High-strength high-toughness low-temperature-resistant ferritic nodular cast iron

A ductile iron, toughness technology, applied in the field of ductile iron materials, can solve problems such as no clear strength index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

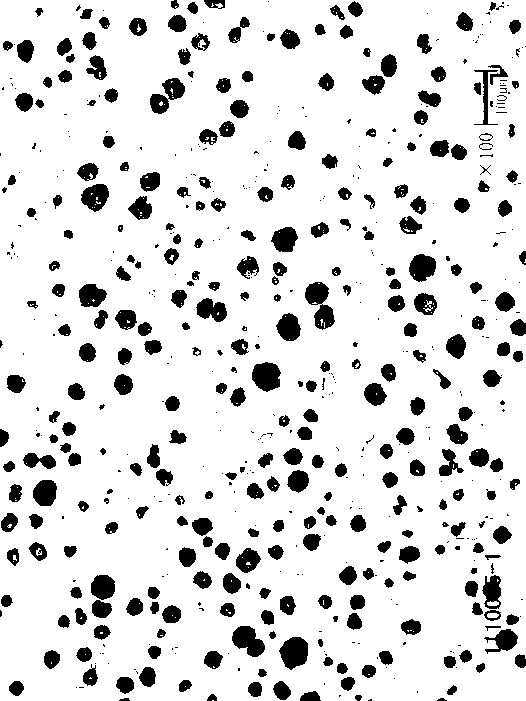

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0019] A high-strength, strong-toughness, low-temperature-resistant ferritic ductile iron, the weight percentages of its components are as follows:

[0020] C 3.62~3.80%, Si 1.90~2.35%, Mn <0.20%,

[0021] RE 0.007~0.018%, Mg 0.043~0.060%, P<0.035%, S≤0.020%,

[0022] The remainder is iron and other impurity elements. In the impurity elements, Mo<0.010%, Ti<0.025%,

[0023] The silicon-carbon ratio is Si / C=0.50~0.63.

[0024] The component parameters of each embodiment are as follows:

[0025] .

[0026] In each of the examples, there are two kinds of co-cast test blocks of 40mm and 70mm.

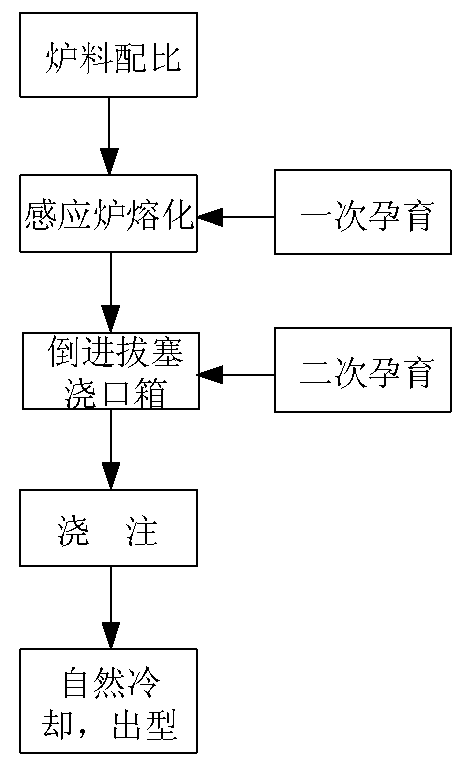

[0027] The smelting and pouring process is as follows:

[0028] 1. 1. Charge ratio: (weight percentage of molten iron, the same below): 40% pig iron for ductile iron, 40% carbon scrap, and 20% ductile iron scrap.

[0029] Then add 1.0~1.30% recarburizer to ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com