High-strength fiber double-layer interweaved composite hose and production method thereof

A high-strength fiber and composite hose technology, applied in layered products, fabrics, textiles, etc., can solve problems such as unsatisfactory, and achieve the effects of small torsion, few interweaving points, and small loss of yarn strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

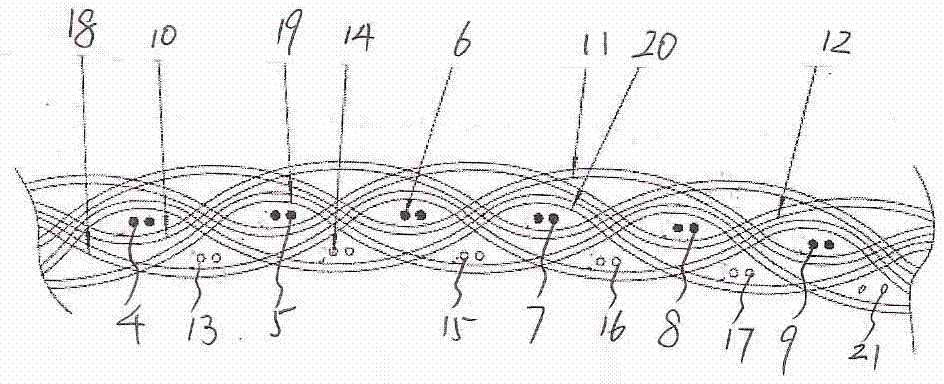

[0016] A high-strength fiber double-layer interweaving composite hose, including a tube blank 1, on the inner and outer surfaces of the tube blank, at least the inner surface composite colloid material layer (in this embodiment, the inner and outer surfaces are respectively provided with TPU material layers 2, 3 , or the inner surface is lined with polymer adhesive glue, and the outer surface is coated with polymer adhesive glue color paste); the tube blank is a double-layer fabric with a double-layer cross section, and the six-way warp is a weaving loop; the double-layer fabric Including the outer layer and the inner layer, the outer layer includes the outer warp threads 4, 5, 6, 7, 8, 9 and the outer layer weft threads 10, 11, 12, and the inner layer includes the inner layer warp threads 13, 14, 15, 16, 17, 21 and the inner layer weft threads 18, 19, 20, the inner layer weft threads both interweave with the inner layer warp threads, and interweave with the outer layer warp th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com