Method for toughening epoxy resin by adopting modified wollastonite

A technology of tough epoxy resin and wollastonite, which is applied in the field of modified wollastonite toughened epoxy resin, can solve problems such as uneven dispersion, limitation of wollastonite application, and decline in mechanical properties of products, so as to increase added value and facilitate Effects of Handling, Tensile Strength and Impact Strength Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Modified wollastonite toughened epoxy resin

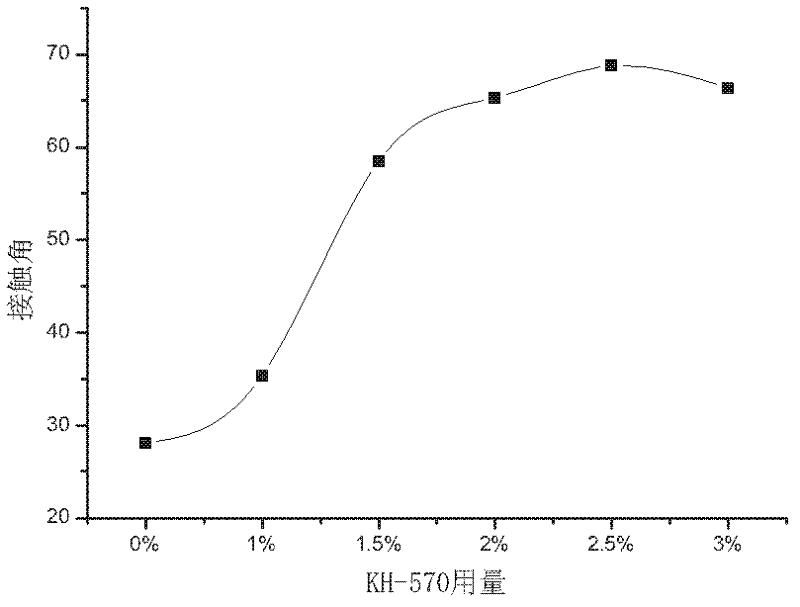

[0034] 1. Hydrolyze the silane coupling agent KH-570 in a mixed solution of absolute ethanol and deionized water (the volume ratio of ethanol and water is 1:4), add it to a 50 round bottom flask, and add a certain amount of silicon gray stone. The flask was placed in water at 80°C, and reacted under electromagnetic stirring for 3 hours. After the reaction, the mixture was suction-filtered, and the sediment was dried in a vacuum oven at 120°C for 12 hours. Grind the dry modified wollastonite in a planetary ball mill for 2 hours to obtain wet-process modified wollastonite.

[0035] 2. The modified wollastonite is mixed with epoxy resin and ground for 3 hours by a three-roller grinder to obtain a masterbatch with a certain solid content. The mass ratio of oxygen resin is 2:3.

[0036] 3. Mix epoxy resin, curing agent, and modified wollastonite masterbatch evenly, add initiator, release agent, and defoamer to mix, and react a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com