High-strength composite steel sheet having excellent moldability and delayed fracture resistance

A composite structure, high-strength technology, used in furnace types, furnaces, heat treatment furnaces, etc., can solve the problem of insufficient delayed damage, and achieve excellent resistance to delayed damage, good tensile flanging, and excellent spot weldability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

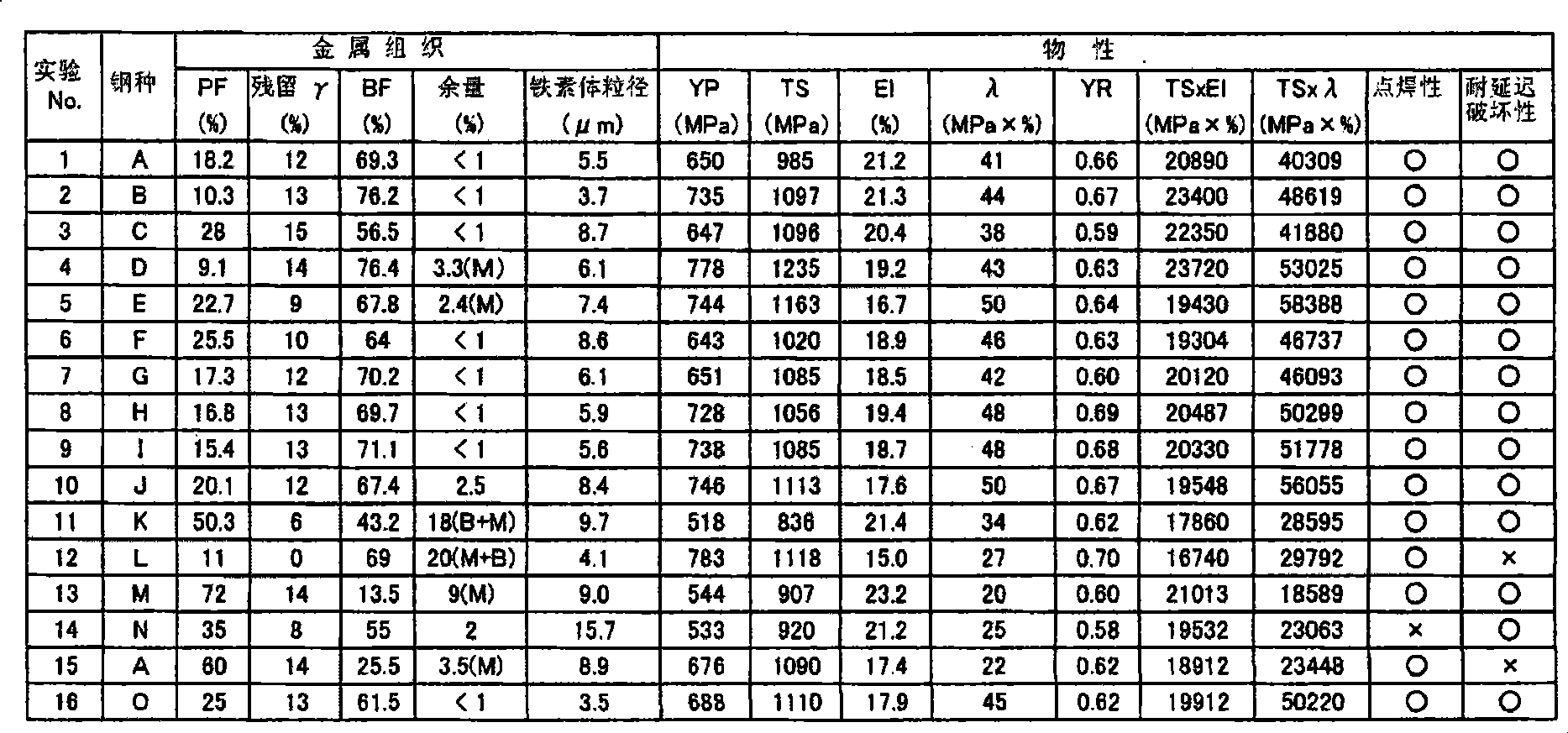

[0083]Hereinafter, the present invention will be described more specifically with examples, but the present invention is not limited by the following examples, and can be modified and implemented within the appropriate range of the present invention without departing from the scope of the preceding and following, which are all included in the technical scope of the present invention.

experiment example

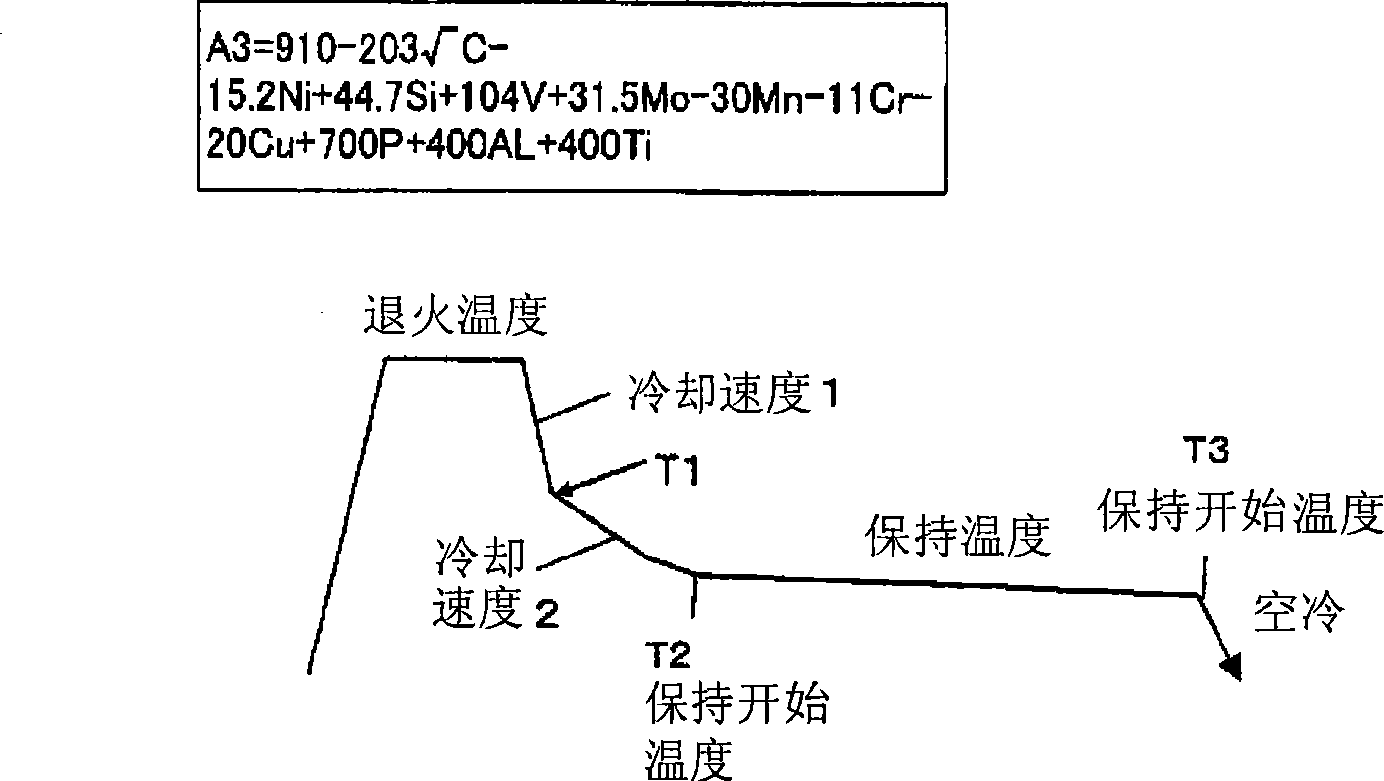

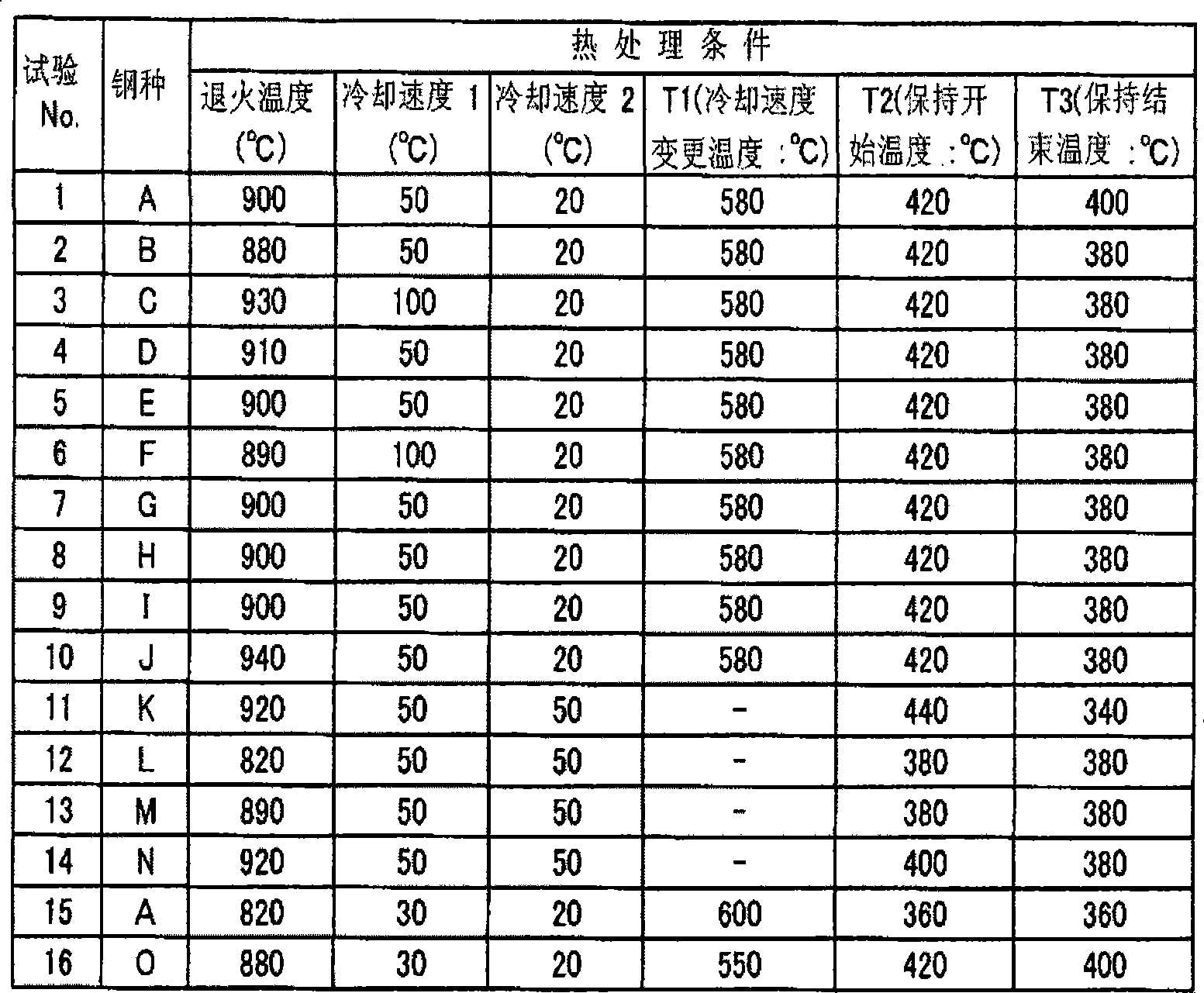

[0085] After smelting the steel materials of the composition shown in Table 1, after continuous casting, hot rolling, pickling, and cold rolling were carried out under the following conditions, and then, according to Table 2 (refer to figure 1 ) under the conditions indicated by heat treatment (annealing), thereby obtaining a cold-rolled steel sheet.

[0086] hot rolled

[0087] Heating temperature: 1200℃×60 minutes

[0088] Completion temperature: 880°C

[0089] Cooling: cooling to 720°C at 40°C / sec, cooling to 500°C at 40°C / sec after air cooling for 10 seconds, followed by furnace cooling at 500°C for 60 minutes.

[0090] Finished plate thickness: 3.2mm

[0091] pickling, cold rolling

[0092] After pickling, it is cold rolled to a plate thickness of 1.2 mm.

[0093] Heat treatment (annealing)

[0094] As shown in Table 2, after heating to the specified annealing temperature for 180 seconds, cool to the specified cooling stop temperature at a specified rate, and keep a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com