Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

804 results about "Nano crystalline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano crystalline ribbons are fruit of complex engineering techniques. It is a suitable alloy made with sophisticated metallurgy followed by rapid quenching with metal spinning technology having cooling Rate of more than 1 million Degree / Seconds.

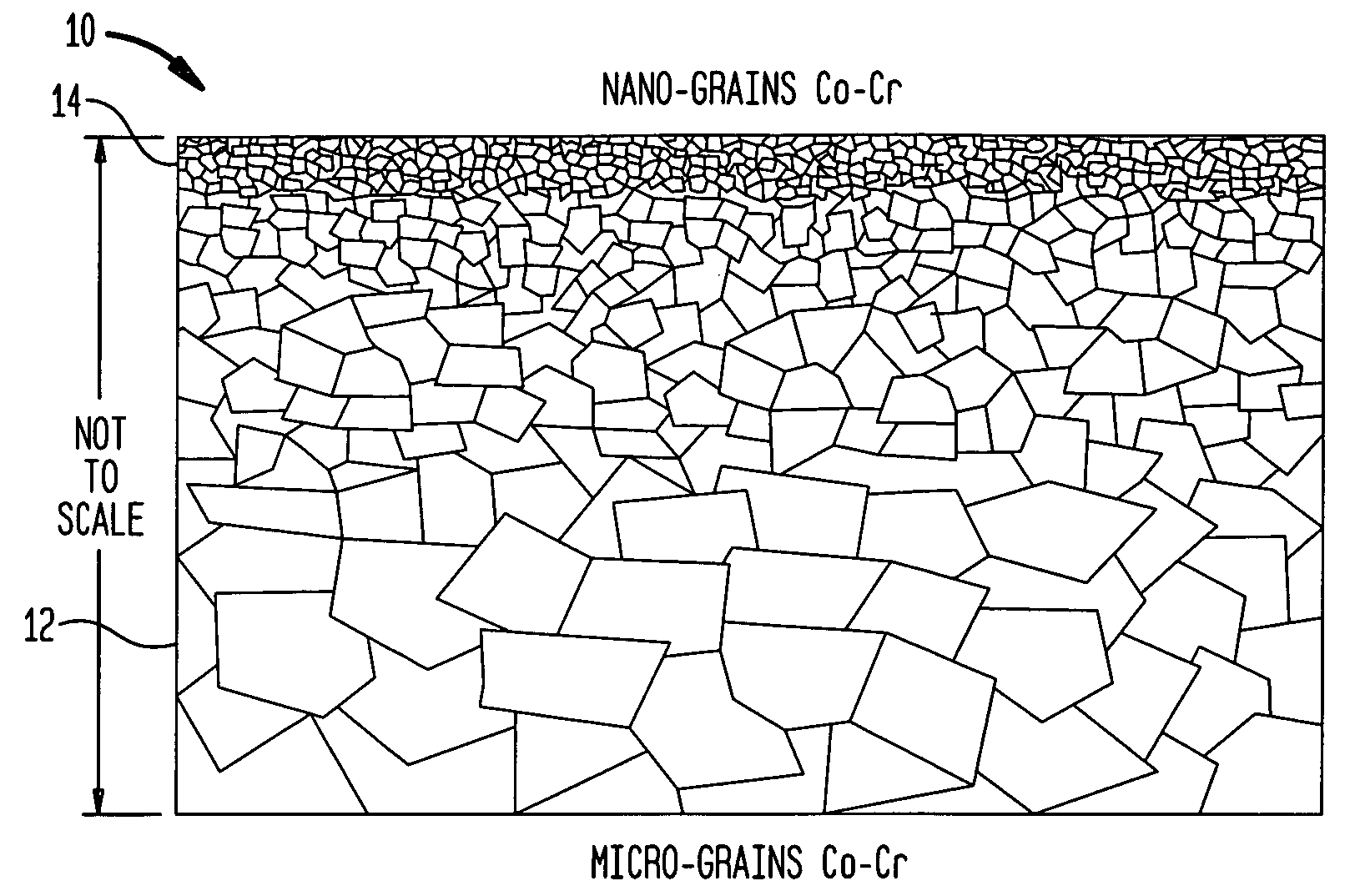

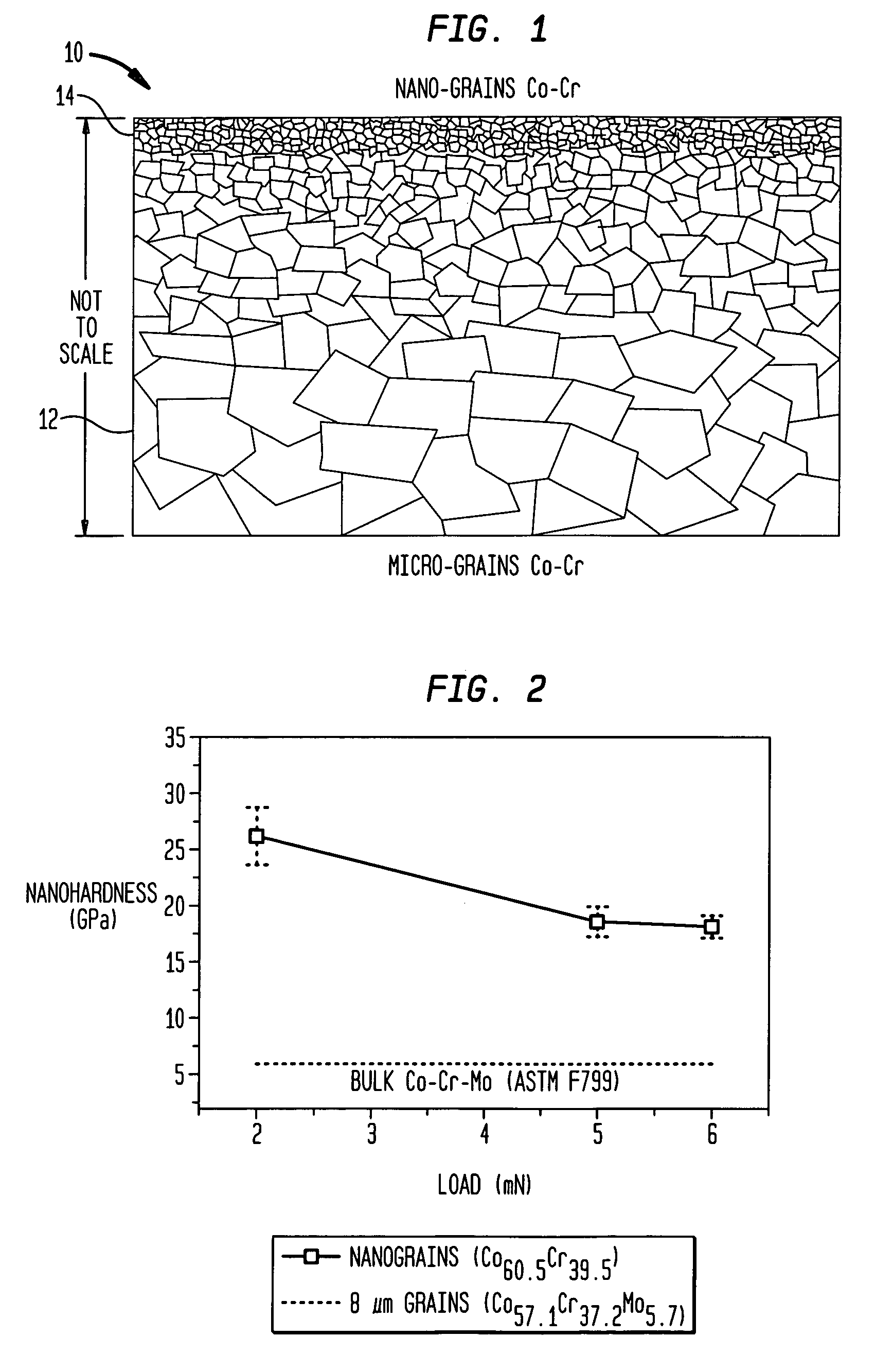

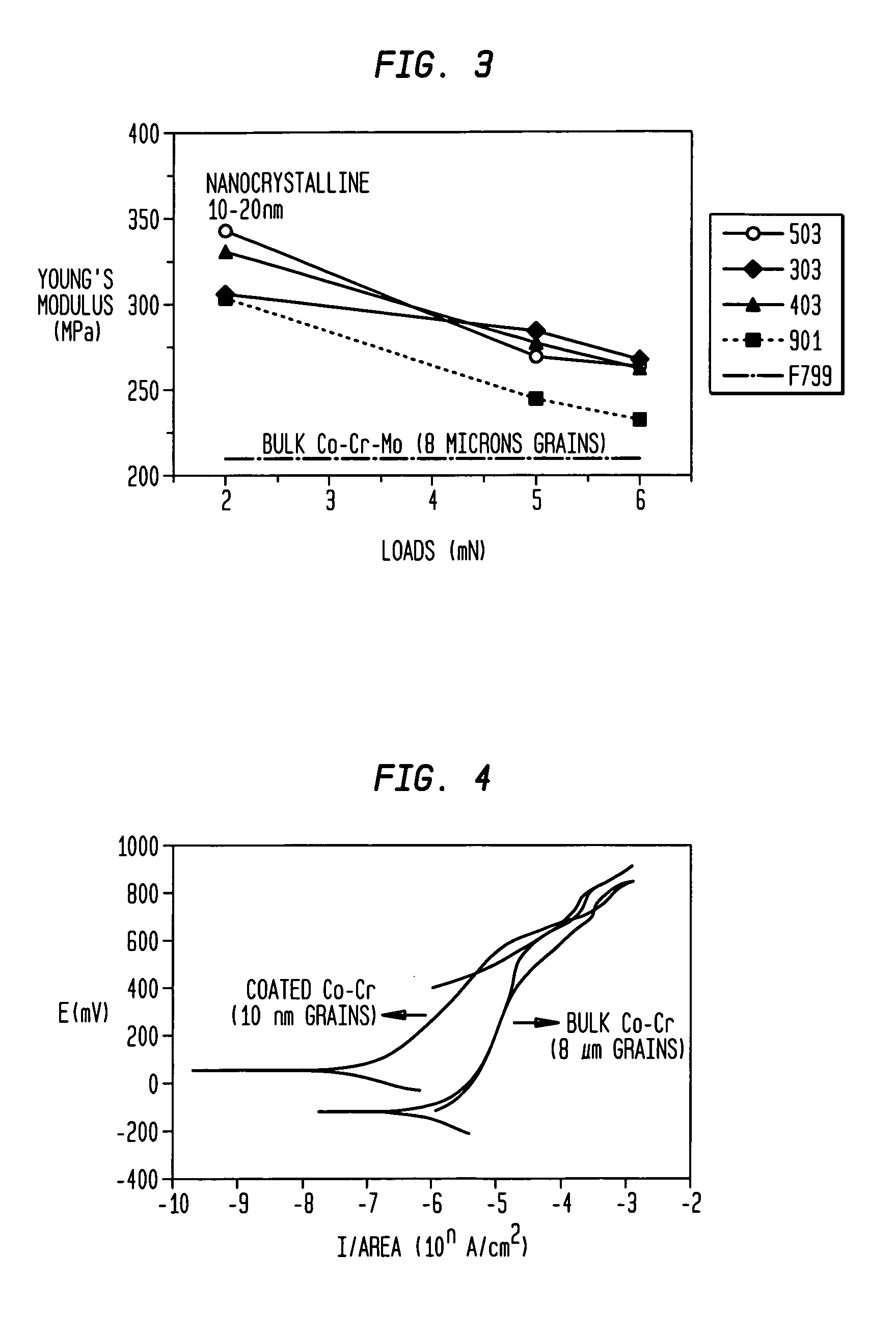

Nano-crystalline, homo-metallic, protective coatings

InactiveUS7048767B2Improve adhesionImpression capsVacuum evaporation coatingHardnessNano crystalline

The present invention provides orthopedic prosthesis having at least one metallic component that includes a metallic substrate on which an integrally formed nano-crystalline coating is formed. The coating and the substrate have at least one metallic constituent in common having an average atomic concentration in the coating that differs from an average atomic concentration in the substrate by less than about 10 percent. Further, the nano-crystalline coatings includes crystalline grains with an average size in a range of about 1 to 999 nanometers, and more preferably in a range of about 10 to 200 nanometers. A transition region that exhibits a graded reduction in average grain size separates the coating from the substrate. The coating advantageously exhibits an enhanced hardness, and a high degree of resistance to corrosion and wear. In one application, the nano-crystalline coatings of the invention are utilized to form articulating surfaces of various orthopedic devices.

Owner:N2 BIOMEDICAL

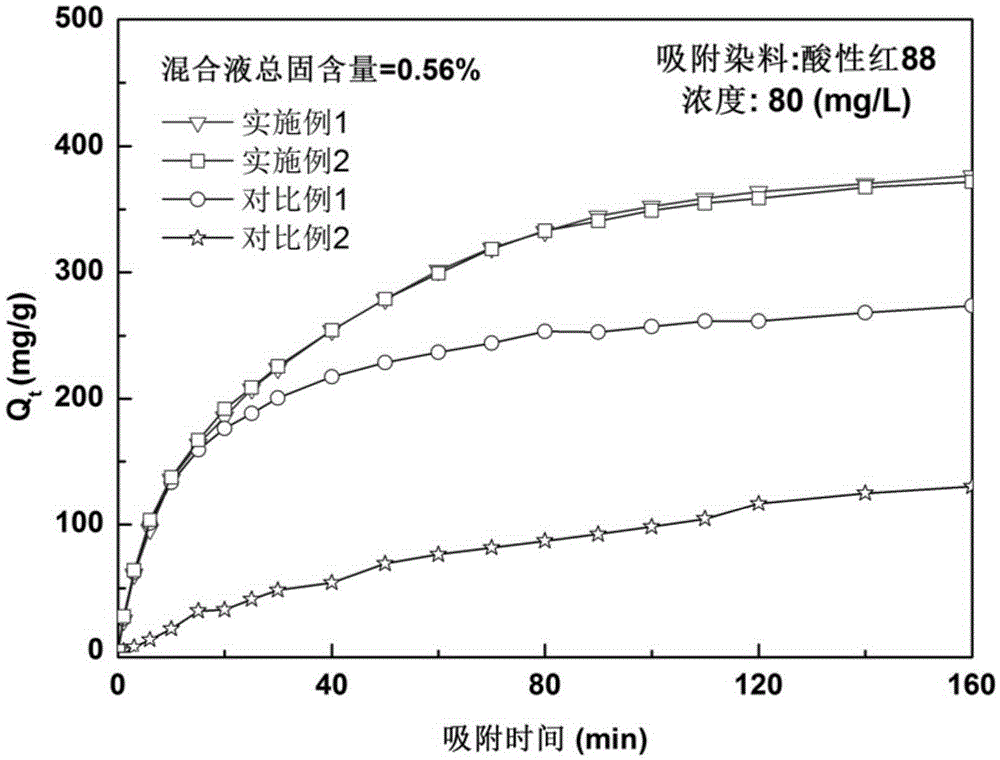

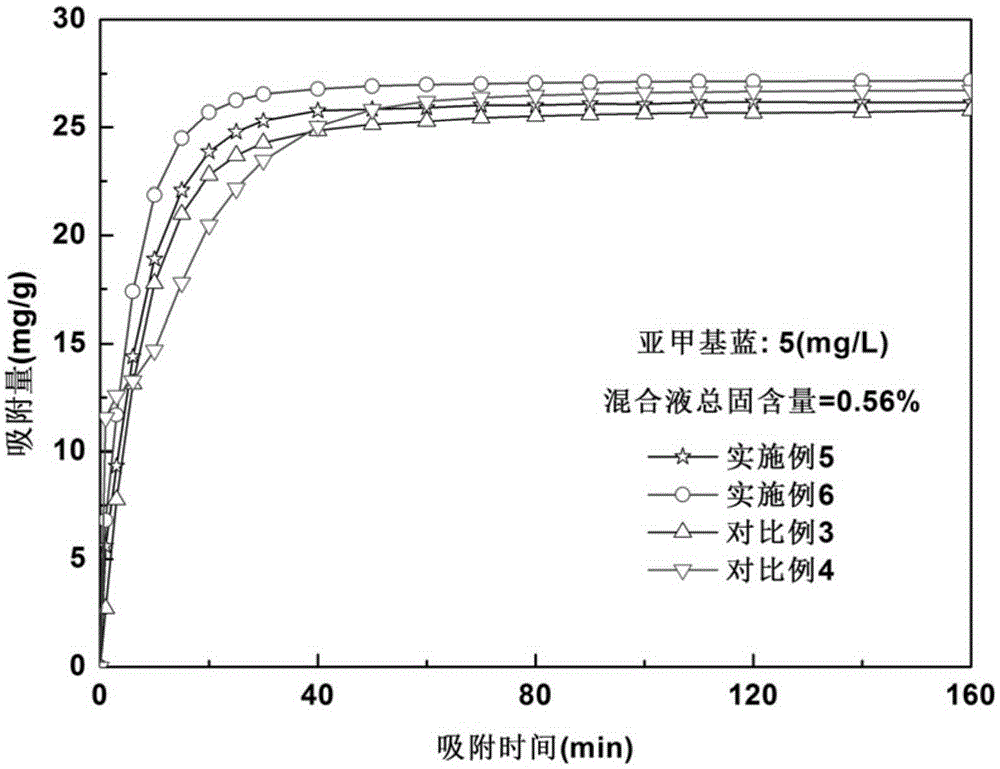

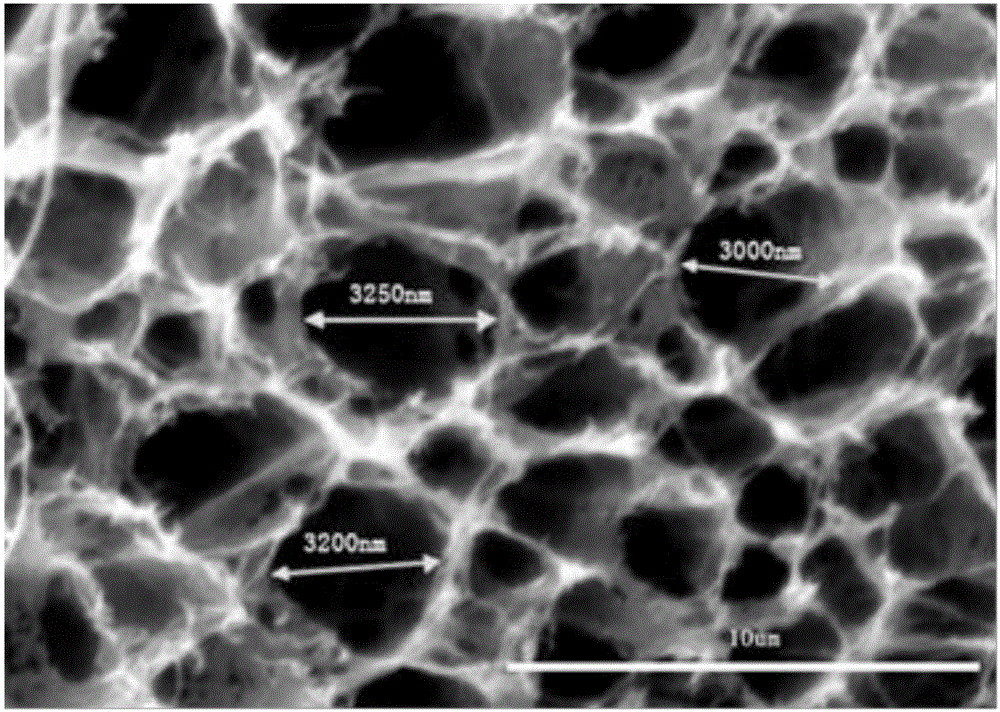

Preparation method of nano-crystalline cellulose-based composite aerogel type organic dye absorption material

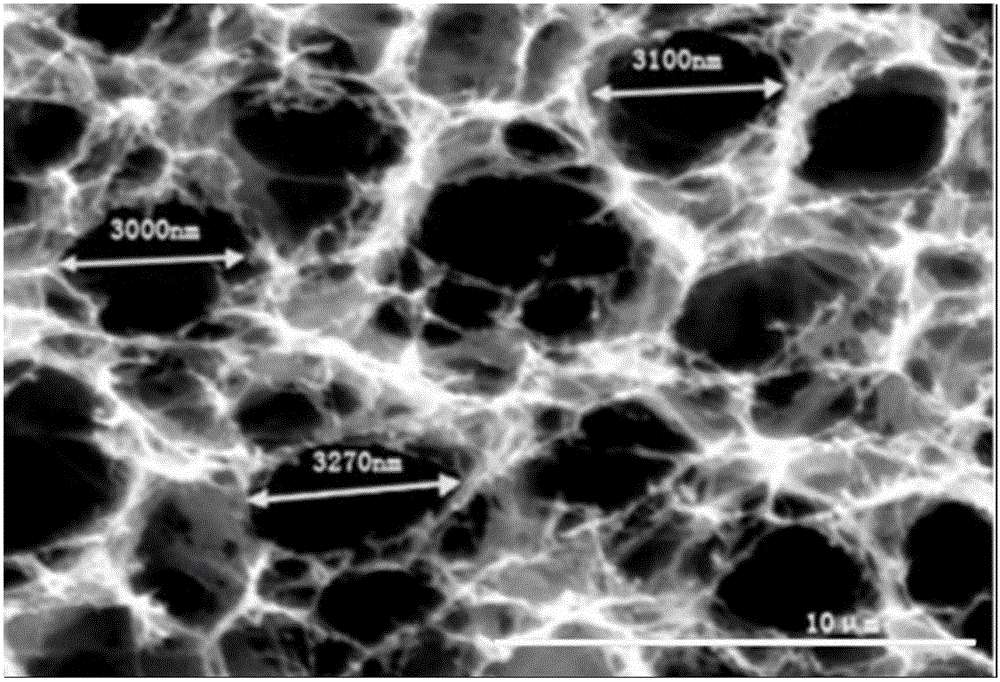

ActiveCN105148868AAdsorption is widely applicableOther chemical processesColloidal chemistry detailsPorosityPretreatment method

The invention discloses a preparation method of a nano-crystalline cellulose-based composite aerogel type organic dye absorption material. The method comprises the following steps: preparing nanofibers having functional surfaces by combining a chemical pretreatment method and a mechanical treatment method; and mixing the nanofibers and a natural absorption material to prepare composite aerogel which is used as the organic dye absorption material, wherein the porosity of the prepared composite aerogel is up to 99% or more, the decolourization ratio of the prepared material on organic dyes can exceed 90%, and the prepared material can be widely applied to absorbing the various water-soluble organic dyes.

Owner:ZHEJIANG FORESTRY UNIVERSITY

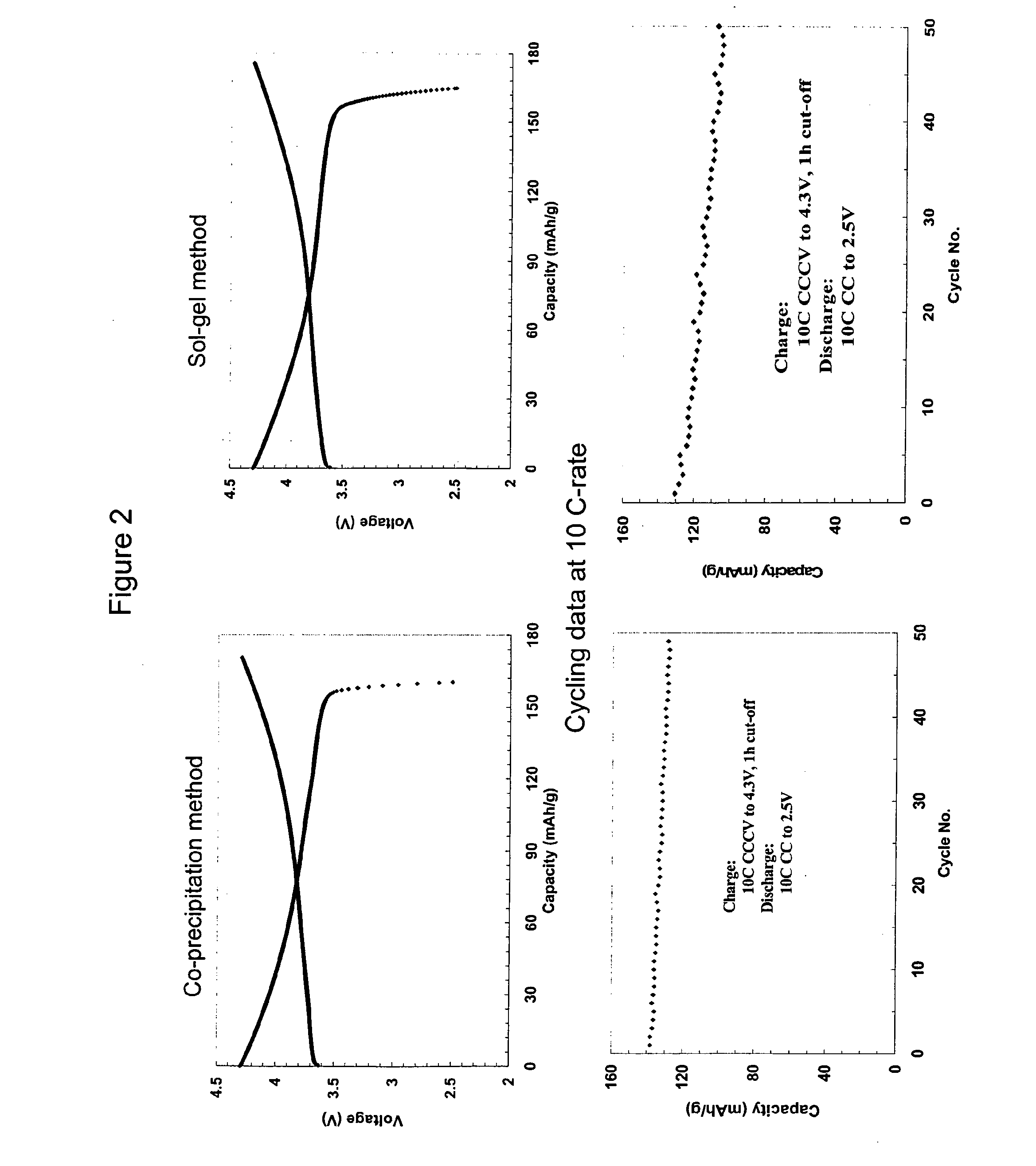

Lithium batteries with nano-composite positive electrode material

ActiveUS20100248033A1Material nanotechnologyElectrode manufacturing processesPhosphateOxidation state

Provided is a positive electrode for a lithium ion battery, the electrode comprising a nano-crystalline layered-layered composite structure of a material having the general formula xLi2MO3(1−x)LiM′O2 in which 0<x<1, where M′ is one or more ion with an average oxidation state of three and with at least one ion being Mn or Ni, and where M is one or more ions with an average oxidation state of four. Another aspect provides a positive electrode for a lithium ion battery, the electrode comprising a nano-crystalline layered-spinel composite structure of a material having the general formula XLi2MnO3. (1−X)LiMn2−yMyO4 in which 0.5<x<1.0, 0≦y<1, and where M is one or more metal cations. Also provided is the positive electrode which comprises a nano-coating of inert oxide, inert phosphate or inert fluoride on the nano-crystalline composite structure. Additional aspects provide a lithium ion battery comprising a negative electrode, an electrolyte and the positive electrode, as well as methods of preparing the positive electrode composite structure and the nano-coating of inert oxide, inert phosphate or inert fluoride.

Owner:EOCELL LTD

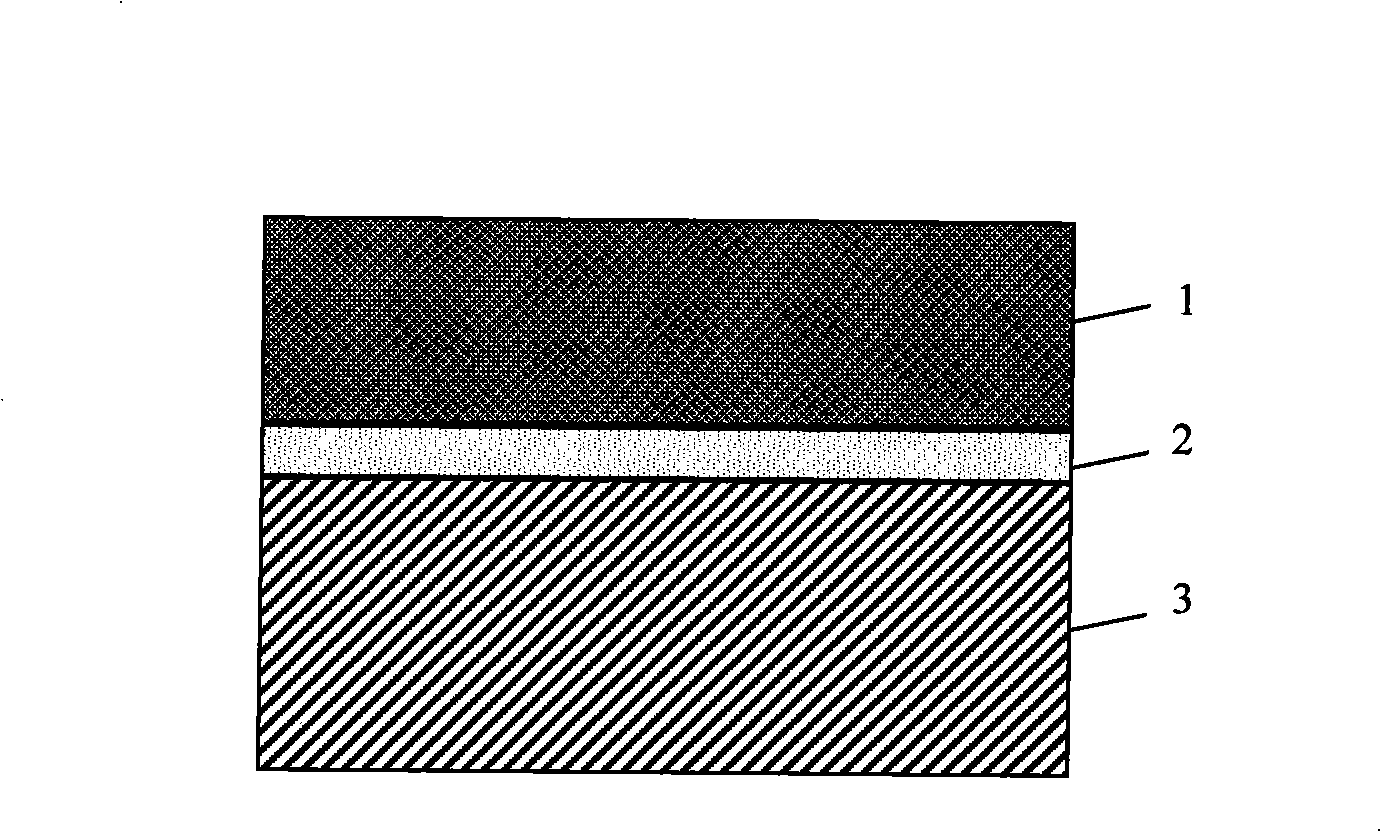

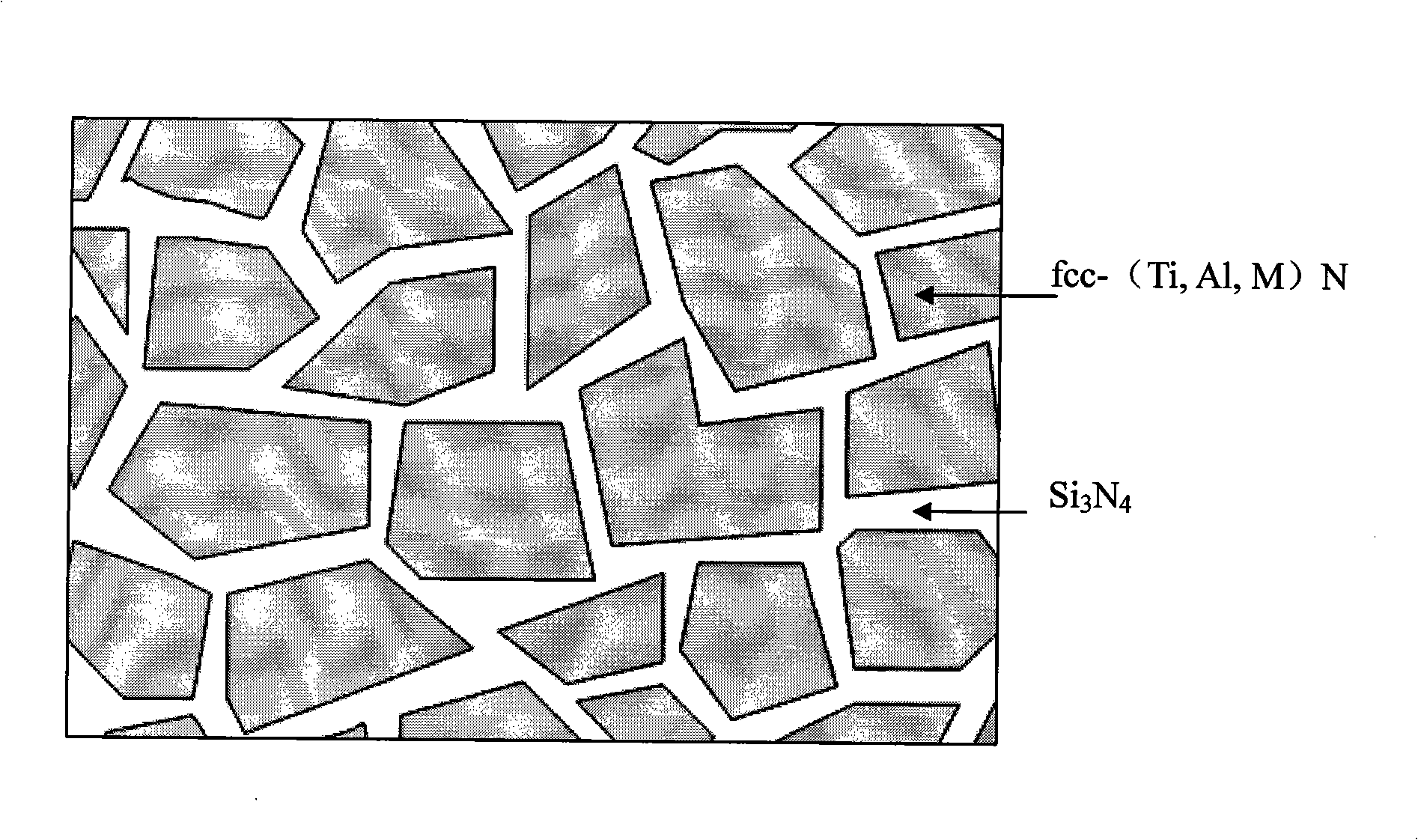

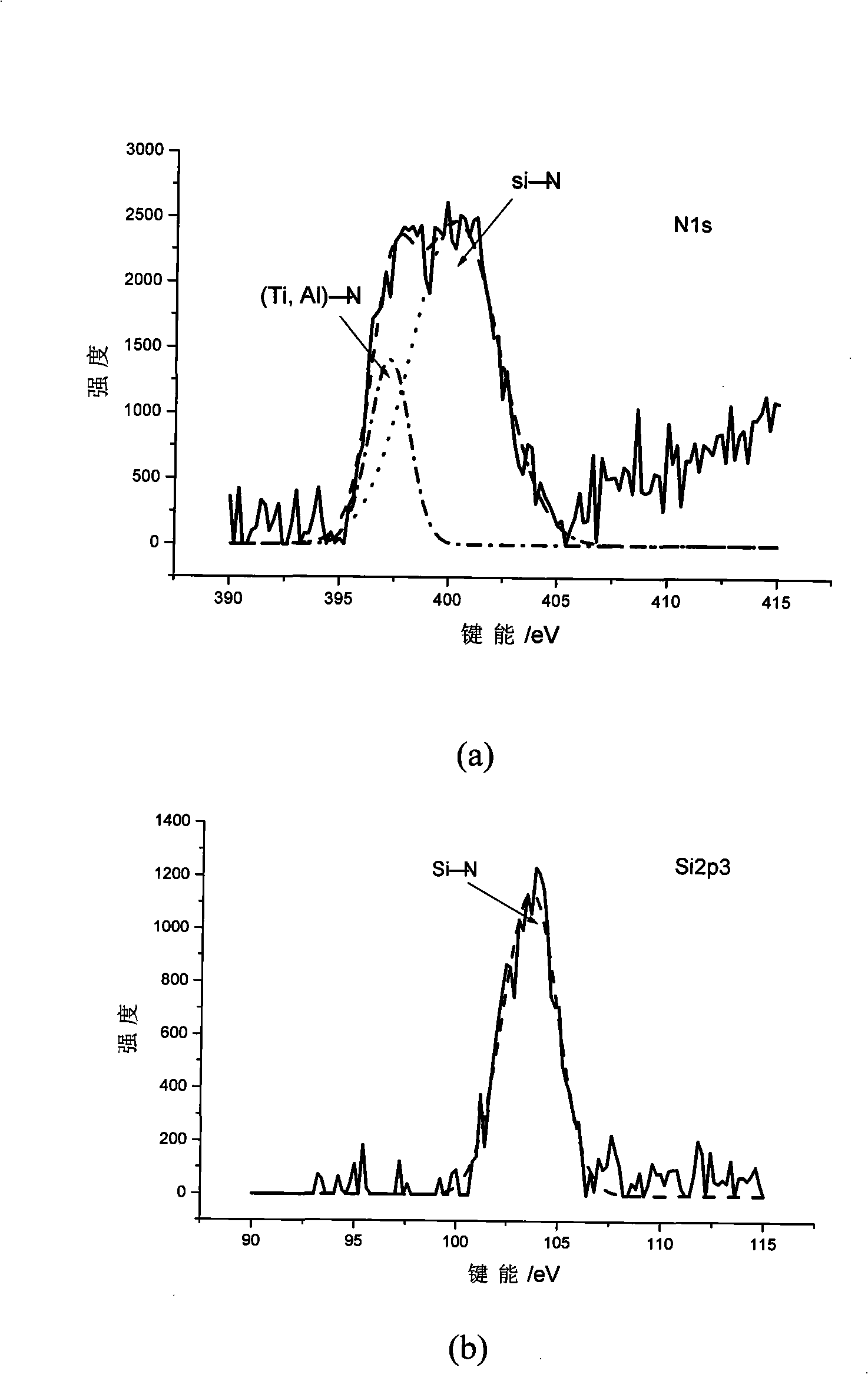

Cemented carbide cutting tool for multi-component coating

ActiveCN101407905AHigh coating hardnessImprove antioxidant capacityVacuum evaporation coatingSputtering coatingAlloyHigh intensity

The invention discloses a cemented carbide cutting tool of a multi-component coating, which comprises a matrix and a coating coated on the matrix by a PVD method; wherein, the coating comprises a matrix binding layer coated on the matrix and a composite mixed crystal structural layer which is coated on the matrix binding layer and contains nano crystalline / amorphous composition; the matrix binding layer comprises at least a Ti-based metal layer which comprises at least one of metal elements of Al, Si and groups of IVB, VB and VIB; the composite mixed crystal structural layer comprises elements of Ti1-a-b-cAlaMbSicN, wherein M is one or a plurality of metal elements of Ta, Nb, Zr, Cr, Hf and W. The cemented carbide cutting tool has the advantages of high wearing resistance, high intensity, high temperature resistance, impact resistance, good binding of the coating and matrix, etc.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

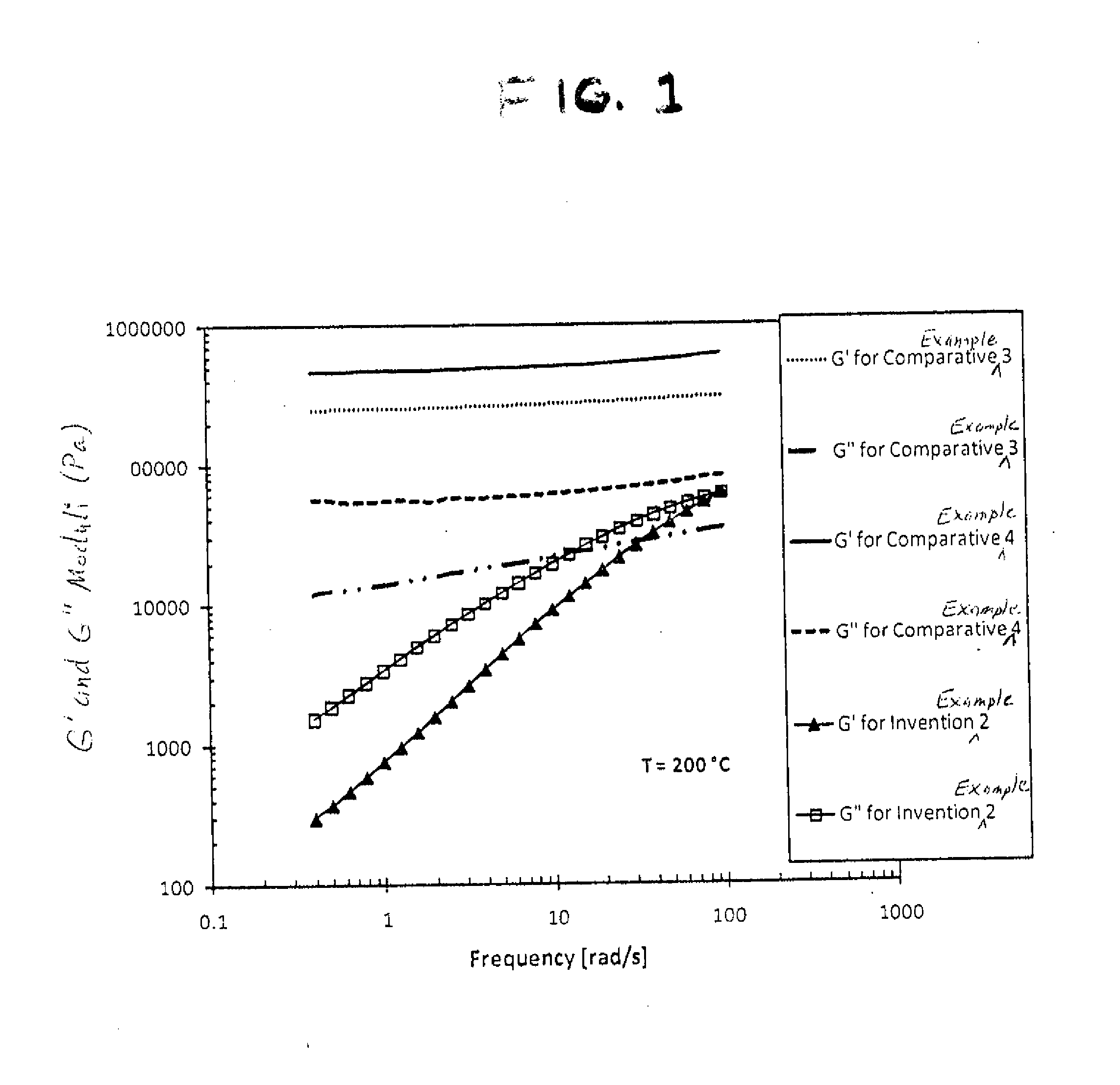

Laser-engraveable flexographic printing precursors

InactiveUS20120240802A1Enhance the imageIncrease elasticityMaterial nanotechnologyLayered productsElastomerPolyolefin

A laser-engravable flexographic printing precursor or other patternable material can be laser-engraved to provide a relief image. The relief image is formed in an elastomeric, relief-forming, laser-engravable layer comprising a thermoplastic elastomeric nanocrystalline polyolefin that is melt processable. The laser-engraveable composition can be readily recycled and reformed into another flexographic printing plate precursor.

Owner:EASTMAN KODAK CO

Preparation method of ZnO / g-C3N4 composite photocatalyst

InactiveCN102950016AHigh crystallinityGood dispersionPhysical/chemical process catalystsWastewaterSolvent

The invention relates to a preparation method of a ZnO / g-C3N4 composite photocatalyst. A two-stage solvent thermal / ultrasonic dispersing method is employed to prepare the ZnO / g-C3N4 composite photocatalyst. After the two-stage solvent thermal treatment, porous ZnO nano crystalline with high dispersion grown on the g-C3N4 can be obtained, and the ZnO nanocrystalline and the g-C3N4 can form a good composite structure; the ultrasonic treatment reduces agglomeration among the ZnO / g-C3N4 composite particles, and improves dispersion of the composite catalyst; and the nano composite particles with high dispersion strengthen effective utilization of sun light by the catalyst, and improve activity of the catalyst. The preparation method provided by the invention has the advantages of cheap raw materials and simple process; and the prepared composite photocatalyst has a broad application prospects in the fields of wastewater treatment and gas purification.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Ceramic-phase-containing iron-based amorphous nanocrystalline composite coating and preparation thereof

ActiveCN101298654AEasy to useExtended service lifeMolten spray coatingOxide ceramicsThermal spraying

The invention belongs to the field of thermal spraying and particularly relates to a composite amorphous and nano-crystalline coating layer with ceramic phase and ferrum base and a preparation method thereof. Carbide or oxide ceramics of Co or Ni ladles are firstly added into a flux core, a flux-cored wire is prepared together with the flux core and a ferrum-base alloy with amorphous ingredients and used as a spraying material, and the electric arc spraying method is adopted for leading the flux-cored wire to be melted, atomized into fused drops and finally deposited on a substrate, thus preparing the composite amorphous and nano-crystalline coating layer with ceramic-phase structure and ferrum base, which has the performance of high bond strength, good wear resistance, corrosion resistance and oxidation resistance as well as remarkably prolonged service life of the substrate, and the composite amorphous and nano-crystalline coating layer with ceramic phase and ferrum base can be widely applied to the restoration and the protection of device parts in the fields of metallurgy, electric power and petroleum, etc.

Owner:CENT IRON & STEEL RES INST

High speed processing method for realizing superfine crystal grain structure on metallic material surface

The invention relates to a method for processing the high-speed deformation on the surface of metallic material with nano structure, and particularly provides a method for realizing high-speed processing of the organization structure of ultra-fine grains. On the condition of room temperature or low temperature, by adopting a mechanical treatment method with high-speed plastic deformation, the nanoscale bulky crystalline grain structure on the surface layer of the metallic material is refined as equiaxial submicron crystalline grain or nano crystalline grain to form an ultra-fine organization structure of the crystalline grain on the surface layer of the metallic material. With the increase of the depth to the processing surface, the size of microstructure has the change of gradient, increasing from nanoscale and submicron size to micron size. Compared with the existing processing method for forming a surface ultra-fine crystalline grain structure, the high-speed processing method of the invention greatly reduces the roughness of the surface of the processed metallic material and increases the thickness of a deformation layer, and has simple processing method and high working efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

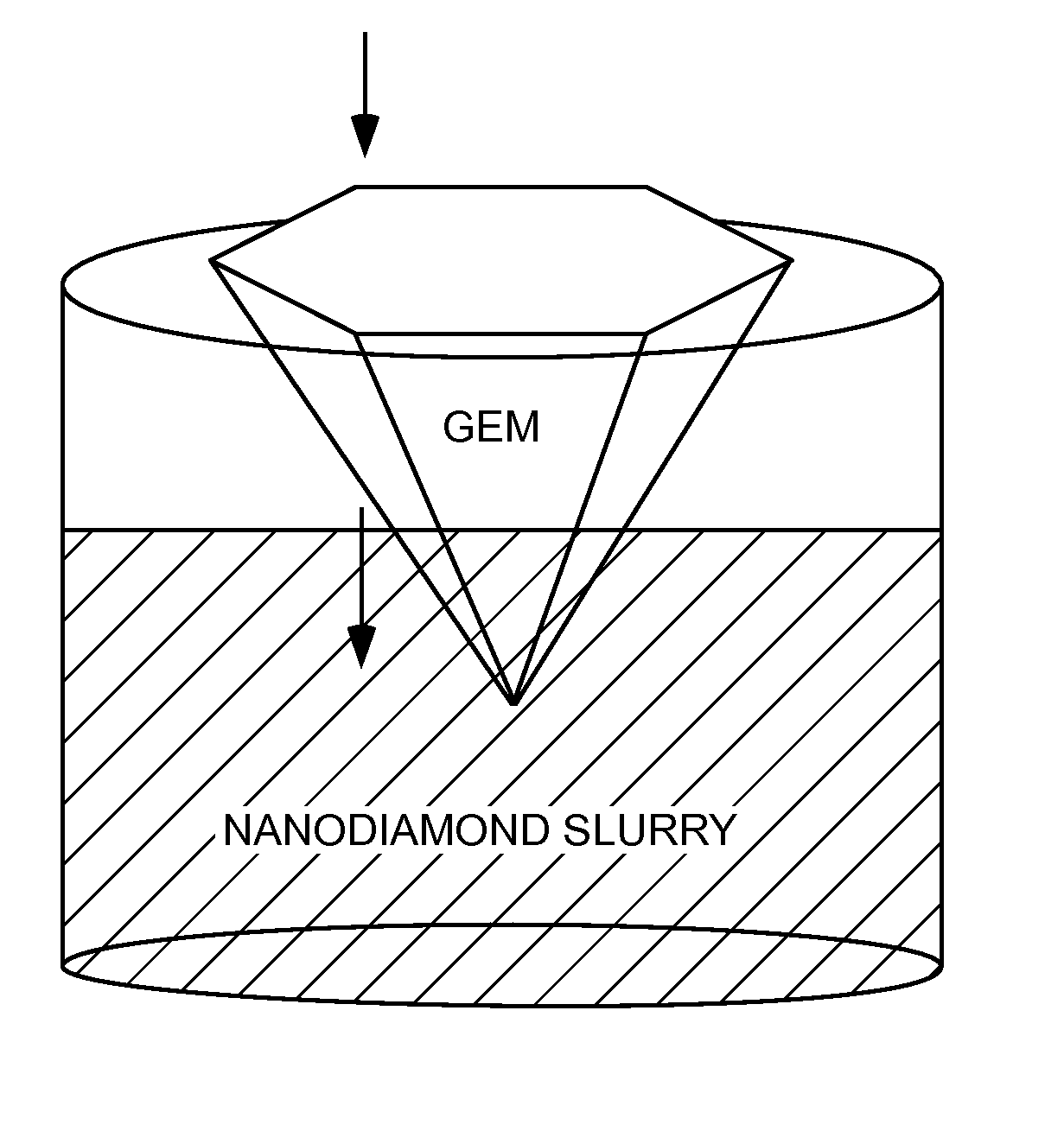

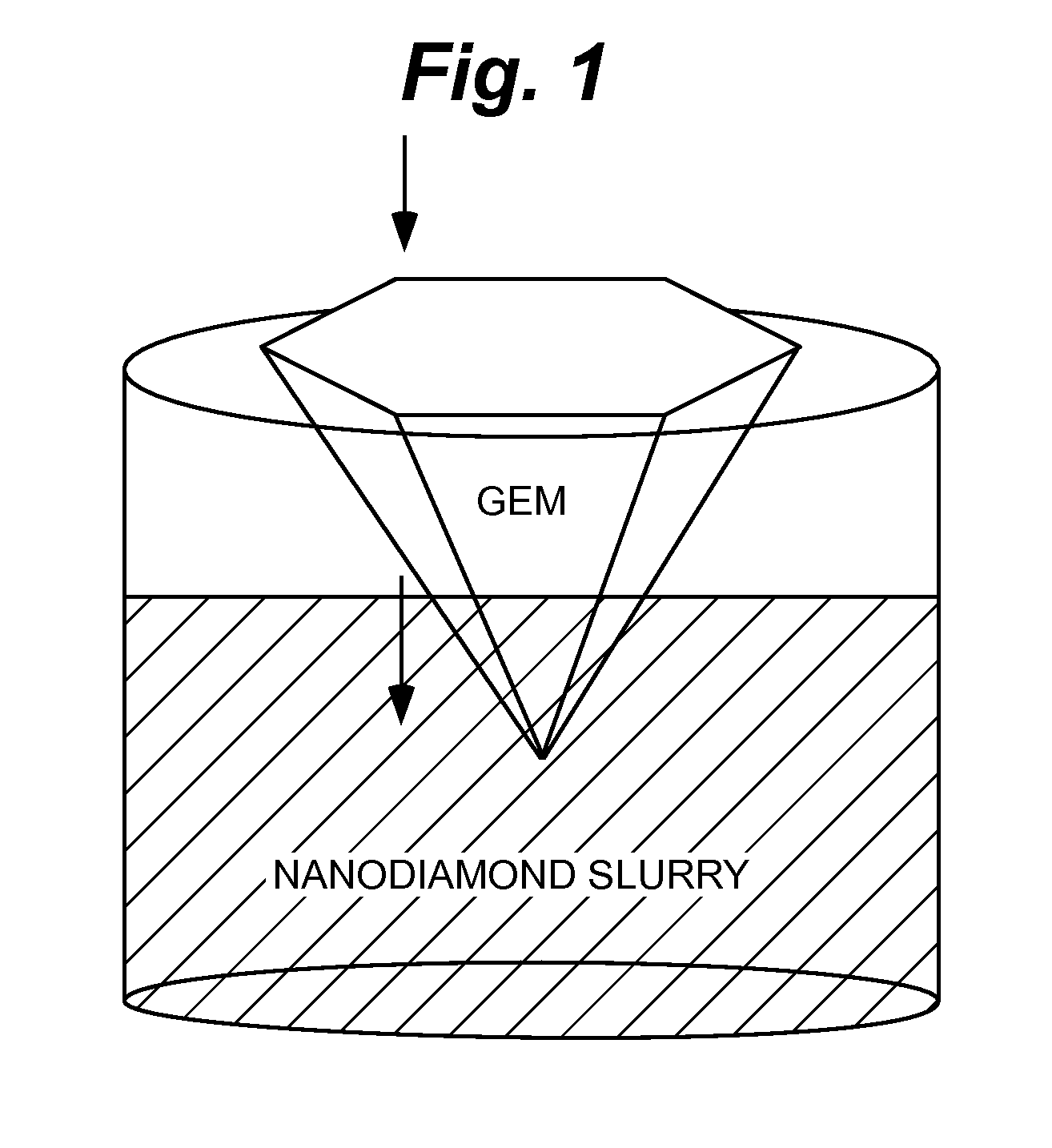

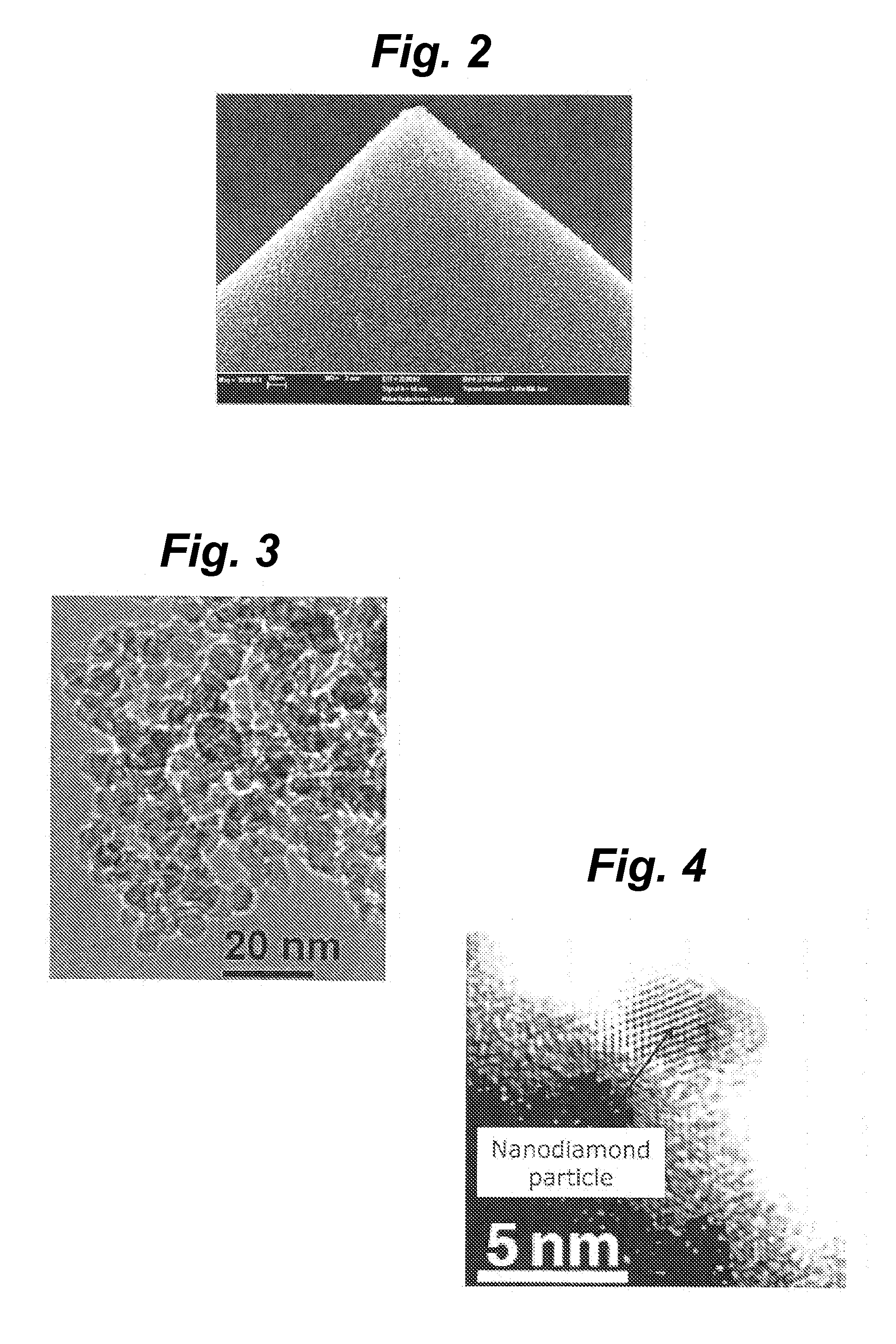

Method for producing nanocrystalline diamond coatings on gemstones and other substrates

ActiveUS20100068503A1Reduce usageEasy to storeElectric discharge heatingLayered productsGemstoneSlurry

A method to apply nano-crystalline diamond onto a selected substrate, including preparing Nanodiamond slurry of nanodiamond particles dispersed in a medium. The medium may include a liquid or a sol-gel. The selected substrate is immersed in the Nanodiamond slurry for a predetermined period of time. Then the substrate is removed from the slurry. The substrate is then dried with a flow of inert gas. The substrate is left coated with a coating of the nanodiamond particles that are highly adherently held by van der Waals forces.

Owner:ARYAMOND SINGAPORE PTE LTD

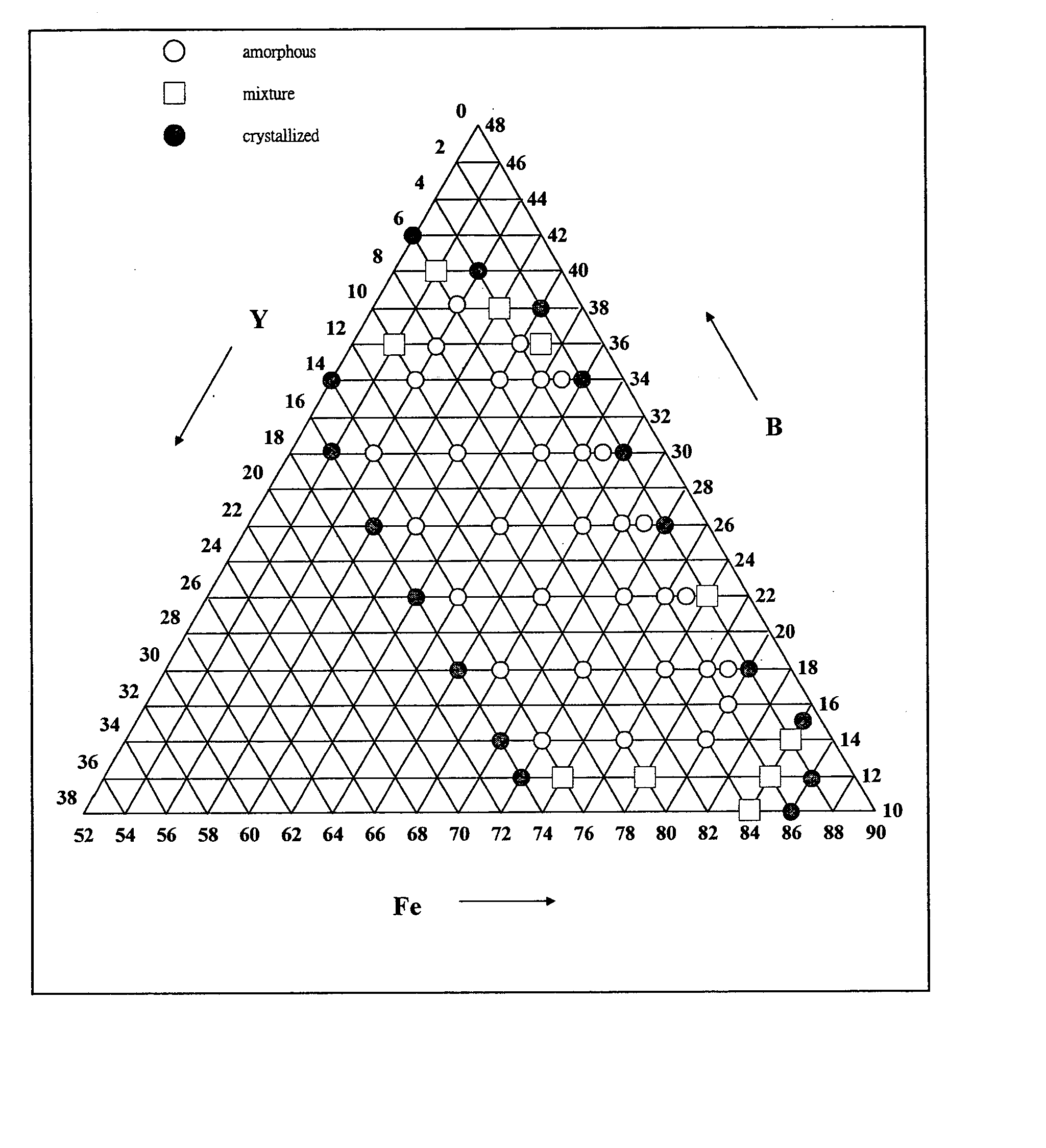

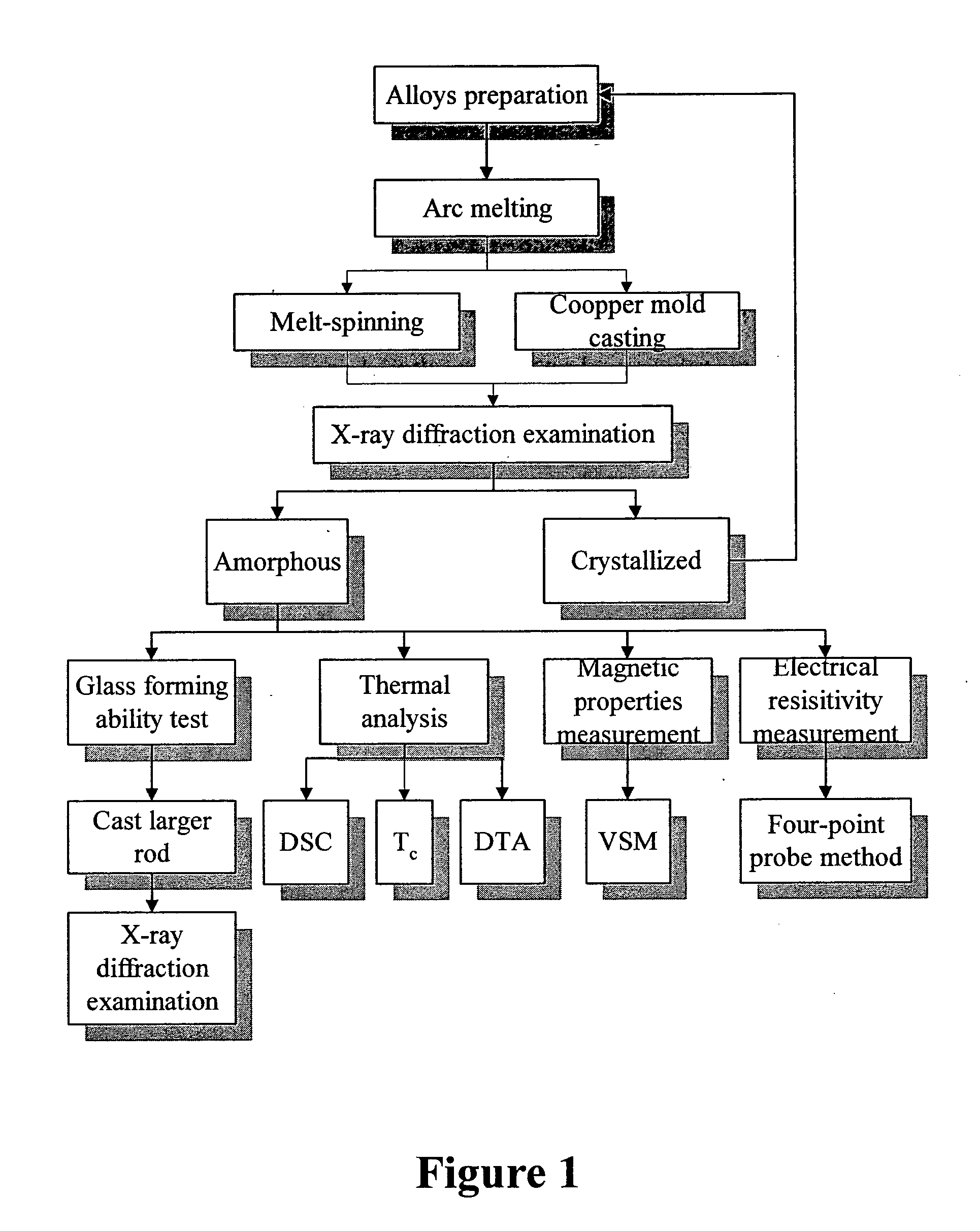

Ternary and multi-nary iron-based bulk glassy alloys and nanocrystalline alloys

InactiveUS20050263216A1High glass forming abilityIncreased electrical resistivityMagnetic materialsAmorphous phaseAtomic radius

Disclosed in this invention is a family of ternary and multi-nary iron-based new compositions of bulk metallic glasses which possess promising soft magnetic properties, and the composition selection rules that lead to the design of such new compositions. The embodiment alloys are represented by the formula MaXbZc, where M represents at least one of ferromagnetic elements such as iron and may partly be replaced by some other substitute elements; X is an element or combinations of elements selected from those with atomic radius at least 130% that of iron and in the mean time is able to form an M-rich eutectic; and Z is an element or combinations of elements selected from semi-metallic or non-metallic elements with atomic radius smaller than 86% that of iron and in the meantime is able to form an M-Z eutectic; a, b, c are the atomic percentage of M, X, Z, respectively, and a+b+c=100%. When 1%<b<15% and 10%<c<39%, the alloys show a bulk glass forming ability to cast amorphous ribbons / sheets at least 0.1 mm in thickness. When 3%<b<10% and 18%<c<30%, the alloys show a bulk glass forming ability to cast amorphous rods at least 1 mm in diameter. The amorphous phase of these as-cast sheets / rods is at least 95% by volume. This invention also discloses the existence of nano-crystalline phase outside of the outer regime of the bulk glass forming region mentioned above.

Owner:NATIONAL TSING HUA UNIVERSITY

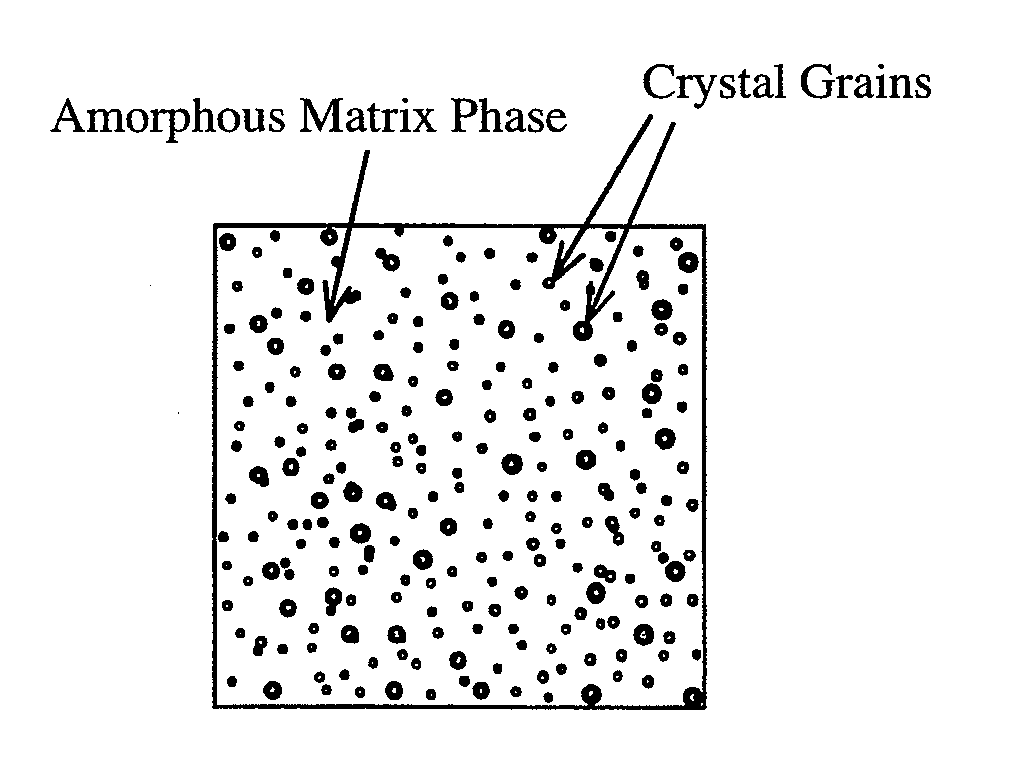

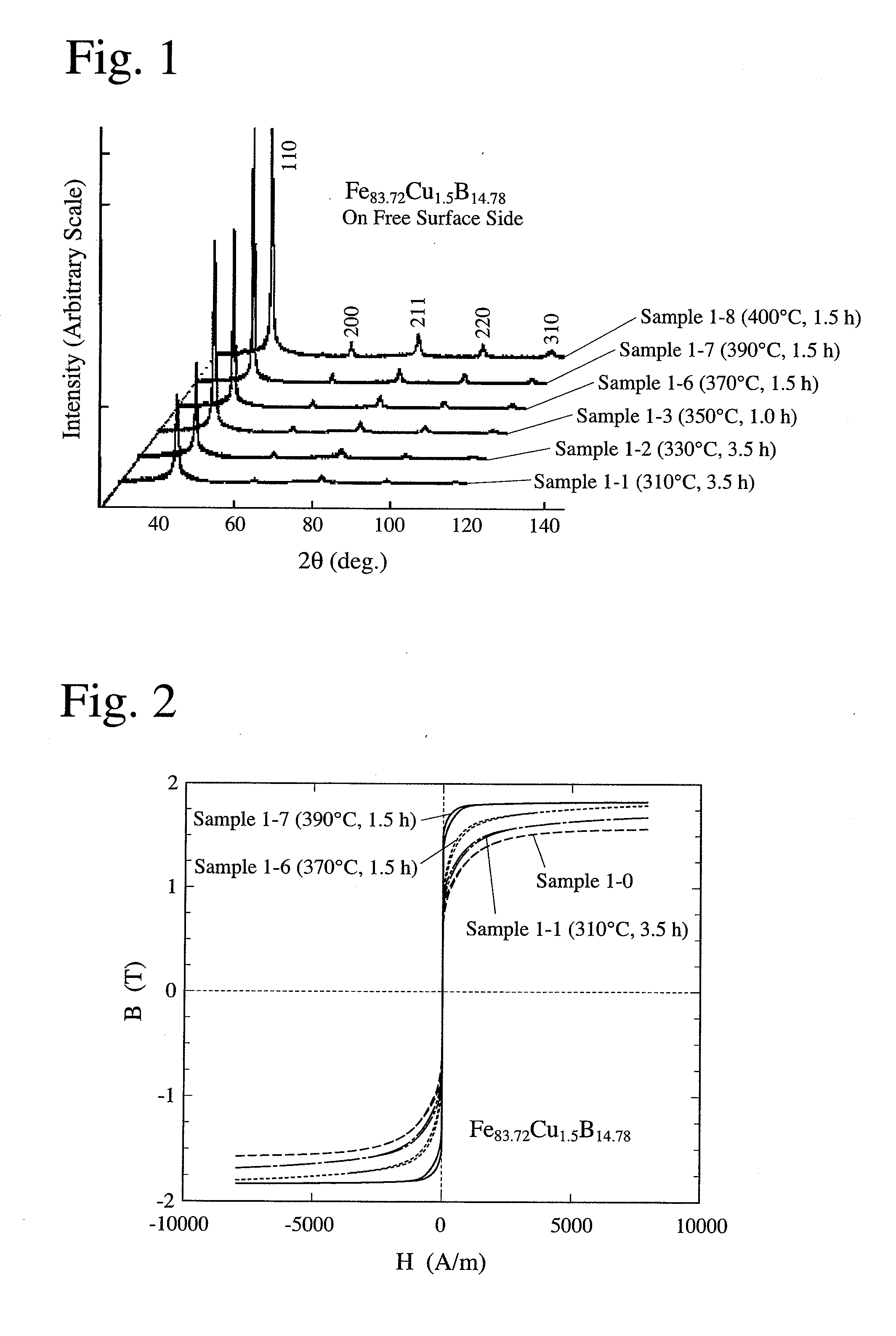

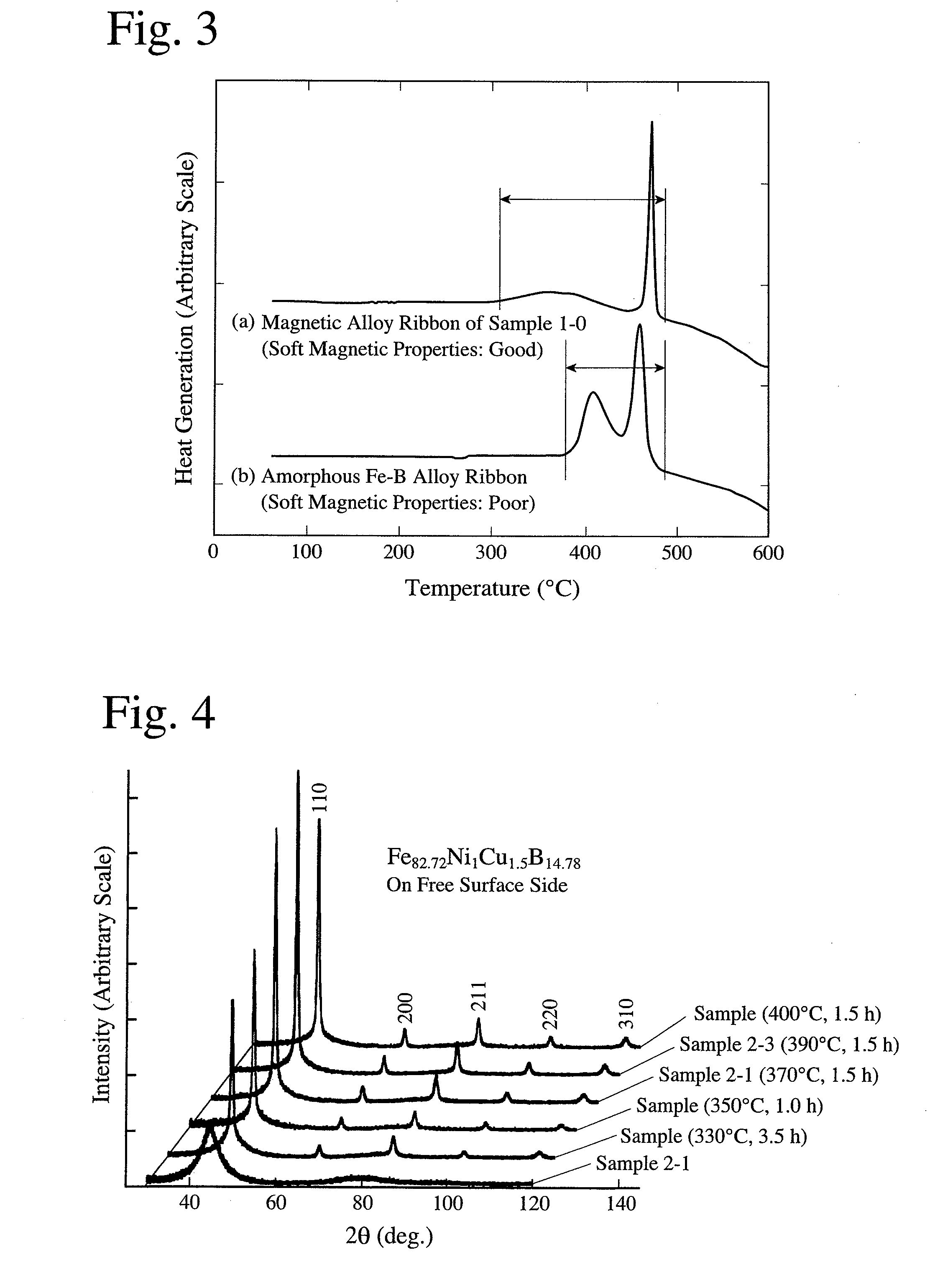

Nano-crystalline, magnetic alloy, its production method, alloy ribbon and magnetic part

ActiveUS20090266448A1High magnetic flux densityLow coercivityMagnetic materialsVolumetric Mass DensityNano crystalline

A magnetic alloy having a composition represented by the general formula of Fe100-x-yCuxBy (atomic %), wherein x and y are numbers meeting the conditions of 0.1≦x≦3, and 10≦y≦20, or the general formula of Fe100-x-y-zCuxByXz (atomic %), wherein X is at least one element selected from the group consisting of Si, S, C, P, Al, Ge, Ga and Be, and x, y and z are numbers meeting the conditions of 0.1≦x≦3, 10≦y≦20, 0≦z≦10, and 10<y+z≦24), the magnetic alloy having a structure containing crystal grains having an average diameter of 60 nm or less in an amorphous matrix, and a saturation magnetic flux density of 1.7 T or more.

Owner:HITACHI METALS LTD

Enhanced scratch resistance of articles containing a combination of nano-crystalline metal oxide particles, polymeric dispersing agents, and surface active materials

InactiveUS20060063911A1Improve scratch resistanceEasy to measureMaterial nanotechnologyIndividual molecule manipulationMetal coatingNanoparticle

A film forming composition comprises a resin, a plurality of nanoparticles, a surface active material and a polymeric dispersant. The film forming composition is substantially transparent and is adapted to be combined with a substrate to enhance abrasion resistance. The film forming composition may be used with wood objects including furniture, doors, floors, for architectural surfaces, for automotive articles and finishes, for metal coatings and coil coatings, for plastic articles, and for wipe-on protective treatments.

Owner:ALTANA CHEM CORP +1

Cationization modification method for nano-crystalline cellulose and preparation method of high-strength cigarette paper

ActiveCN102180979ALess investmentHigh strengthReinforcing agents additionPaper/cardboardFiberReaction temperature

The invention belongs to the field of production of special paper, and in particular relates to a cationization modification method of nano-crystalline cellulose and a method for preparing high-strength cigarette paper from the modified nano-crystalline cellulose. Specific to the characteristic of high specific surface area of nano-crystalline cellulose, KOH and a method for adding an etherification reaction accelerant are adopted, the reaction temperature is lowered below 50 DEG C, cationization modification is performed on the nano-crystalline cellulose, and the modified nano-crystalline cellulose has the characteristics of retention and enhancement, so that the modified nano-crystalline cellulose has a wider application prospect; in the method for preparing cigarette paper, softwood pulp is not used, and higher natural air permeability and higher bonding strength of a product are ensured under the condition of reducing broadleaf wood fiber devillicate and fibrillation, so that energy consumption in the production process of paper, in particular in the pulping process, is remarkably lowered, equipment investment of a paper mill is reduced, high-strength cigarette paper is manufactured, the page quality is improved, higher strength and air permeability of the product are achieved, and the requirements on energy conservation and emission reduction are met.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

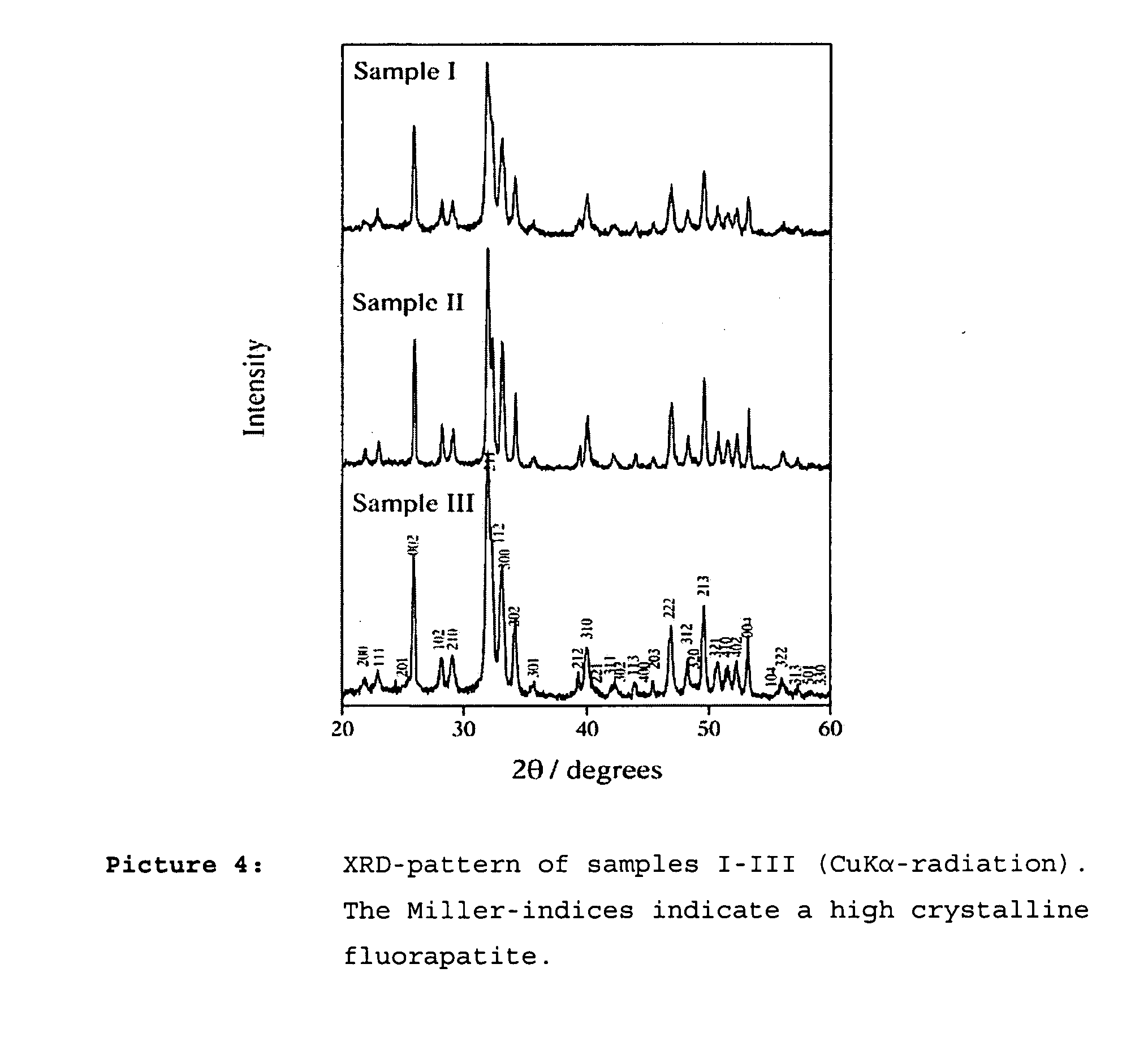

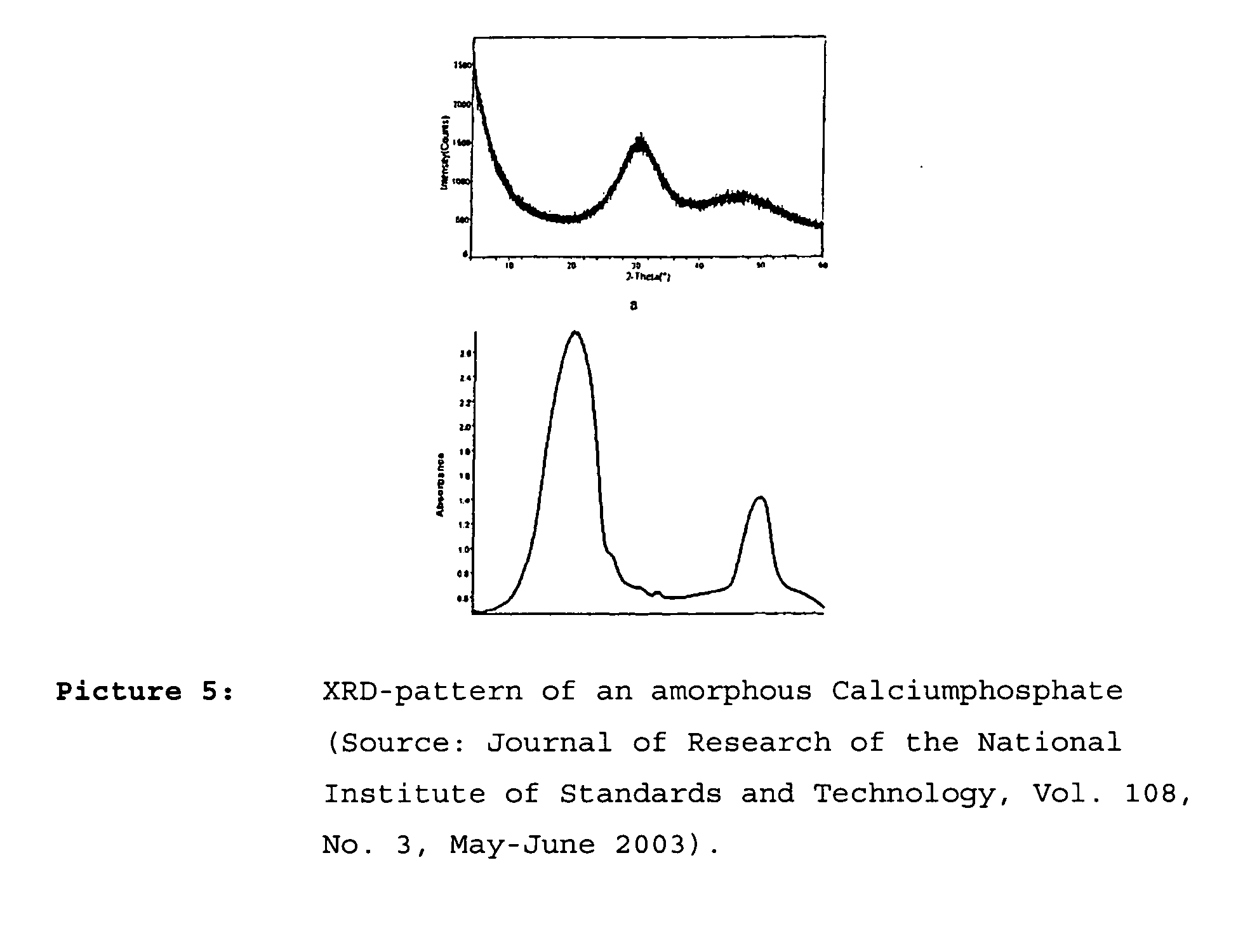

Composition containing nano-crystalline apatite

This invention describes compositions containing nano-crystalline apatite useful as bone—or preferably as tooth restorative materials. The materials produced, using the composition have improved properties in the areas of esthetics, hardness, translucency, surface polishability, strength and the capability to release and to take ions up in respect of a biological environment.

Owner:S & C POLYMER SILICON & COMPOSITE SPEZIALITATION +1

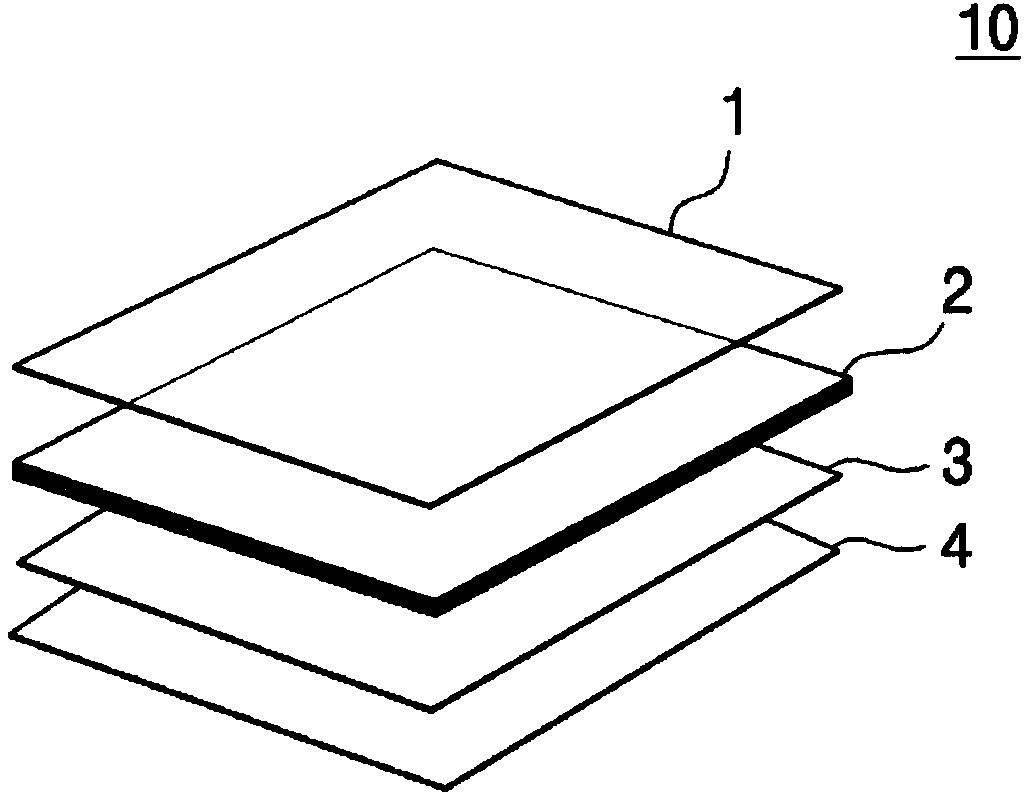

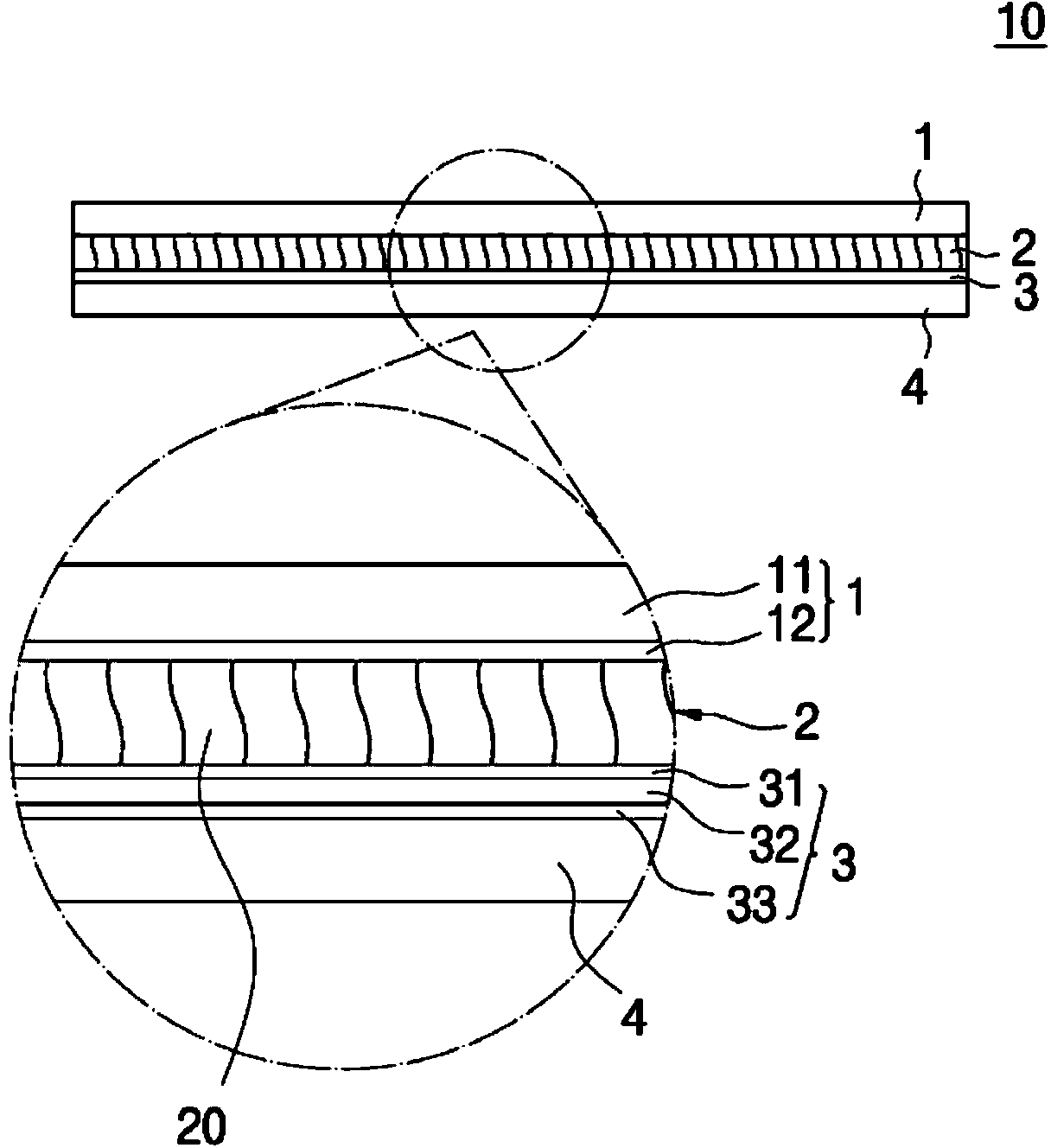

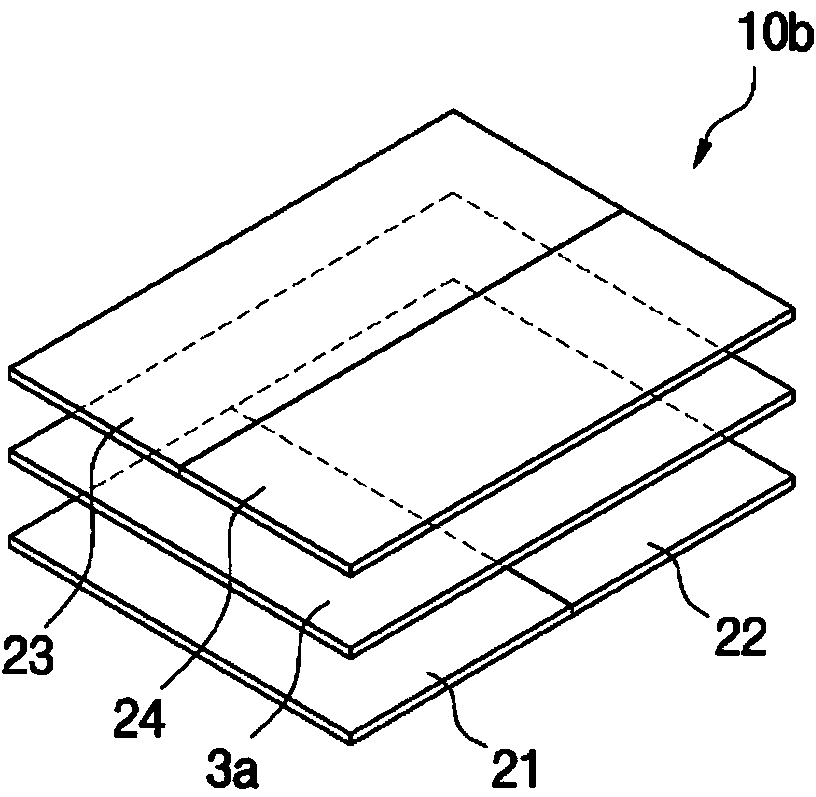

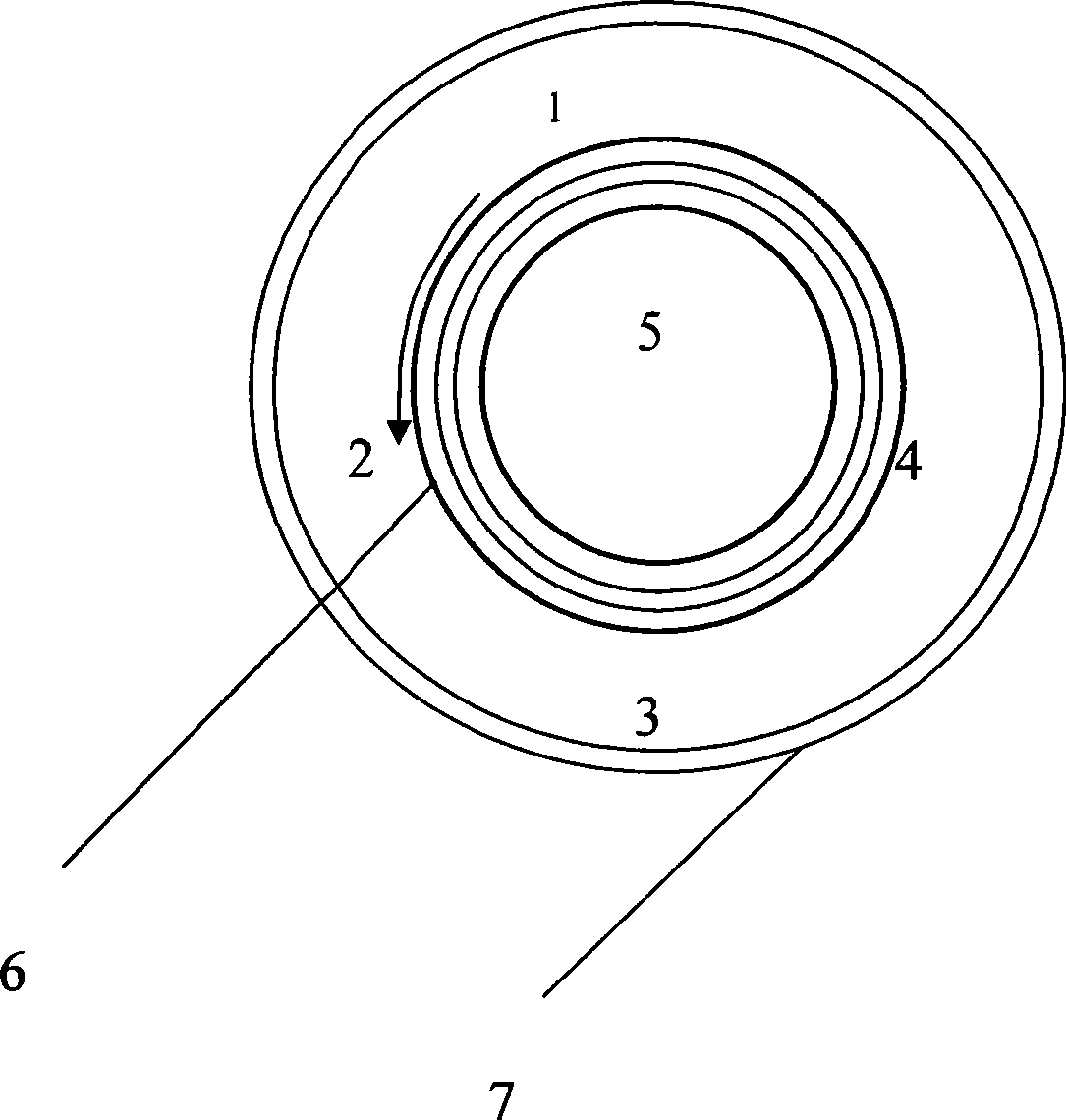

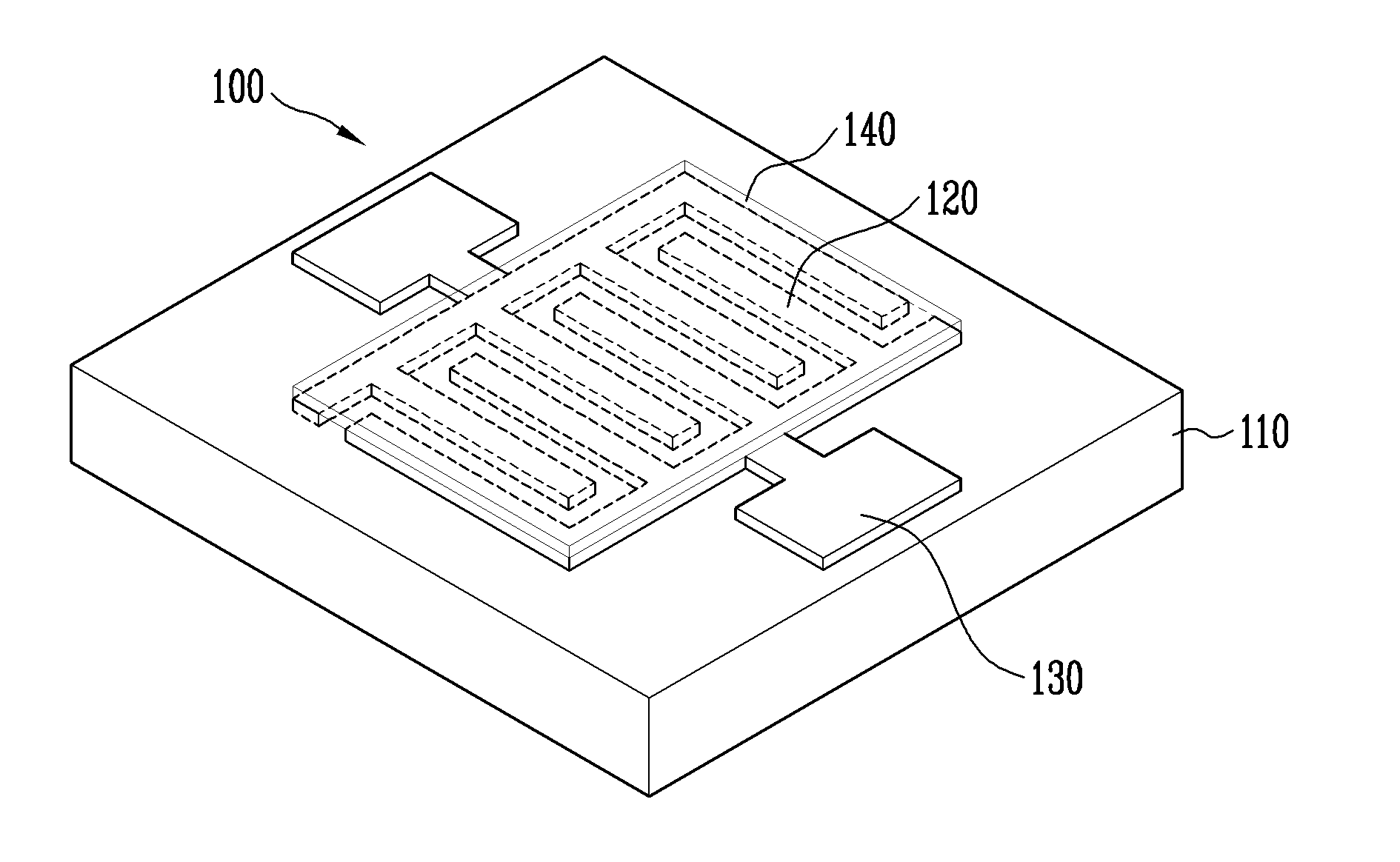

Magnetic field shielding sheet for digitizer, manufacturing method thereof, and portable terminal device using same

ActiveCN104054409AImprove permeabilityBroaden your optionsShielding materialsNanomagnetismTerminal equipmentAlloy

The present invention relates to: a magnetic field shielding sheet for a digitizer which minimizes an influence on a geomagnetic sensor, shields the electromagnetic field generated from various constituent elements of a main body of a portable terminal device when preparing a digitizer function for the portable terminal device, and can simultaneously improve the sensitivity of an electronic pen; a manufacturing method thereof; and the portable terminal device using the same. The magnetic field shielding sheet of the present invention comprises: a thin magnetic sheet having at least one layer which is formed with a nano-crystalline alloy and is divided into a plurality of fine pieces by flake treatment; a protective film attached to one side of the thin magnetic sheet through a first adhesive layer; and double-sided tape attached to the other side of the thin magnetic sheet through a second adhesive layer formed on one side, wherein the thin magnetic sheet is characterized by heat-treating an amorphous ribbon formed with the nano-crystalline alloy at a temperature of 300 DEG C to 700 DEG C.

Owner:AMOSENSE

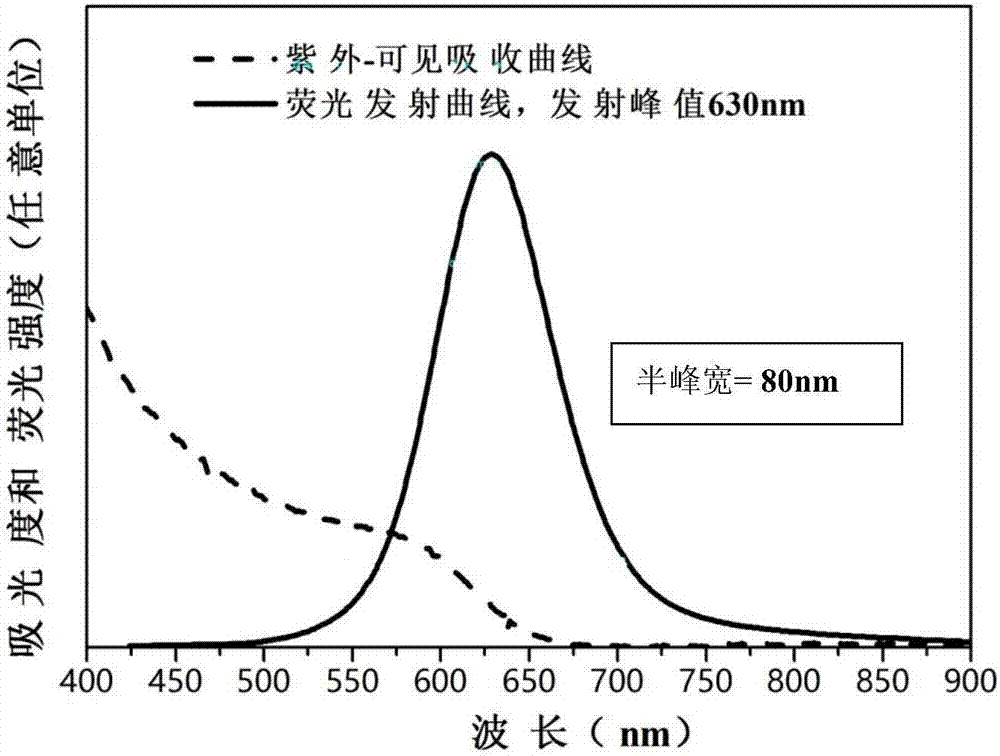

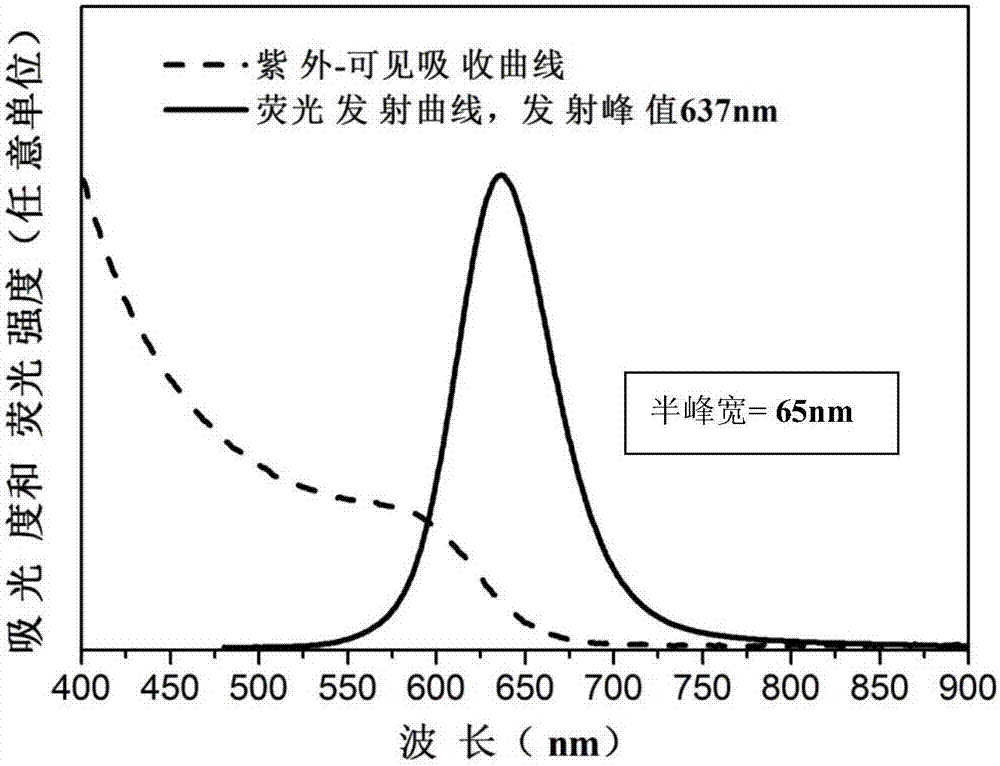

Preparation method of indium phosphide quantum dots

InactiveCN107098324AUniform size distributionGood optical performanceLuminescent compositionsPhosphidesIndiumSurface oxidation

The invention provides a preparation method of indium phosphide quantum dots. The preparation method comprises the following steps: firstly mixing an indium precursor, an acid ligand and a non-coordinating solvent and preparing a uniform indium precursor solution; then adding hydrogen phosphide at a temperature of 100-130 DEG C, raising the temperature to a second temperature and keeping for a period of time; finally regulating the solution to a third temperature and adding a precursor substance required by a synthetic shell to obtain the shell-coated indium phosphide quantum dots. The indium phosphide quantum dots with nuclear shell structures are synthesized by adopting the method of low-temperature nucleating, raised temperature-curing and high-temperature shell-coating; the nucleation and growth processes of indium phosphide nano crystalline nucleuses can be controlled at a low temperature, so that the synthesized quantum dots are uniform in size distribution; meanwhile, the risk of surface oxidation of the indium phosphide nano crystalline nucleuses can also be effectively avoided at a low temperature, so that the optical performance of the indium phosphide quantum dots are improved to a certain degree.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

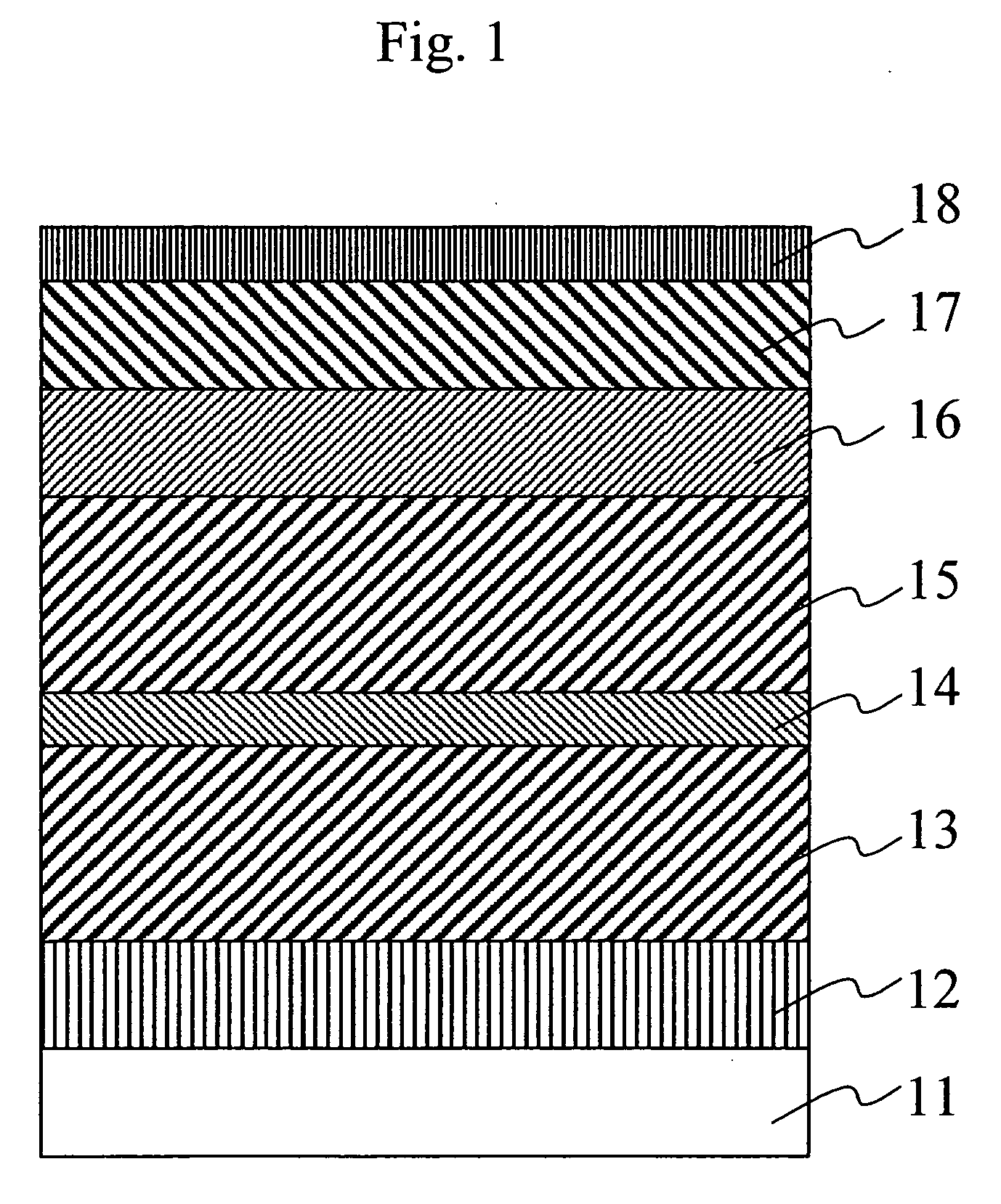

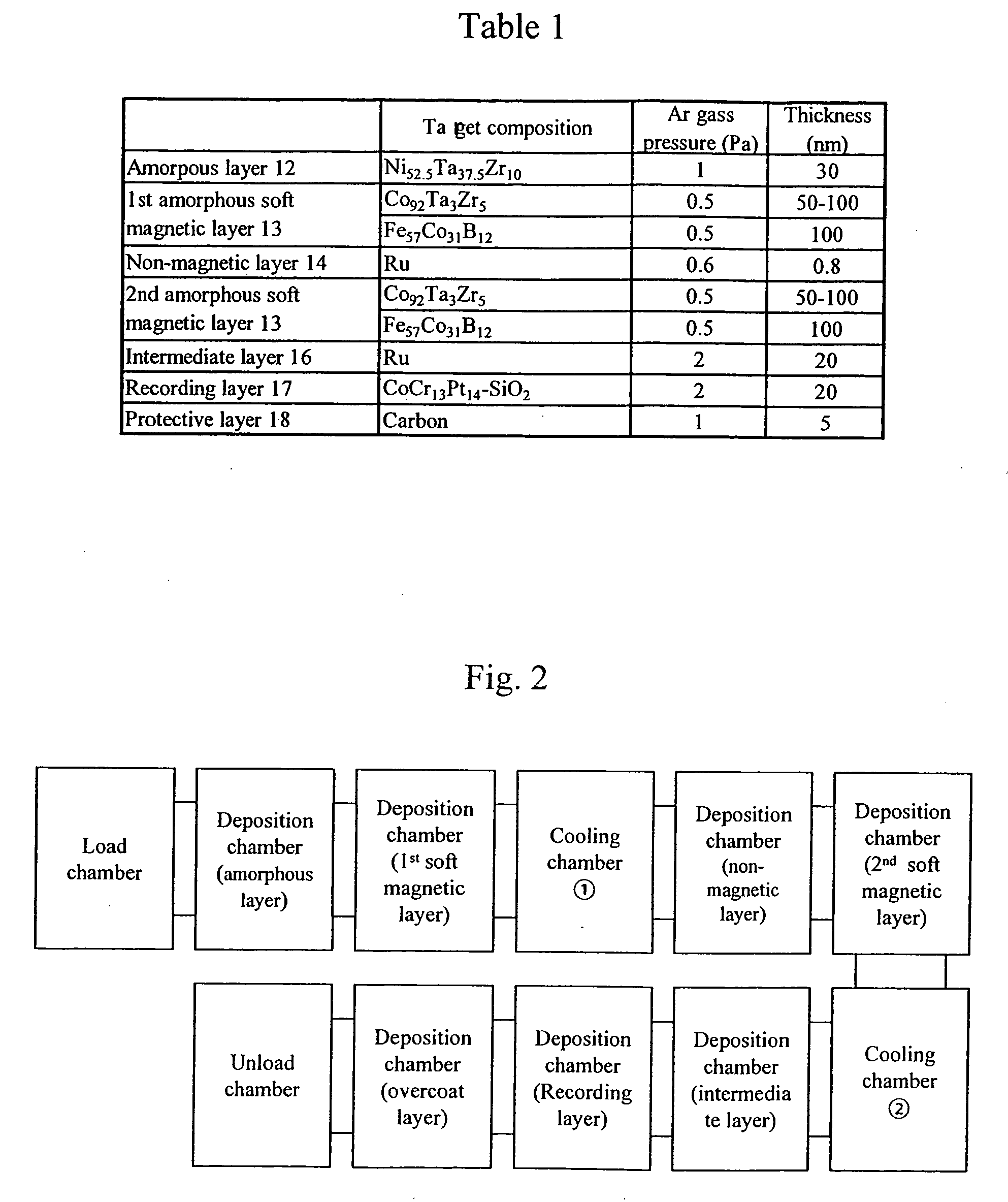

Perpendicular magnetic recording medium, manufacturing process of the same, and magnetic recording/reproducing apparatus using the same

ActiveUS20050244679A1Suppressing amplitude modulationSuppressing spike noiseMagnetic field orientationBase layers for recording layersSignal qualityAntiferromagnetic coupling

Embodiments of the invention provide a perpendicular magnetic recording medium improved for fly ability, high in read signal quality, and capable of suppressing magnetic decay of recorded magnetization to be caused by stray fields. In one embodiment, a perpendicular recording layer is formed over a substrate with a soft magnetic underlayer therebetween, then an amorphous or nano-crystalline layer is formed between the substrate and the soft magnetic underlayer. The soft magnetic underlayer includes first and second amorphous soft magnetic layers, as well as a nomnagnetic layer formed between those first and second amorphous soft magnetic layers. The first and second amorphous soft magnetic layers are given uniaxial anisotropy in the radial direction of the substrate respectively and coupled with each other antiferromagnetically.

Owner:WESTERN DIGITAL TECH INC

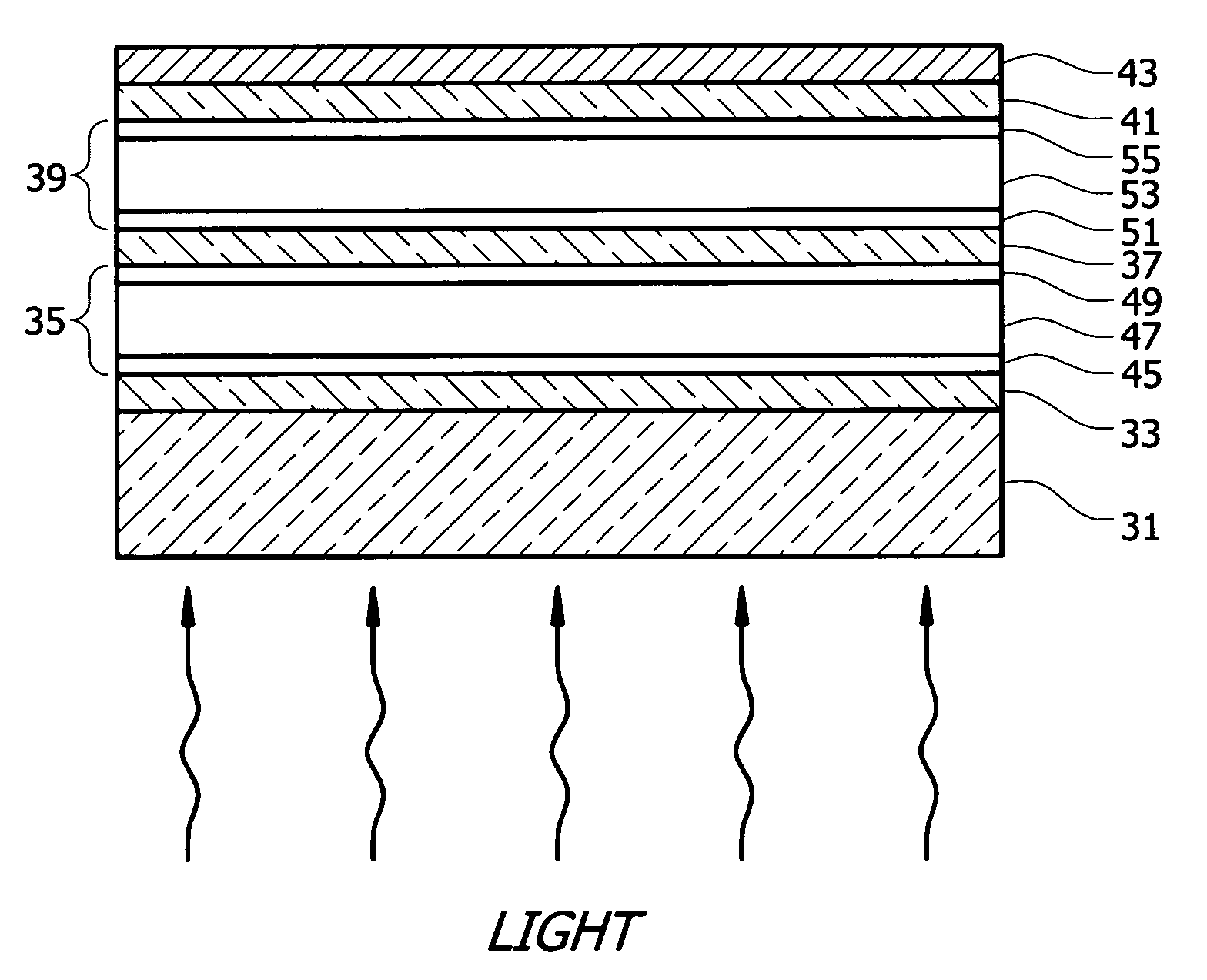

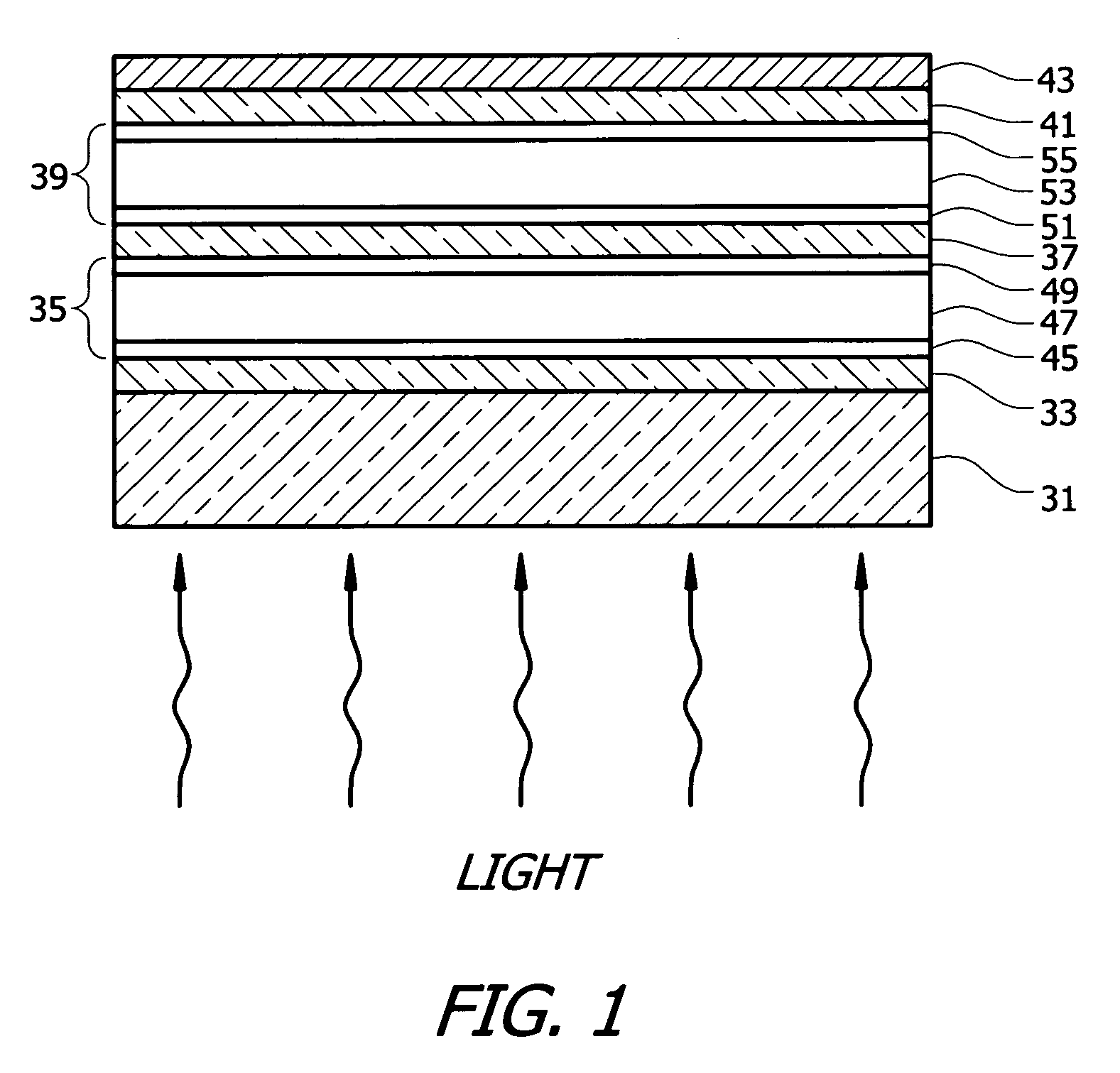

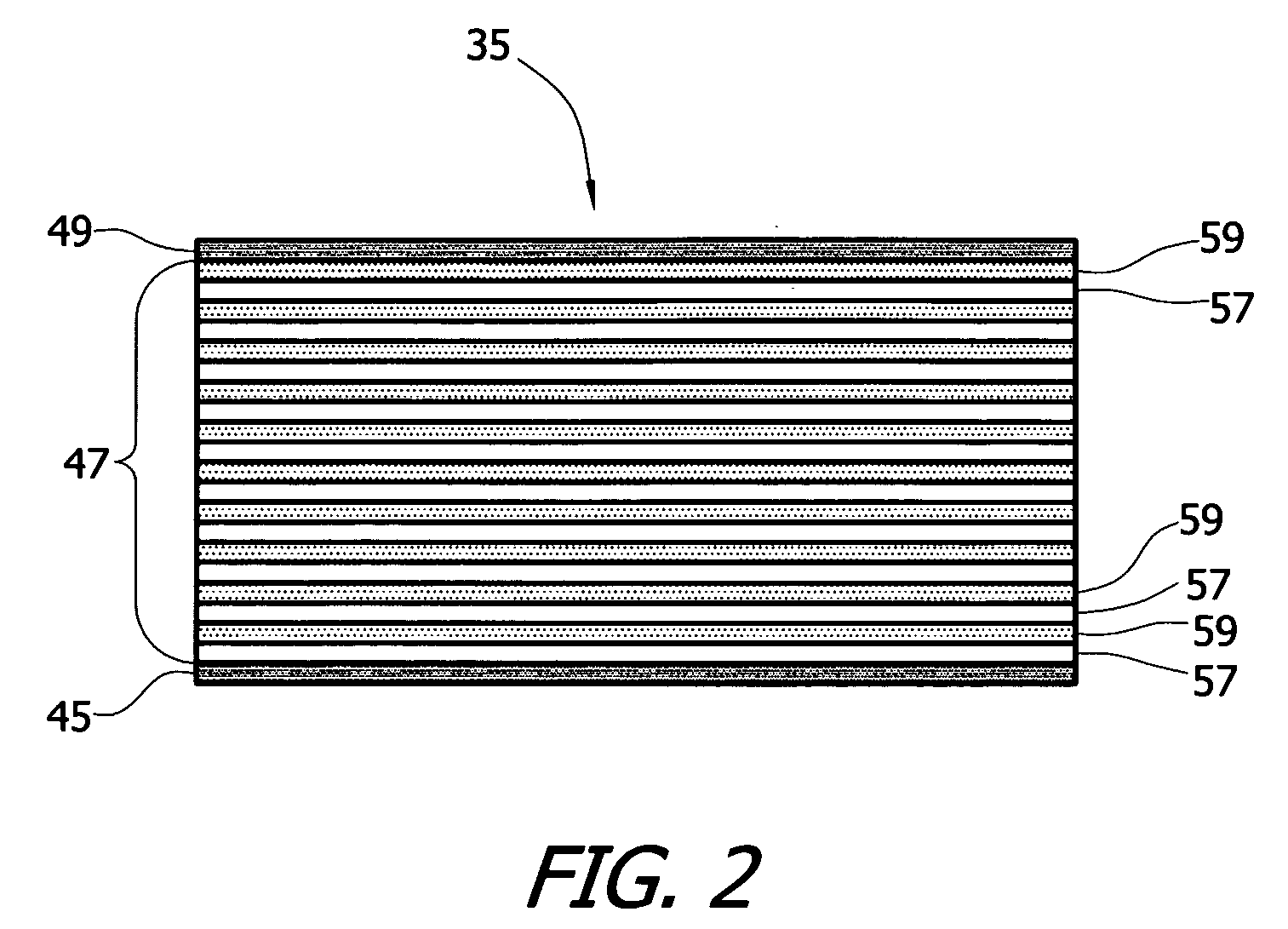

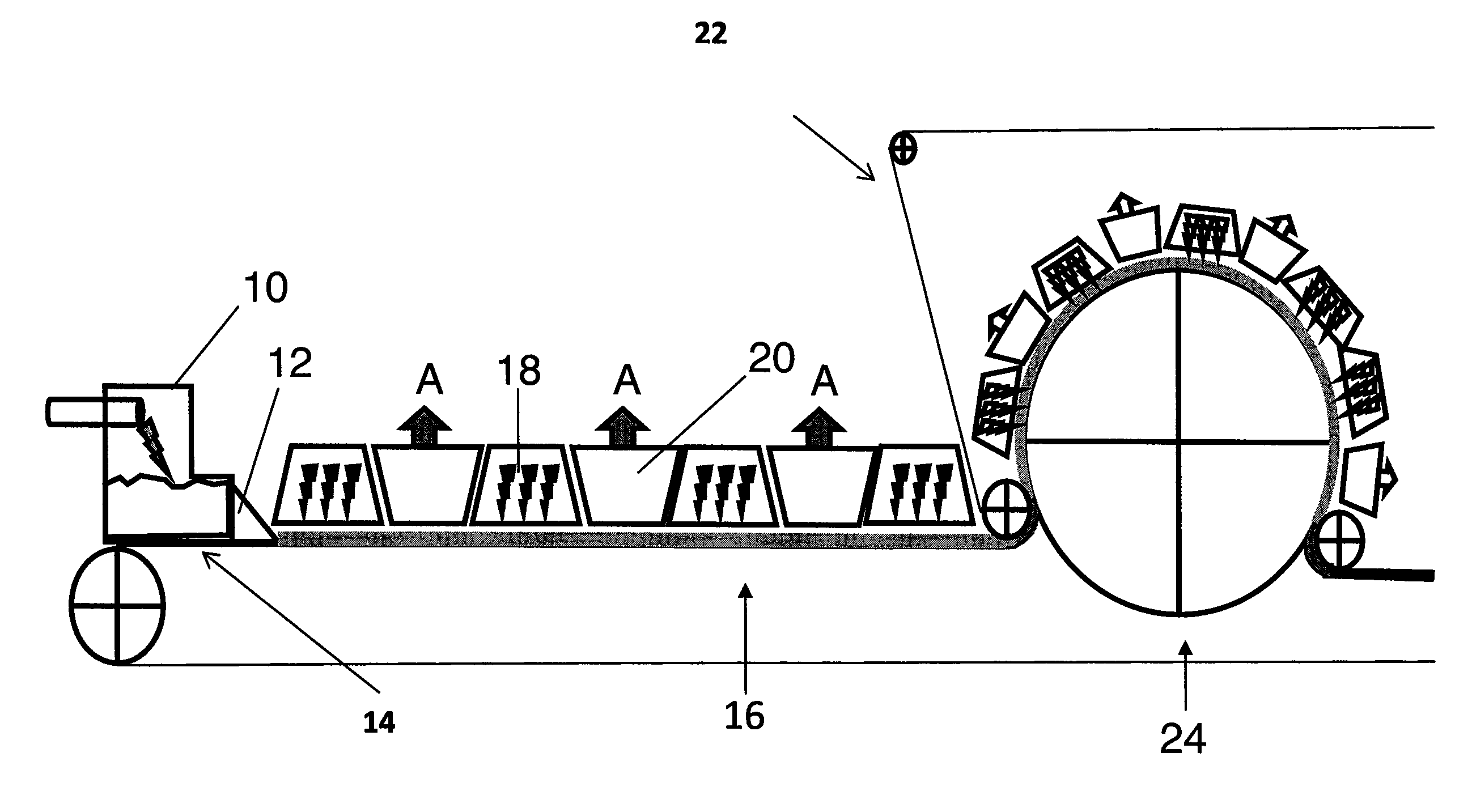

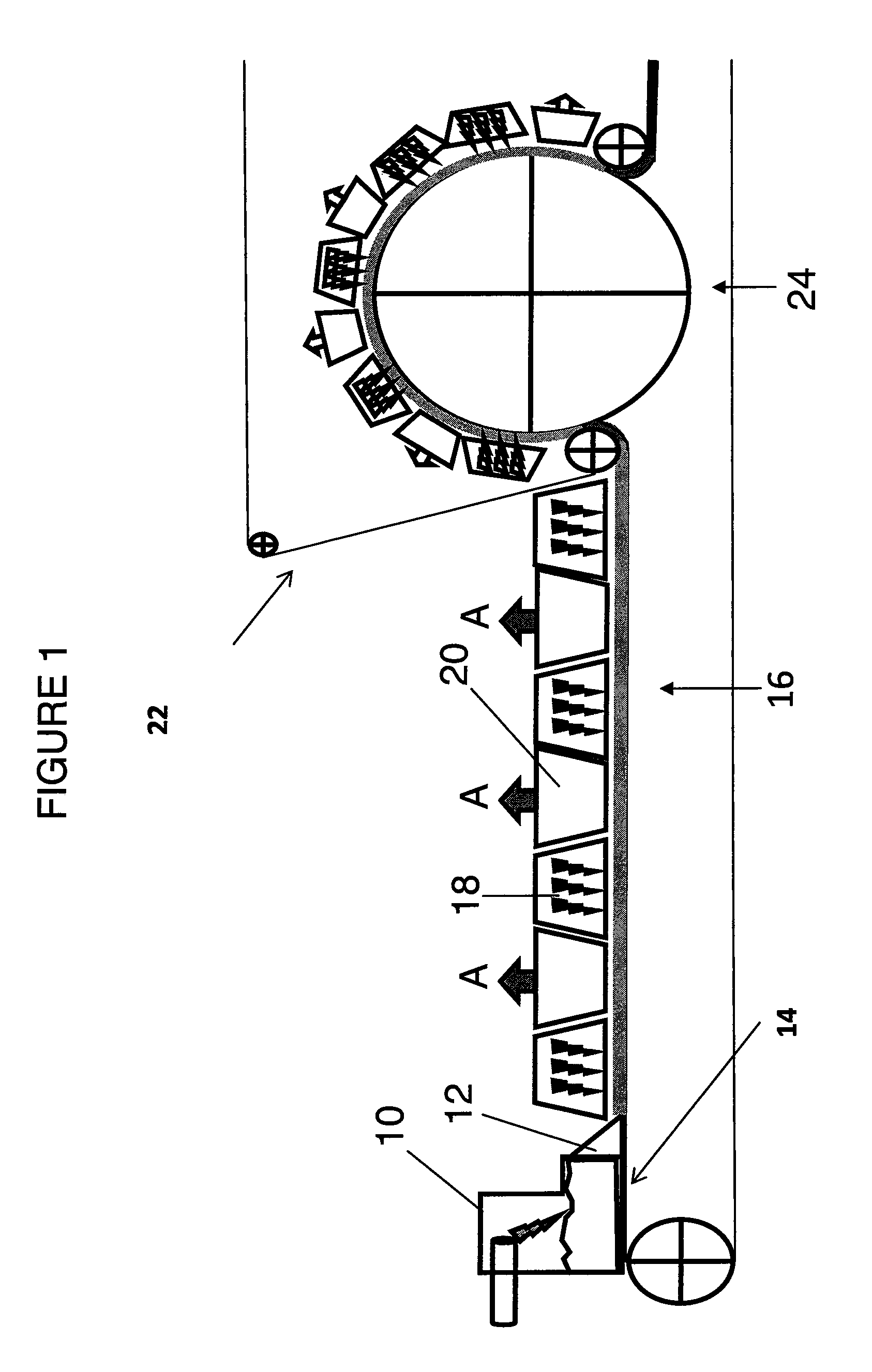

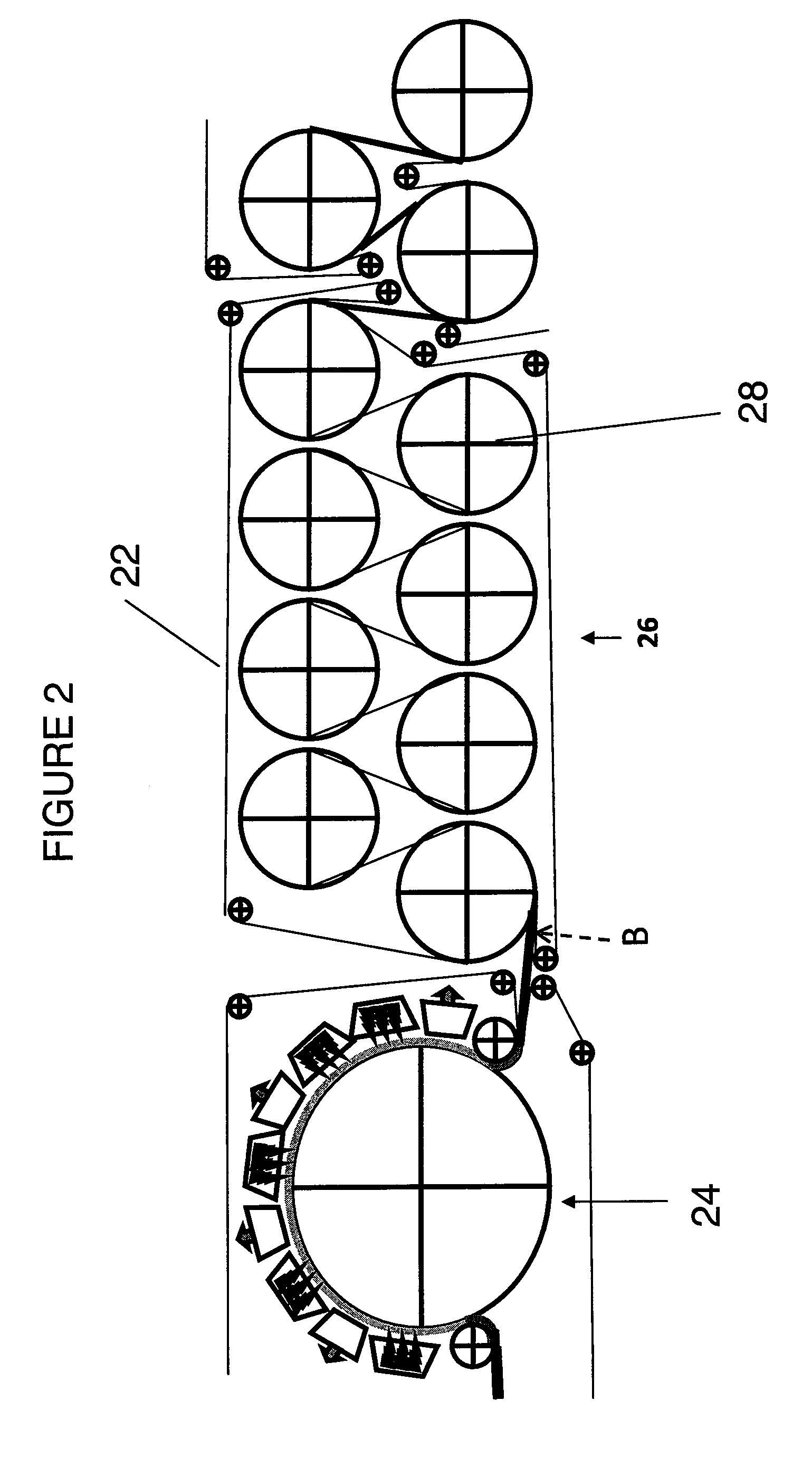

Multiple junction photovolatic devices and process for making the same

InactiveUS20100300505A1PV power plantsSemiconductor/solid-state device manufacturingForming gasGas phase

A photovoltaic device having multiple photoelectric conversion cells disposed in a tandem configuration and a chemical vapor deposition method for fabricating the same are disclosed. Each photoelectric conversion cell has a different band gap energy and includes a p-type semiconductor layer, an intrinsic semiconductor layer and an n-type semiconductor layer in sequential touching contact. Each semiconductor layer is formed of a nano-crystalline semiconductor containing silicon as a principal constituent. The semiconductor layer may be deposited by a novel chemical vapor deposition method which utilizes plasma and laser energies simultaneously to decompose a film forming gas, thereby forming a semiconductor film on a substrate. The chemical vapor deposition process may be carried out on a continuously conveying substrate, thereby permitting high throughput production of the photovoltaic device.

Owner:CHEN YUNG T

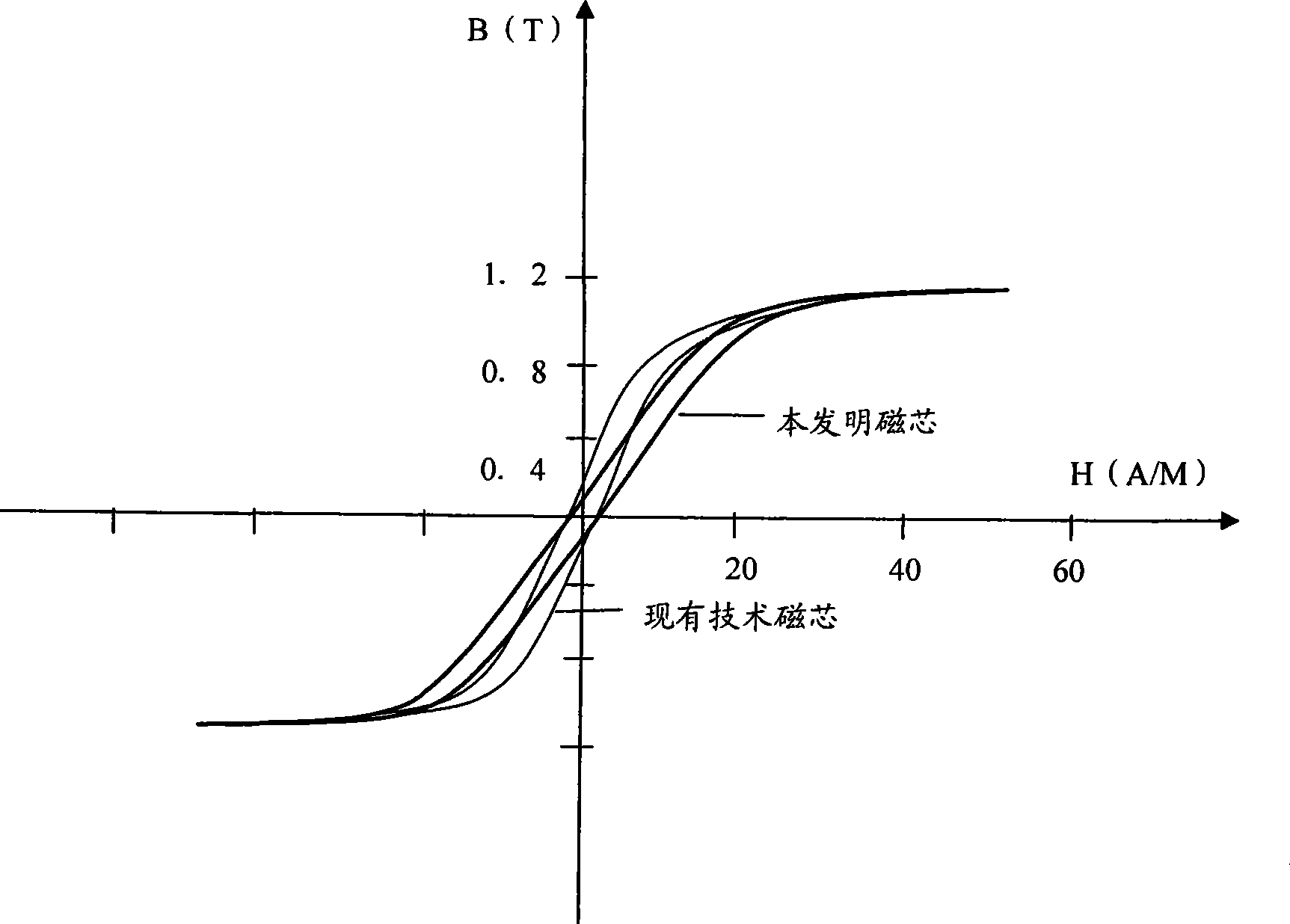

Current transformer iron core of amorphous and nano-crystalline magnetically soft alloy and preparation method thereof

ActiveCN105047348AReduce magnetic lossReduce lossTransformers/inductances magnetic coresInductances/transformers/magnets manufactureChemical compositionAlloy

The invention discloses a current transformer iron core of amorphous and nano-crystalline magnetically soft alloy and a preparation method of the current transformer iron core. The chemical component atomic percent of the iron core is FeaSibBcMdCueM'f, wherein a is not more than 85 and is not less than 65; b is not more than 25 and is not less than 5; c is not more than 15 and is not less than 0; d is not more than 15 and is not less than 0; e is not more than 5 and is not less than 0, and f is not more than 1 and is not less than 0, and a plus b plus c plus d plus e plus f equals to 100, and M is at least one of Nb, Mo or V, and M' is at least one of Sn, Al, Y and Sb. The preparation method comprises the steps as follows: preparing materials according to atomic percent and smelting to prepare a mother alloy; then crushing the prepared mother alloy to re-melt and covering steel-making slagging constituent to prevent oxidation and deslagging; preparing amorphous alloy ribbons with the re-melted mother alloy by using a single roll rapid solidification ribbon preparation method under ordinary pressure, and finally winding the amorphous alloy ribbons as the amorphous iron core, and performing isothermal annealing crystallization in a vacuum annealing furnace to obtain the amorphous and nano-crystalline magnetically soft alloy of a mutual inductor iron core. The iron core of the invention has high saturation flux density, high permeability, and low magnetic loss so that the mutual inductor has ultrahigh precision and accuracy class.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD +1

Tenacious metallic nano-crystalline bulk material with high hardness and high strength, and its manufacturing method

InactiveCN1685071AEasy to manufactureApplicable to solidification forming processTransportation and packagingMetal-working apparatusBorideExplosive forming

The invention provides a high hard, strength and tough nano-crystal metal bulk material and a preparation process thereof. The metal bulk material comprises an aggregate of metal nano-crystal grains, wherein an oxide, nitride, carbide, boride or the like of a metal or semimetal exists as a crystal grain growth inhibitor between and / or in the nano-crystal grains. The respective fine powders of nano-metal bulk material-forming components are mechanically alloyed (MA), using a ball mill or the like, thereby preparing nano-metal powders. Then, hot forming-by-sintering treatment such as spark plasma sintering, extrusion and rolling or explosive forming is applied to the powders to obtain a high hard, strength and tough nano-crystal metal bulk material.

Owner:NANO TECH INST

Method for preparing hybrid film through graphene/nano crystalline cellulose dispersion liquid

The invention relates to a method for preparing hybrid film through graphene / nano crystalline cellulose dispersion liquid. The preparation method comprises the following steps: respectively dispersing oxidized graphene obtained by oxidation treatment and nano crystalline cellulose in a dispersing agent, and then, gradually dripping nano crystalline cellulose dispersion liquid into oxidized graphene dispersion liquid to obtain graphene / nano crystalline cellulose dispersion liquid, adding a reducing agent under ultrasonic or mechanical stirring condition to reduce the oxidized graphene, inserting the crystalline cellulose between graphene pieces to prevent aggregation between the graphene layers and to form uniformly dispersed and stable graphene / nano crystalline cellulose dispersion liquid, and then, preparing a graphene / nano crystalline cellulose hybrid film through such methods as spin coating, spray coating, film casting, and the like. The prepared hybrid film has high uniformity, and the higher the content of the graphene in the hybrid film, the stronger the thermal stability and conductivity of the hybrid film are; the higher the content of nano crystalline cellulose in the hybrid film is, the smaller the contact angle of the hybrid film is, and the stronger the hydrophilicity is.

Owner:WUHAN TEXTILE UNIV

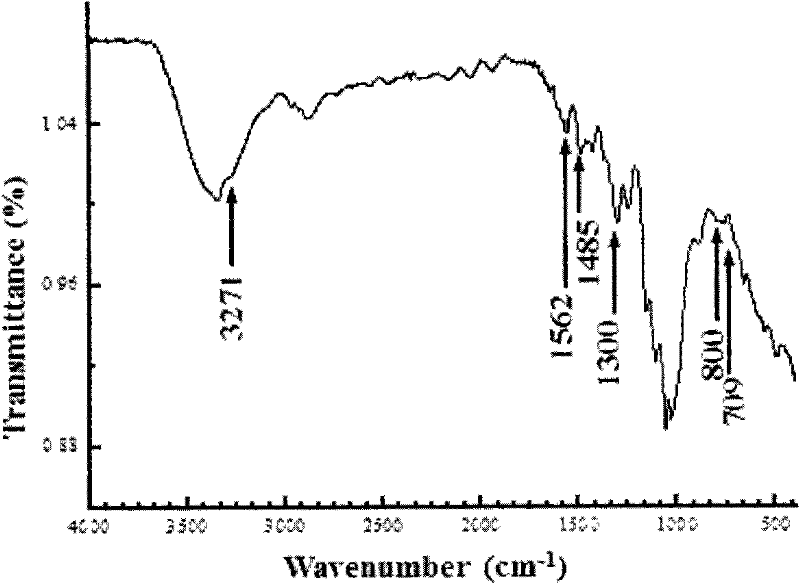

Preparation method and product of nanocellulose crystal/polyaniline composite material

InactiveCN102295786AReduce manufacturing costIncrease productivityLiquid crystal compositionsIn situ polymerizationSynthesis methods

The invention discloses a method for preparing nano-cellulose crystal / polyaniline composite material and a product thereof. In the method, firstly, the cellulose is hydrolyzed by acid to obtain nano-cellulose crystals, and the suspension of the nano-cellulose crystals spontaneously forms lyotropic cholesteric liquid crystals at a certain concentration. Then, the nanocellulose crystal / polyaniline composite material product with reversible redox properties is prepared by in-situ polymerization reaction of the polyaniline conductive monomer in the nanocellulose crystal cholesteric liquid crystal. The invention has the advantages of low cost, simple synthesis method, high production efficiency and the like.

Owner:QINGDAO UNIV OF SCI & TECH

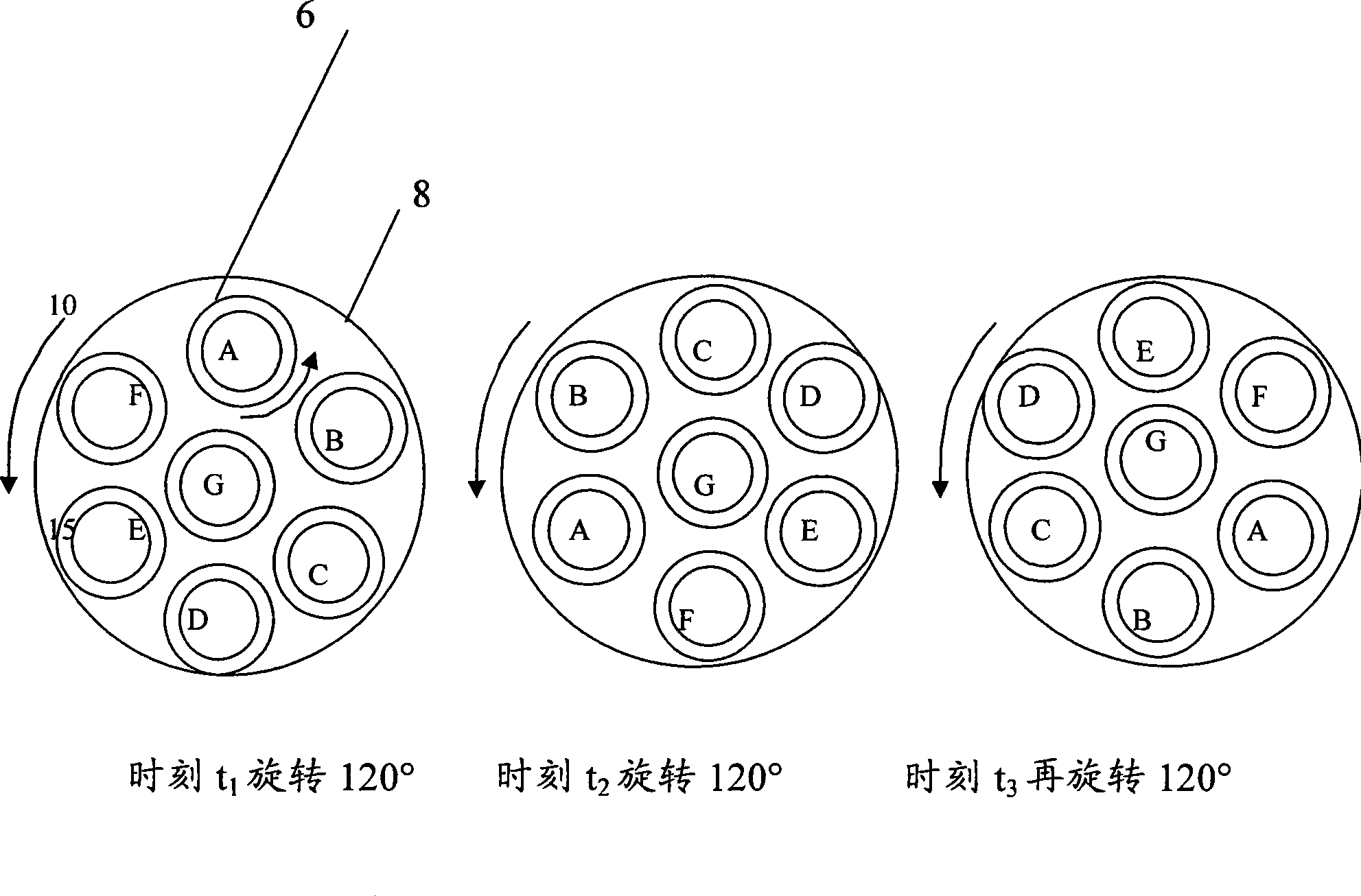

Iron based nanocrystalline magnet core for large power inverter power source and production method

ActiveCN101477868AGood tape making processReduce lossInorganic material magnetismTransformers/inductances magnetic coresPower inverterDownstream processing

The invention relates to a soft magnetic core used for a high-power inverter power supply, and a manufacturing method thereof. The magnetic core is made of an Fe-based amorphous nano-crystalline belt material through winding , and comprises components according to weight percentages as follows: 81%-85% of Fe, 0.01%-5% of Co, 7%-9% of Si, 1.5%-2.5% of B, 1%-2% of Cu, 4%-7% of M, and 0.001%-0.04% of M', wherein M is one or more of Nb, Mo, V, W and Ta, and M' is at least one of Al and Ti. The magnetic core is subjected to anneal in a protective atmosphere or a vacuum; when in anneal, the position of the magnetic core in a furnace is movable or rotatable, a holding temperature is 520-600 DEG C, the holding time is 1-2 hours, and a temperature rise speed is 100 DEG C per hour. The magnetic core manufactured by adopting the method has lower loss, better manufacturing technique properties, and good soft magnetic characteristics; moreover, the downstream processing after the heat treatment is applicable to various technique methods.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

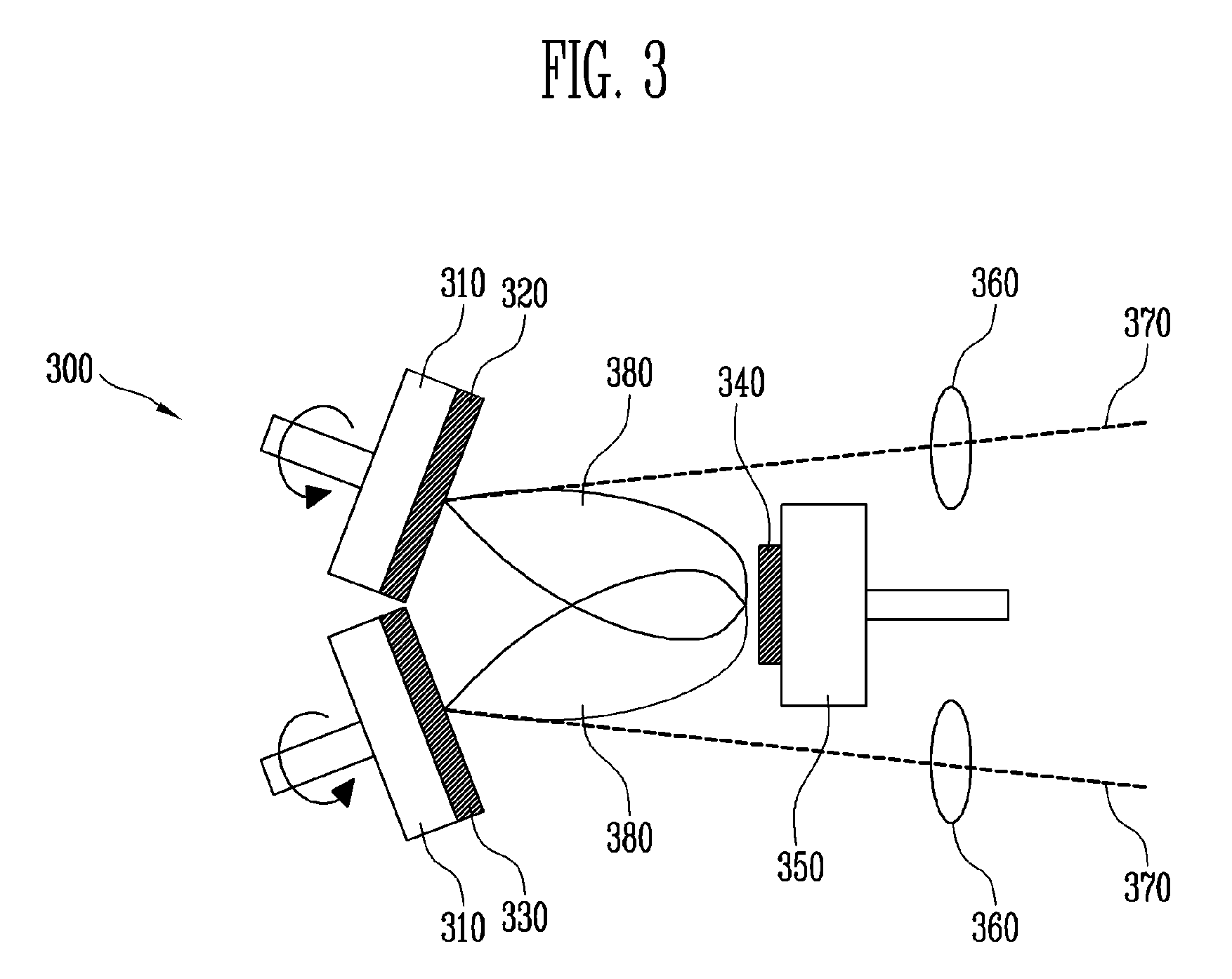

Nano-crystalline composite-oxide thin film, environmental gas sensor using the thin film, and method of manufacturing the environmental gas sensor

InactiveUS20090148347A1Excellent gas reactivity characteristicHigh sensitivityOxide/hydroxide preparationIndividual molecule manipulationProduct gasEnergy expenditure

A nano-crystalline composite-oxide thin film for an environmental gas sensor, an environmental gas sensor using the thin film, and a method of manufacturing the environmental gas sensor are provided. The nano-crystalline composite-oxide thin film is formed of hetero-oxide nano-crystalline particles having independent crystalline phases from each other, and the environmental gas sensor including the thin film has excellent characteristics including high sensitivity, high selectivity, high stability and low power consumption.

Owner:ELECTRONICS & TELECOMM RES INST

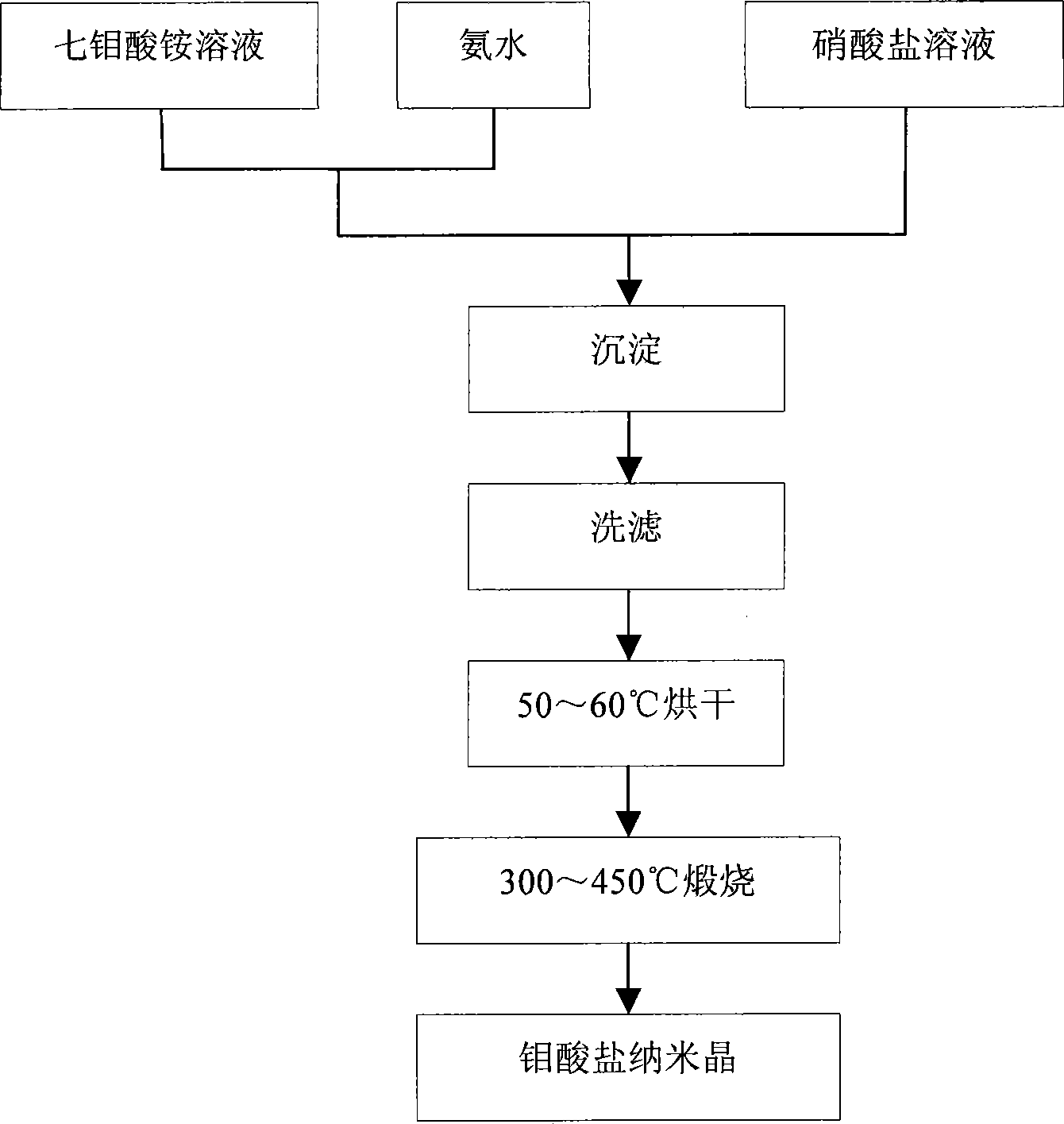

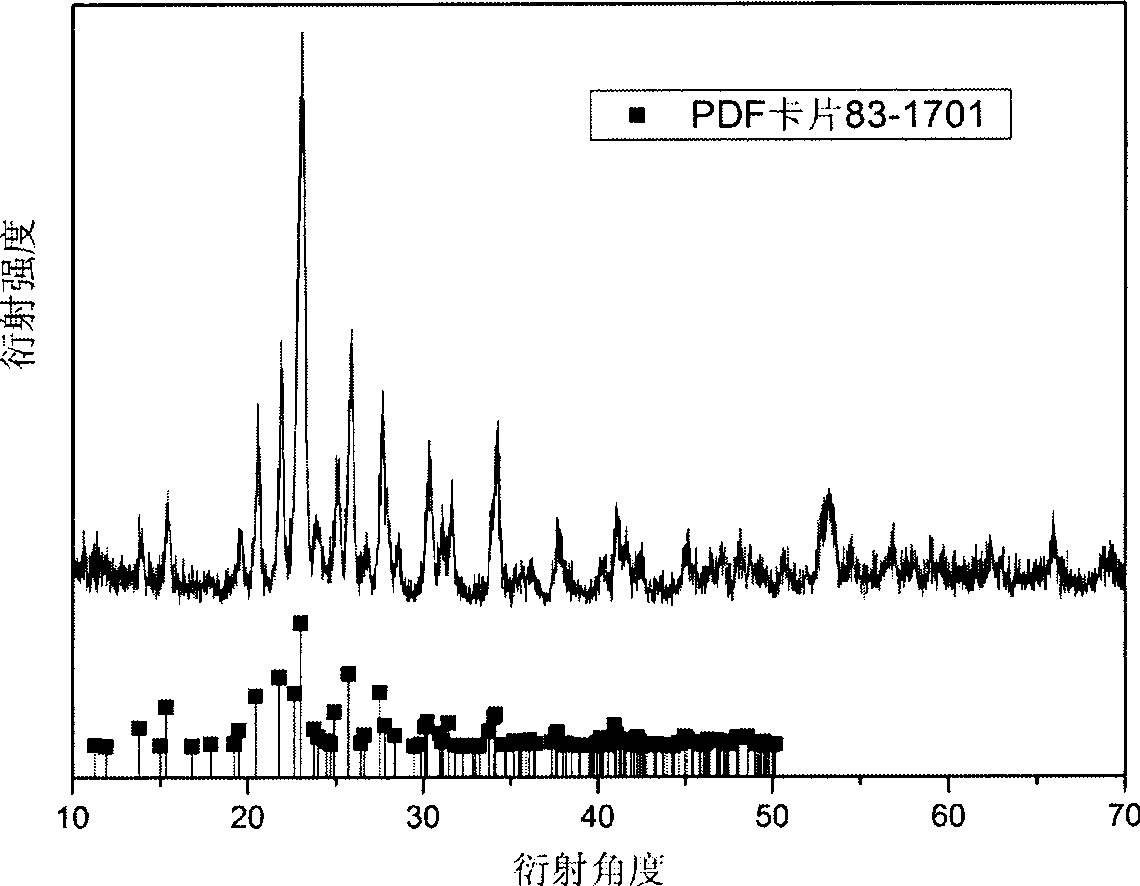

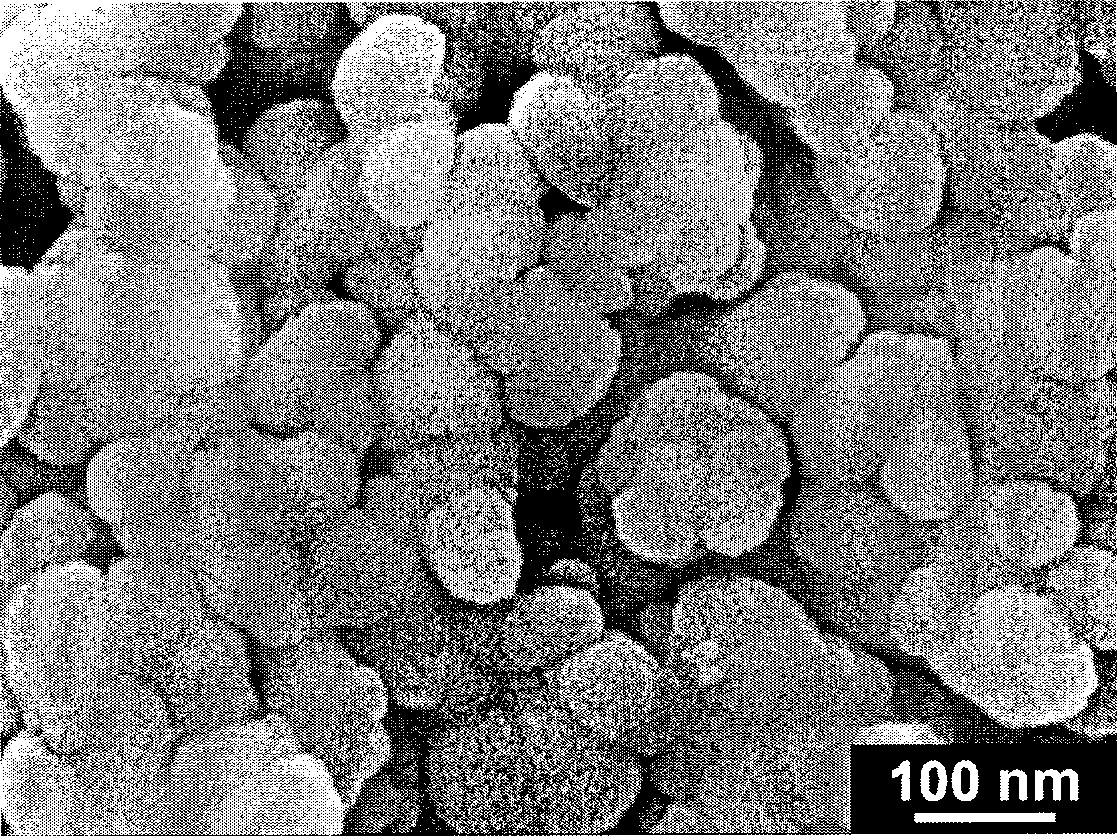

Method for preparing molybdate nanocrystalline

InactiveCN101391817AQuick and efficient preparationThe experimental process is simpleMolybdeum compoundsSolventCrystallinity

The invention provides a method for preparing molybdate nano-crystalline, which is characterized in that: with hexaammonium molybdate and nitrate as raw materials, the method for preparing molybdate nano-crystalline comprises steps as follows: preparing mixed solution of ammonium paramolybdate and ammonia as well as solution of nitrate with a certain concentration; stirring forcibly at the room temperature and dripping the solution of nitrate into the solution of ammonium paramolybdate and ammonia to form precipitate; and filtering, drying and heat treating the precipitate to prepare the molybdate nano-crystalline. The prepared molybdate nano-crystalline is in the different shapes of nanometer grain, nanometer rod, nanometer wire or nanometer sheet. With cheap raw materials and easy operation, the molybdate synthesis method provided by the invention does not need complex instruments or expensive solvent, thus being a method for the quick preparation of the molybdate nano-crystalline. With different nanometer patterns, the prepared molybdate is provided with high degree of crystallinity and purity. The method for preparing molybdate nano-crystalline has the advantages of simple technique, easy control, environmental protection, and safe and reliable operation, and can be used for batch production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Carbon nanotube-nano-crystalline cellulose-polyvinyl alcohol composite conductive gel and preparation method and application thereof

The invention belongs to the field of macromolecule composite conductive materials, and discloses a carbon nanotube-nano-crystalline cellulose-polyvinyl alcohol composite conductive gel and a preparation method and application thereof. The gel is prepared from the following steps: a: preparing carbon nanotube dispersion liquid; b: preparing nano-crystalline cellulose suspension; c: taking the mixture of the carbon nanotube and the nano-crystalline cellulose, adding the mixture into polyvinyl alcohol aqueous solution, adding a crosslinking agent, stirring until gel is formed to obtain the gel. The gel can be used for preparing flexible conductive materials and has a better application prospect.

Owner:NANJING FORESTRY UNIV

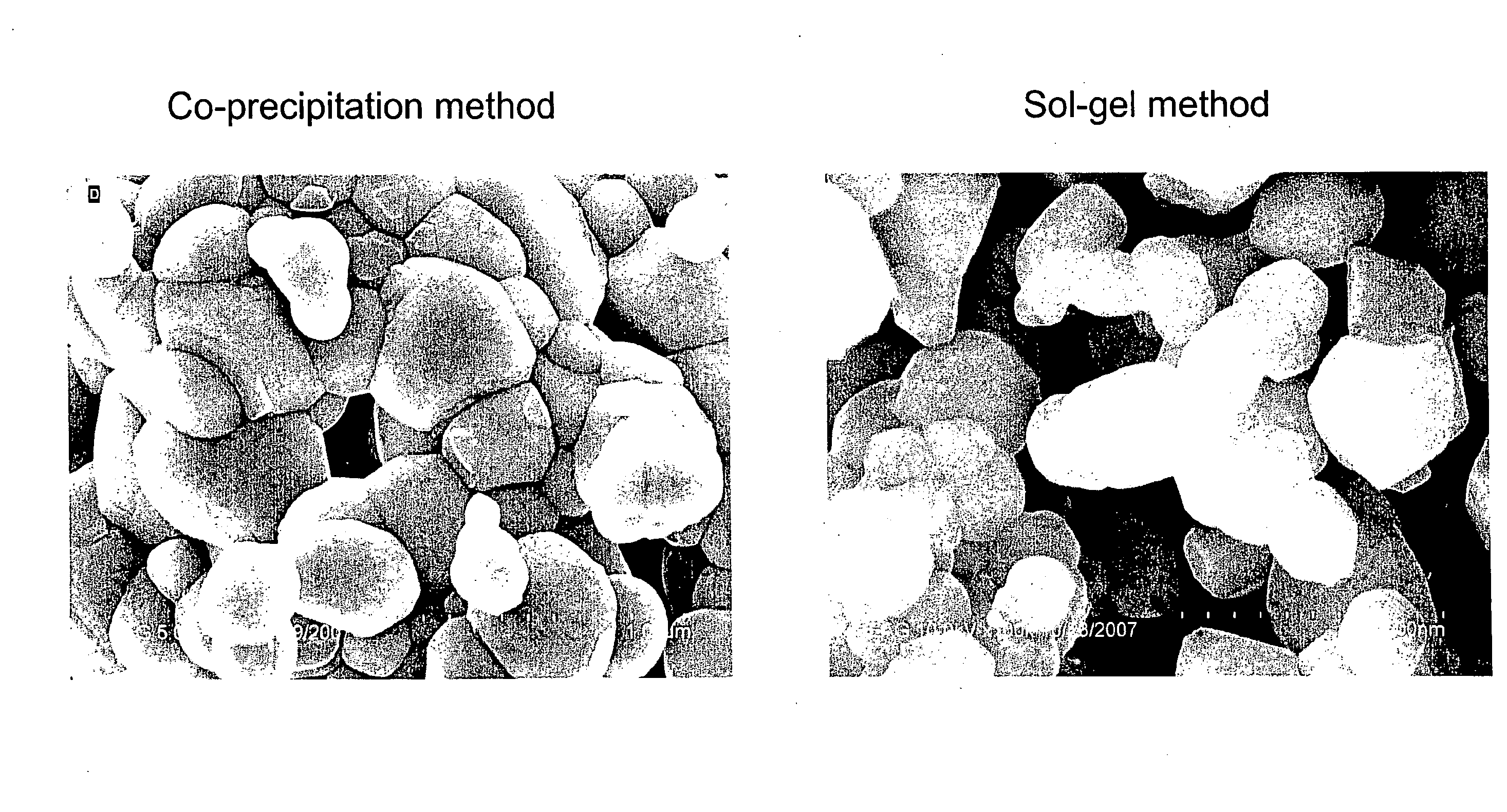

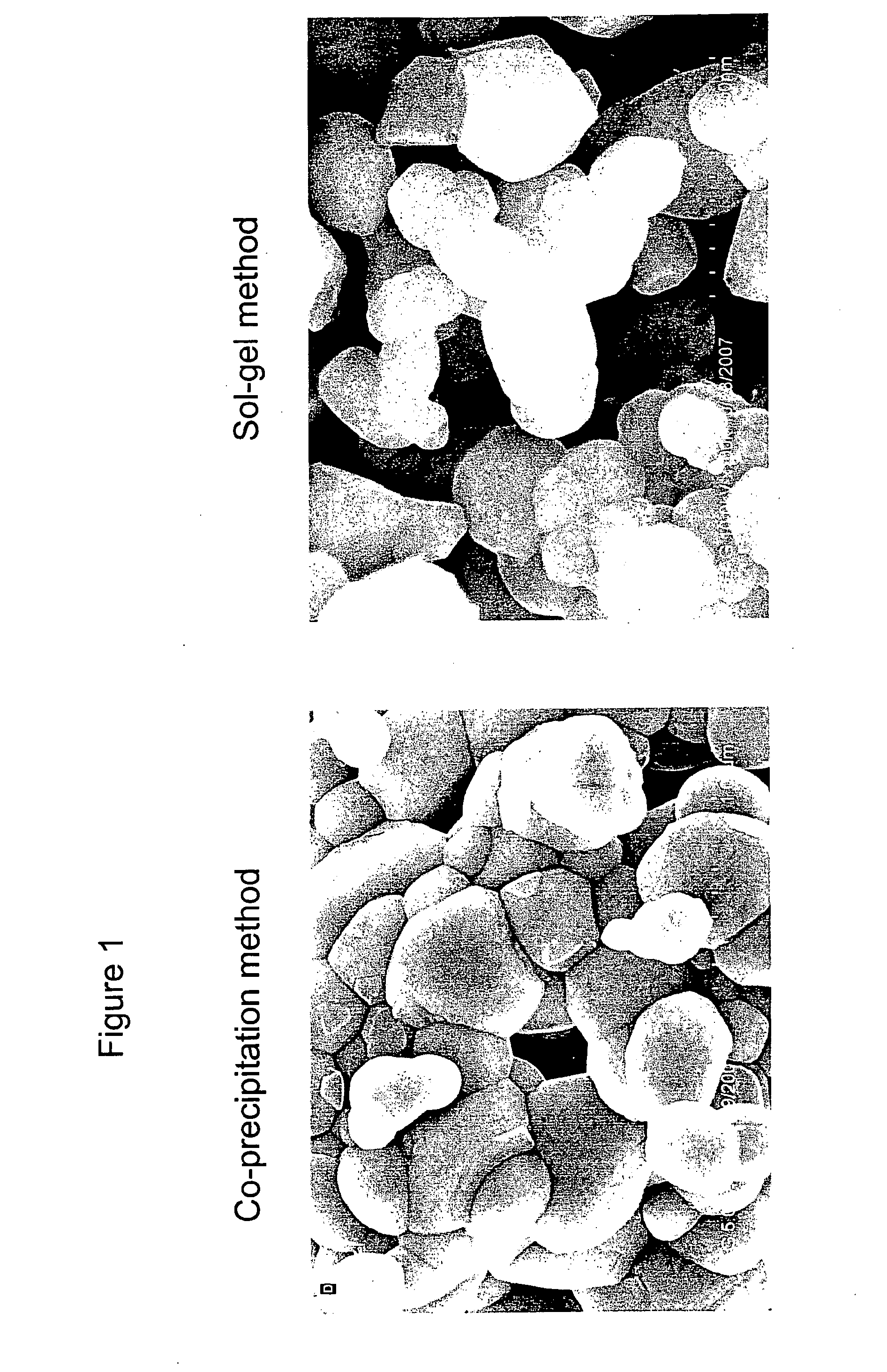

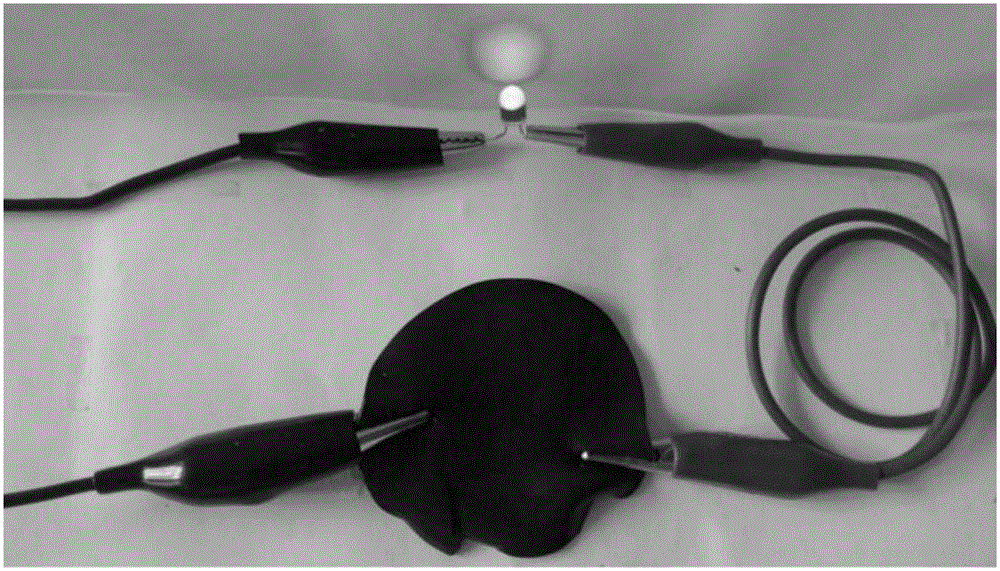

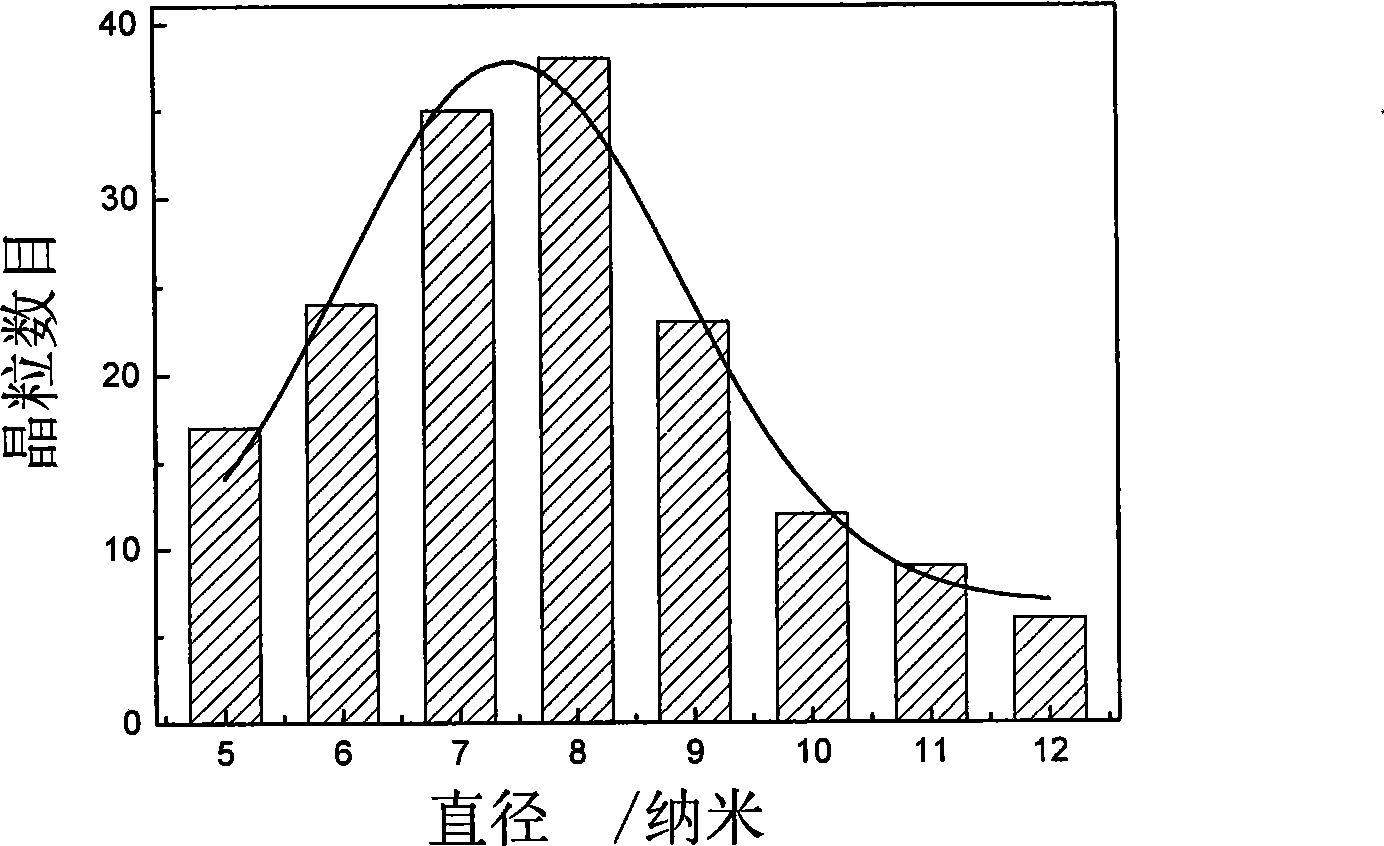

Nano-crystalline Fe*O* particles with high absorption capacity and preparation method thereof

InactiveCN101445277AImprove adsorption capacityImprove propertiesOther chemical processesFerroso-ferric oxidesChemical reactionHigh absorption

The invention relates to nano-crystalline Fe3O4 particles with high absorption capacity and a preparation method thereof which belong to the field of material science. The microstructure of the particles comprises equiaxed nano-grains, and the particle size of the nano-grains is 5-100nm; the average particle size is 8-25nm, and the saturated magnetization MS is 6.7-7.2 multiplied by 10<minus 3>A / m. The preparation method is as follows: solution containing ferric ions and ferrous ions is prepared, ammonia solution is added under nitrogen atmosphere, ultrasonic waves are transmitted to carry out the ultrasonic dispersion, and heating, stirring and reaction are carried out; solids are washed till neutral by water under the condition of a magnetic field; water is removed by drying after the centrifugal separation. The invention utilizes the simple chemical reaction co-precipitation technology and combines the ultrasonic stirring, the centrifugal separation, the vacuum drying and other technologies to obtain the Fe3O4 powder materials with the average particle size of 8-25nm and the higher saturated magnetization.

Owner:NORTHEASTERN UNIV

Method of manufacturing nano-crystalline cellulose film

The present invention provides a method of manufacturing a film containing nano-crystalline cellulose.

Owner:KRUEGER GMBH & CO KG

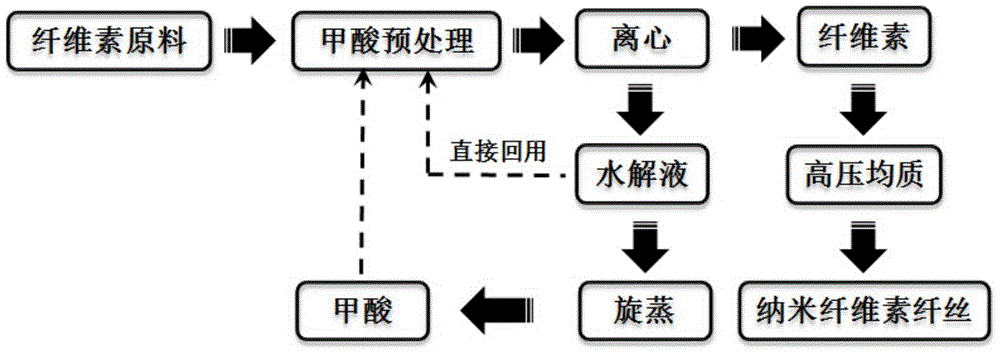

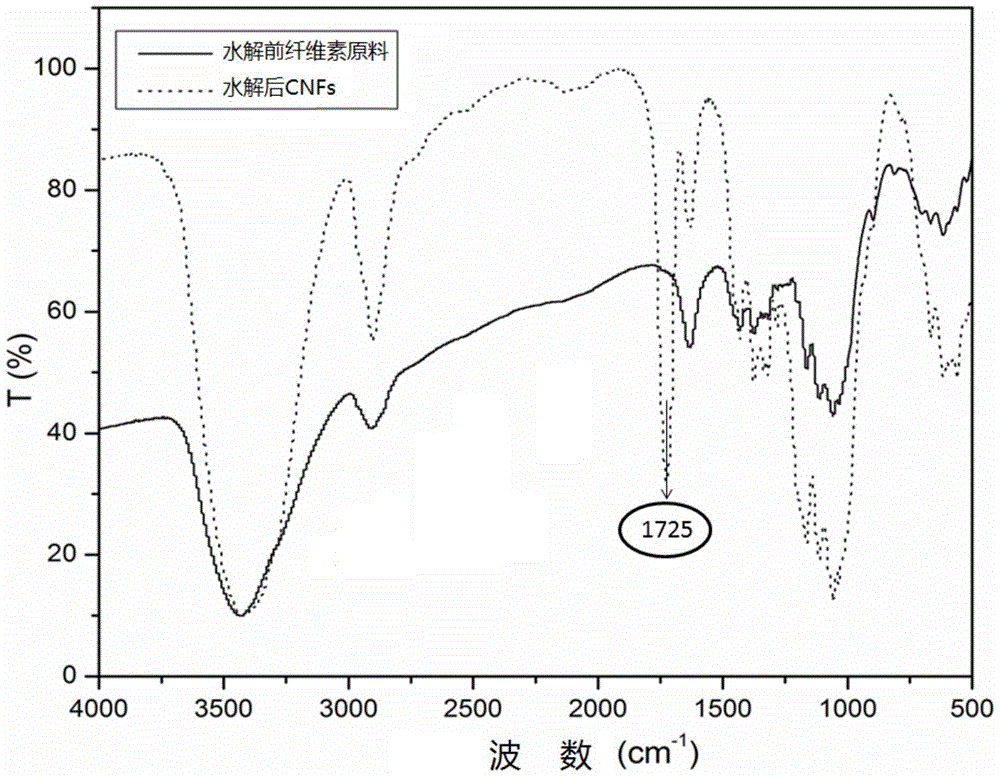

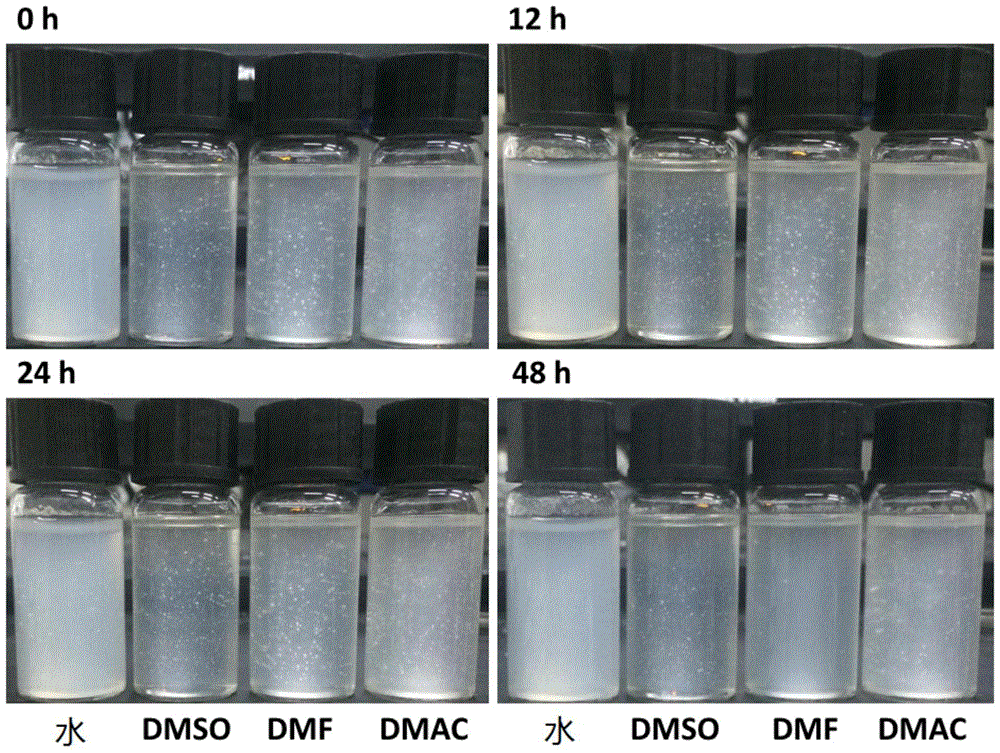

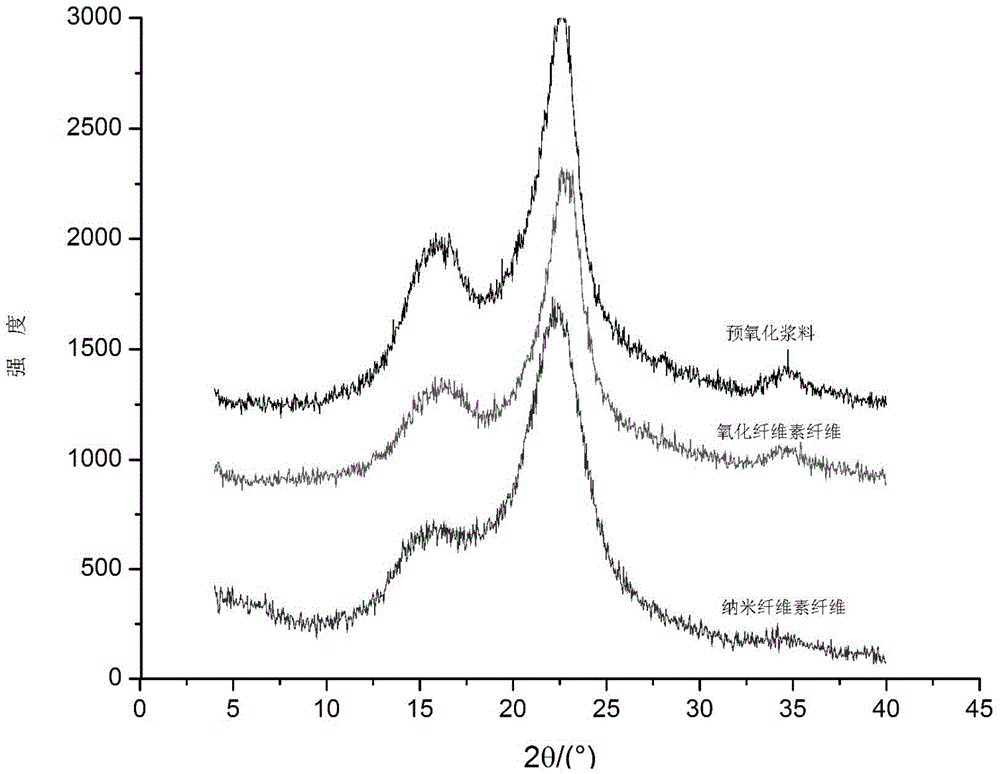

Method combining formic acid preprocessing and high-pressure homogenization to prepare nano-crystalline cellulose fibrils

The invention relates to a green, economical and sustainable method for preparing nano-crystalline cellulose fibrils. The method includes the steps of firstly, cellulose raw material is added into a formic acid solution, and heating and stirring are performed for hydrolysis to obtain preprocessed cellulose; secondly, the preprocessed cellulose is separated from hydrolysate through centrifugal settling, the settled cellulose is centrifugally washed with water, and the washed cellulose is diluted into a cellulose suspension with certain concentration; thirdly, the separated hydrolysate can be directly recycled at least once, the recycled hydrolysate can recycle formic acid through reduced-pressure distillation, and the recycled formic acid can be recycled; fourthly, the cellulose suspension obtained in the second step is homogenized for certain times under certain pressure through a high-pressure homogenizing machine to obtain the colloidal nano-crystalline cellulose fibrils. The method has the advantages that no catalysts are used, and the method is relatively mild in reaction condition, easy in reaction control, simple to operate and environmental friendly.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Nano-crystalline cellulose fiber high in carboxyl group content and preparation and application thereof

InactiveCN105463606AIncrease the total carboxyl contentGuaranteed crystallinityOther chemical processesArtificial filaments from cellulose derivativesPolymer scienceFreeze-drying

The invention belongs to the technical field of biomass nanometer materials and discloses a nano-crystalline cellulose fiber high in carboxyl group content and preparation and application thereof. A preparation method comprises the steps of preheating fiber slurry for 0.5-1.5h with sodium periodate at the temperature of 50-60 DEG C; adding a sodium chlorite solution and acetum into the slurry to be reacted for 1-3h at the temperature of 30-50 DEG C, adding TEMPO, NaClO2 and NaClO, and performing microwave heating to the temperature of 55-65 DEG C to enable the mixture to be reacted for 1-3h; performing ultrasonic dispersion and freeze drying to obtain the nano-crystalline cellulose fiber high in carboxyl group content. According to the nano-crystalline cellulose fiber, hydroxyl at the positions of C2 and C3 of cellulose is oxidized into a formyl group which is oxidized into carboxyl by sodium chlorite, hydroxyl at the position of C6 is selectively oxidized into carboxyl through a TEMPO neutral oxidation system, and accordingly the total carboxyl group content of the fiber is greatly increased, and obtained products can be used for advanced treatment of waste water at the middle section of paper making.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com