Polylactic resin composition film and preparation method thereof

A technology of polylactic acid resin and composition, which is applied in the direction of coating, etc., can solve the problems of high processing equipment requirements, unfavorable sustainable development, reduction of petroleum resources, etc., achieve good processing fluidity, improve processing difficulties, and improve processing flow sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

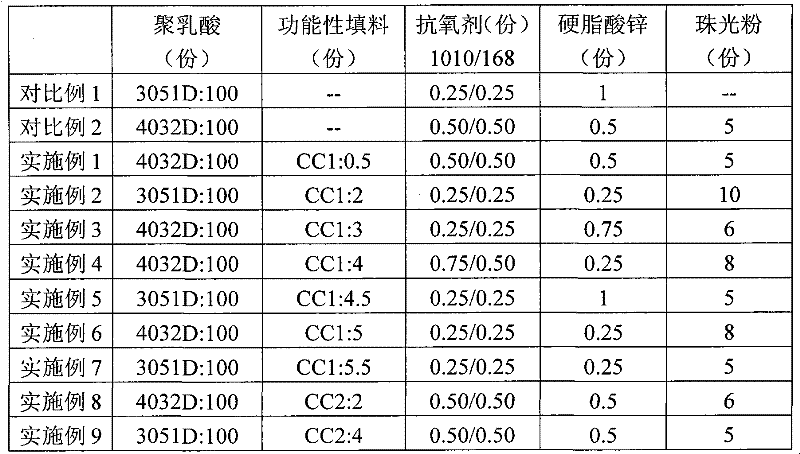

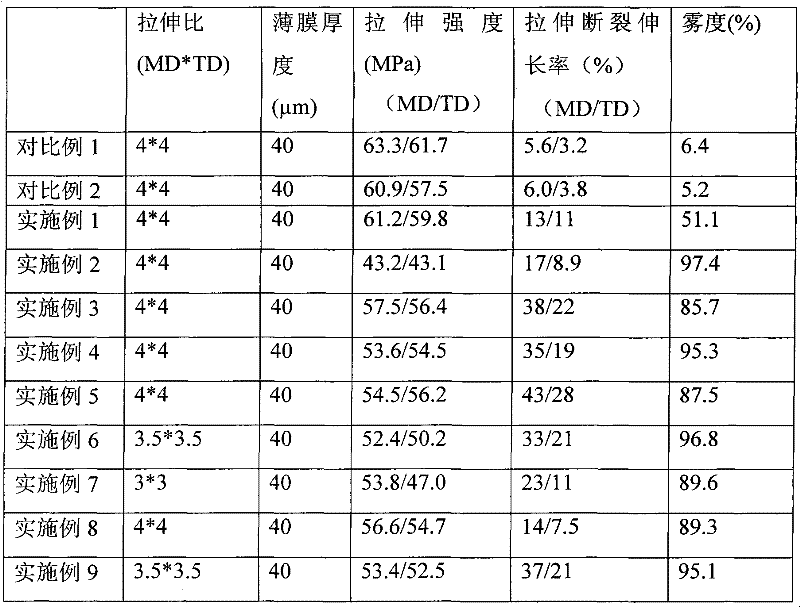

Embodiment 1-9

[0049] The vacuum-dried polylactic acid resin PLA and antioxidant (1010 and 168 weight ratio 1:1 mixture), lubricant zinc stearate, pearl powder, nano Calcium carbonate and / or light calcium carbonate after surface modification treatment by silane coupling agent KH550 are mixed uniformly in a high-speed mixer according to the amount; the mixed materials are added to the feeder of the WP40 twin-screw extruder, The material enters the twin-screw through the feeder, melts and mixes evenly through the screw, extrudes, granulates, and dries. During the processing, the temperature of the screw is kept between 170-200° C., and the rotational speed of the screw is controlled between 200-350 rpm.

[0050] The extruded and dried material is cast into a film with a thickness of 200-500 μm through a casting machine (Shantou Guanghua Machinery Industry Co., Ltd.). , the temperature of barrel zone 2, zone 3, zone 4, ring network zone and diversion zone is 180°C, 170°C, 170°C, 170°C, 170°C r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com