Knitting method for anti-stretch and anti-laddering dense and thick weft-knitted fabric

A knitted fabric and loosening technology, which is applied in the weaving field of dense weft-knitted fabrics, can solve the problems of easy stretching and deformation of the fabric, unstable shape, and the number of layers cannot exceed two layers, etc., to achieve good dimensional stability, fabric extend the effect of small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The embodiment of the present invention is that weft and flat coil yarns 1, 2, 4, and 5 adopt 100D polyester low elastic yarn, rib coil yarns 3 and 6 adopt 32 cotton yarns, and weft insertion yarns 4 and 8 adopt 150D polyester low elastic yarn. The dense weft-knitted fabric with less stretching and less loosening is woven on a double-face circular knitting machine with a gauge of 18 needles.

[0033] The embodiment of the present invention weaves according to the following steps:

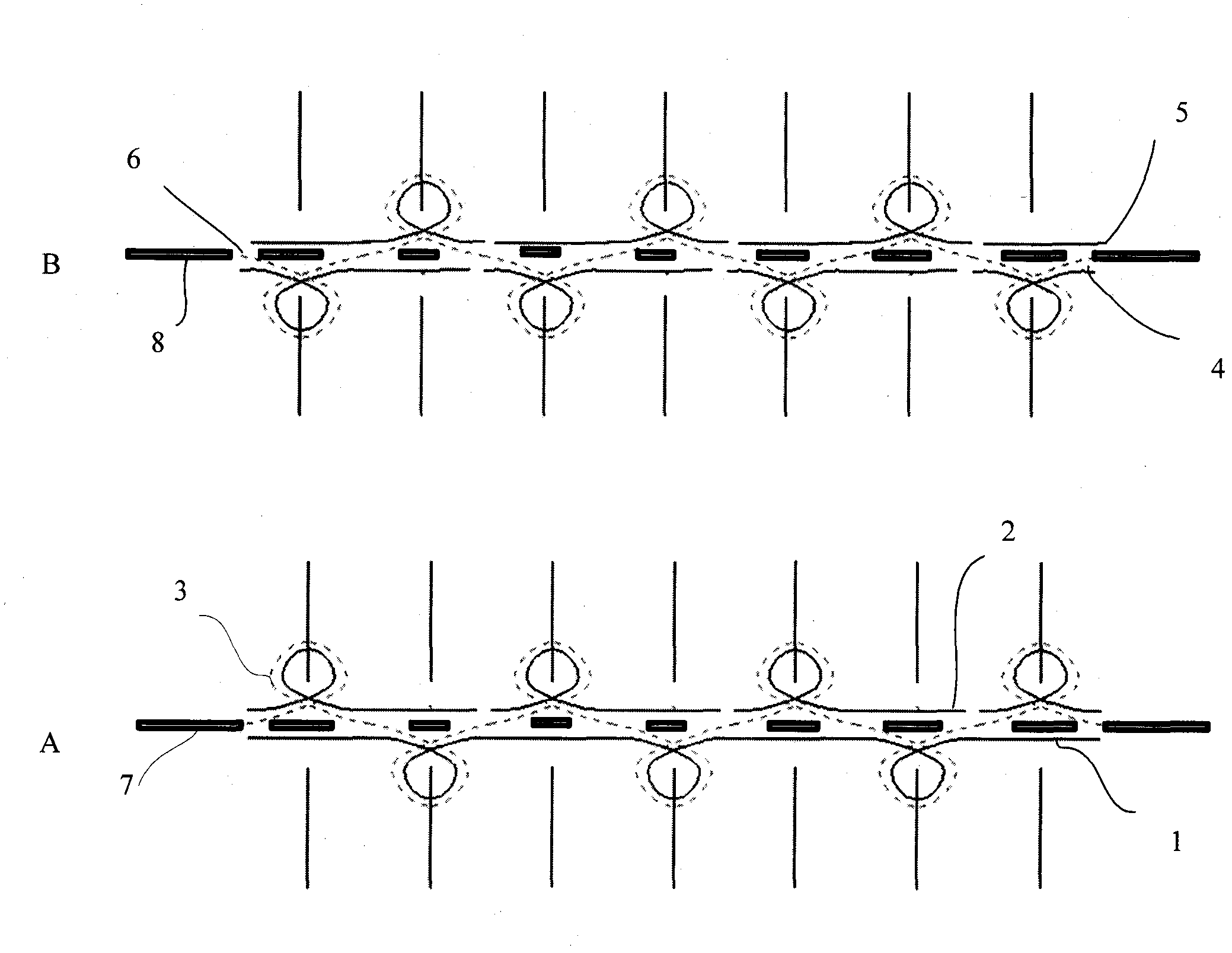

[0034] Step 1: Knit the first half of the full weave cycle of dense weft-knitted fabric with less stretching and less detachment in knitting path A, such as figure 1 shown.

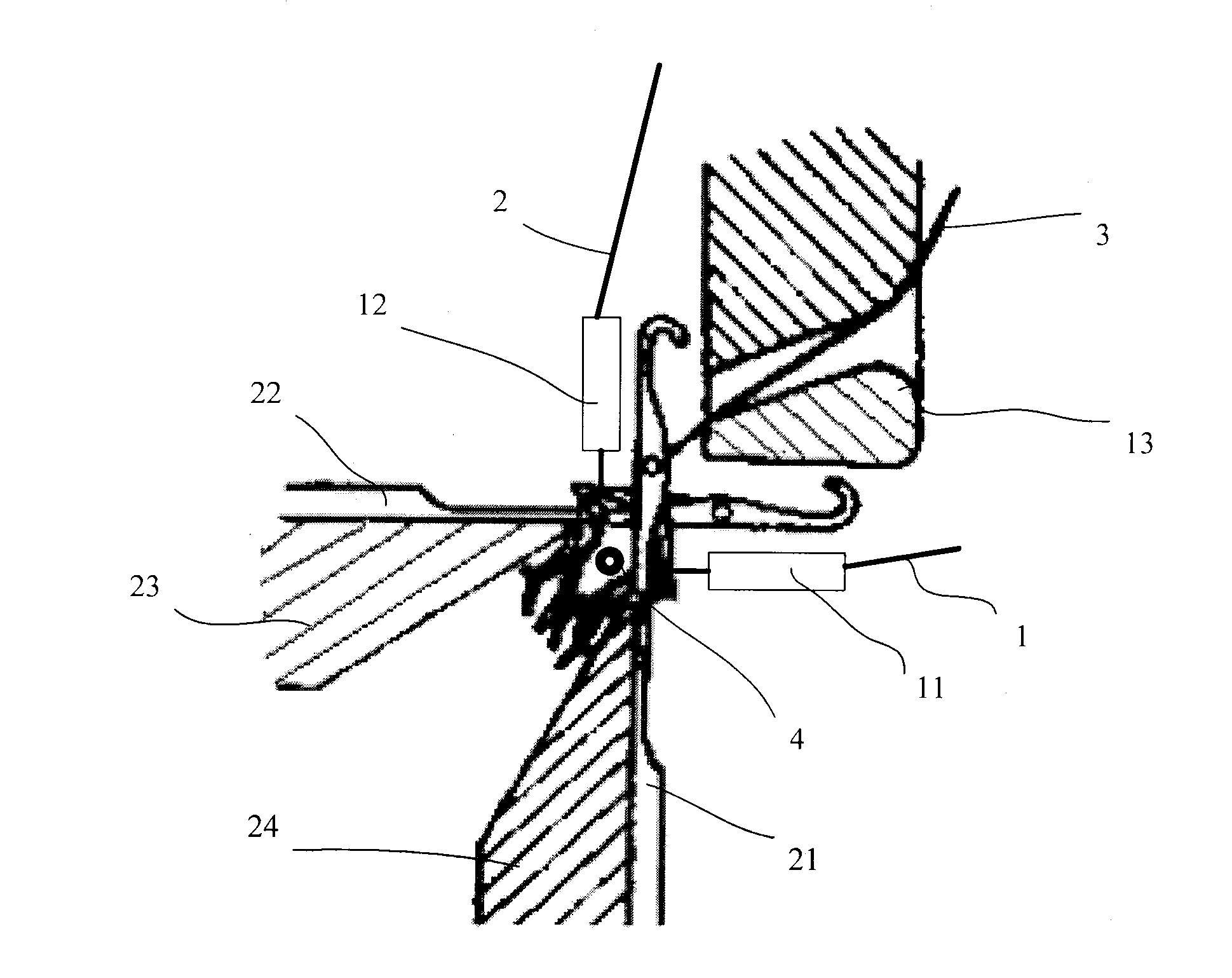

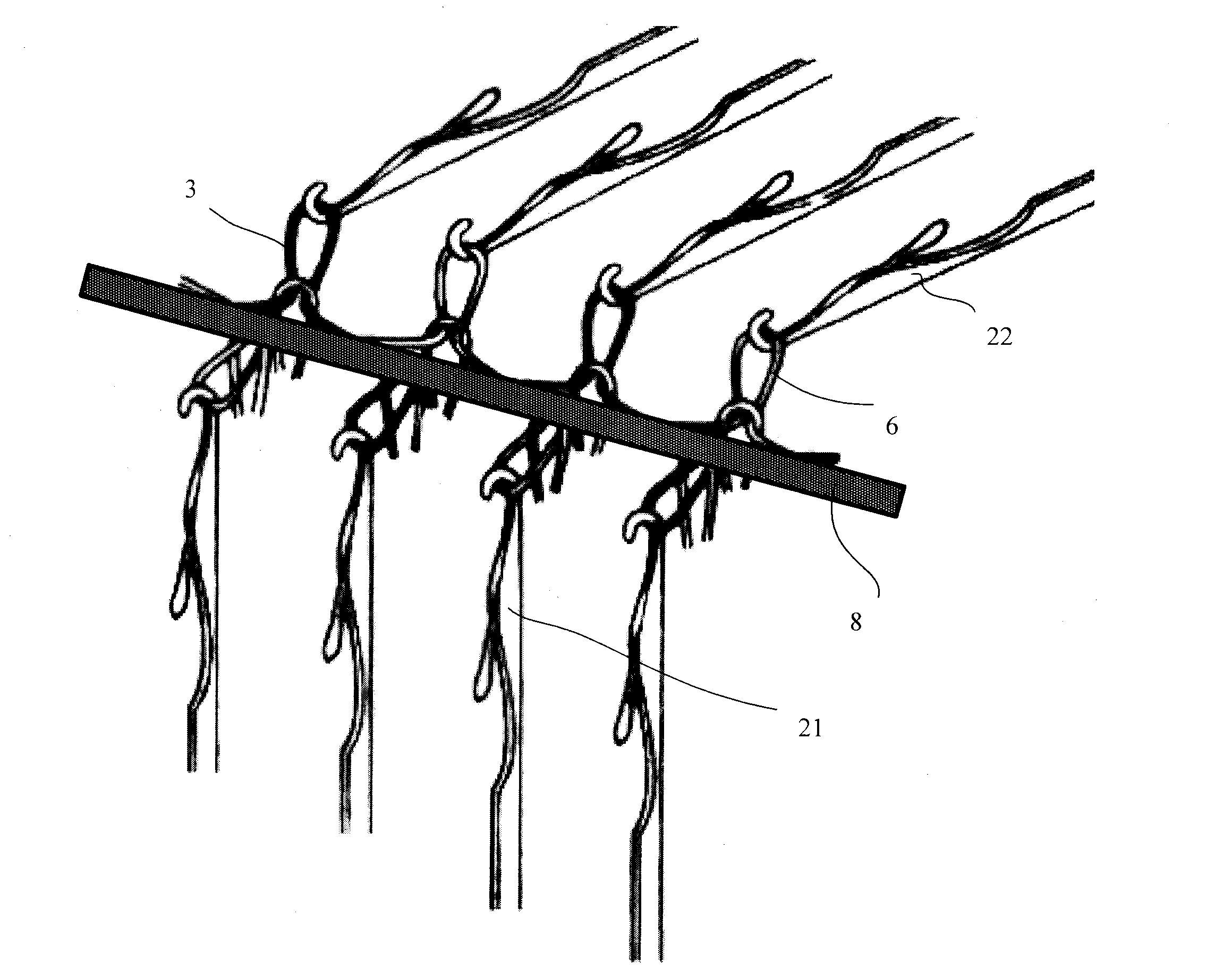

[0035] First, before the knitting needles 21 on the front needle bed 24 and the knitting needles 22 on the rear needle bed 23 start to withdraw the needles and withdraw the loops, put the weft insertion yarn 4 between the old loops of the knitting needles 21 and 22 ,See figure 2 , image 3 ;

[0036] Then, the knit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com