Automatic electroplating equipment for zipper head

A technology of electroplating equipment and zipper pullers, which is applied in the field of zipper manufacturing, can solve the problems of harsh site environment, low production efficiency, peeling, etc., and achieve the effect of improving electroplating quality, high electroplating quality and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

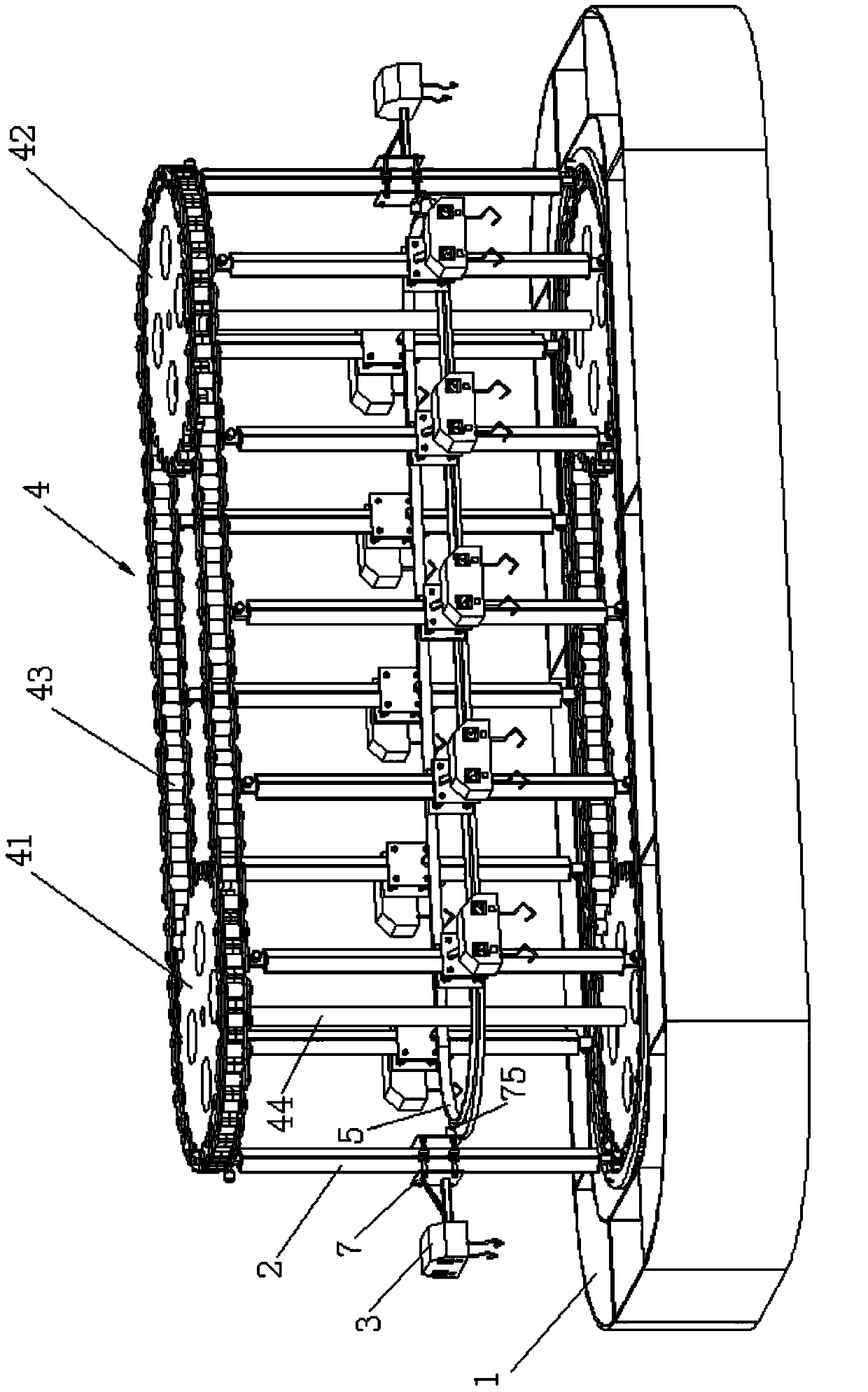

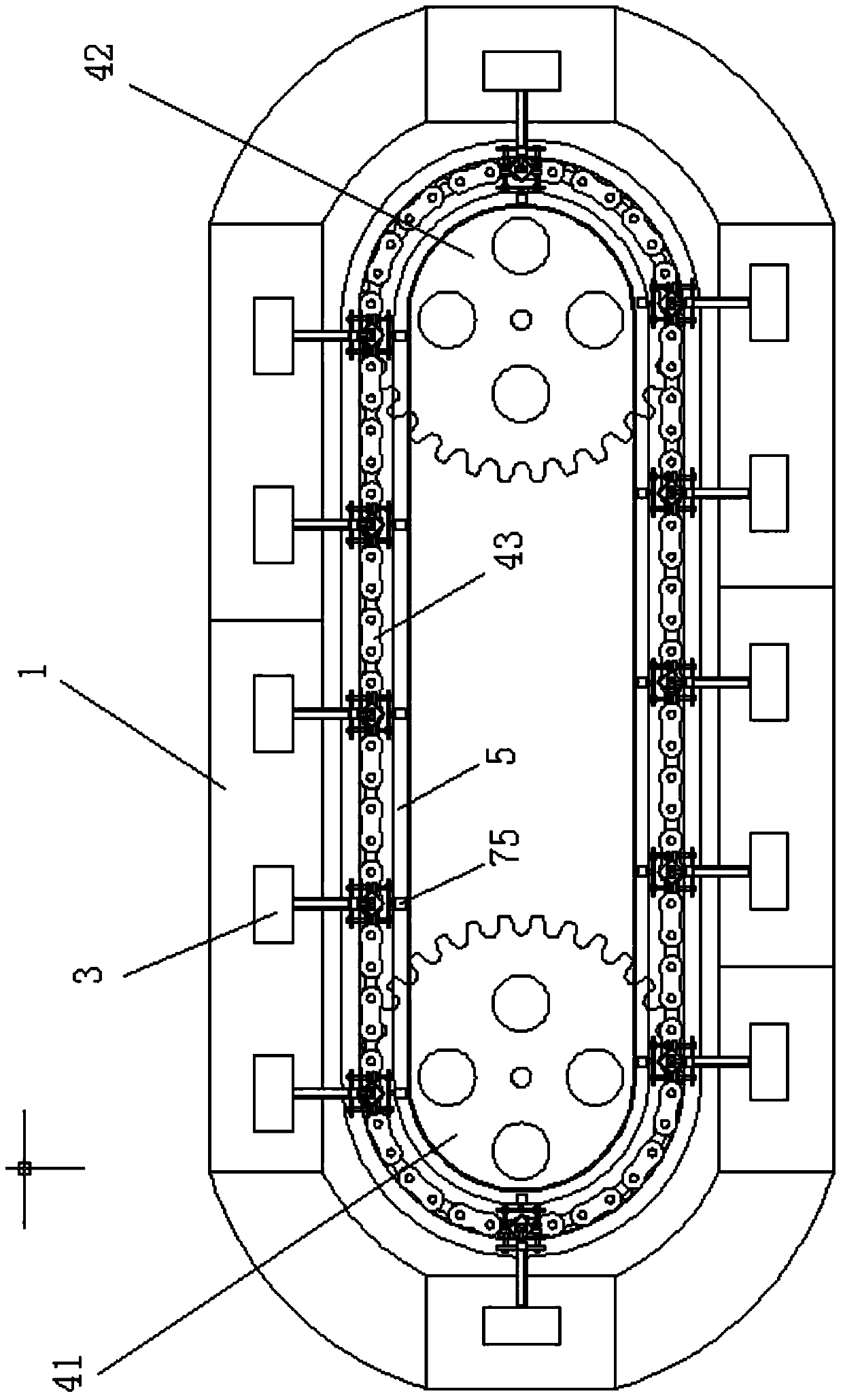

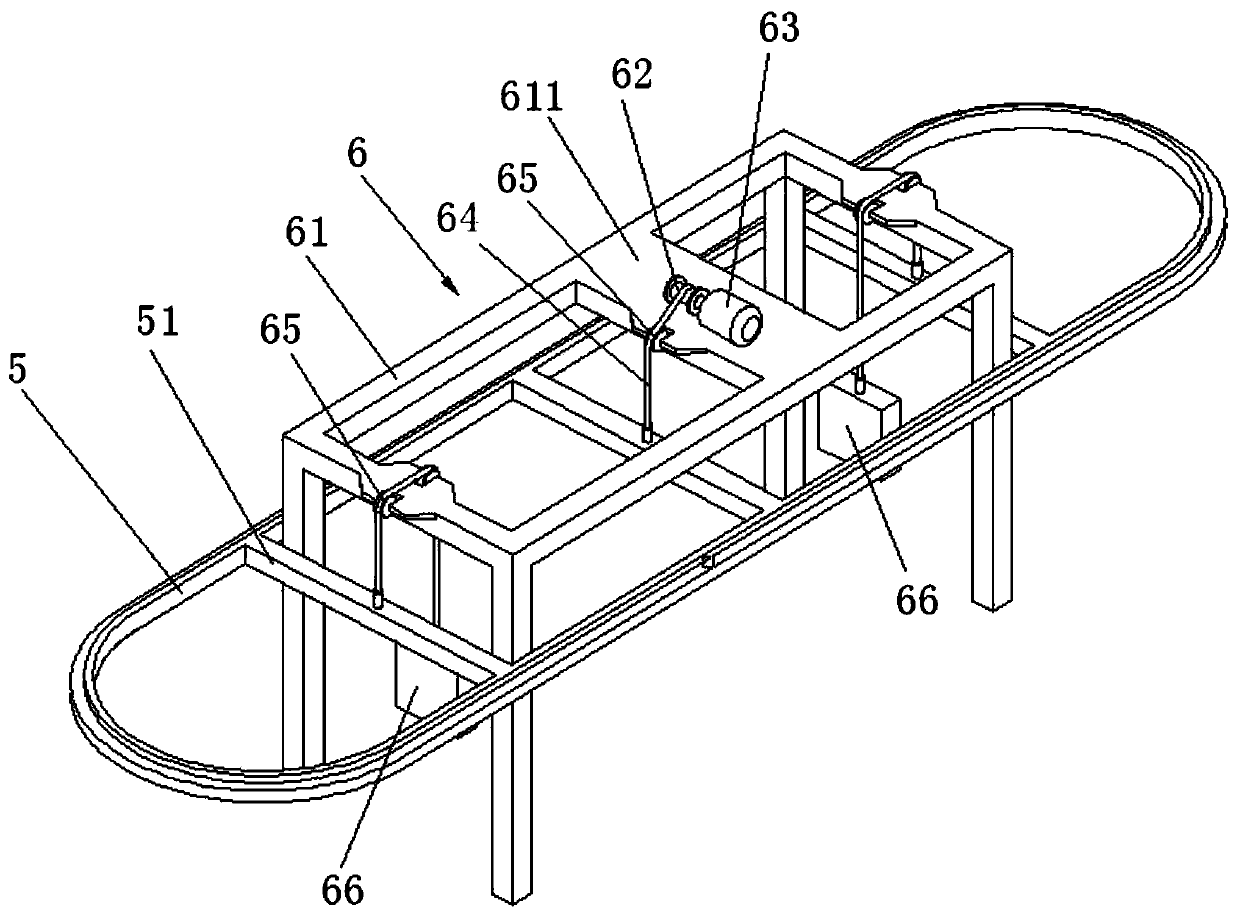

[0028] see Figure 1 to Figure 3 , an automatic electroplating equipment for zipper pulls, including a plating tank 1, a vertical guide rail 2, an anode generator 3, a traveling device 4, a circular track 5, a lifting device 6 and a control system. Wherein, several plating tanks 1 comprise cleaning, degreasing pre-plating treatment tanks, plating treatment tanks in plating and post-plating passivation treatment tanks, etc. These plating tanks 1 are connected end to end to form a closed ring, in order to make the device structure It is compact and saves the work space. The closed ring formed by the plating tank 1 is a quasi-elliptical ring formed by connecting two parallel long sides and arc edges at both ends. In the ring surrounded by the plating tank 1, a running device 4 is provided. The running device 4 includes two sets of vertically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com