High-moisture-absorption four-groove polyester fiber fabric

A polyester fiber, high moisture absorption technology, applied in the field of textile fabrics, can solve the problems of poor perspiration performance and poor moisture absorption ability, and achieve the effect of improving perspiration performance, improving moisture absorption capacity, and increasing the adhesion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

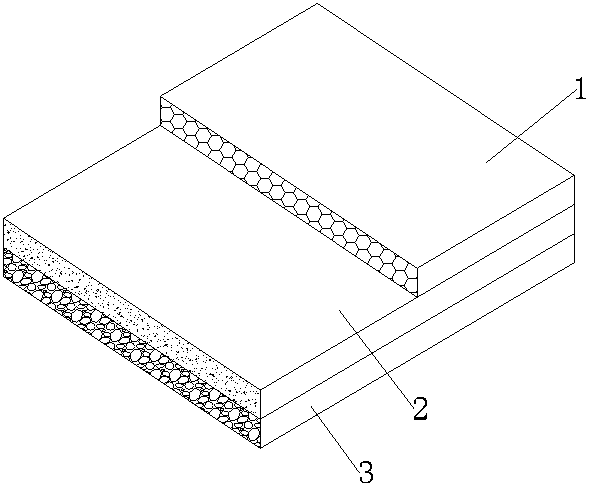

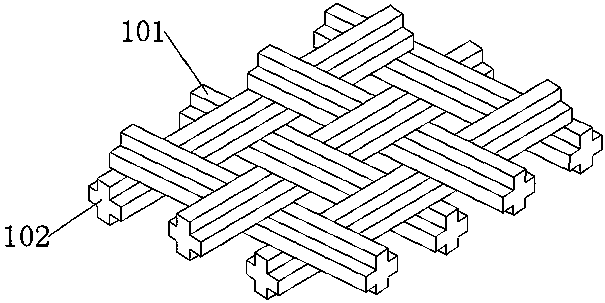

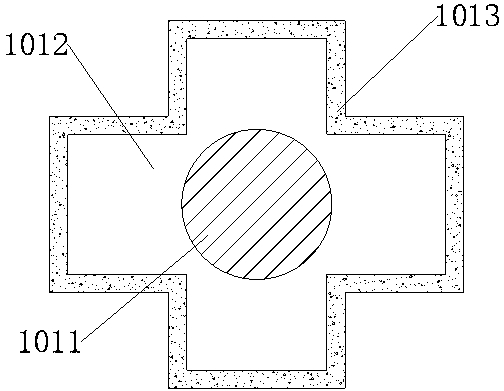

[0020] refer to Figure 1-4 , a high moisture absorption four-groove polyester fiber fabric, comprising fabric main body 1, polyester fiber weft 101, polyester fiber warp 102 and high moisture absorption component 2, fabric main body 1 includes a number of polyester fiber weft 101 and polyester fiber warp 102, polyester fiber The weft 101 and the polyester fiber warp 102 are provided with more than two groups, and the adjacent two groups of polyester fiber wefts 101 are respectively woven on the upper and lower ends of the polyester fiber warp 102, and the adjacent two groups of polyester fiber warp 102 are respectively woven on the polyester fiber weft. On the upper and lower ends of 101, the polyester fiber weft 101 and the polyester fiber warp 102 are woven interlacedly, the inside of the polyester fiber weft 101 is filled with a polyester filling layer 1012, and the lower end surface of the fabric main body 1 is provided with a high moisture absorption component 2, and the ...

Embodiment 2

[0022] refer to figure 2 and image 3 , a high moisture absorption four-groove polyester fiber fabric, which is basically the same as Example 1, the cross-sectional area and length of the polyester fiber weft 101 and the polyester fiber warp 102 are the same, and the polyester fiber weft 101 and the polyester fiber warp 102 are vertically arranged, so that The polyester fiber weft threads 101 and the polyester fiber warp threads 102 are evenly arranged, thereby enhancing the tensile strength of the fabric main body 1 .

[0023] Furthermore, the inside of the polyester fiber weft 101 and the polyester fiber warp 102 are provided with through holes, and the inside of the through hole is connected with an elastic fiber core 1011, and the elastic fiber core 1011 can be stretched along the polyester fiber weft 101. When the fabric When the main body 1 is deformed, the polyester fiber weft 101 and the elastic fiber core 1011 inside the polyester fiber warp 102 are extended under f...

Embodiment 3

[0025] refer to figure 2 and image 3 , a highly hygroscopic four-groove polyester fiber fabric, which is basically the same as Example 1, furthermore, the outer wall of the polyester fiber weft 101 and the polyester fiber warp 102 is provided with a conductive fiber layer 1013, when the fabric main body 1 is in a dry environment , it is easy to generate static electricity due to friction. At this time, the conductive fiber layer 1013 eliminates the static electricity by ground discharge or corona discharge, thereby realizing the antistatic effect, and the inner wall size of the conductive fiber layer 1013 is equal to the polyester fiber weft 101 and the polyester fiber weft 101. The size of the outer wall of the fiber warp 102 realizes the close and seamless fit of the conductive fiber layer 1013 and the polyester fiber weft 101, and the conductive fiber layer 1013 can be bent to ensure that the conductive fiber layer 1013 still has Anti-static effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com