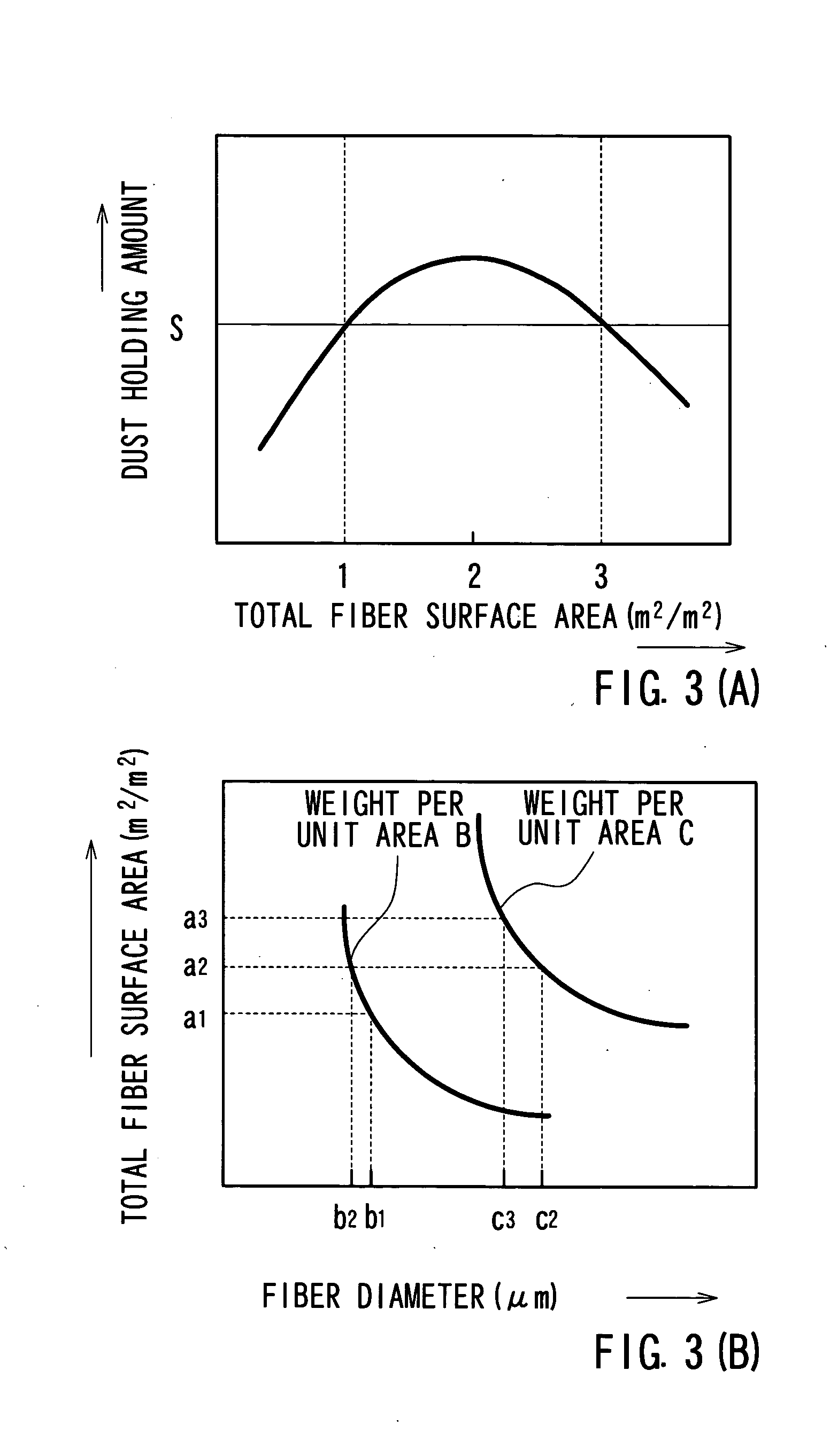

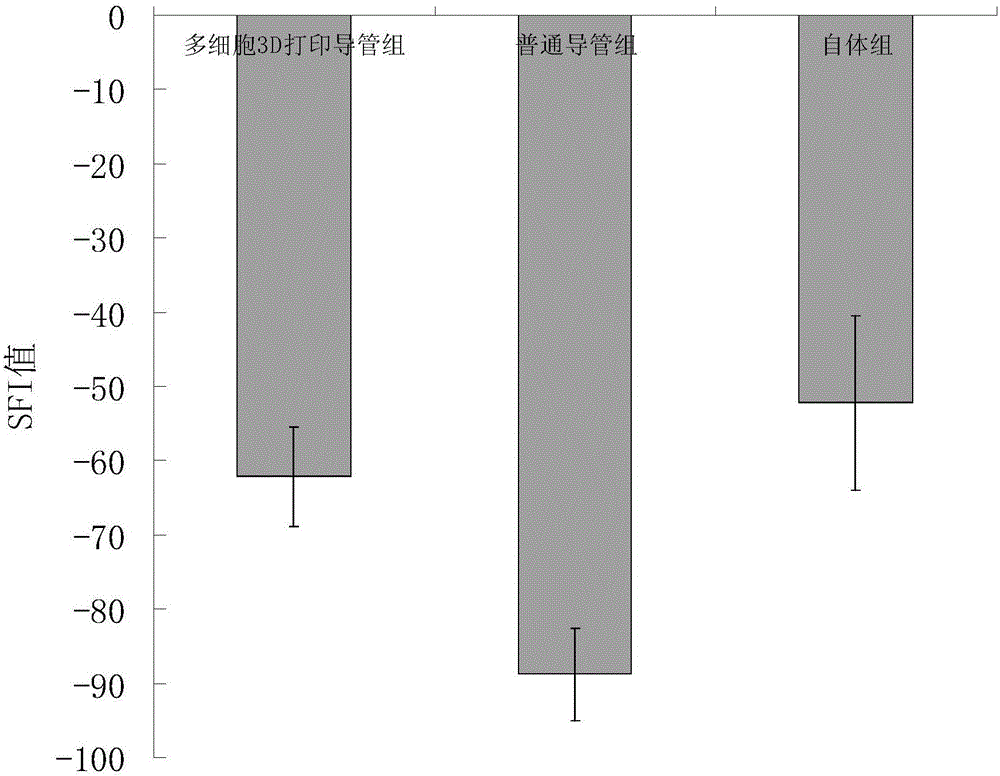

Filter elements for filters

InactiveUS20060156701A1Increasing total available dust-holding amountIncrease volumeCombination devicesDispersed particle filtrationEngineeringNonwoven fabric

A filter element has an upstream-side filter layer and a downstream-side filter layer. The downstream-side filter layer is attached to the upstream-side filter layer. A non-woven fabric made of resin fibers formed by a spinning process constitutes the upstream-side filter layer. The resin fibers have an average diameter within a range of 2.5 μm and 10 μm. The non-woven fabric has a weight per unit area within a range of approximately 2.5 g / m2 to 15 g / m2. The downstream-side filter layer has a finer mesh than the mesh of the upstream-side filter layer.

Owner:TOYOTA BOSHOKU KK +1

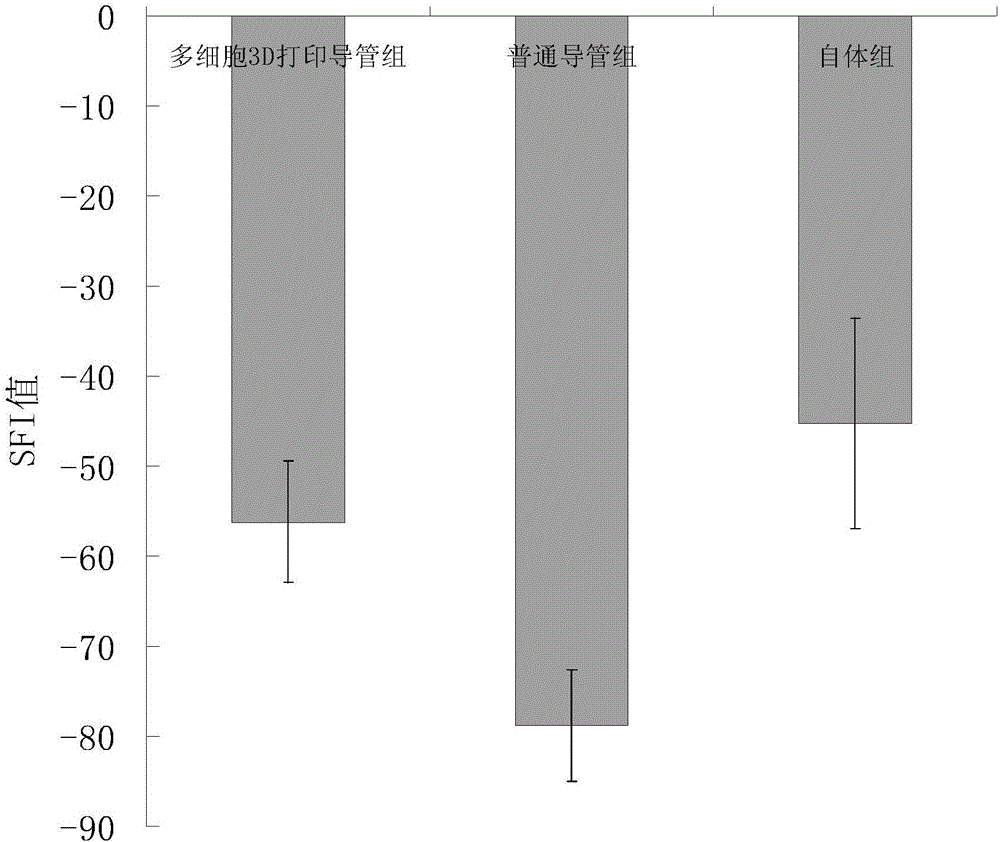

Nerve conduits based on three-dimension printing of multiple types of cells and producing method thereof

InactiveCN106215241AImprove hydrophilicityAdjust the density and loosenessAdditive manufacturing apparatusTissue regenerationBiologic scaffoldMolecular materials

The invention relates to a method for producing nerve conduits based on three-dimension printing of multiple types of cells. The method comprises the following steps: a high-molecular material is used for producing filaments, the filaments are assembled into braided lines, and the braided lines are produced into tubular external layered braided supports and internal braided supports of nerve conduits; a normal pressure plasma is used for carrying out surface treatment for the tubular external layered braided supports and internal braided supports; multiple types of cells are obtained, each type of cell is respectively dissolved into biological solvents in order to produce biological ink, and the ink is placed into different printing ink cartridges; biological printing parameters are adjusted, the biological ink is printed on external surfaces of the braiding type tubular internal and external layered biological supports; the tubular external layered braided supports and the internal braided supports are assembled, and high-molecular glue is used for carrying out adhesion and fixation of two ends of nerve conduits. The method has the following characteristics and beneficial effects: the nerve conduits employ the high-molecular degradable material as the material, the material is easily available, and the material has certain strength and good biological compatibility.

Owner:ZHEJIANG PROVINCIAL PEOPLES HOSPITAL

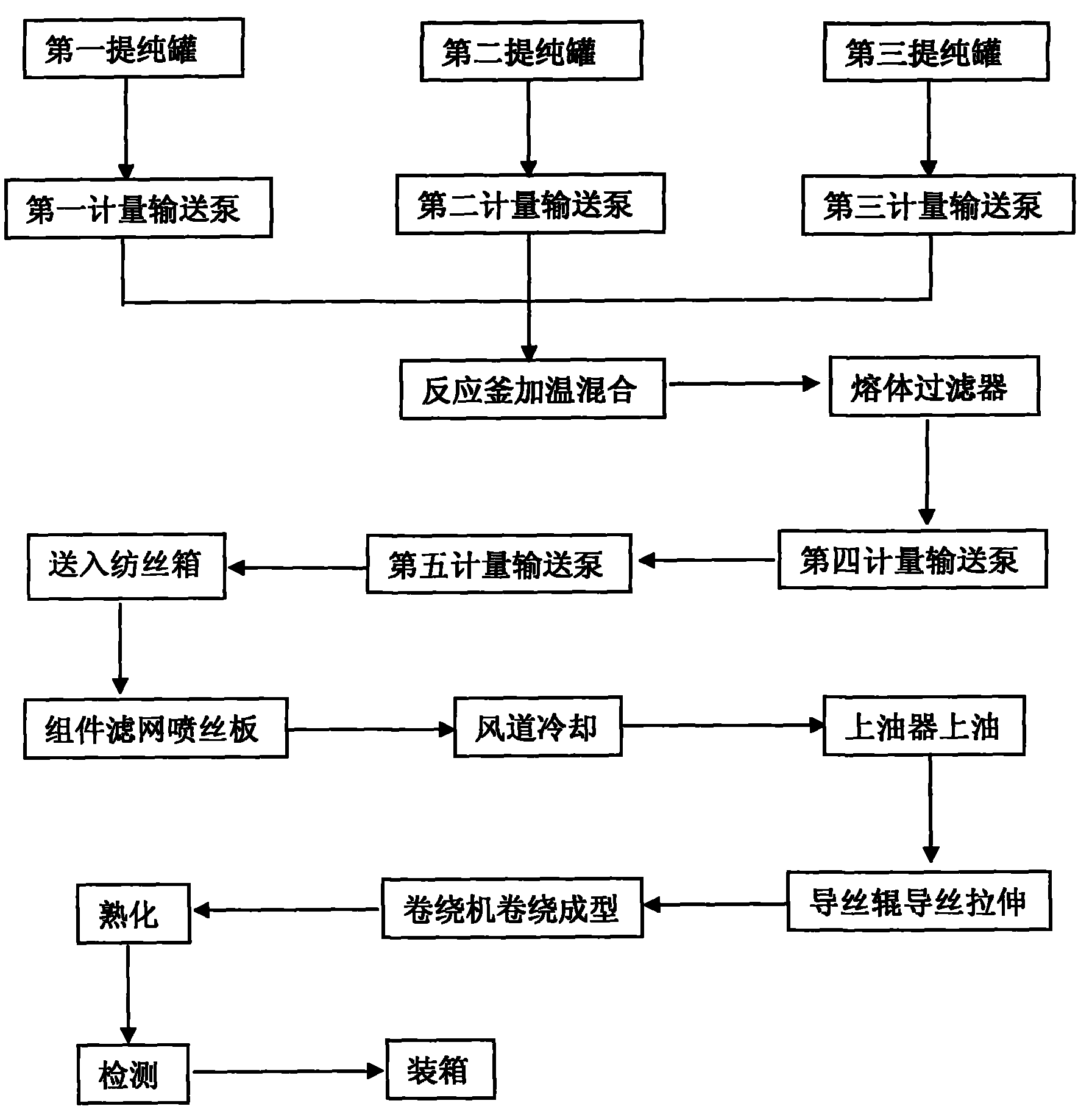

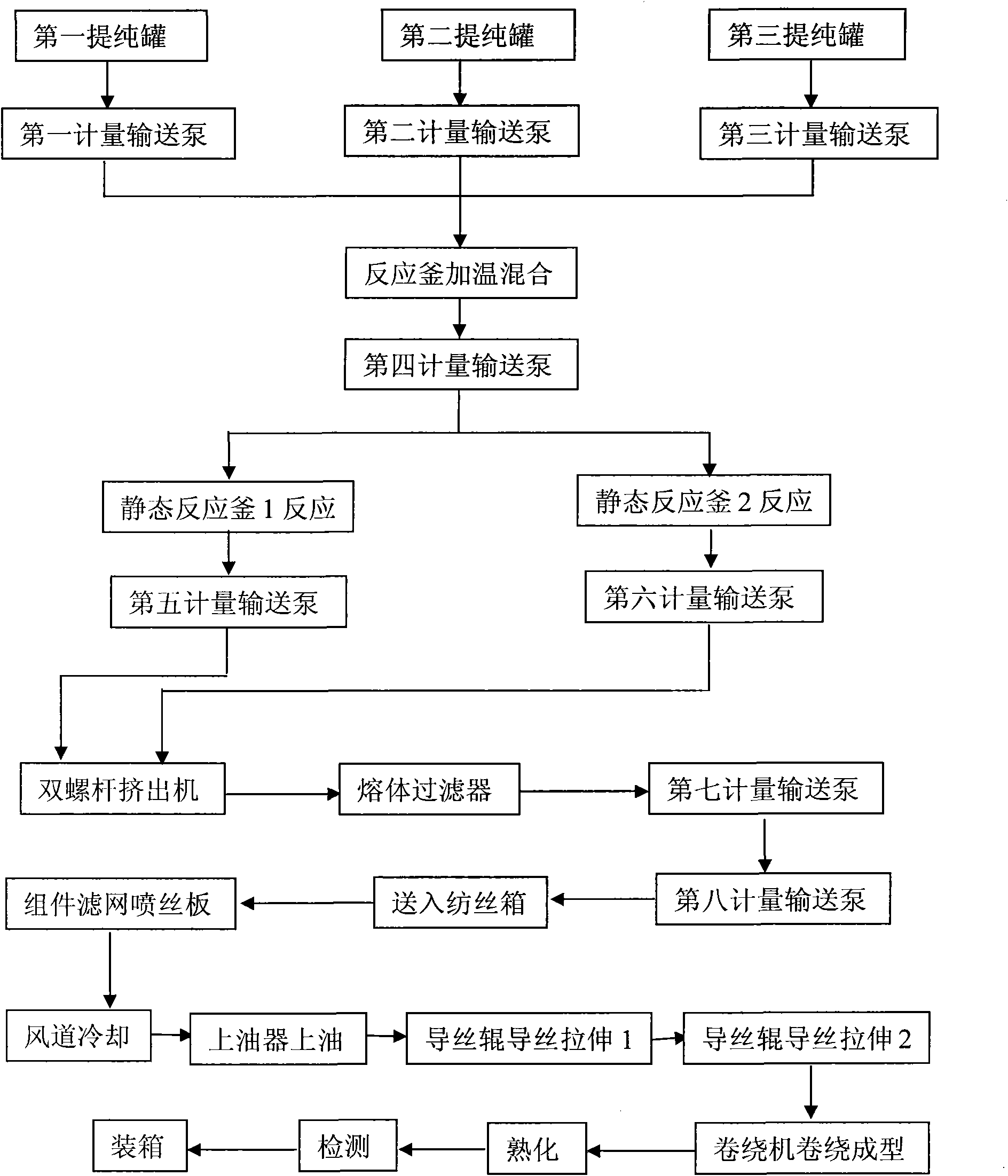

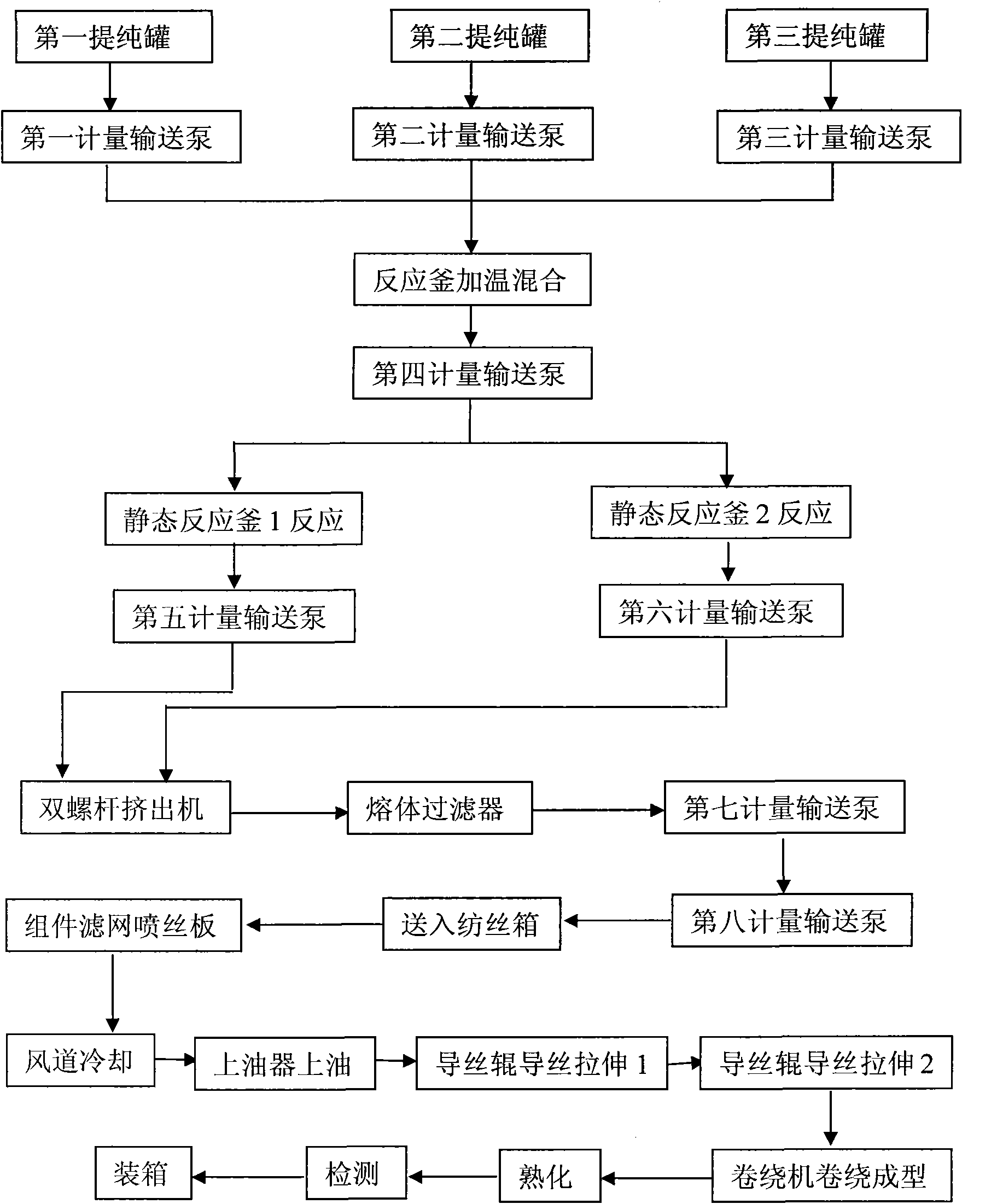

A processing process of high-modulus low-shrinkage high-colour-fastness polyester filament yarn by direct melt spinning and real-time injection

ActiveCN104294393AImproved elongation and uniformityLow bending stiffnessMelt spinning methodsFilament-forming treatmentLow modulusMelt spinning

The invention relates to a processing process of high-modulus low-shrinkage high-colour-fastness polyester filament yarn by direct melt spinning and real-time injection. By the special design of steps including subjecting a polyester raw material to shrinkage reducing processing, performing modulus-increasing blending and melting melt processing, performing low-frequency real-time compression and injection, subjecting the melt to multi-stage direct-melting and spinning, passing through a filter screen, spinning, cooling, applying oil, stretching, and the like, and by special optimization of related parameters, the technical difficult problems of fiber in the prior art, namely low modulus, low strength and poor natural-color fasteness are overcome, and the objective of purification, high color fasteness, high modulus and low shrinkage is achieved. Under the obvious improvement on the high color fasteness, the high modulus and the low shrinkage which are good properties, stability, thermal resistance, resistance to hot water, elasticity resilience, elongation and homogeneity are largely improved.

Owner:福建百宏聚纤科技实业有限公司

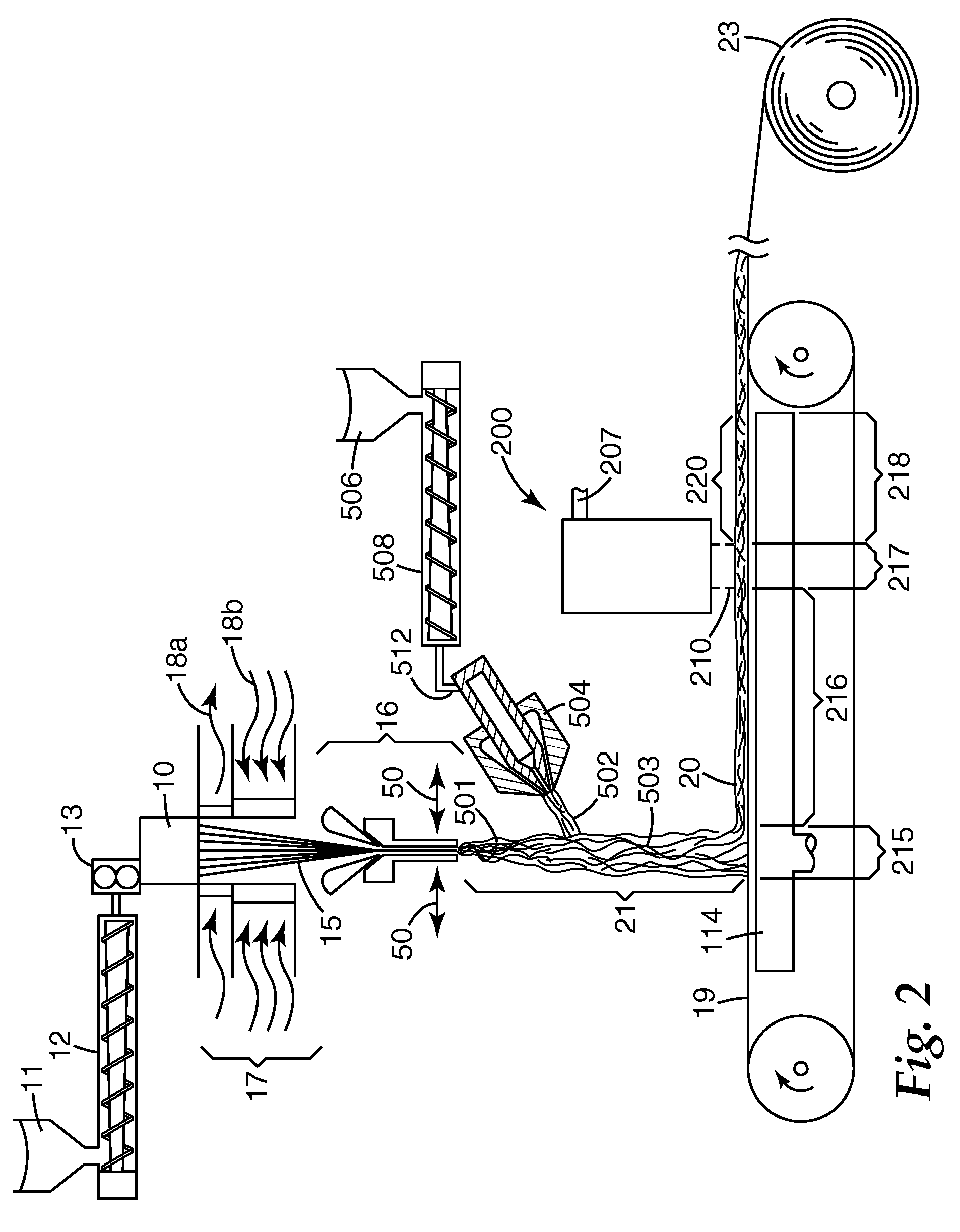

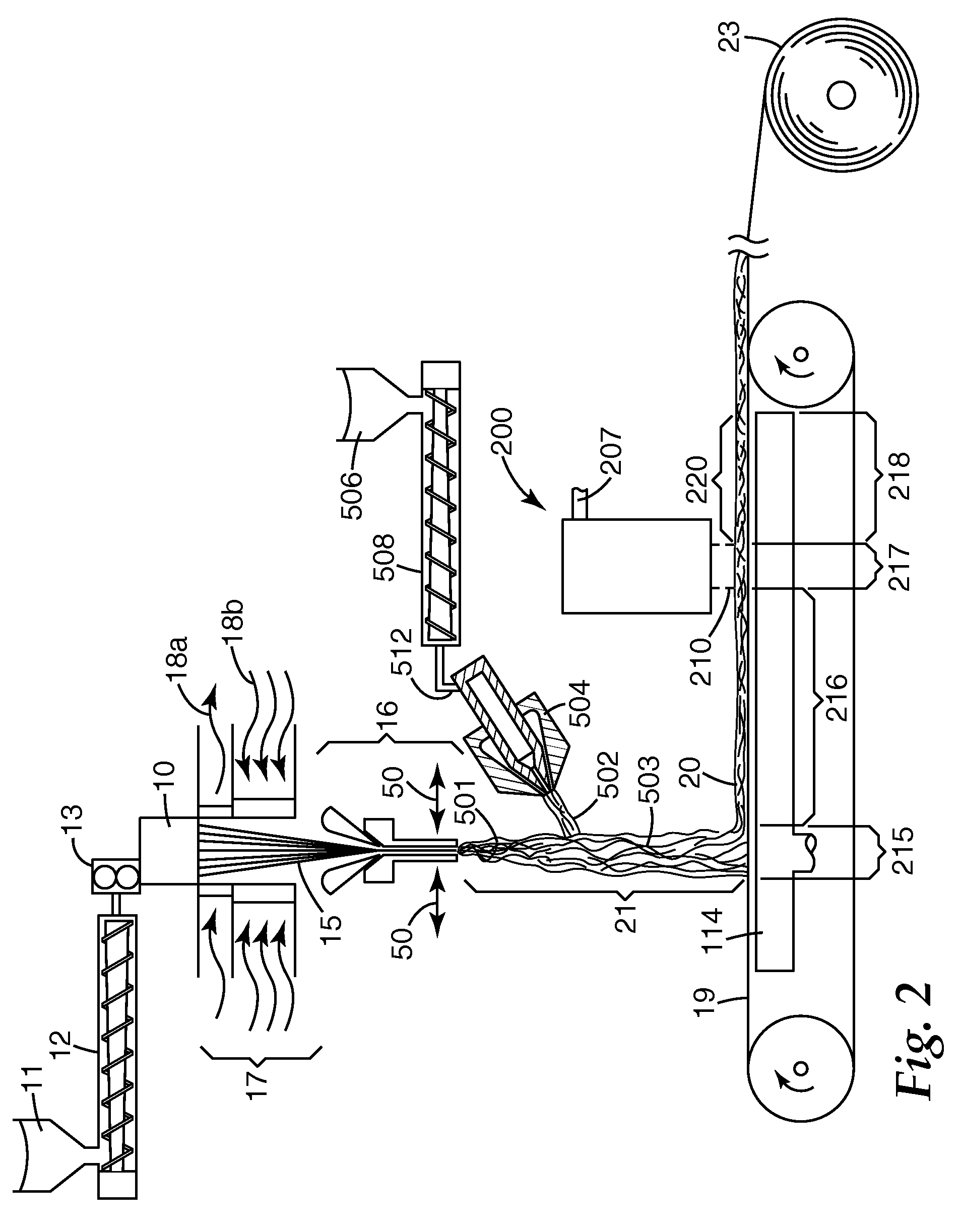

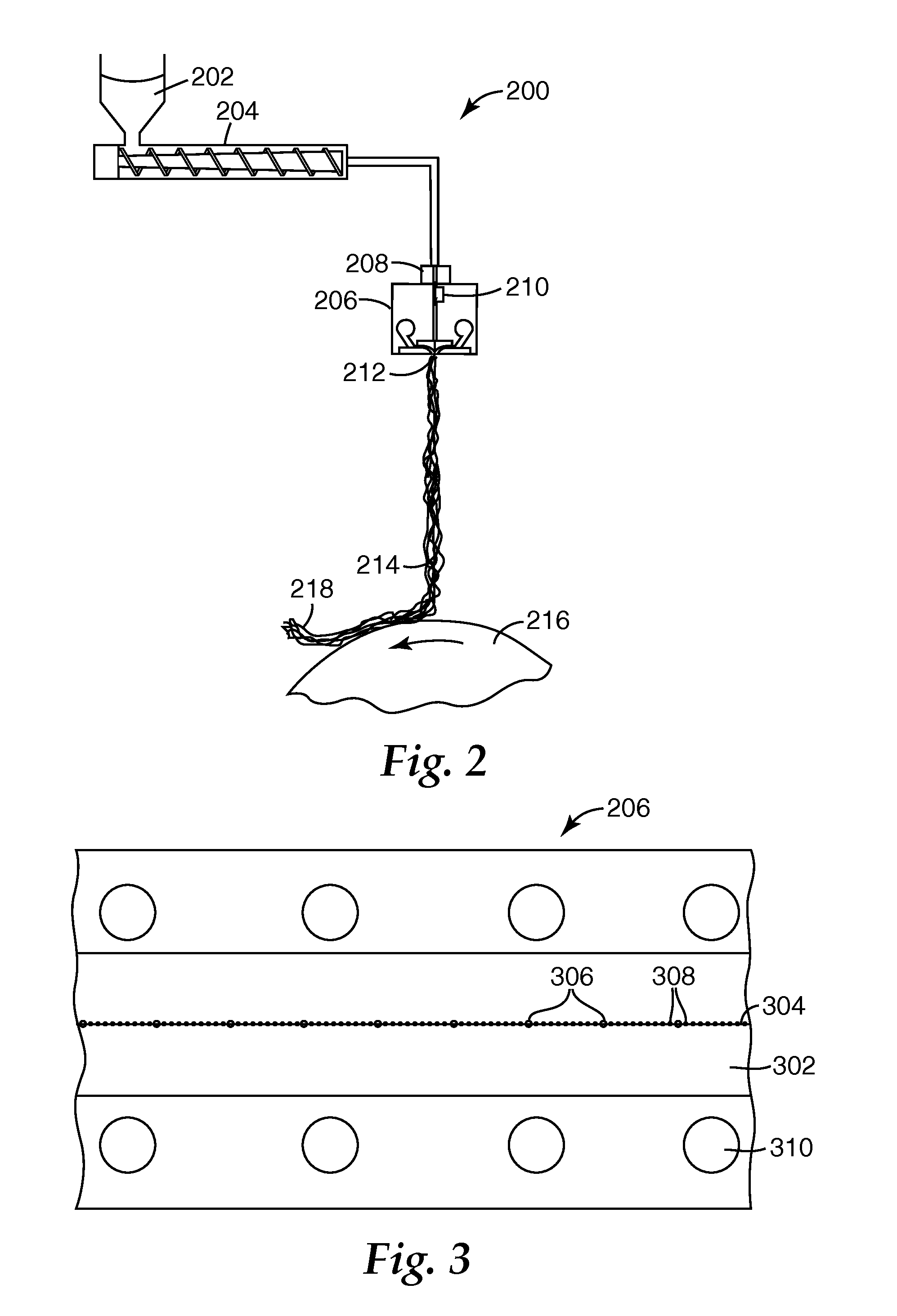

Method for making shaped filtration articles

InactiveUS8029723B2Good molding effectIncrease fiber surface areaElectric discharge heatingDispersed particle filtrationPolymer scienceFiltration

Shaped filtration articles are made from a monocomponent nonwoven web formed by flowing first and second fiber-forming materials of the same polymeric composition through first and second die cavities in respective fluid communication with first and second sets of orifices in a meltblowing die tip. The first fiber-forming material flows at a lesser flow rate or viscosity through the first die cavity and first set of orifices to form a set of smaller size filaments and the second fiber-forming material flows at a greater flow rate or viscosity through the second die cavity and second set of orifices to form a set of larger size filaments. The collected nonwoven web contains a meltblown bimodal mass fraction / fiber size mixture of intermingled continuous microfibers and larger size fibers of the same polymeric composition.

Owner:3M INNOVATIVE PROPERTIES CO

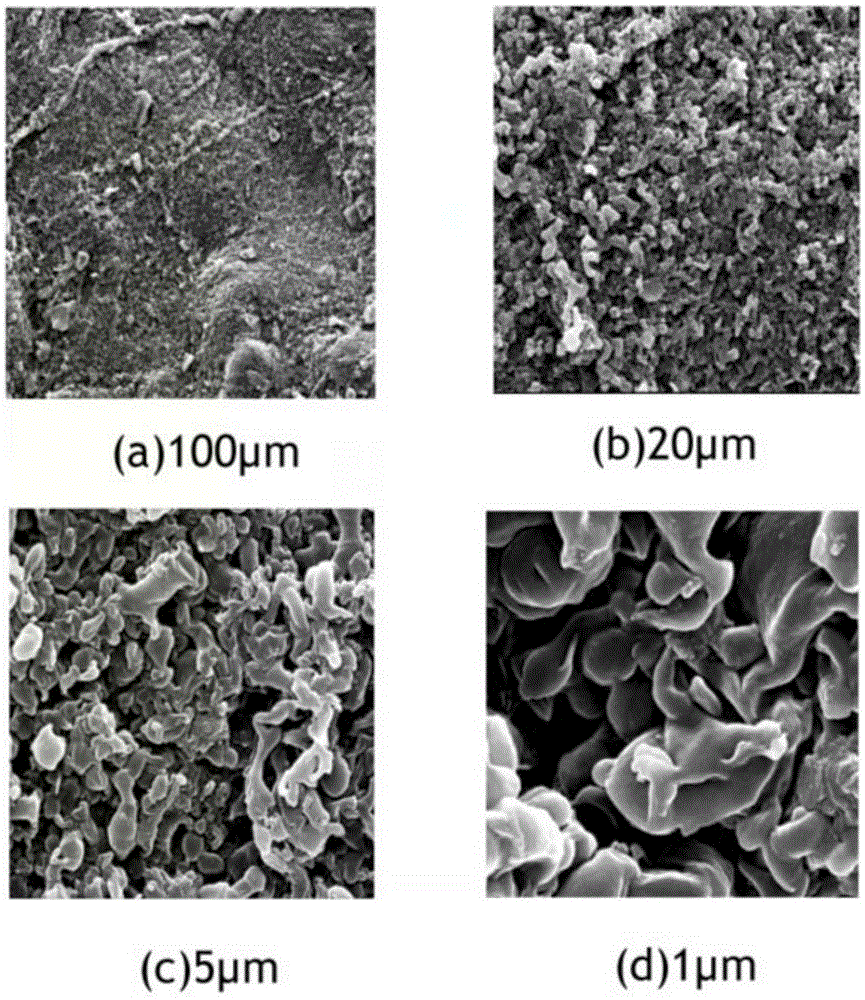

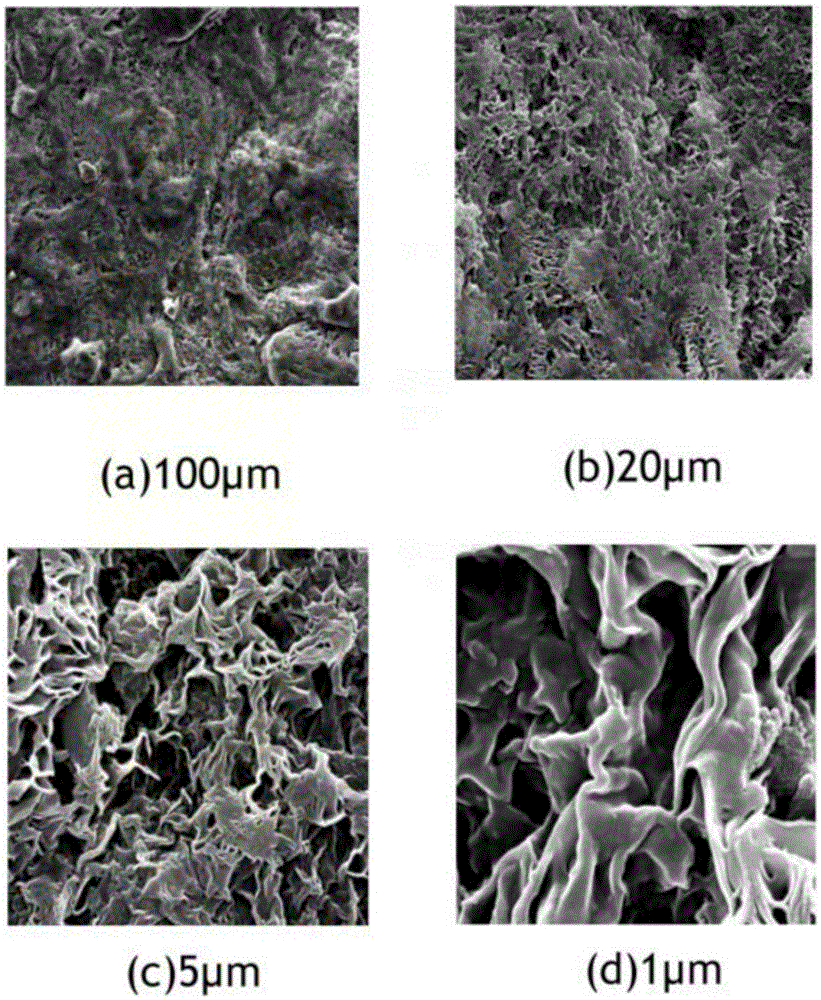

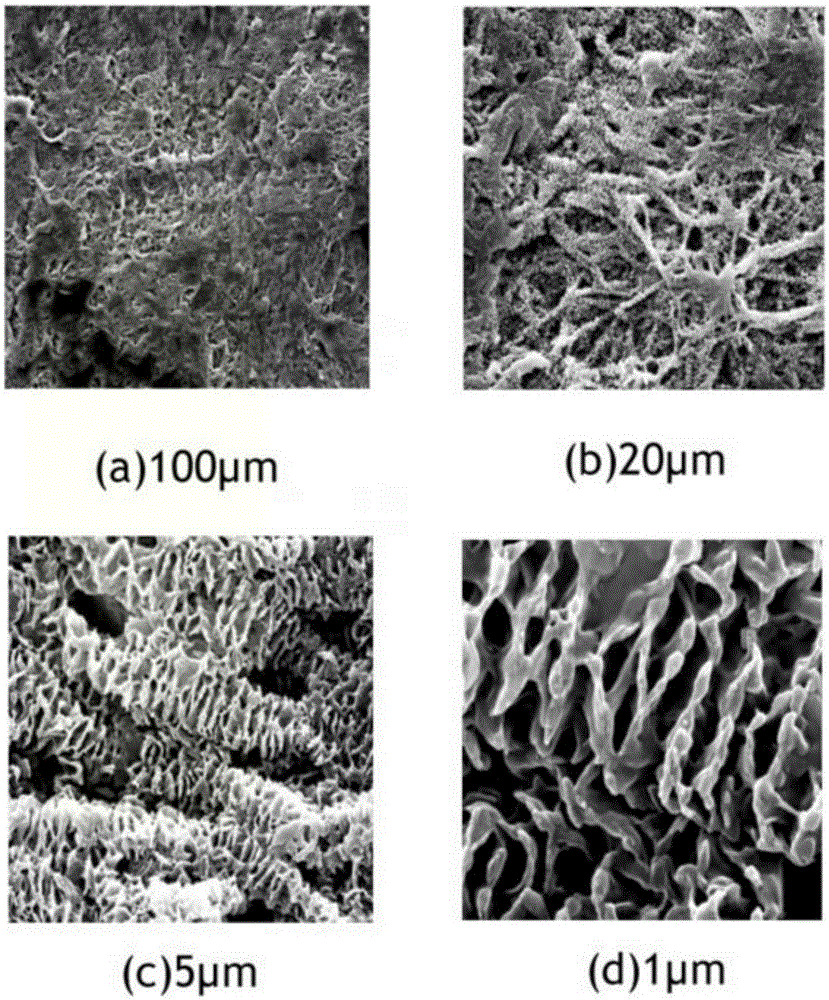

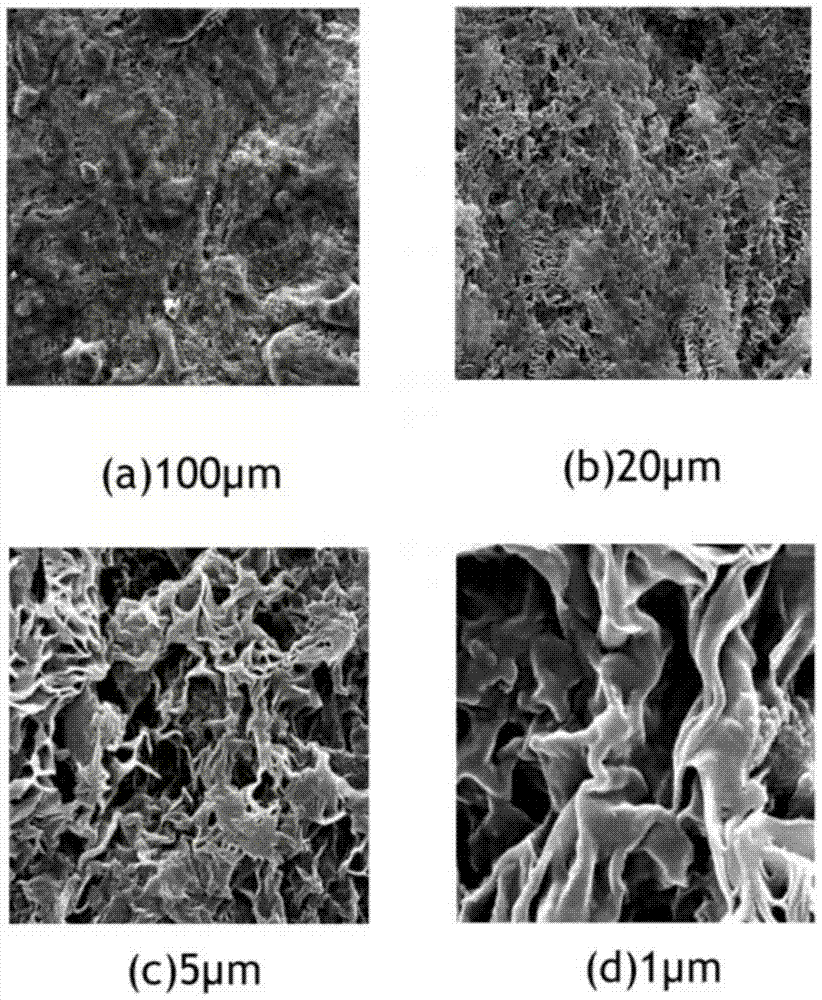

Polycaprolactone and silk fibroin electrospun fibrous membrane with surface of continuous laminated micro-nano structure and preparation method and application thereof

The invention discloses a polycaprolactone and silk fibroin electrospun fibrous membrane with the surface of a continuous laminated micro-nano structure and a preparation method and application thereof. The preparation method comprises the steps that 1, silk fibroin and polycaprolactone are dissolved into hexafluoroisopropanol and are stirred and dissolved at room temperature to obtain a mixed solution; 2, electrostatic spinning is performed on the mixed solution to prepare a polycaprolactone and silk fibroin blended membrane; 3, vacuum drying is performed on the polycaprolactone and silk fibroin blended membrane, then, the polycaprolactone and silk fibroin blended membrane is subjected to a heating reaction with a PCL monomer and a stannous octoate catalyst under the nitrogen protection, and the polycaprolactone and silk fibroin electrospun fibrous membrane is obtained. The polycaprolactone and silk fibroin electrospun fibrous membrane obtained through the preparation method has the surface layer laminated micro-nano structure fiber morphology, the specific surface area and the fiber diameter are greatly increased, the probability that the hydrophobicity of the electrospun membrane is converted into hydrophile is increased, the fiber specific surface area is greatly increased, and the space maintaining capacity, the dynamic mechanics performance and the degradation performance are greatly improved.

Owner:KUNMING MEDICAL UNIVERSITY

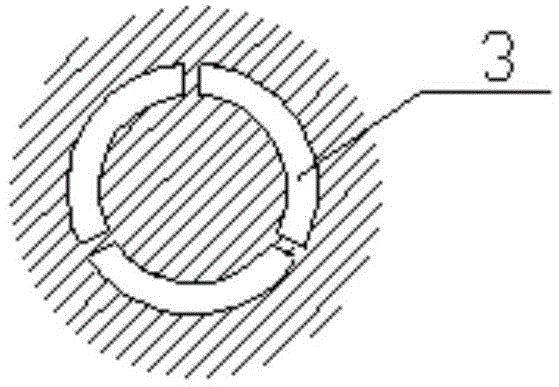

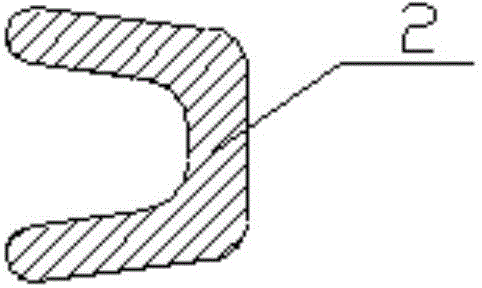

U-shaped hollow Dacron draw-textured yarn and preparation method thereof

ActiveCN104562240AWith moisture wicking functionImprove breathabilityHollow filament manufactureFilament/thread formingPolyesterYarn

The invention discloses a U-shaped hollow Dacron draw-textured yarn and a preparation method thereof. The technical process includes the steps of: adding polyester melt; sequentially passing through a booster pump, a melt transport pipe, a spinning box, a metering pump and a spinning assembly including a spinneret plate; cooling, oiling and winding; further sequentially passing through a pre-netting device, a yarn cutter, a first roller, a first heat box, a cooling plate, a false twister, a tension meter, a second roller, a network nozzle, a second heat box, a third roller and an oil wheel; winding for shaping, namely obtaining the required product. According to the preparation method, two kinds of jet micropores are designed on the same spinneret plate, namely U-shaped holes and hollow holes, so that the a bunch of yarns include U-shaped yarns as well as hollow yarns; meanwhile, through the arrangement design of the two kinds of jet micropores, the hollow yarns are wrapped in the U-shaped yarns, so that the damage to the sections of the hollow yarns in a sequential false twisting process is greatly reduced, and the functionality of the product is significantly promoted. The fabric prepared according to the invention has very wide application prospect in the field of garment materials and fabrics.

Owner:JIANGSU HENGLI CHEM FIBER

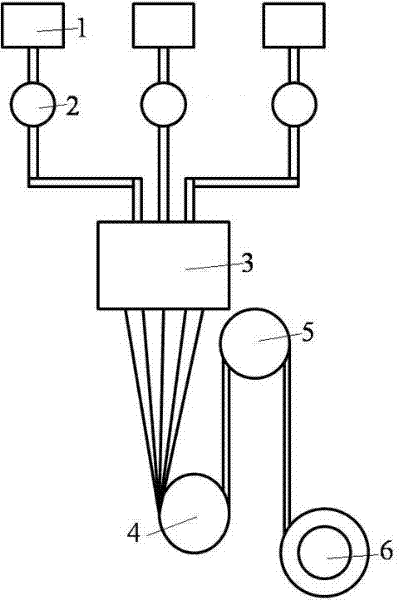

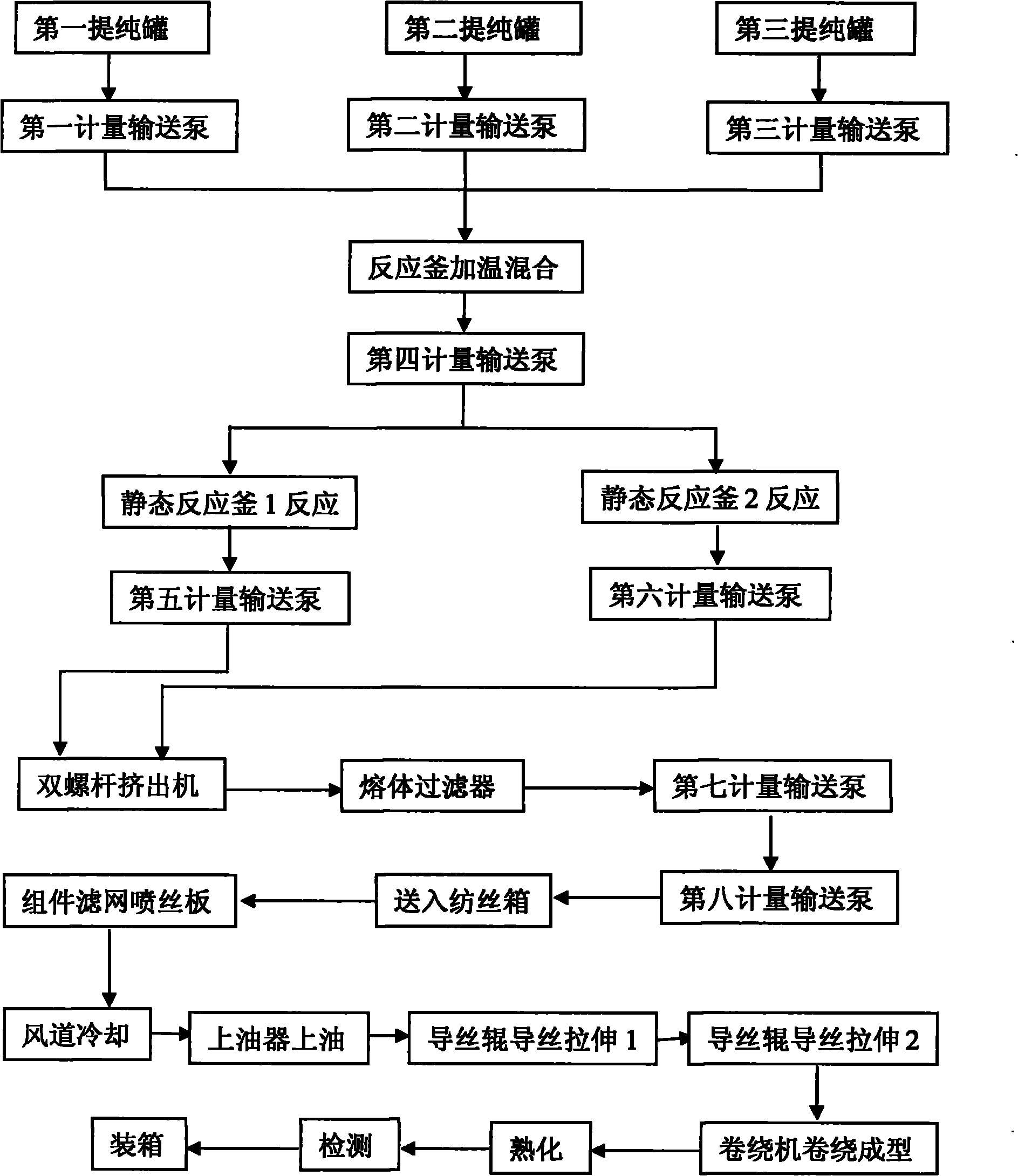

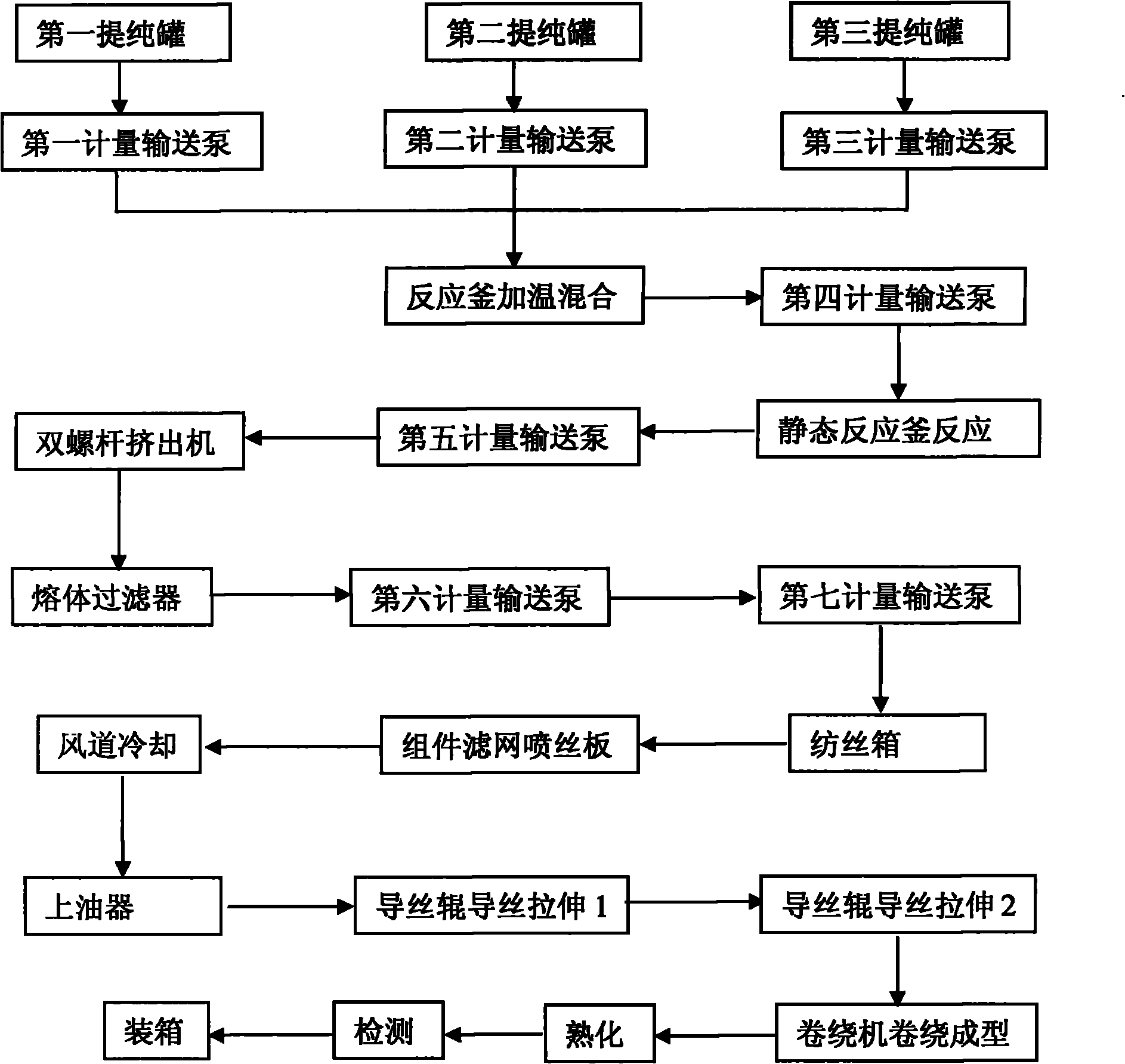

Melting and direct-spinning superfine denier (4.6-5.5 denier) high-elastic modulus polyurethane fiber equipment

InactiveCN102115919AImprove water absorptionIncrease fiber surface areaMonocomponent polyurethanes artificial filamentArtificial thread manufacturing machinesFiberHigh density

The invention discloses melting and direct-spinning superfine denier (4.6-5.5 denier) high-elastic modulus polyurethane fiber equipment. The equipment is characterized in that the equipment comprises a purification tank, a reaction tank, a metering and conveying pump, a reaction kettle warming mixer, a static reaction kettle, a double-screw extruder, a melt filter, a thread spinning box, a component filter screen spinneret plate, an air duct cooling system, an oiling device, a godet guide thread stretching device, and a winder winding and forming device. The equipment has the advantages that the produced superfine denier polyurethane fibers have very small bending rigidity and very soft hand feel; the surface areas of the fibers are very large, so that the spreadability, the bulkiness andthe heat retention property of fabrics are obviously improved, and the fabrics achieve a powerful cleaning function; when the superfine fibers are manufactured into super-high density fabrics, the size of gaps among the fibers is between the diameter of a water drop and the diameter of a water vapor droplet, so that the superfine fabrics have the waterproof and vapor-permeable effects; and when the superfine fibers are processed into fabrics like towels which can be wetted by water, the fabrics have high water absorbability, so that moisture of washed hair can be quickly absorbed by the towels, and the hair can be quickly dried. The equipment can be applied to various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

Method for producing direct melt filtration fused direct spun ultrafine denier polyurethane fibers

InactiveCN102051705AImproved elongation and uniformityLow bending stiffnessSpinnerette packsSpinning head liquid feederFlexural rigidityNitrogen pressure

The invention discloses a method for producing direct melt filtration fused direct spun ultrafine denier polyurethane fibers. The method is characterized by comprising the following steps of: proportioning raw material components, feeding materials under negative pressure, applying 0.8MPa nitrogen pressure, extruding by a twin-screw extruder, filtering by a melt filter, cooling spun filaments by an air channel, oiling by an oiling machine, curing by a drying room, and detecting and packing. The invention has the advantages that: the ultrafine denier polyurethane fibers have small bending stiffness, soft handfeel and large surface area; the coverage, bulkiness and heat retention of a fabric are remarkably improved, and the fabric has strong cleaning function; the ultrafine fibers are prepared into an ultra-dense fabric, a gap among the fibers is between the diameter of a water drop and the diameter of a water vapor microdrop, and the ultra-dense fabric has a waterproof and ventilated effect; and the ultrafine fibers are processed into a towel fabric which can be wetted by water, and the towel fabric has high water absorption, and water of washed hair can be rapidly absorbed by using the towel, so that the hair is rapidly dried. The method can be applied to various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

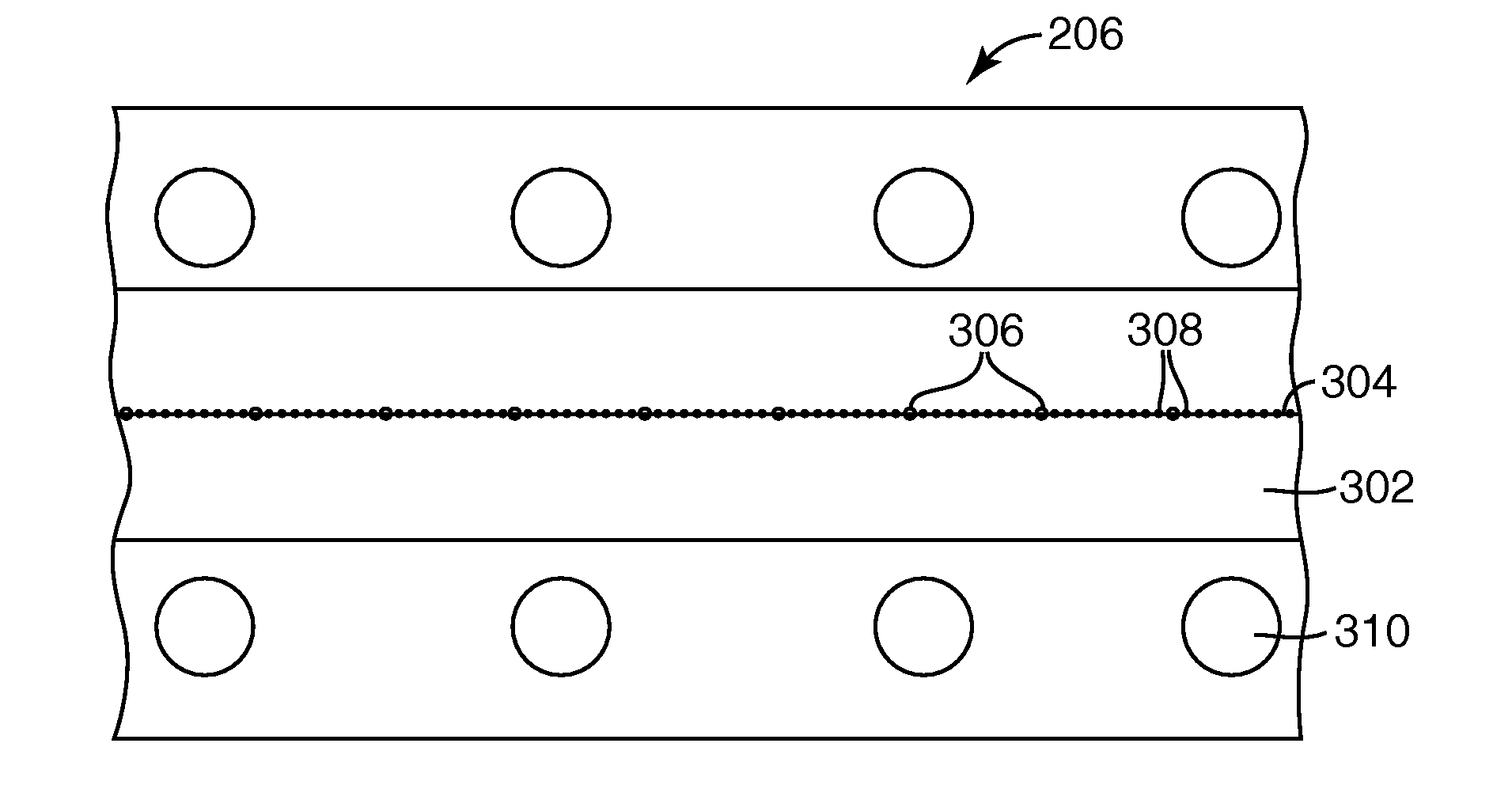

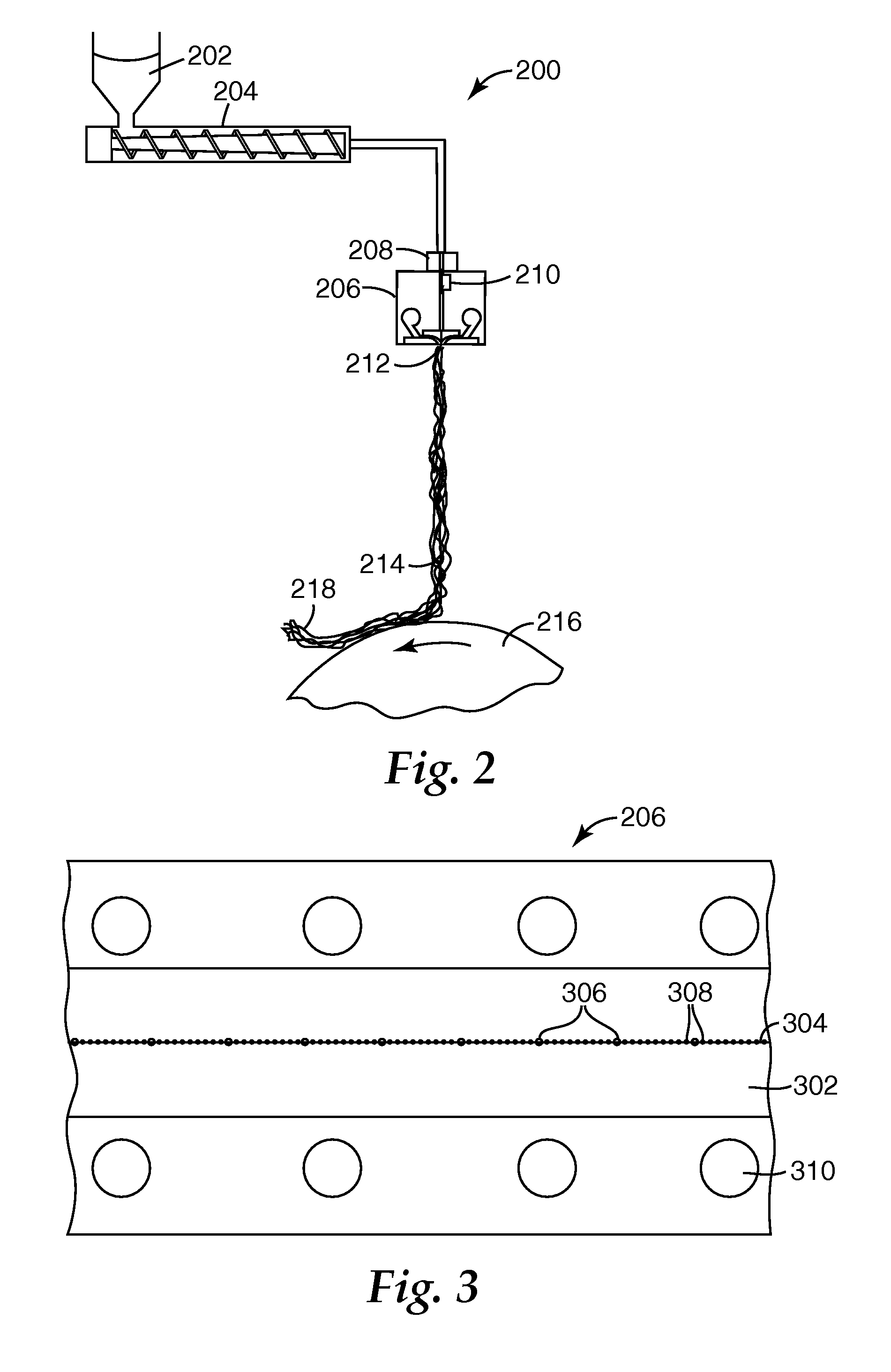

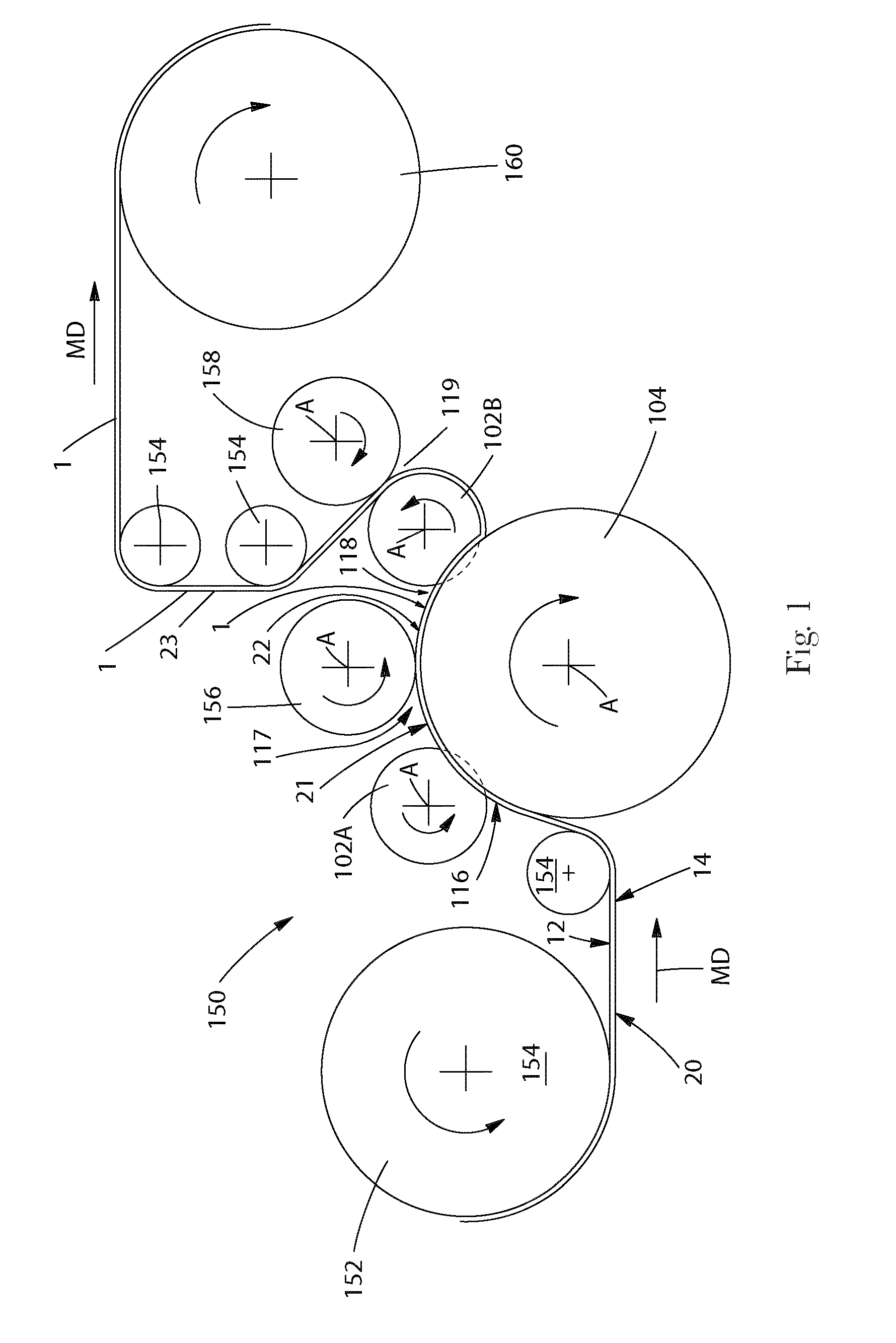

Monocomponent monolayer meltblown web and meltblowing apparatus

ActiveUS20100201041A1Narrow distributionReduced service lifeDispersed particle filtrationFilament/thread formingPolymer scienceAir filter

A porous monocomponent nonwoven web contains a bimodal mass fraction / fiber size mixture of intermingled continuous microfibers and larger size fibers of the same polymeric composition. There are at least five times as many microfibers as larger size fibers, and a histogram of the mass fraction of fibers vs. fiber size exhibits a larger size fiber mode greater than 10 μm. The web may be made by flowing fiber-forming material through a die cavity having larger size orifices and at least five times as many smaller size orifices to form filaments, attenuating the filaments into fibers and collecting the attenuated fibers to form the nonwoven web. The web is especially well suited to the manufacture of self-supporting three dimensional articles such as molded cup-shaped respirators and pleated air filters.

Owner:3M INNOVATIVE PROPERTIES CO

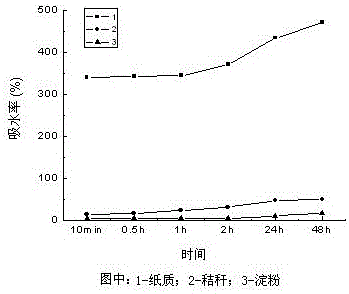

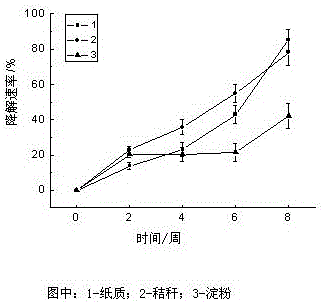

Paper-based degradable nutrition bowl and preparation method

The invention discloses a paper-based degradable nutrition bowl and a preparation method thereof. The paper-based degradable nutrition bowl is prepared from, by dry mass, 20-90% of paper, 0-0.5% of adhesive and the balance crop straw. The preparation method includes the steps that the crop straw is smashed to reach the mesh number of 60-100; the paper is soaked in water, wherein the paper accounts for 5-8% of the total mass of the paper and the water; stirring is conducted for 10-15 min at the normal temperature, and standing is conducted to make paper pulp; the straw powder and the adhesive are added in proportion, and mixing and stirring are conducted for 5-8 min at the normal temperature; the raw material pulp is sucked into a paper pulp molding forming machine for compression forming; after demoulding, the formed product is naturally aired for 2-5 days or put into an air-blast drying oven to be dried, and the finished product paper-based degradable nutrition bowl can be obtained. The nutrition bowl is light, simple in process, capable of meeting the seedling culture requirements of heat preservation, soil moisture preservation, degradability and the like and capable of solving the problem of environmental pollution caused by waste, pollution is hardly caused in the production process, and industrial production and large-scale application and popularization are easy.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

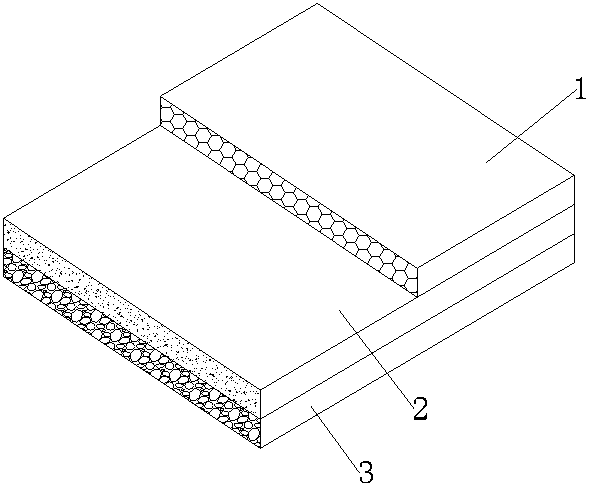

A kind of preparation method of composite artificial dura mater

ActiveCN106390204BExtensibility adjustmentImprove quality controlPeptide/protein ingredientsProsthesisFiberSide effect

The invention relates to a composite type artificial dura mater, comprising two hydrogel layers and a woven layer, wherein the woven layer is arranged between the two hydrogel layers, the woven layer is a degradable polymer material, and cell growth factors are contained in the hydrogel layers. The composite type artificial dura mater disclosed by the invention has the following beneficial effects: (1) the artificial dura mater is made from the degradable polymer material and biological protein which are easily available, and has good biocompatibility; (2) atmospheric pressure plasma jet treatment increases the fiber surface area of the woven layer, decreases a contact angle of a material surface, and improves water transmissibility, degradation speed and cellular affinity; (3) regulation on physical characteristics of the artificial dura mater, such as malleability, toughness, mechanical strength and the like can be realized by regulating a weaving method; and 4) the composite type artificial dura mater is favorable for wound repair, and silver ions enable artificial skin to have good antibacterial performance, so that toxic and side effects on a human body due to the use of a chemical antibacterial medicine are avoided, and storage life of the artificial skin is prolonged.

Owner:ZHEJIANG PROVINCIAL PEOPLES HOSPITAL

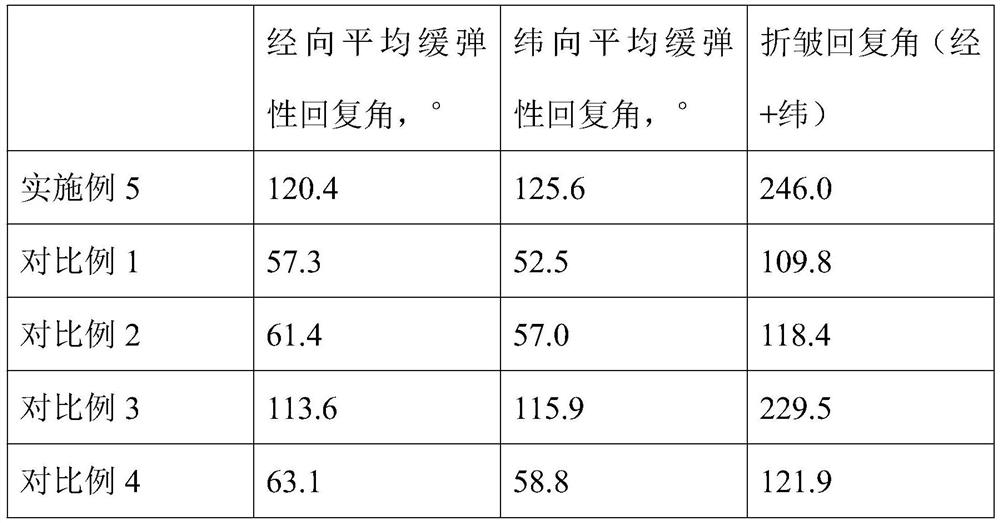

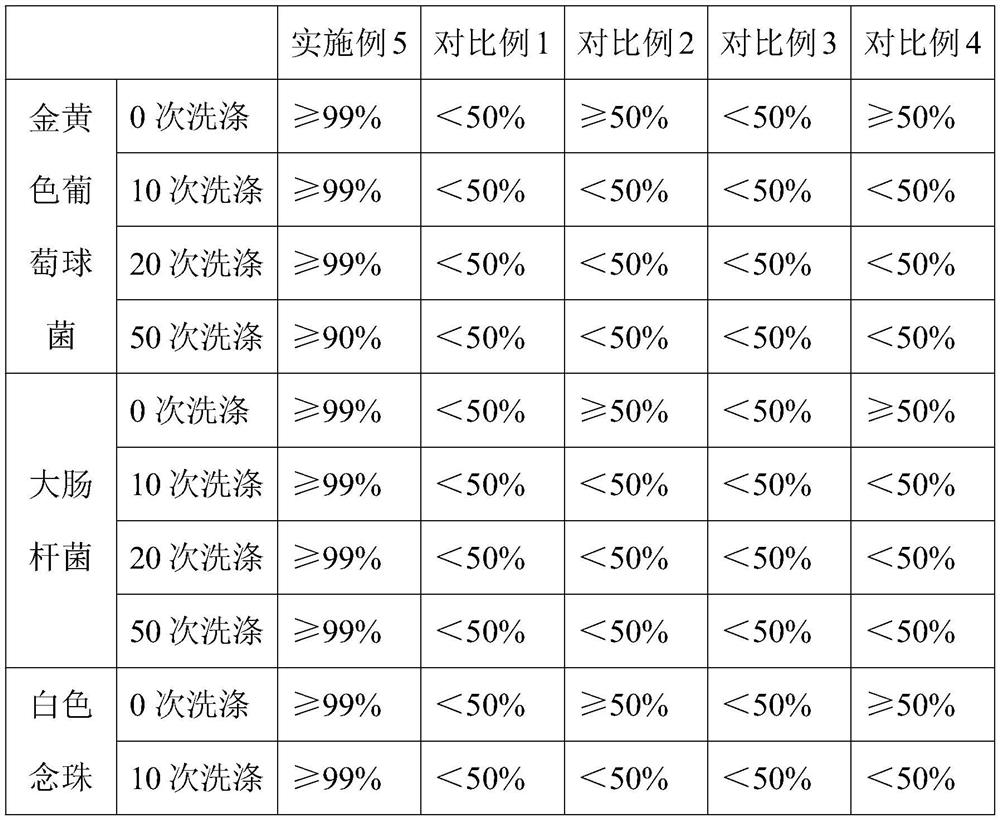

Cotton fiber-based durable antibacterial fiber fabric and preparation method thereof

PendingCN113699786AImprove surface activityImprove breathabilityBiochemical fibre treatmentWrinkle resistant fibresCotton fibreCeric ammonium nitrate

The invention discloses a cotton fiber-based durable antibacterial fiber fabric. The durable antibacterial fiber fabric is prepared from cotton fibers, ceric ammonium nitrate, an anion modifier, an amino-terminated hyperbranched polymer and graphene oxide. The invention discloses a preparation method of the cotton fiber-based durable antibacterial fiber fabric. The preparation method comprises the following steps of alkalizing the cotton fibers, soaking the cotton fibers in an ammonium ceric nitrate solution, performing ultrasonic treatment under the protection of nitrogen, adding the anion modifier, continuing ultrasonic treatment, taking out the cotton fibers, washing the cotton fibers, and drying the cotton fibers to obtain pretreated cotton fibers; adding the amino-terminated hyperbranched polymer into an ethanol water solution, performing uniform stirring, adding the pretreated cotton fibers into a mixture under the protection of nitrogen, performing stirring for 1-2 hours at 50-70 DEG C, performing washing, and performing drying in vacuum to obtain grafted cotton fibers; and adding the graphene oxide into dilute acid, performing uniform stirring, adding the grafted cotton fibers, performing stirring at 70-90 DEG C for 1-2 hours, taking out the cotton fibers, washing the cotton fibers, drying the cotton fibers, and performing spinning and weaving to obtain the cotton fiber-based durable antibacterial fiber fabric.

Owner:陈小琴

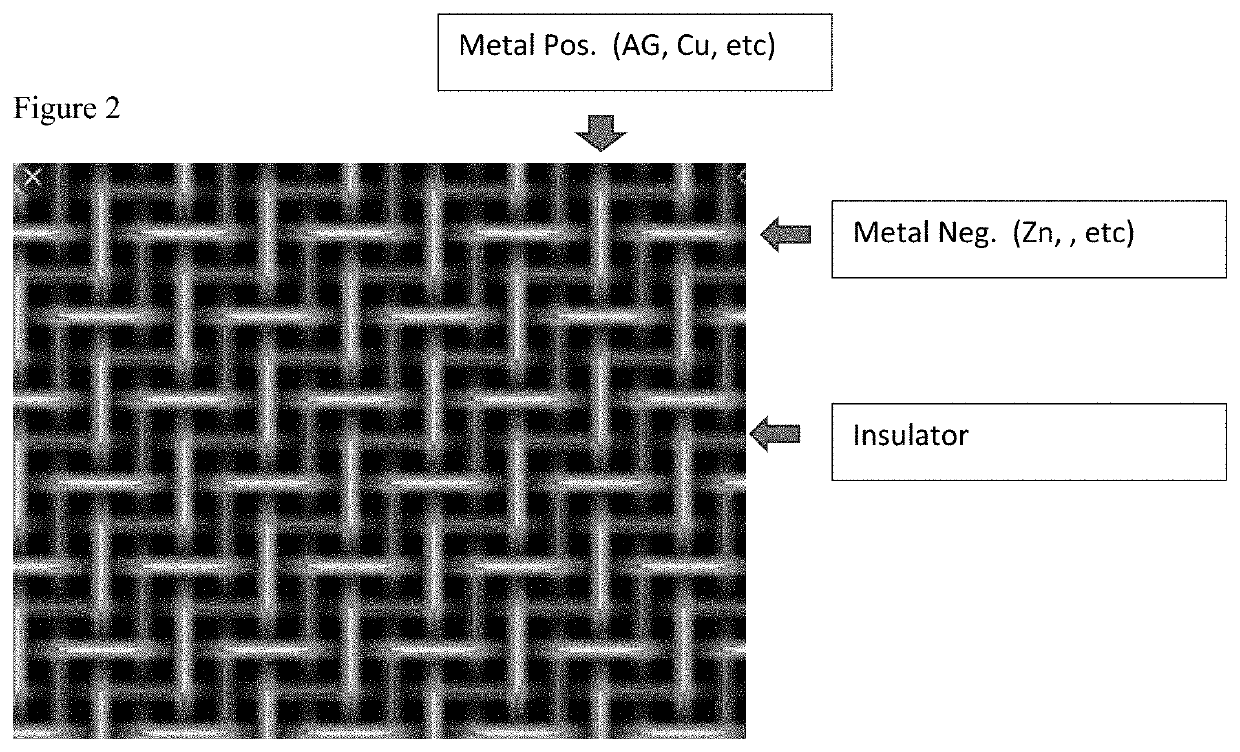

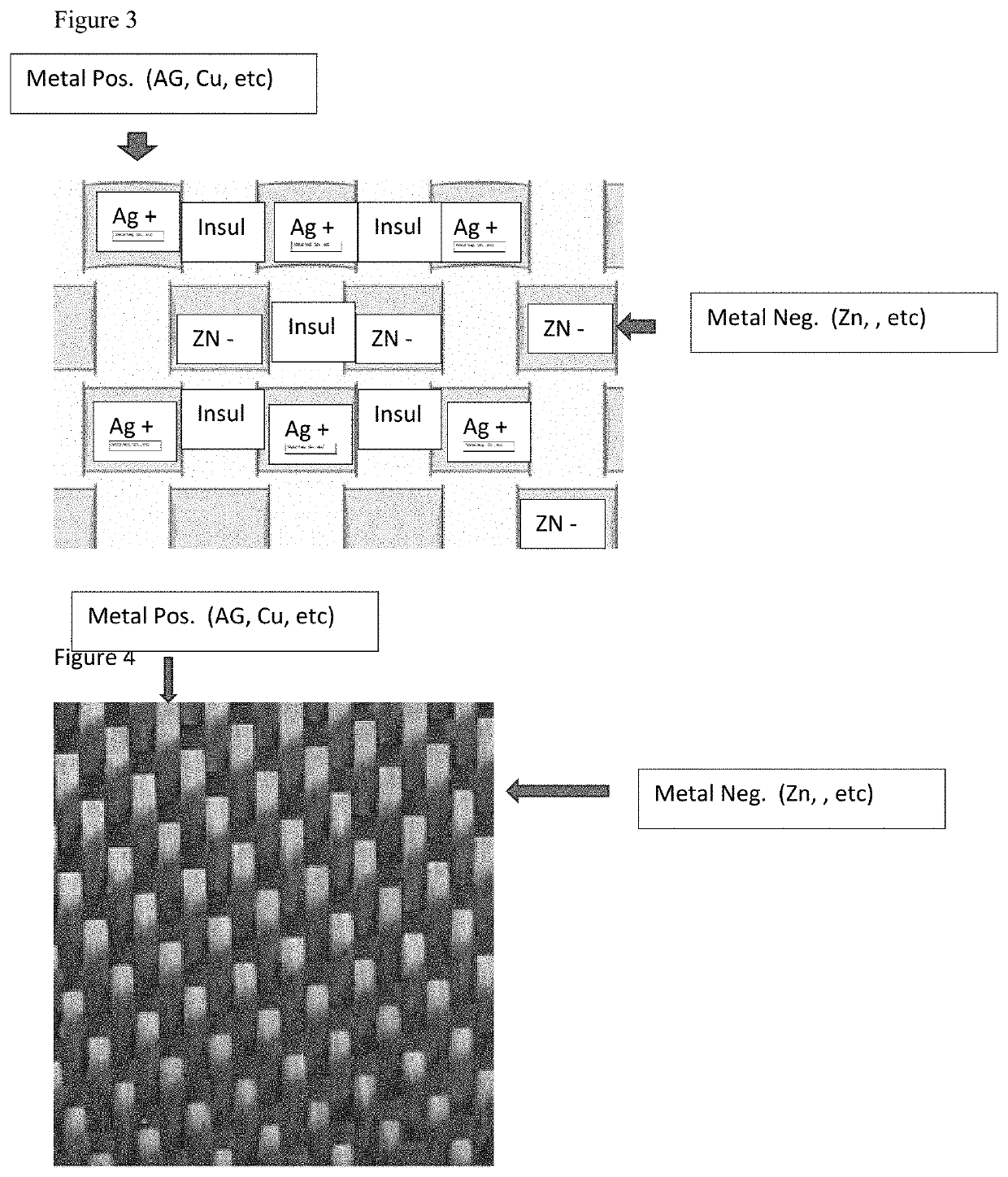

Covid mask

PendingUS20210321696A1Increases Collagen Collagen ratioAid in skin tissue healthUltrasound therapyElectrotherapyBiotechnologyElectrical battery

Disclosed is a method and device for inactivating or killing airborne bacteria, fungi, molds and viruses by passing the air through a filter material formed of a fabric having particles of zinc disposed in discrete physically isolated locations, wherein the particles of zinc and oxygen from the air form half cells of a battery whereby to create an electrical field that inactivates or kills airborne bacteria, fungi, molds and viruses passing through the filter material.

Owner:FIRST STEP HLDG LLC

Fiber having cell affinity and fiber product produced using same

PendingCN112030556AIncrease fiber surface areaImprove cell and/or material attachmentFibre typesTissue regenerationPolymer chemistryPolyethylene terephthalate

Provided are: a fiber having cell affinity, which is a polyethylene terephthalate fiber surface-treated with collagen, and which has a profiled cross-section; and a fiber product produced using the fiber.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

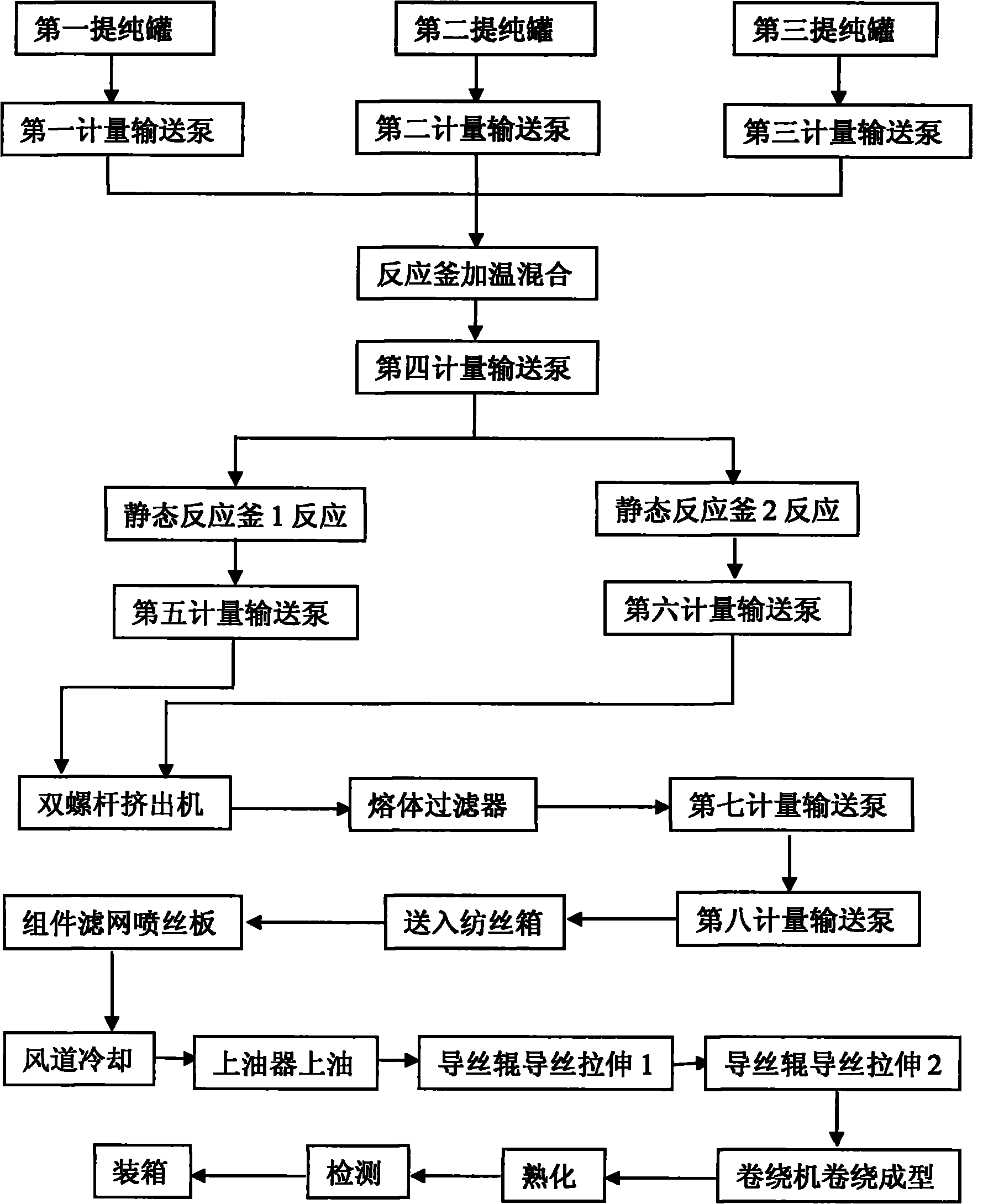

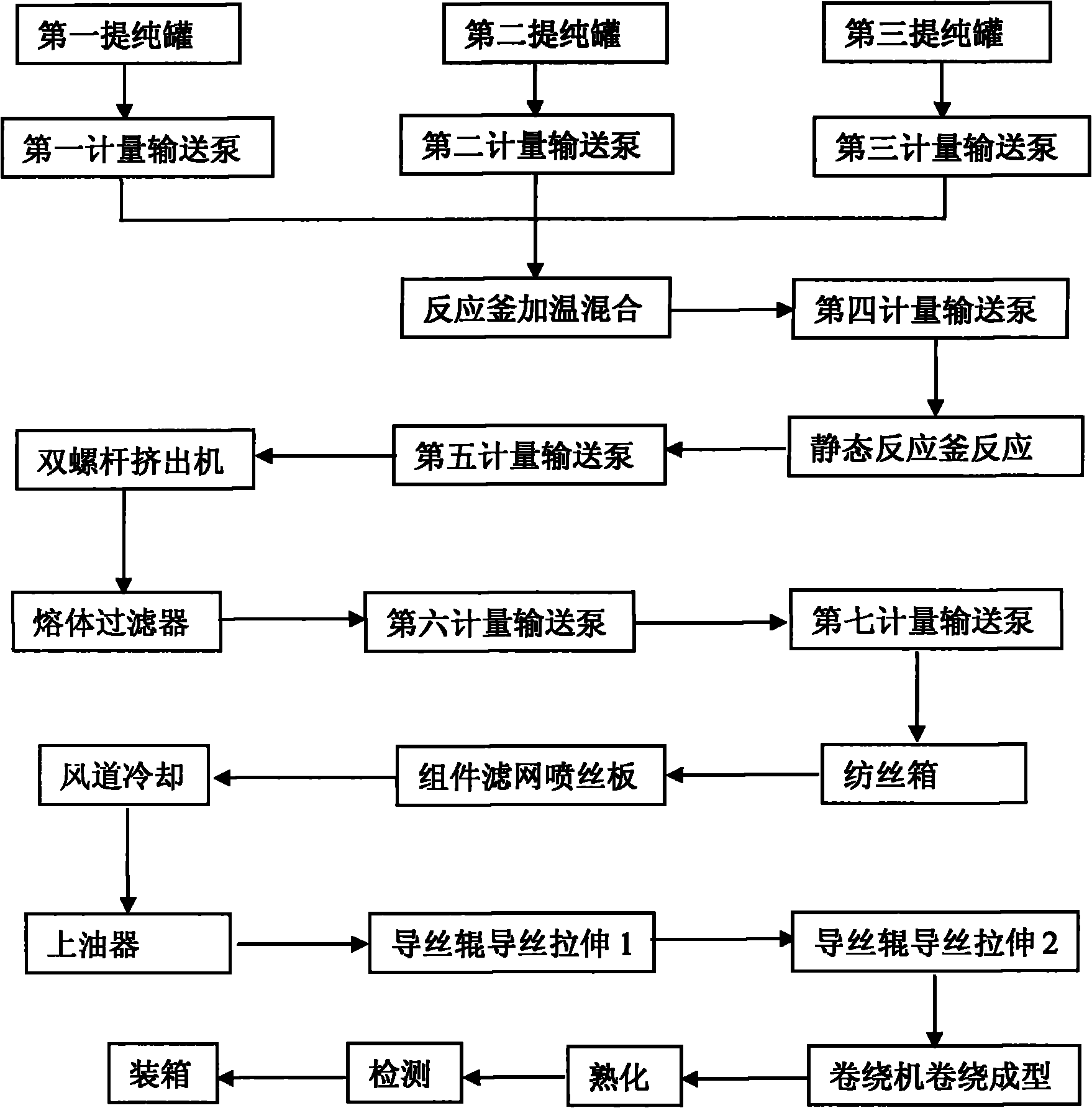

Equipment for producing direct melt filtration fused direct spun ultrafine denier polyurethane fibers

InactiveCN102051698AImprove water absorptionIncrease fiber surface areaArtificial thread manufacturing machinesSpinning head liquid feederFiberFiltration

The invention discloses equipment for producing direct melt filtration fused direct spun ultrafine denier polyurethane fibers. The equipment comprises a purification tank, a reaction tank, a metering delivery pump, a reactor heating mixer, a melt filter, a spinning box, a component filter screen spinning plate, an air channel cooling system, an oiling machine, a guide wire roller guide wire stretching device and a winder winding forming device. The invention has the advantages that: the ultrafine denier polyurethane fibers have small bending stiffness, soft handfeel and large surface area; the coverage, bulkiness and heat retention of a fabric are remarkably improved, and the fabric has strong cleaning function; the ultrafine fibers are prepared into an ultra-dense fabric, a gap among the fibers is between the diameter of a water drop and the diameter of a water vapor microdrop, and the ultra-dense fabric has a waterproof and ventilated effect; and the ultrafine fibers are processed into a towel fabric which can be wetted by water, and the towel fabric has high water absorption, and water of washed hair can be rapidly absorbed by using the towel, so that the hair is rapidly dried. The equipment can be applied to various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

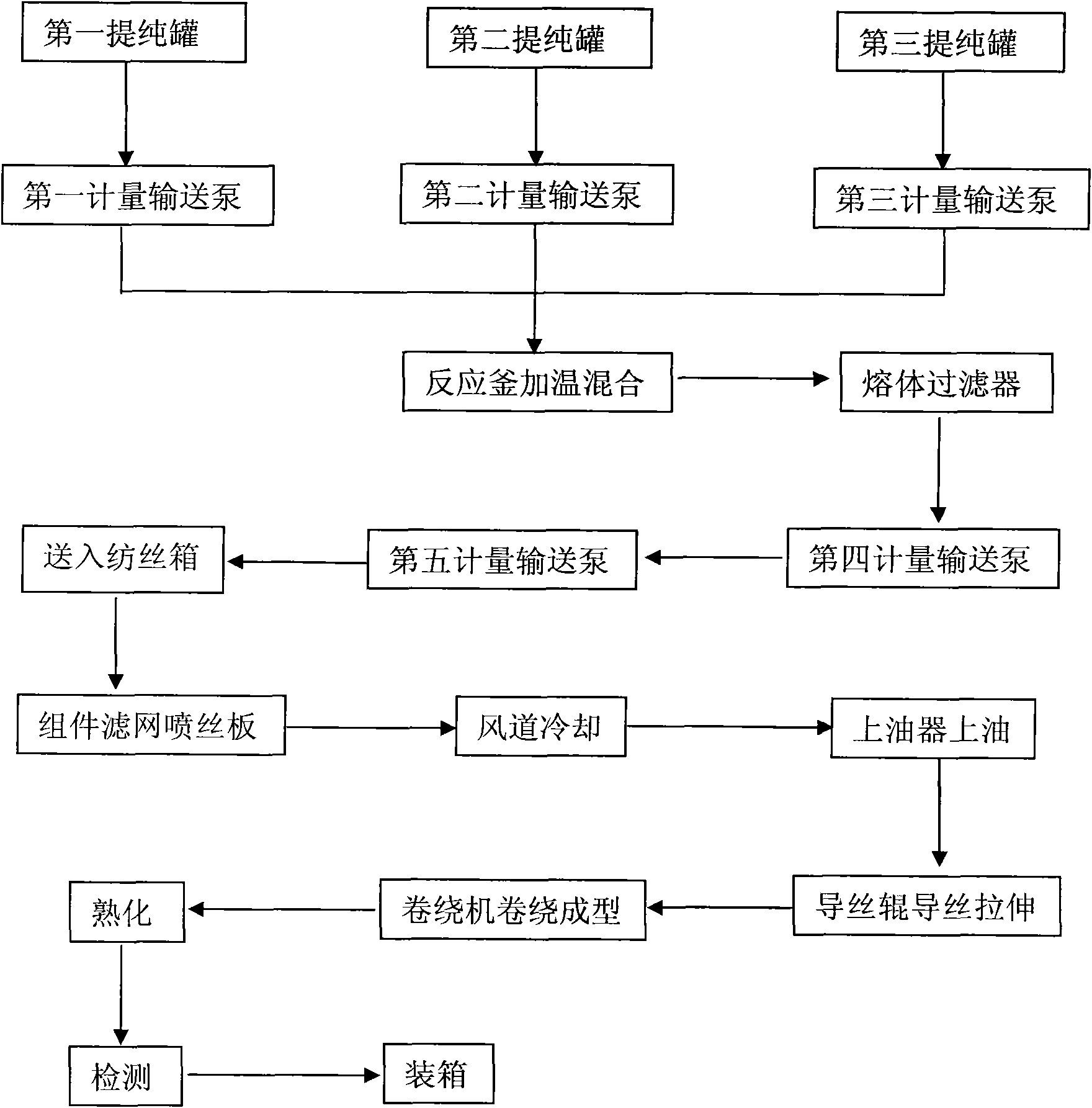

Method for producing melt direct spinning superfine (4.6-5.5) denier high elastic modulus polyurethane fibers

InactiveCN102021673AImproved elongation and uniformityLow bending stiffnessSpinning head liquid feederFilament/thread formingSpontaneous reactionMoisture

The invention provides a method for producing melt direct spinning superfine (4.6-5.5) denier high elastic modulus polyurethane fibers, which is characterized by comprising the following steps: raw materials, charging under negative pressure, addition of 0.8MPa nitrogen pressure, high-temperature spontaneous reaction in two static reactors in turn, a double-screw extruder, filtration in a melt filter, jetted yarn cooling in an air duct, oiling by an oiling machine, curing in a drying room and detecting and casing. The method has the following advantages: the superfine denier polyurethane fibers have low bending stiffness and quite soft feel; the surface areas of the fibers are large, thus obviously improving the coverage, bulkiness and heat retention of the fabrics and having extremely strong cleaning function; the superfine fibers are made into superhigh density fabrics and the size of the gaps between the fibers range from the diameter of the water drops to the diameter of the vapor droplets, thus having waterproof and non-airproof effects; and the superfine fibers are processed into such fabrics which can be moistened by water as towels and the towels have high water absorbability and can rapidly absorb the moisture of the washed hairs to rapidly dry the hairs. The method can be applied in various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

High-moisture-absorption four-groove polyester fiber fabric

PendingCN109397804AGuaranteed drynessImprove moisture absorption capacitySynthetic resin layered productsFilament/thread formingPerspirationFiber layer

The invention discloses a high-moisture-absorption four-groove polyester fiber fabric, which comprises a fabric main body, polyester fiber weft yarns, polyester fiber warp yarns and a high-moisture-absorption assembly, wherein the fabric main body comprises a plurality of polyester fiber weft yarns and polyester fiber warp yarns; the quantity of the polyester fiber weft yarns and the polyester fiber warp yarns is respectively two or more than two groups; the two adjacent groups of polyester fiber weft yarns are respectively woven on the upper and lower end surfaces of the polyester fiber warpyarns; the two adjacent groups of polyester fiber warp yarns are respectively woven on the upper and lower end surfaces of the polyester weft yarns. Through the high heat dispersion performance of a mica fiber layer, sweat can be fast volatilized, and thus the dryness of the high-moisture-absorption assembly is ensured, so that the moisture absorption capability of the high-moisture-absorption assembly is improved; and the cross section of the polyester fiber is in a unique cross shape, and the fiber surface area is larger than the conventional round cross section, so that the adhesion area ofthe sweat is increased, and the perspiration performance is improved.

Owner:HUAXIANG (CHINA) HIGH FIBER CO LTD

Polycaprolactone silk fibroin electrospun fiber membrane with continuous lamellar micro-nano structure on the surface and its preparation method and application

The invention discloses a polycaprolactone and silk fibroin electrospun fibrous membrane with the surface of a continuous laminated micro-nano structure and a preparation method and application thereof. The preparation method comprises the steps that 1, silk fibroin and polycaprolactone are dissolved into hexafluoroisopropanol and are stirred and dissolved at room temperature to obtain a mixed solution; 2, electrostatic spinning is performed on the mixed solution to prepare a polycaprolactone and silk fibroin blended membrane; 3, vacuum drying is performed on the polycaprolactone and silk fibroin blended membrane, then, the polycaprolactone and silk fibroin blended membrane is subjected to a heating reaction with a PCL monomer and a stannous octoate catalyst under the nitrogen protection, and the polycaprolactone and silk fibroin electrospun fibrous membrane is obtained. The polycaprolactone and silk fibroin electrospun fibrous membrane obtained through the preparation method has the surface layer laminated micro-nano structure fiber morphology, the specific surface area and the fiber diameter are greatly increased, the probability that the hydrophobicity of the electrospun membrane is converted into hydrophile is increased, the fiber specific surface area is greatly increased, and the space maintaining capacity, the dynamic mechanics performance and the degradation performance are greatly improved.

Owner:KUNMING MEDICAL UNIVERSITY

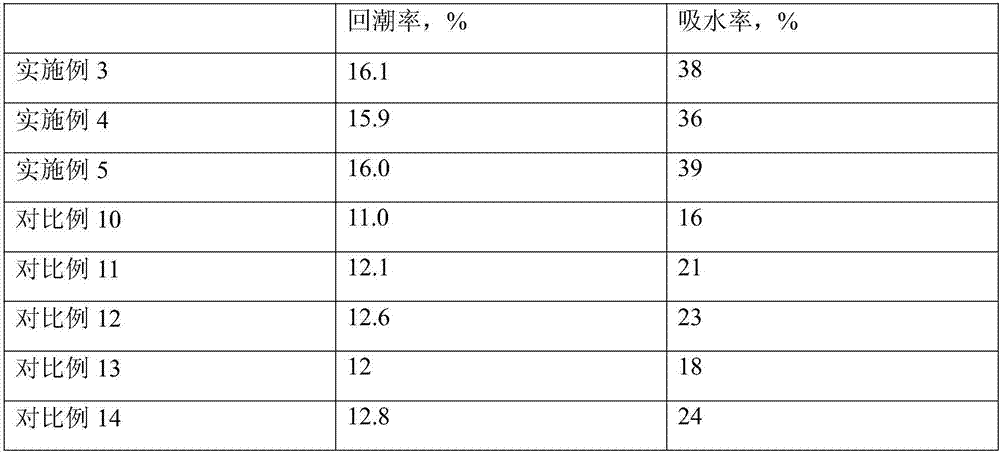

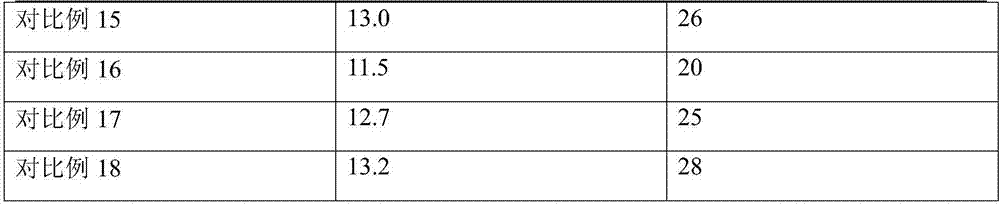

Technology for preparing stretch-proof fabric with high moisture absorption and moisturizing performance from silk

InactiveCN107338651AGood moisturizing performanceHigh degree of bindingAnimal fibresDichloromethaneMonomethoxypolyethylene glycol

The invention provides a technology for preparing stretch-proof fabric with high moisture absorption and moisturizing performance from silk. The technology comprises the steps as follows: silk is sequentially subjected to degumming and swelling treatment, methoxy polyethylene glycol and dichloromethane are added and uniformly mixed, acetic acid is added and uniformly mixed, a Jones reagent is dropwise added, temperature adjustment, stirring, filtration and washing are performed, and prefabricated silk fiber is obtained; the prefabricated silk fiber is aired, then dipped in a moisturizing solution, left to stand, dried, dipped in a silk fibroin aqueous solution and taken out, the extra solution on the surface is removed, ethanol steam setting, washing and drying are performed, and the stretch-proof fabric with high moisture absorption and moisturizing performance is obtained. The obtained silk fabric has excellent moisture absorption up to 39% or above, cannot break easily, has good toughness and excellent mechanical performance and has the breaking strength up to 576 Mpa and elongation at break up to 126% or above.

Owner:长沙善道新材料科技有限公司

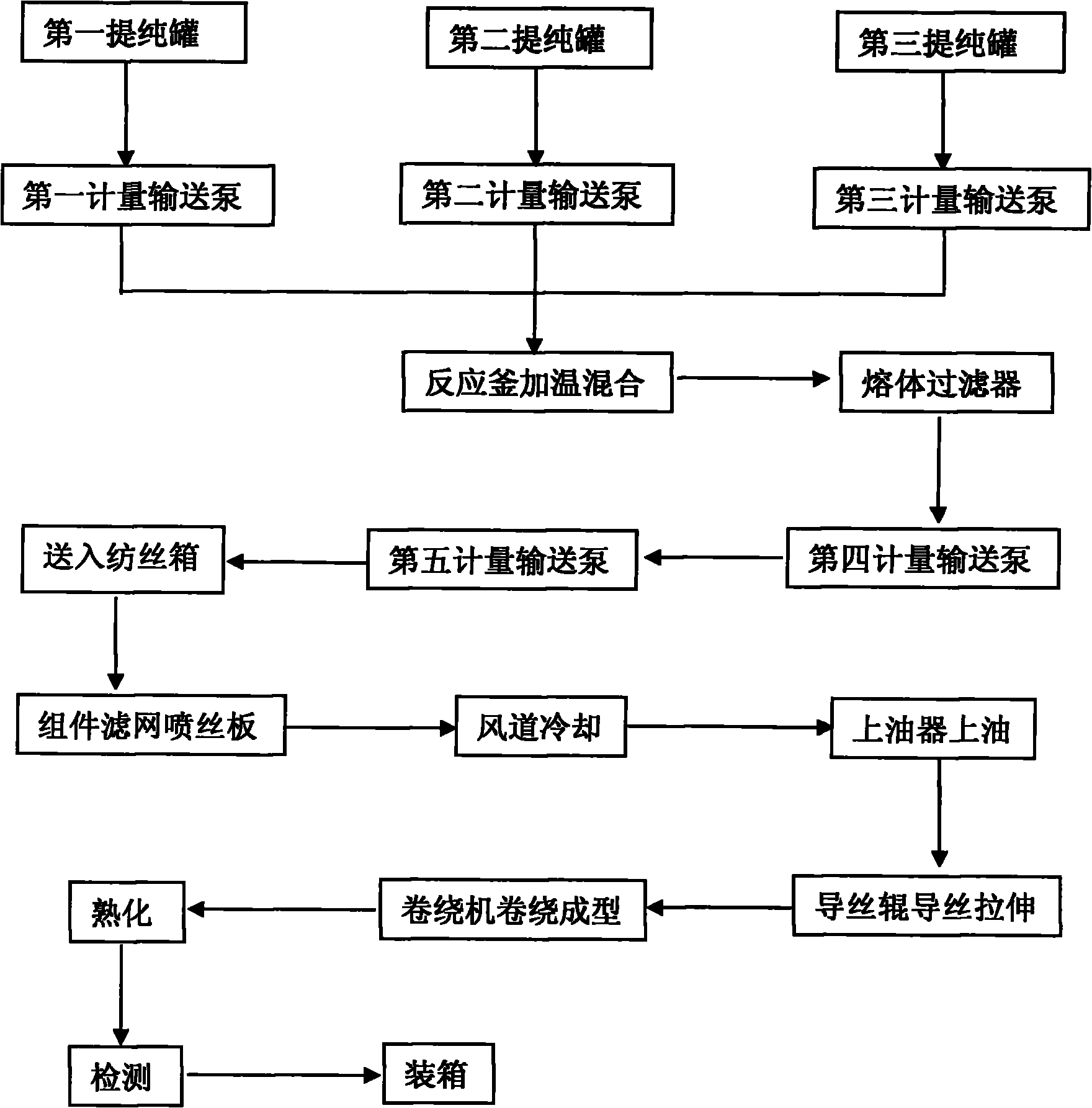

Melt spinning method of superfine denier spandex fibers through reaction in single static reaction kettle

InactiveCN102080274AImprove water absorptionIncrease fiber surface areaArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentThermal insulationMicrofiber

The invention provides a melt spinning method of superfine denier spandex fibers through the reaction in a single static reaction kettle. The method is characterized by comprising the following steps: taking raw material components; feeding under a negative pressure; applying the nitrogen pressure of 0.8MPa; carrying out a high-temperature natural reaction in the static reaction kettle; conveying the materials to a double screw extruder; filtering by a melt filter; cooling the ejected silk via an air channel; applying oil by an oiling device; drawing guide silk by a two-pass silk guide roller; and curing in a drying room, detecting and packing. The obtained superfine denier spandex fibers have the advantages of small bending rigidity and particularly soft hand feeling; meanwhile the surface area of the fibers is very large, thus the coverage, bulkiness and thermal insulation property of fabrics are obviously improved and the extremely strong cleaning function is achieved; the superfine fibers can be made into super-high density fabrics, and the clearances among the fibers are remained between droplet diameter and steam microdrop diameter, thus having waterproof and air permeability effects; and when the fibers are processed into wettable towel fabrics, the moisture can be quickly absorbed from washed hair so as to quickly dry hair by utilizing the towel with high water absorbability. The obtained superfine denier spandex fibers can be applied to various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com