Method for welding butt-jointed seam of upward plate through manual arc welding

A technology of manual arc welding and butt welding, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc. It can solve the problems of unfused interlayers, large falling tendency of molten iron, and difficult operation, so as to improve plasticity and toughness, reduce Welded joints to ensure the effect of numerical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Choose two 300×125×12mm steel plates, the material is 16Mn, and grind the groove and the surface within 15mm to give a metallic luster; the welding material is J507 (E5015), the diameter is 3.2mm, and it is dried at 350°C as required , keep warm for 2 hours, then put it in the heat preservation tube, and turn on the power, take it out as you use it.

[0027] Matching parameters: the angle between the groove surface and the central vertical surface is 32°±2, the root gap is 3.5-4.0mm, the blunt edge is 1.5-2.0mm, and the misalignment is less than 0.5 mm. After the preparation, tack welding is carried out at both ends of the test piece with a length of 10-15mm. Do proper anti-deformation before welding.

[0028] Power supply polarity: the bottom layer is positive connection, and the filling layer and cover layer are reverse connection.

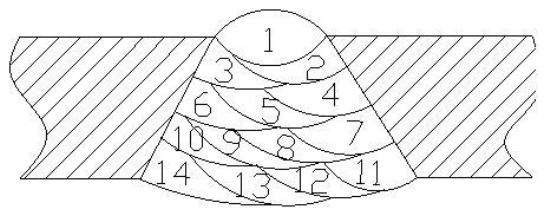

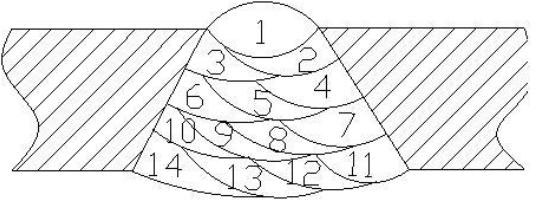

[0029] The number of layers is five layers and fourteen layers, that is: one layer for the base layer, one layer for the filling layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com