Melt spinning method of superfine denier spandex fibers through reaction in single static reaction kettle

A technology of spandex fiber and reactor, which is applied in the direction of melt spinning, fiber treatment, fiber chemical characteristics, etc., to achieve the effects of improved elongation and uniformity, high water absorption, and soft fiber feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

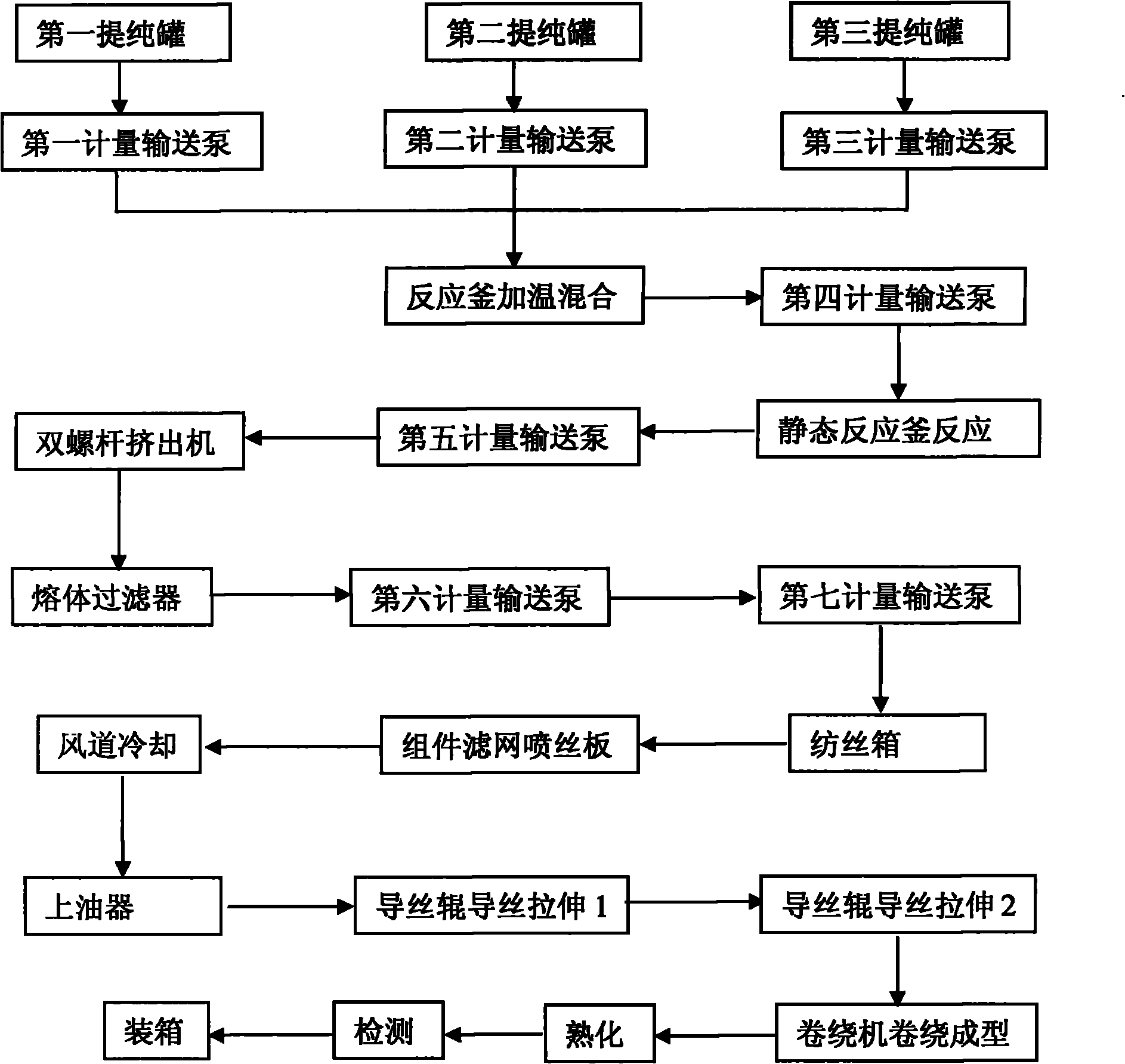

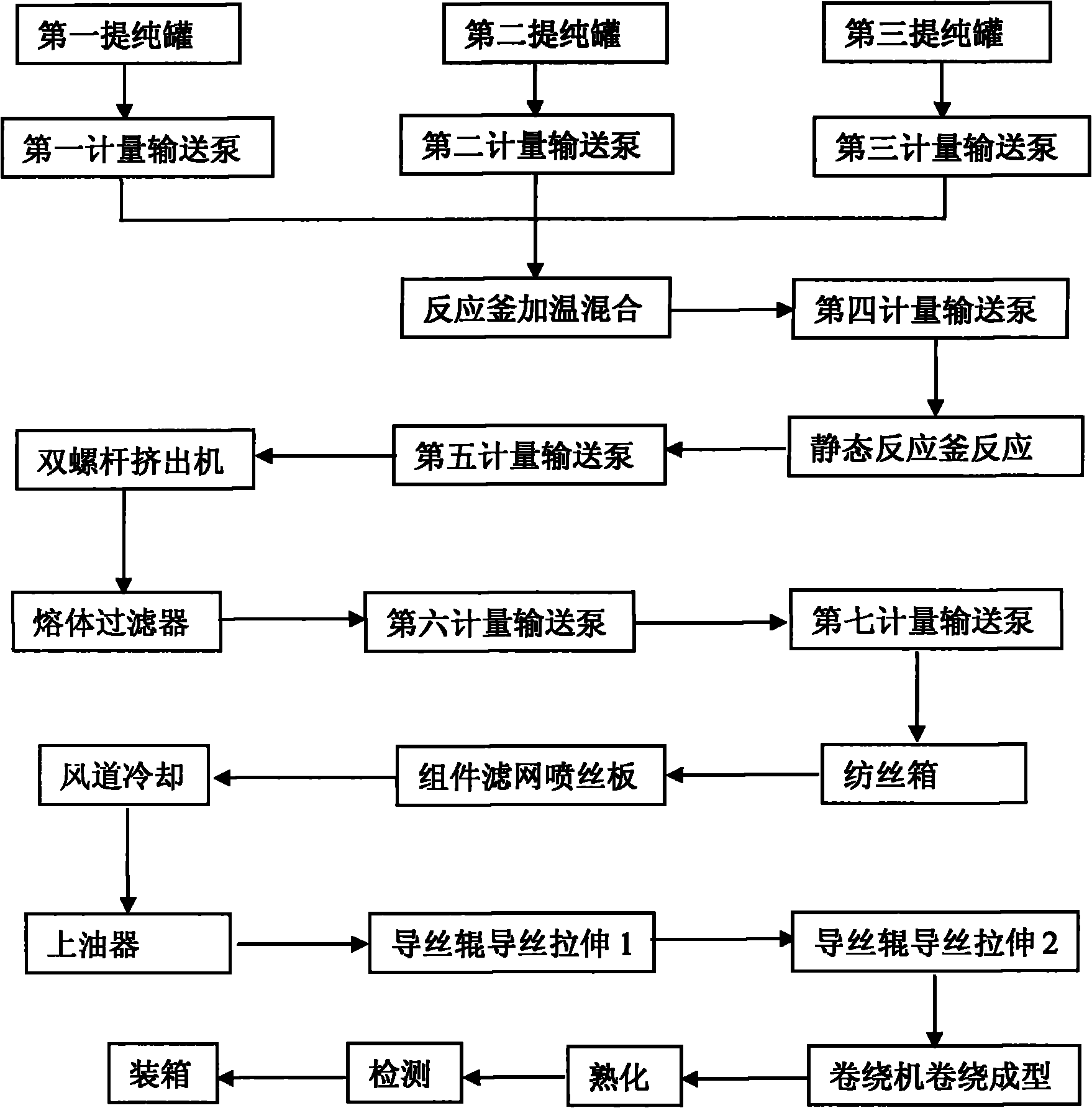

Image

Examples

Embodiment 1

[0018] 1. Take 75 kg of polyester polyol, 20 kg of isocyanate, and 5 kg of butanediol;

[0019] 2. Negative pressure feeding, evacuate to negative 0.8MPa pressure, add polyester polyol raw material into the first purification tank through the first feeding valve set on the first purification tank, temperature 103-105 ℃, heat for 45 minutes Purify; the raw material butanediol is added into the second purification tank through the second feeding valve arranged on the second purification tank, the temperature is 106-108 ° C, and it is purified by heating for 45 minutes; the isocyanate is purified through the The third feeding valve is added to the third purification tank, the temperature is 110-112 ° C, and the heating is carried out for 50-55 minutes for purification;

[0020] 3. Add 0.8MPa nitrogen pressure, pass the raw material in the first purification tank through the first metering delivery pump, the raw material in the second purification tank through the second met...

Embodiment 2

[0027] 1. Take 62 kg of polyester polyol, 30 kg of isocyanate, and 8 kg of butanediol;

[0028] 2. Negative pressure feeding, vacuumize to negative 0.8MPa pressure, feed polyester polyol raw material into the first purification tank through the first feeding valve installed on the first purification tank, temperature 103-105 °C, heat 41- Purify in 45 minutes; the raw material butanediol is added into the second purification tank through the second feed valve installed on the second purification tank, the temperature is 106-108 ° C, and heated for 50 minutes for purification; isocyanate is purified by setting in the third purification tank Add the third feeding valve on the top into the third purification tank at a temperature of 110-112°C and heat for 53 minutes for purification;

[0029] 3. Add 0.8MPa nitrogen pressure, pass the raw material in the first purification tank through the first metering delivery pump, the raw material in the second purification tank through ...

Embodiment 3

[0036] 1. Take 70 kg of polyester polyol, 25 kg of isocyanate, and 5 kg of butanediol;

[0037] 2. Negative pressure feeding, vacuumize to negative 0.8MPa pressure, feed polyester polyol raw material into the first purification tank through the first feeding valve installed on the first purification tank, temperature 103-105 °C, heat 41- Purify in 45 minutes; the raw material butanediol is added into the second purification tank through the second feed valve installed on the second purification tank, the temperature is 106-108 ° C, and it is heated for 54 minutes for purification; isocyanate is purified by setting in the third purification tank Add the third feeding valve on the top into the third purification tank at a temperature of 110-112°C and heat for 55 minutes for purification;

[0038] 3. Add 0.8MPa nitrogen pressure, pass the raw material in the first purification tank through the first metering delivery pump, the raw material in the second purification tank th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com