Iron based nanocrystalline magnet core for large power inverter power source and production method

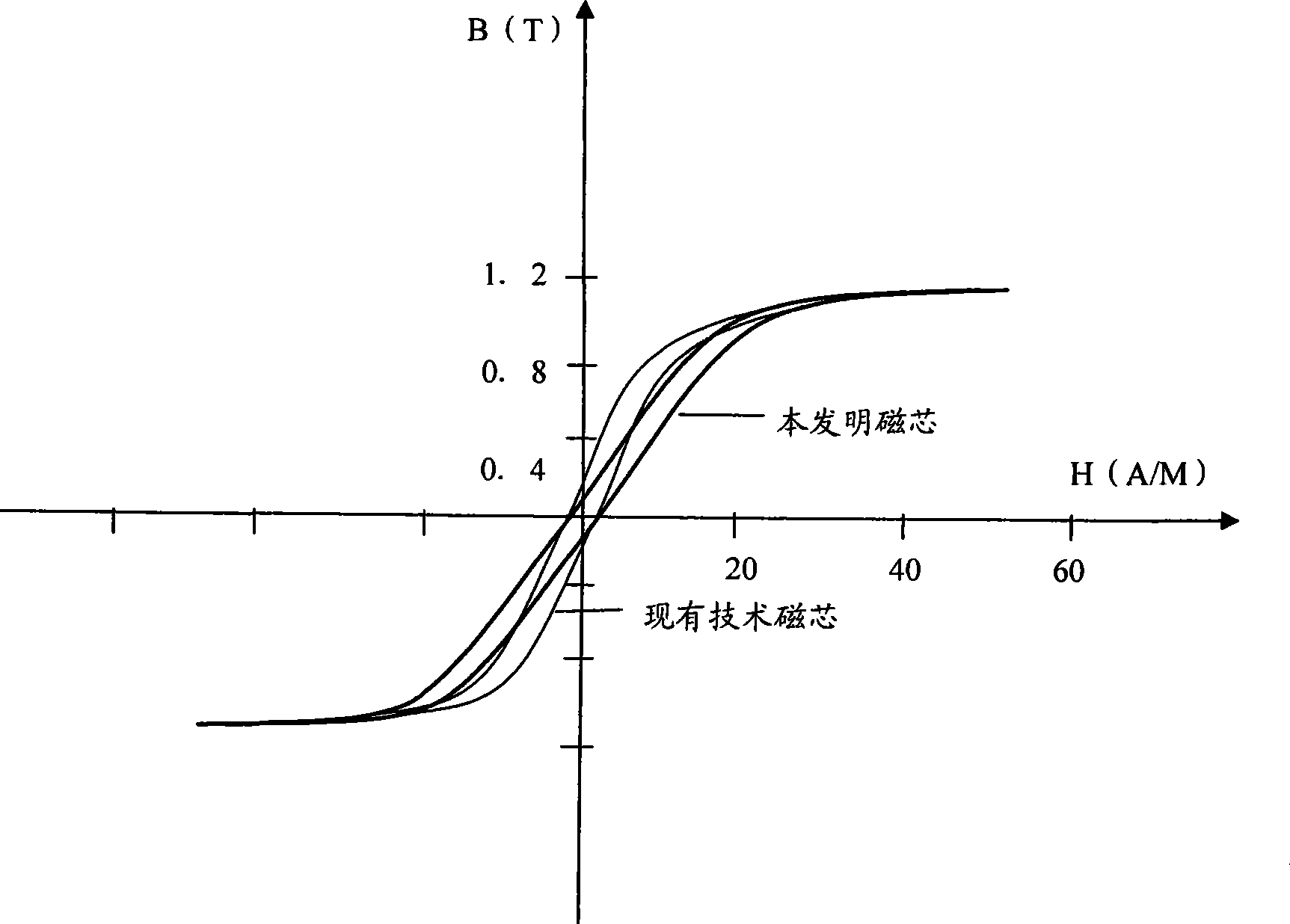

A technology of iron-based nanocrystals and inverter power supply, which is applied in the direction of transformer/inductor magnetic core, inductor/transformer/magnet manufacturing, circuit, etc. Temperature rise and other issues, to achieve good transverse magnetic field treatment effect, large magnetic induction anisotropy, low remanence induction intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

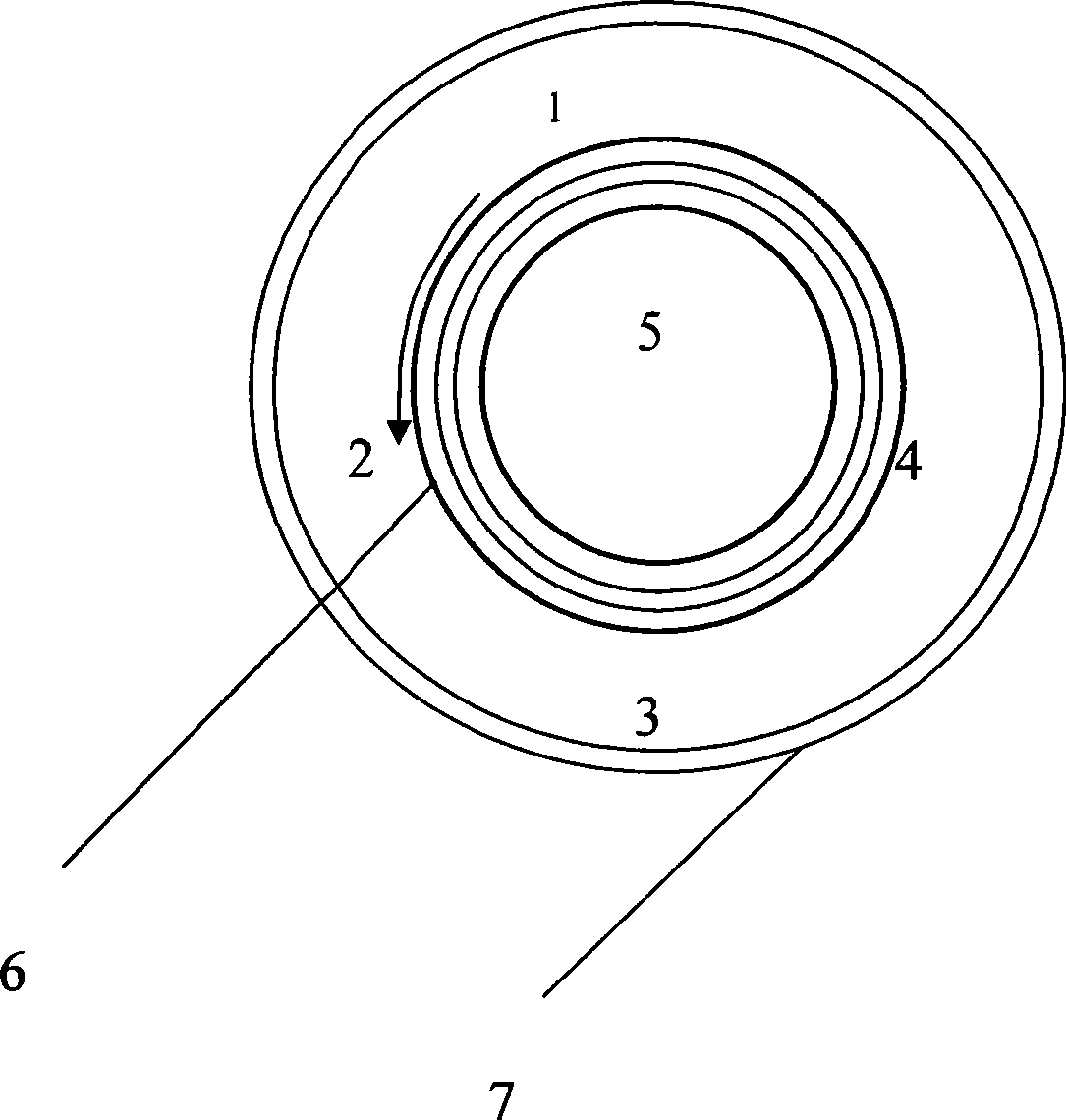

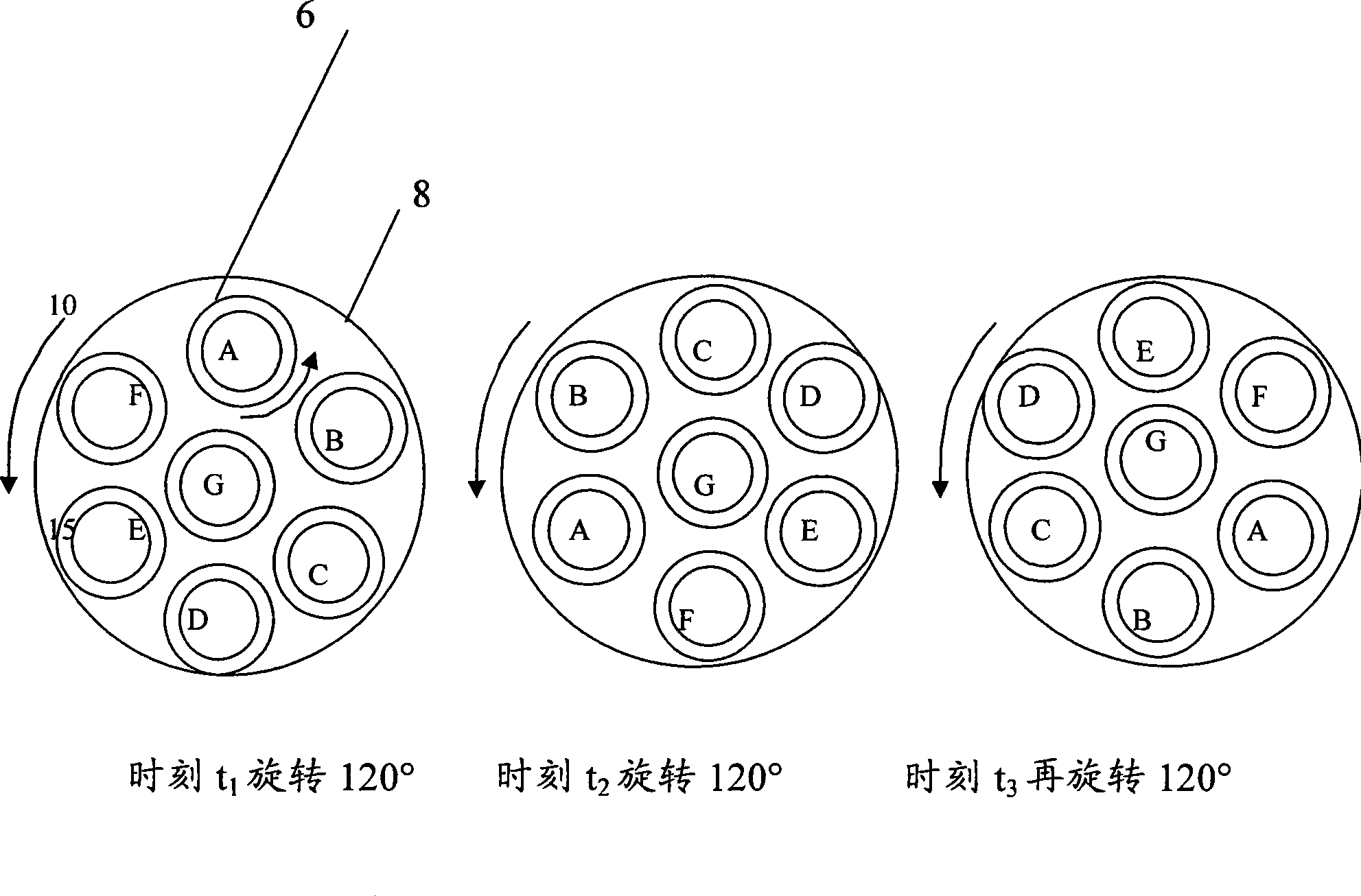

[0059] A master alloy whose composition is Fe82.5Cu1.2Co0.5Nb5.6Si8.7B1.5 (containing 0.018% Al) is made into a smooth strip with a thickness of 24 μm by a single roll method, a width of 30 mm, and a lateral thickness tolerance of less than 1 μm. Winding Put the ring-shaped magnetic core into a tubular transverse magnetic field furnace and hold it at 560°C for 1 hour. During the holding period, the magnetic core rotates 90° along the central axis every 5 minutes. Apply stress-free protective film evenly, put it into a protective box with mesh after curing, and measure the loss value with the attenuation oscillation transient analysis method, the loss P5 / 20k=21w / kg, the magnetic properties of the core are shown in Table 2.

[0060] Table 1 is a comparison table of the performance of the magnetic core of this embodiment and the transformer manufactured by the method of Chinese patent ZL96106793.4 after one hour of operation. It can be seen from Table 1 that a 315A inverter weld...

Embodiment 2

[0065] The master alloy whose composition is Fe82.9Cu1.29Co0.1Mo5.8Si8.0B1.9 (containing 0.01% Al and 0.008% Ti) is made into a bright thin strip with a thickness of 24 μm and a width of 40 mm by a single roll method, and is wound become The circular magnetic core is put into a tube-type transverse magnetic field furnace and kept at 530°C for 1 hour. During the heat preservation period, the magnetic core is rotated 90° along the central axis every 8 minutes. After the heat preservation is completed, it is cooled to room temperature with the furnace. The surface of the magnetic core is electrostatically sprayed to form a layer of epoxy resin film with a thickness of about 0.2mm on the surface. The magnetic properties of the magnetic core are measured by the attenuation oscillation transient analysis method, as shown in Table 2.

Embodiment 3

[0067] Other conditions are identical with embodiment 1, and composition is different from embodiment 1. The specific ingredients are shown in Table 2. Table 2 reflects the chemical composition of the present embodiment and comparative examples, the magnetic permeability μ, remanence ratio and loss value at f=20kHz, Bm=0.5T, where μ=μ 1 +iμ 2 .

[0068] Table 2

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| loss value | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com