Toughening-strengthening heat treatment method of high nitrogen austenitic stainless steel

A technology of high nitrogen austenite and heat treatment method, applied in the field of high nitrogen austenitic stainless steel strengthening and toughening heat treatment, can solve the problems of reducing plasticity and toughness, damaging the mechanical properties of materials, not meeting performance requirements or high quality requirements, etc. To achieve the effect of toughening or enhancing performance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with an embodiment the present invention is further described as a case.

[0031] 1. Selection of high-nitrogen austenitic stainless steel and heat treatment process for the test

[0032] It is a high-nitrogen austenitic stainless steel after hot rolling, and its composition is 0Cr21Mn17MoNbN0.93, see Table 1.

[0033] Table 1. Chemical composition (wt%) of the steel used in the test

[0034] C Cr mn N Mo P S Si Nb Ni Fe 0.023 21.43 16.87 0.93 2.43 ≤0.012 ≤0.004 0.27 0.21 0.40 the remaining

[0035] The heat treatment technology of solid solution-aging-spheroidization was selected.

[0036] 2. Main heat treatment process parameters and tissue inspection

[0037] 2.1. The original state before the test is a hot-rolled state.

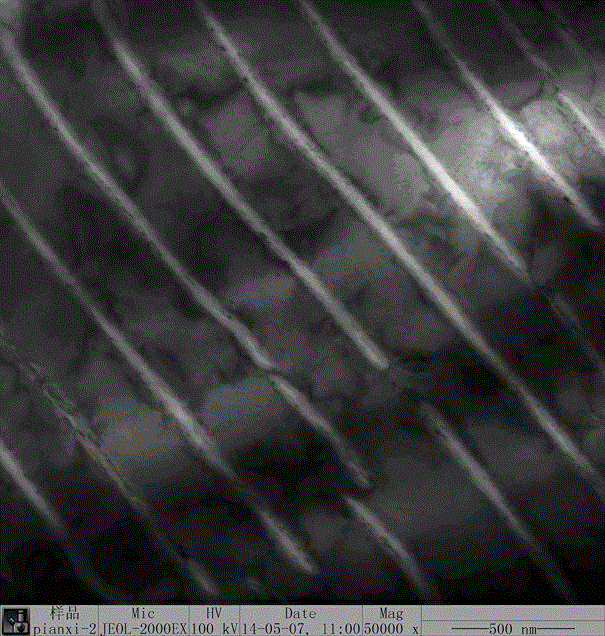

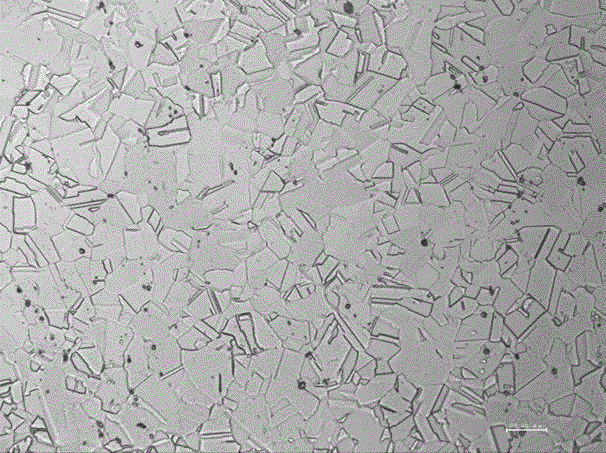

[0038] 2.2. Solution treatment, temperature 1140°C and heat preservation for 8 hours, quench the sample to obtain a single austenite structure, as shown in the attached figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com