A kind of tin plating leveling method for circuit board

A circuit board and tin plating technology, applied in printed circuits, printed circuit manufacturing, electrolytic components, etc., can solve the problems of uneven thickness of the coating, uneven tin content, too thin, etc., to improve the quality of electroplating, maintain uniform concentration, The effect of enhancing liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further detailed explanation through specific implementation mode below:

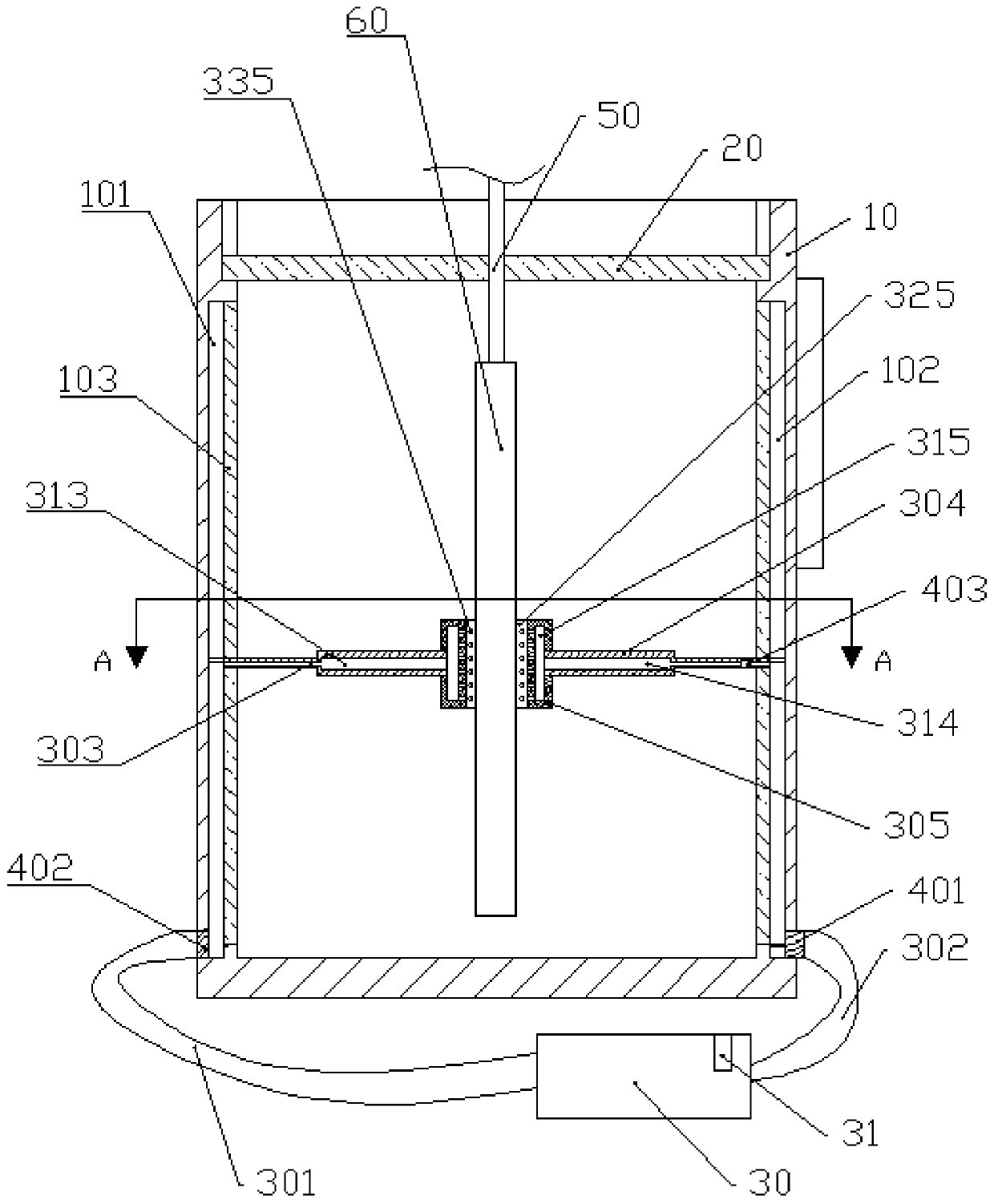

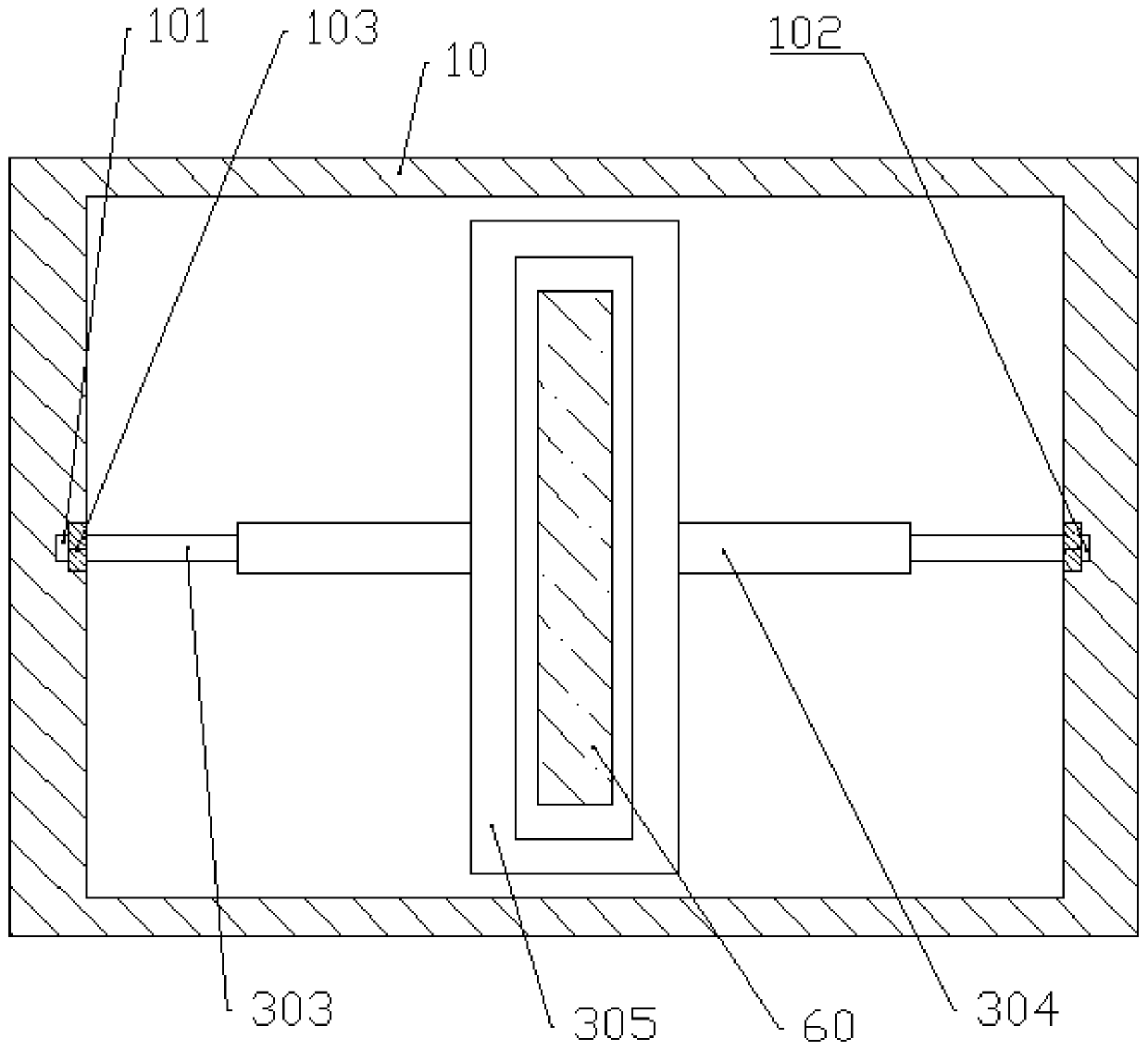

[0021] The reference signs in the drawings of the description include: electroplating tank 10, first chute 101, second chute 102, sealing strip 103, cover plate 20, water pump 30, feeding tank 31, first communicating pipe 301, second communicating pipe Pipe 302, first pole 303, first accommodation chamber 313, second pole 304, second accommodation chamber 314, spray block 305, third accommodation chamber 315, vertical through groove 325, through hole 335, fan blade 401 , the first one-way valve 402 , the second one-way valve 403 , the conductive rod 50 , and the circuit board 60 .

[0022] The tinning equipment in the embodiment is basically as attached figure 1 And attached figure 2 Shown: including electroplating box 10, cover plate 20, spraying mechanism and vertically arranged conductive rod 50, cover plate 20 is detachably connected to the upper end of electroplating box 10, and is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com