Non-tombarthite ferrite ball iron and preparing method thereof

A technology of ferrite and nodular iron, which is applied in the field of preparation of ferrite nodular iron, can solve the problems of many inclusions, difficult inoculation treatment, high safety and reliability requirements for pressure-added magnesium ladle, and achieves the effect of simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

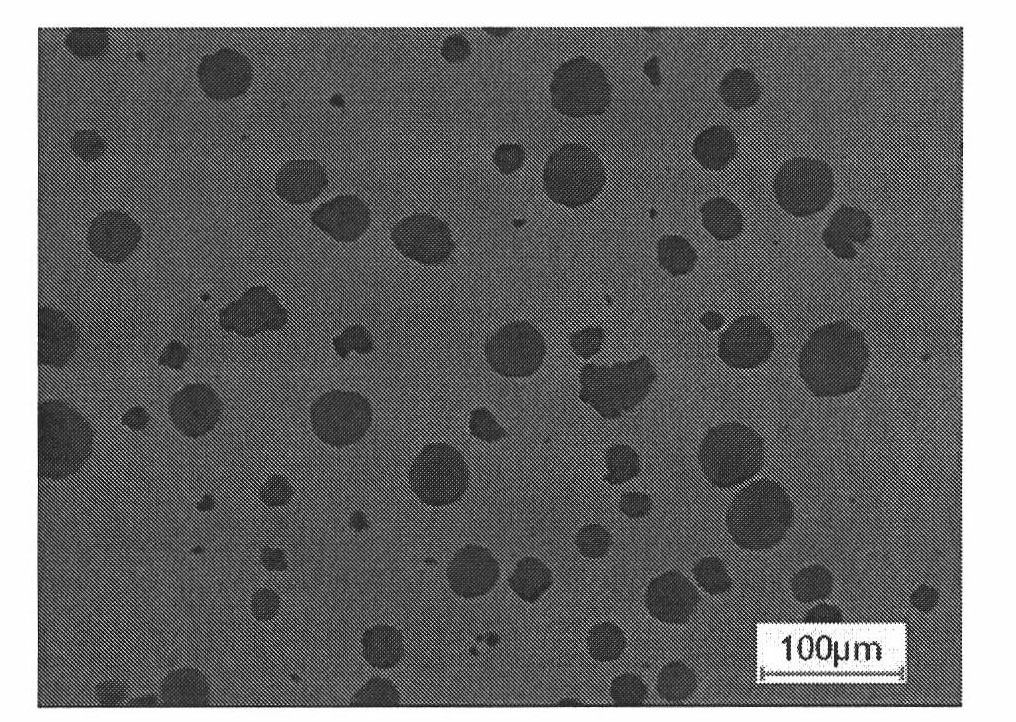

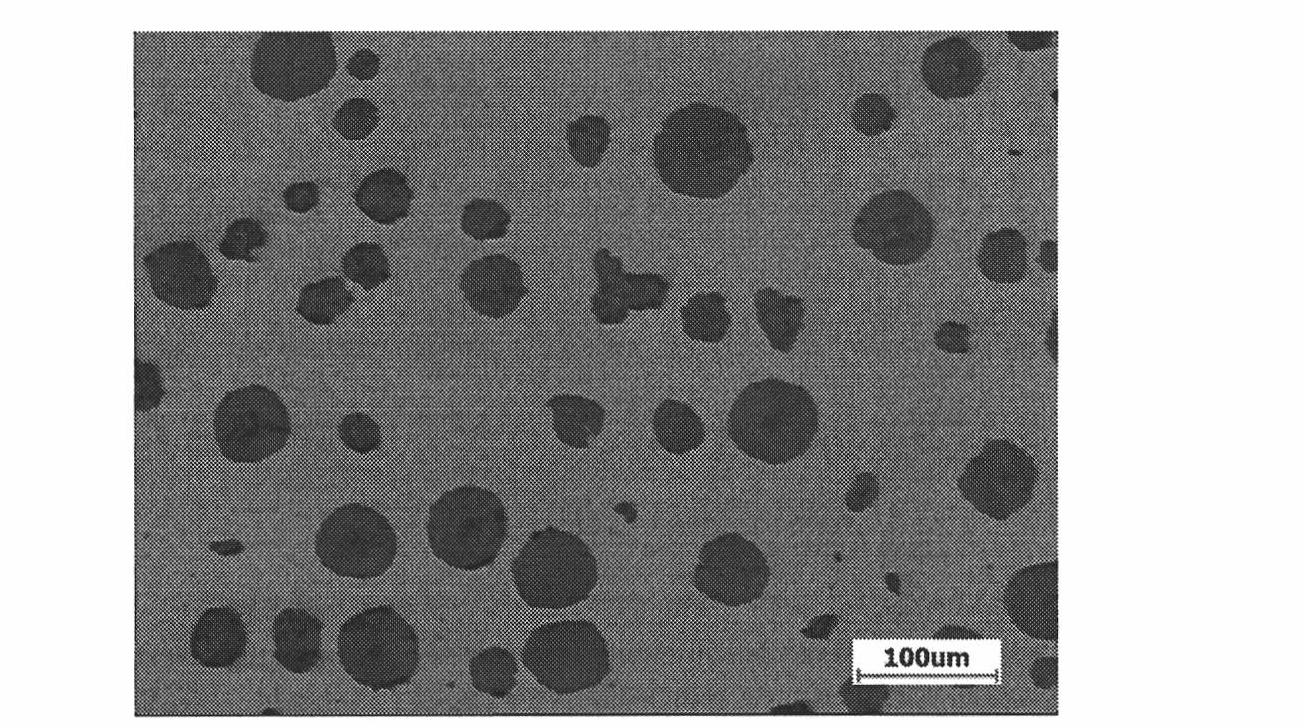

Image

Examples

Embodiment 1

[0021] 10 tons of molten iron is desulfurized outside the cupola and then fed into the electric furnace through the transfer ladle to raise the temperature. The temperature of the molten iron is raised to 1450°C and exits the electric furnace. Spheroidization and inoculation are carried out in the ladle;

[0022] Spheroidization and inoculation treatment: Pour a total of 5 tons of heated molten iron into the ladle for spheroidization and inoculation treatment. The temperature of the spheroidization reaction is 1400°C. The weight of agent is 1.1% of the weight of molten iron, and the add-on amount of nodulizer is 55kg, adopts the weight percentage of Mg in the nodulizer to be 6.0%, calculate 3.3kg, the weight percentage of Si is 40.0%, calculate 22kg, the rest is iron. And according to the weight of the poured molten iron, weigh 75SiFe with 0.3% of the molten iron weight as a covering, 15kg in total, add the spheroidizing agent to the molten iron by flushing, and the spheroidiz...

Embodiment 2

[0029] 10 tons of molten iron is desulfurized outside the cupola and then fed into the electric furnace through the transfer ladle to raise the temperature. The temperature of the molten iron is raised to 1470°C and exits the electric furnace. Spheroidization and inoculation are carried out in the ladle;

[0030] Spheroidization and inoculation treatment: Pour a total of 5 tons of heated molten iron into the ladle for spheroidization and inoculation treatment. The temperature of the spheroidization reaction is 1420°C. The weight of agent is 1.2% of the weight of molten iron, and the add-on amount of nodulizer is 60kg, adopts the weight percent content of Mg in the nodulizer to be 6.0%, calculates 3.6kg, and the weight percentage content of Si is 40.0%, calculates 24kg, the rest is iron. And according to the weight of the poured molten iron, weigh 75SiFe with 0.3% of the molten iron weight as a covering, 15kg in total, add the spheroidizing agent to the molten iron by flushing,...

Embodiment 3

[0037] 10 tons of molten iron is desulfurized outside the cupola and then added to the electric furnace through the transfer ladle to raise the temperature. The temperature of the molten iron is raised to 1480°C to be released from the furnace, and the spheroidization and inoculation are carried out in the ladle;

[0038] Spheroidization and inoculation treatment: Pour 5 tons of molten iron after heating and carburization treatment into the ladle for spheroidization and inoculation treatment. The spheroidization reaction temperature is 1430°C. The amount of nodulizer added is determined according to the weight of the poured molten iron. The weight of nodulizer is 1.3% of the weight of molten iron, 65kg in total, 9.0% in weight of Mg, 5.85kg in total, 46.0% in weight of Si, 29.9kg in total, and the rest is iron. And according to the weight of the poured molten iron, weigh 75SiFe with 0.2% of the molten iron weight as a covering, 10kg in total, add the spheroidizing agent to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com