Epoxy resin composition as well as prepreg and laminated board made of same

A technology of epoxy resin and prepreg, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of high dielectric loss tangent, Tg drop, signal attenuation, etc., to ensure stability and consistency, high glass transition temperature, heat resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

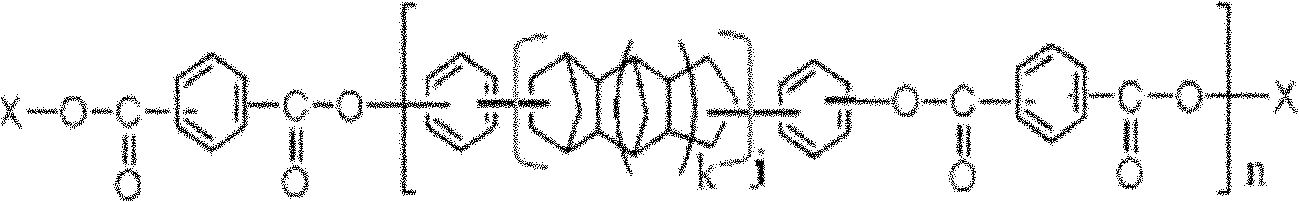

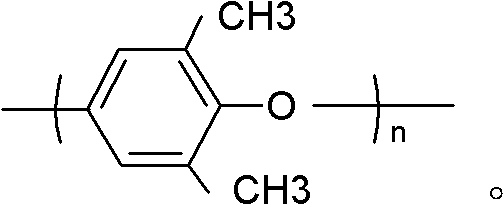

[0039] Add 100g of dicyclopentadiene epoxy resin (brand: HP-7200H Japan DIC company, epoxy equivalent: 272~284) in the beaker, then add modified PPO (polyphenylene ether) resin 100g (self-made, Mn= 1000~5000), active ester curing agent 130g (Japan DIC company, brand: 94605), start the mixer, stir the above components evenly, then add 0.3g of imidazole curing accelerator, adjust the solid content of the glue to an appropriate level with methyl ethyl ketone Viscosity, and finally add spherical silicon differential, BT-93 flame retardant, dispersing aid, etc. Stir at room temperature for 6-8 hours to mature, take the glass fiber cloth for impregnation and gluing, and perform semi-curing treatment in an oven to make a prepreg. Finally, the 8 prepregs prepared above were stacked neatly, covered with 1OZ copper foil on both sides, and cured in a hot oil press at a curing condition of 200°C / 120min to obtain a copper-clad laminate. The properties of the board are shown in the table b...

Embodiment 2

[0041] Manufacturing process and condition are as embodiment 1, change resin ratio as shown in the table below;

Embodiment 3

[0043] Manufacturing process and condition are as embodiment 1, change resin ratio as shown in the table below;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com