Preparation method of toughened aluminum oxide ceramic

A technology for toughening alumina ceramics, applied in the field of preparation of toughened alumina ceramics, to achieve the effects of reducing production costs, promoting coagulation, and improving induction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing toughened alumina ceramics, characterized in that: the preparation steps are as follows:

[0047] Step 1, put the sludge from the aluminum profile factory into the reaction kettle, slowly stir and add hydrochloric acid dropwise until the pH is 3, let it stand for 1 hour, collect the mixed filtrate after filtering and washing;

[0048] Step 2, passing ammonia gas into the mixed filtrate, stirring evenly until no flocculation precipitate occurs, and obtaining the precipitated mixture after suction filtration;

[0049] Step 3, adding polyvinylpyrrolidone to the aqueous ethanol solution, and then slowly adding the precipitation mixture to obtain a stable suspension;

[0050] Step 4, adding nano-aluminum powder into the suspension, aeration and reflux reaction for 2 hours, adding a curing agent after the reaction to form a mixed suspension;

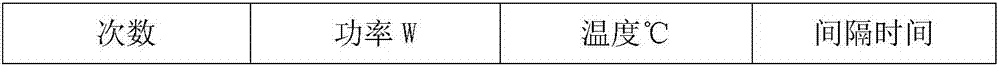

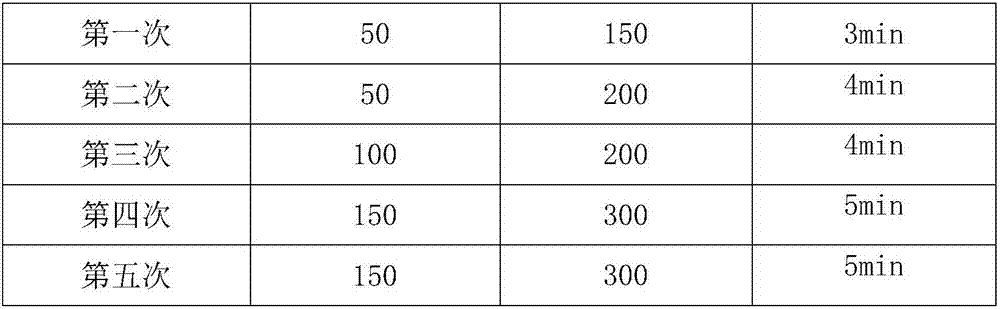

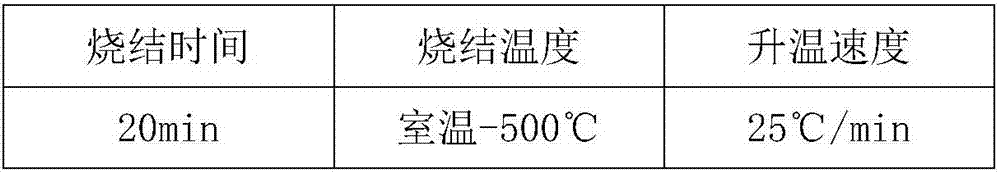

[0051] Step 5, putting the mixed suspension into a vacuum distillation device for vacuum distillation for 2 ho...

Embodiment 2

[0062] A method for preparing toughened alumina ceramics, characterized in that: the preparation steps are as follows:

[0063] Step 1, put the sludge from the aluminum profile factory into the reaction kettle, slowly stir and add hydrochloric acid dropwise until the pH is 5, let it stand for 3 hours, and collect the mixed filtrate after filtering and washing;

[0064] Step 2, passing ammonia gas into the mixed filtrate, stirring evenly until no flocculation precipitate occurs, and obtaining the precipitated mixture after suction filtration;

[0065] Step 3, adding polyvinylpyrrolidone to the aqueous ethanol solution, and then slowly adding the precipitation mixture to obtain a stable suspension;

[0066] Step 4, adding nano-aluminum powder into the suspension, aeration and reflux reaction for 4 hours, adding a curing agent after the reaction to form a mixed suspension;

[0067] Step 5, put the mixed suspension into a vacuum distillation device for vacuum distillation for 4 h...

Embodiment 3

[0078] A method for preparing toughened alumina ceramics, characterized in that: the preparation steps are as follows:

[0079] Step 1, put the sludge from the aluminum profile factory into the reaction kettle, slowly stir and add hydrochloric acid dropwise until the pH is 4, let it stand for 2 hours, and collect the mixed filtrate after filtering and washing;

[0080] Step 2, passing ammonia gas into the mixed filtrate, stirring evenly until no flocculation precipitate occurs, and obtaining the precipitated mixture after suction filtration;

[0081] Step 3, adding polyvinylpyrrolidone to the aqueous ethanol solution, and then slowly adding the precipitation mixture to obtain a stable suspension;

[0082] Step 4, adding nano-aluminum powder to the suspension, aeration and reflux reaction for 3 hours, adding a curing agent after the reaction to form a mixed suspension;

[0083] Step 5, put the mixed suspension into a vacuum distillation device for vacuum distillation for 3 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com