Cemented carbide cutting tool for multi-component coating

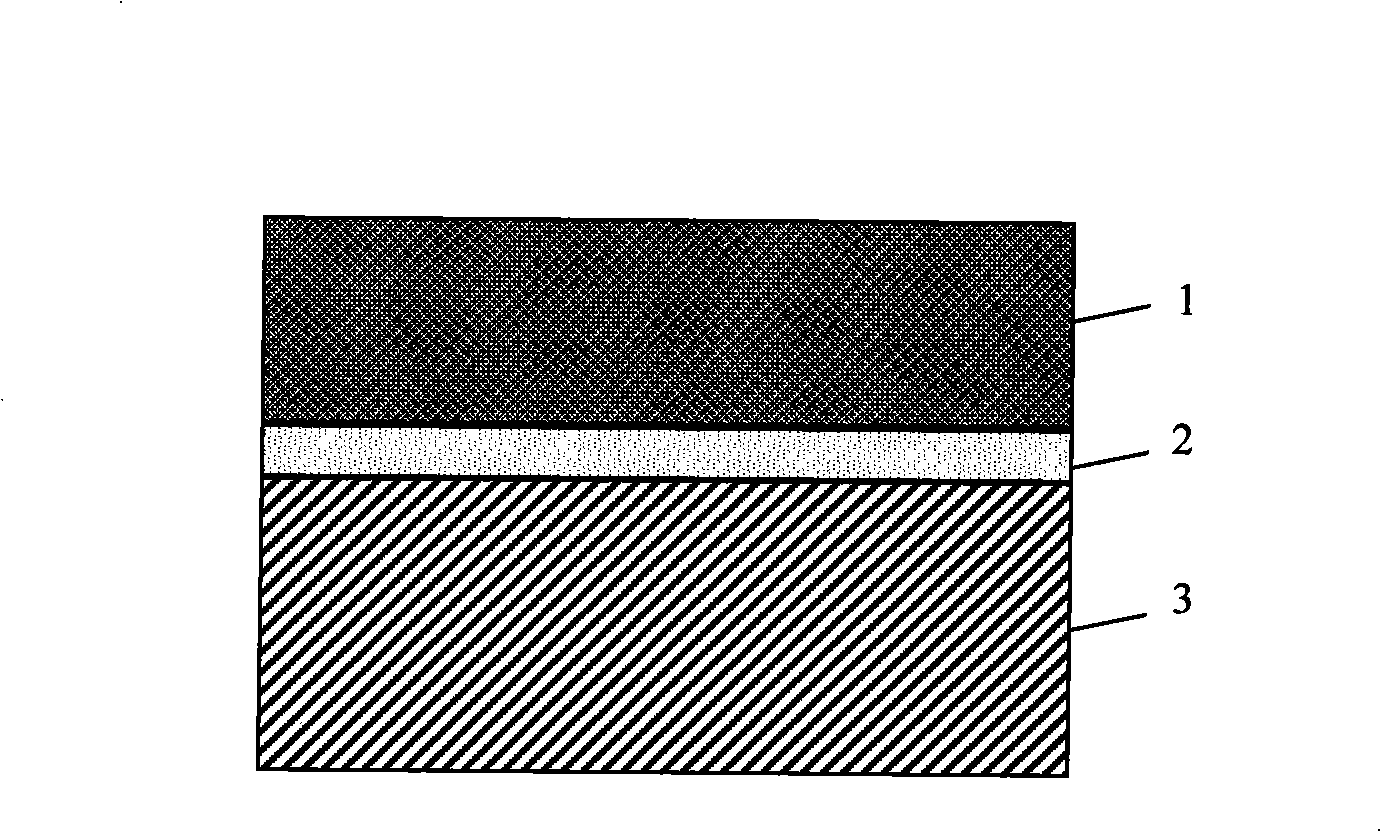

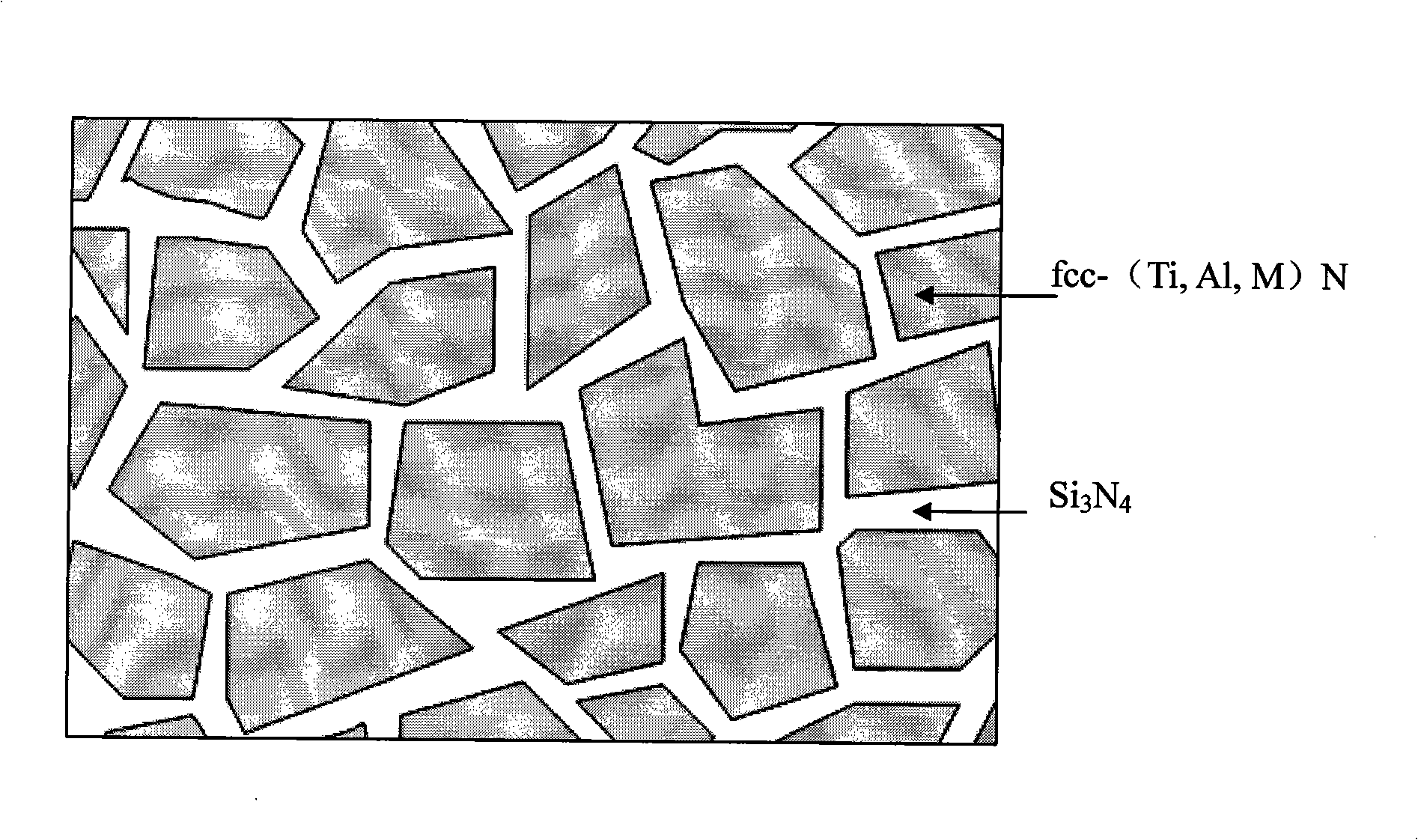

A technology of cemented carbide and cutting tools, which is applied in the direction of coating, metal material coating technology, layered products, etc., can solve the problems of poor toughness, poor toughness of coating, easy softening, etc., and achieve improved wear resistance and Oxidation resistance, improved shear strength and high temperature creep resistance, improved strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

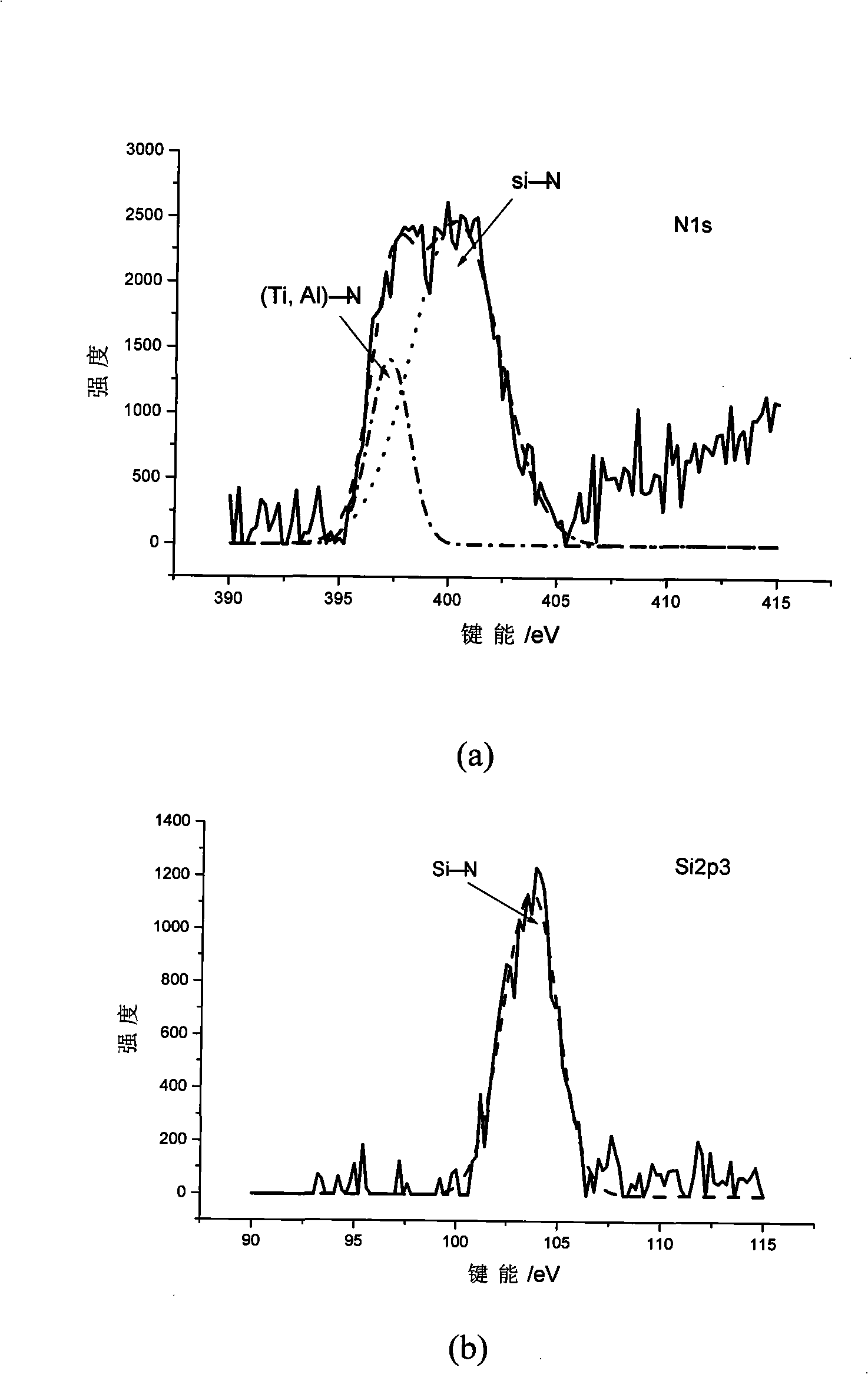

Method used

Image

Examples

Embodiment 1

[0037] A kind of coated blade of the present invention, blade model is CNMG120408 type standard blade, and its substrate is cemented carbide, comprises the Co that percentage by weight is 10%, the TaC of 0.5%, the Cr of 0.5% 2 C 3 , the balance is WC with a particle size of 0.8 μm; the basic parameters of the blade coating are shown in Table 1.

[0038] Comparative inserts 1 and 2 have the same model and the same composition of cemented carbide substrates as the coated inserts of Example 1, and the coating is TiAlN coating. The basic parameters of the coating are shown in Table 1.

[0039] Table one: the blade coating of embodiment 1 and the parameter of contrast coating

[0040]

[0041] The cutting conditions and processing parameters of the above three inserts are as follows:

[0042] The processing material is 1Cr18Ni9Ti;

[0043] The processing method is cylindrical turning;

[0044] Cutting speed Vc=120m / min;

[0045] Cutting depth ap = 1.0mm;

[0046] Feed per ...

Embodiment 2

[0052] A kind of coated blade of the present invention, blade model is SEET12T3 type standard blade, and its matrix is cemented carbide, comprises the Co that weight percent is 10%, the TaC of 1%, surplus is the WC of particle size 3 μm; Blade coating The basic parameters are shown in Table 2.

[0053] The comparative insert 3 has the same model and the same composition of cemented carbide substrate as the coated insert in Example 2, and its coating is TiAlN coating. The basic parameters are shown in Table 2.

[0054] Table two: the blade coating of embodiment 2 and the parameter of contrast coating

[0055]

[0056] The cutting conditions and processing parameters of the above two inserts are as follows:

[0057] The processing material is 1Cr18Ni9Ti;

[0058] The processing method is plane milling;

[0059] Cutting speed Vc=200m / min;

[0060] Cutting depth ap = 1.0mm;

[0061] Cutting width ae=30mm;

[0062] Feed per tooth f=0.2mm / r;

[0063] Cooling method: wate...

Embodiment 3

[0069] A coating tool of the present invention is a standard two-edged flat end mill with a diameter of 6mm, and its substrate is hard alloy, including 10% Co by weight and 0.5% Cr 2 C 3 , the balance is WC with a particle size of 0.8 μm; two different types of blade coatings (3-1, 3-2) are used respectively, and the basic parameters are shown in Table 3.

[0070] Comparative tool 4 has the same model and the same composition of cemented carbide substrate as the coated tool in Example 3, and its coating is TiAlN coating. The basic parameters are shown in Table 3.

[0071] Table three: the parameter of the tool coating of embodiment 3 and contrast coating

[0072]

[0073] The cutting conditions and processing parameters of the above three tools are as follows:

[0074] The processing material is 1Cr18Ni9Ti;

[0075] The processing method is reciprocating side milling;

[0076] Cutting speed Vc=70m / min;

[0077] Cutting depth ap = 3.0mm;

[0078] Cutting width ae=0.5mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com