High speed processing method for realizing superfine crystal grain structure on metallic material surface

A technology of metal materials and ultra-fine grains, applied in the field of ultra-fine grain structures, can solve the problems of large consumption of trays and pellets, cumbersome operating procedures, and large surface roughness, achieving strong applicability and simple processing methods , the effect of high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Treatment of pure copper materials using surface high-speed deformation technology:

[0027] Equipment: Surface high-speed deformation processing equipment;

[0028] Spindle speed: 600rpm;

[0029] Deformation strain rate: 10 3 -10 4 the s -1 ;

[0030] Deformation strain: 3-5;

[0031] Deformation temperature: 20°C;

[0032] Processing passes: 8;

[0033] Pure copper material: purity 99.97% (weight percent), annealed at 600° C. for 3 hours, grain size 20 μm.

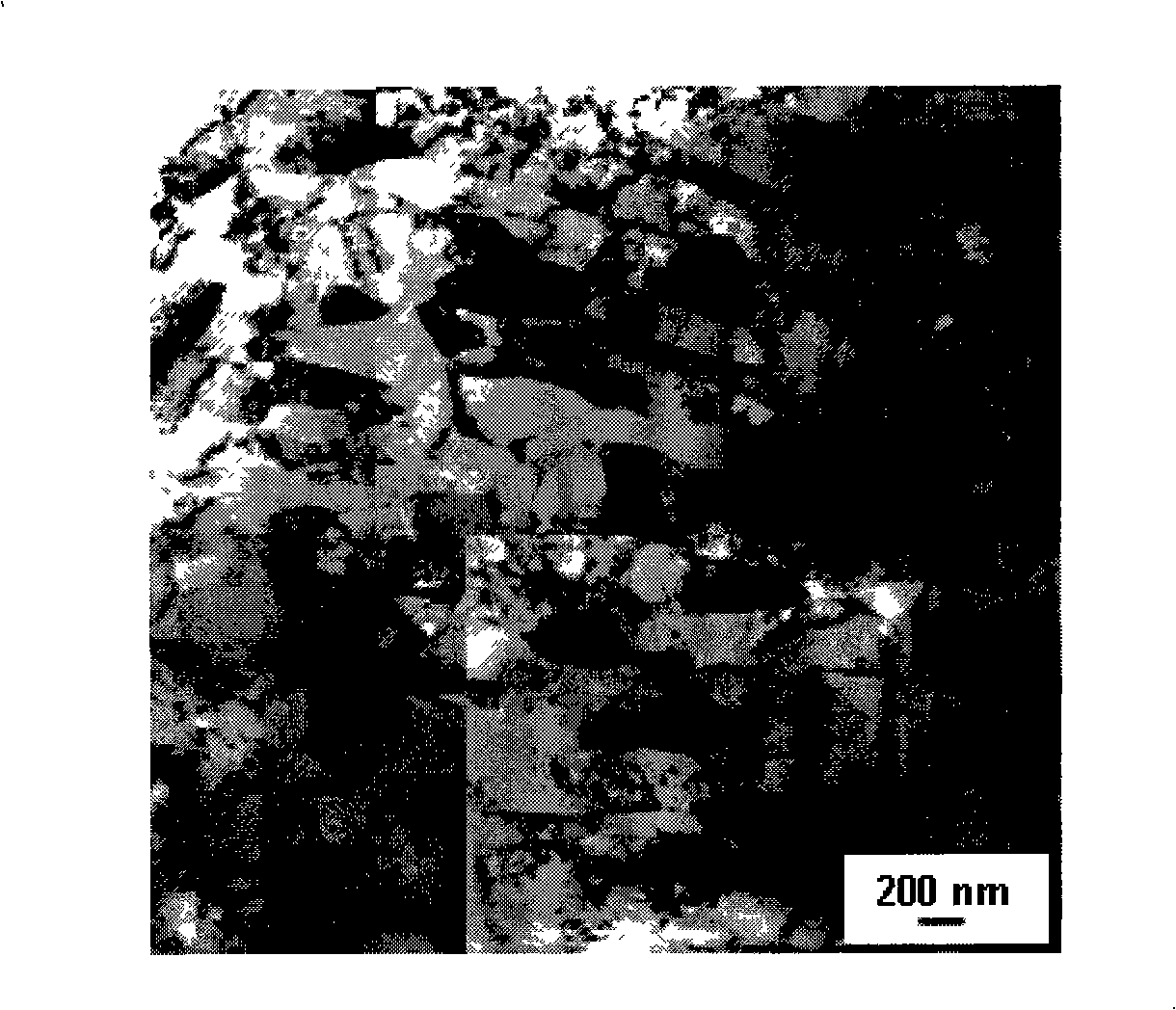

[0034] Treatment to obtain pure copper materials with surface refinement, such as figure 1 , the thickness of the surface layer is about 60 μm, and its microstructure is mainly characterized by nearly equiaxed submicron grains / sub-grains, with a short axis dimension of 164nm and a long axis dimension of 351nm.

Embodiment 2

[0036] Treatment of pure copper materials using surface high-speed deformation technology:

[0037] Equipment: Surface high-speed deformation treatment equipment;

[0038] Spindle speed: 1000rpm;

[0039] Deformation strain rate: 10 3 -10 4 the s -1 ;

[0040] Deformation strain: 3-5;

[0041] Deformation temperature: 20°C;

[0042] Processing passes: 8;

[0043] Pure copper material: purity 99.97%, annealed at 600°C for 3 hours, grain size 20μm.

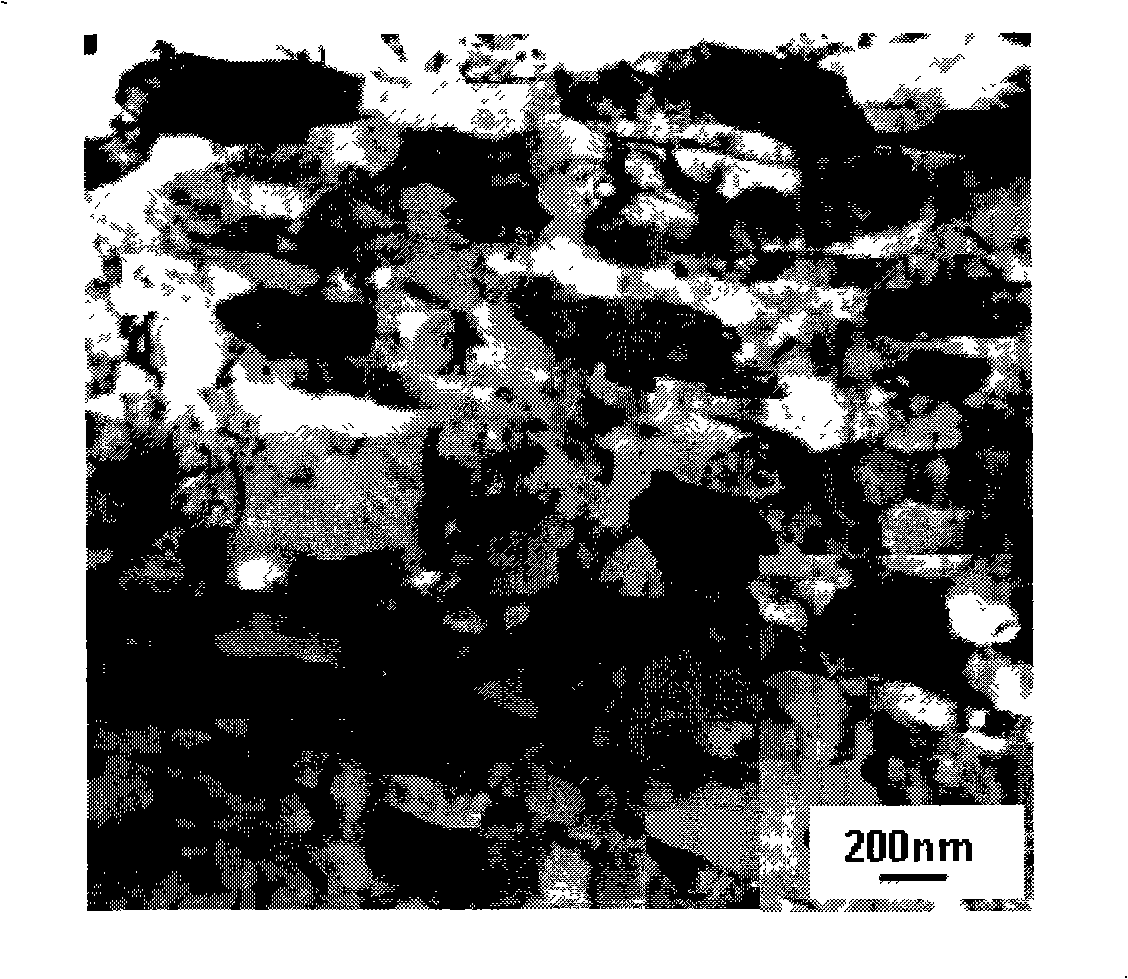

[0044] The processed surface structure is as figure 2 , the thickness of the surface layer is about 30 μm, the short axis dimension is 178nm, and the long axis dimension is 587nm.

Embodiment 3

[0046] Treatment of pure copper materials using surface high-speed deformation technology:

[0047] Equipment: Surface high-speed deformation processing equipment;

[0048] Spindle speed: 600rpm;

[0049] Deformation strain rate: 10 3 -10 4 the s -1 ;

[0050] Deformation strain: 3-5;

[0051] Deformation temperature: 20°C;

[0052] Processing passes: 6;

[0053] Pure copper material: purity 99.97%, annealed at 600°C for 3 hours, grain size 20μm.

[0054] The thickness of the treated surface layer is about 30 μm, the short axis dimension is 158nm, and the long axis dimension is 604nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| deformation temperature | aaaaa | aaaaa |

| deformation temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com